Method of reducing hydraulic system power of multi layer hot press and practical appts

A multi-layer hot press and hydraulic system technology, which is applied in the field of hydraulic mechanisms, can solve the problems of shortening the closing and pressurizing time of the hot press, increasing the use cost of the hydraulic system, and heating the hydraulic system, so as to shorten the closing and pressurizing time , use safety guarantee, the effect of blocking oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

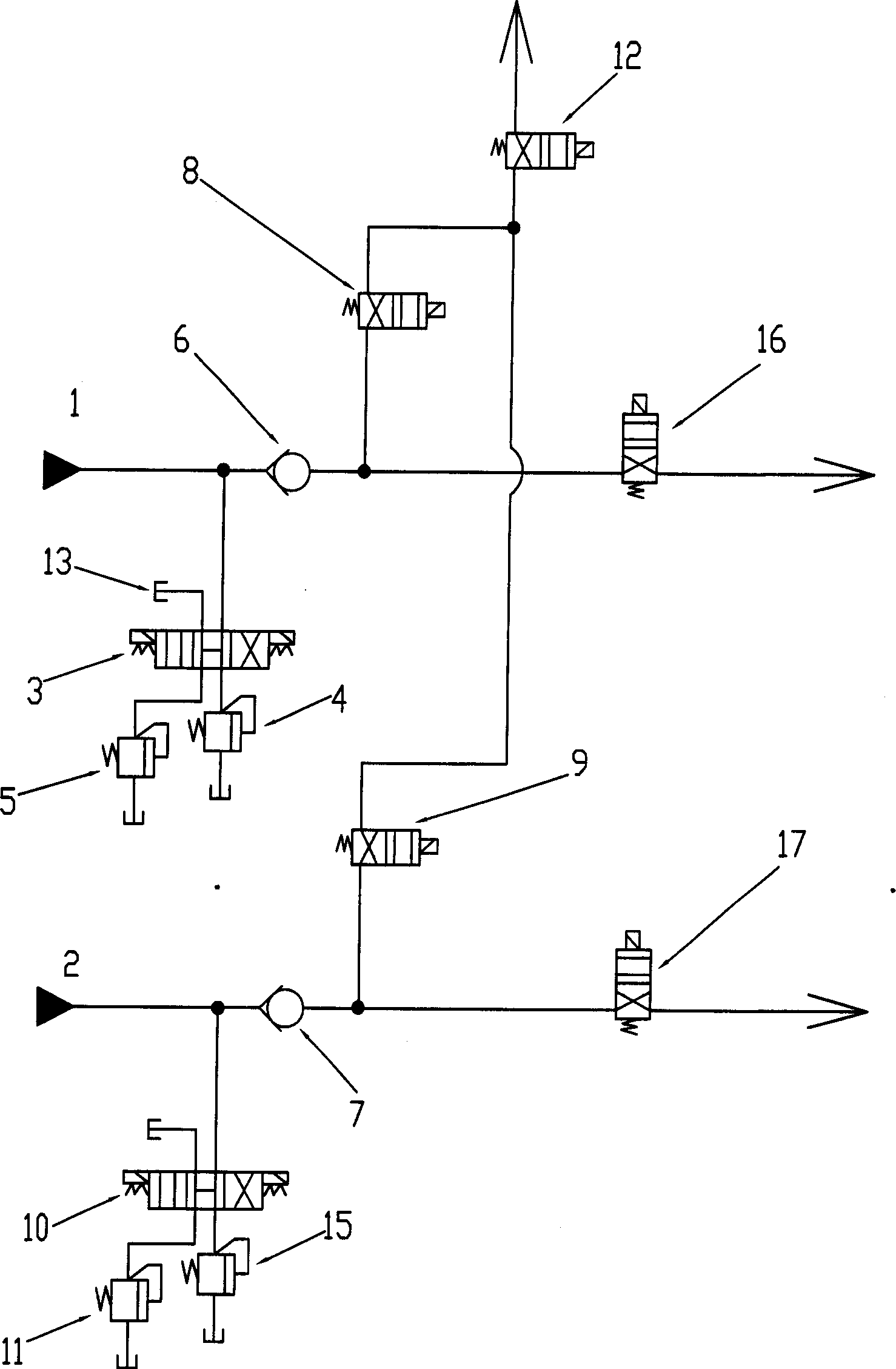

[0009] A method for reducing the power of the hydraulic system of a multi-layer hot press. When the loading machine and the unloading machine stop rising and are in a downward state, respectively cut off the connection between the loading machine and the unloading machine and the corresponding pump oil source. Connect the oil circuit, use the pump oil source of the loading machine and the pump oil source of the unloading machine to deliver pressure oil to the hot press; when the loading machine is in the rising state, disconnect the pump oil source of the loading machine and the hot press The connecting oil circuit between the loading machine and the pump oil source of the loading machine supplies oil to the loading machine; when the unloading machine is in the rising state, disconnect the connecting oil circuit between the pump oil source of the unloading machine and the hot press , so that the pump oil source of the unloader supplies oil to the unloader.

[0010] See attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com