Device and method for simulating test of pore water pressure of asphalt pavement

A technology for pore water pressure and simulation testing, which is used in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc. The effect of easy opening and closing, increased test frequency, and reduced inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

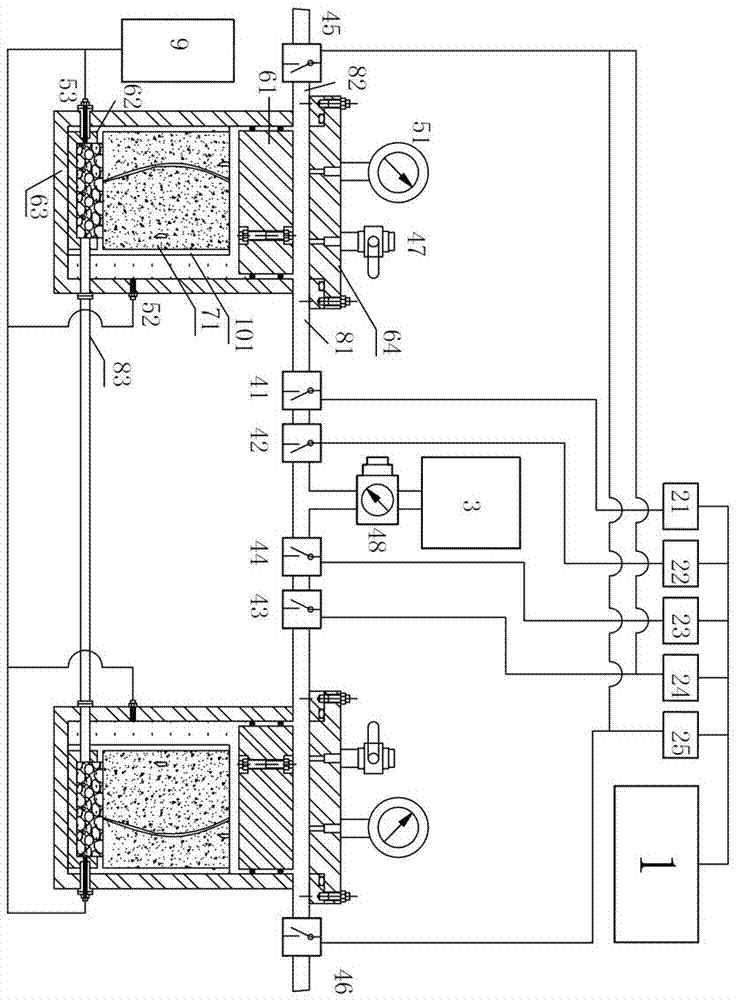

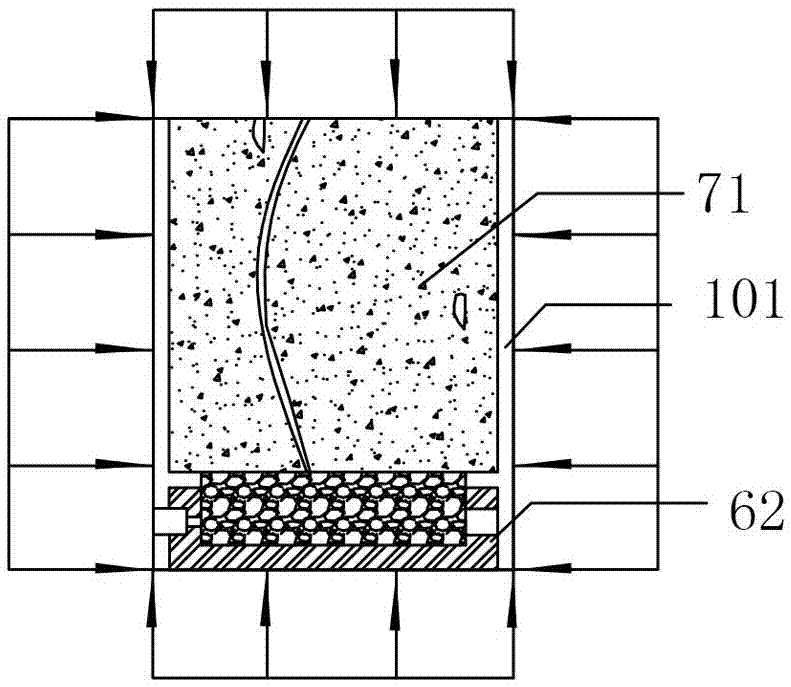

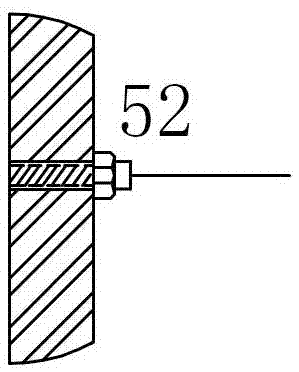

[0045] like Figure 1~4 Shown, a kind of asphalt pavement pore water pressure simulation testing device comprises at least two pressure vessels 63, and each pressure vessel 63 is provided with asphalt concrete specimen 71, open container 62, the bottom of asphalt concrete specimen 71 and the opening Adhesive 101 is filled between the opening annular parts of container 62 (adhesive 101 in this embodiment is specifically epoxy resin, phenolic resin can achieve the same technical effect), and the side wall of asphalt concrete specimen 71 is coated with adhesive agent 101; the lower part of the side wall of the open container 62 is symmetrically provided with two mounting holes, one of which is provided with a first pressure sensor 52 for measuring the external water pressure of the asphalt concrete specimen 71, and the other mounting hole is provided with a The second pressure sensor 53 for measuring the water pressure at the bottom of the asphalt concrete test piece 71;

[0046...

Embodiment 2

[0058] like Figure 5 As shown, the specific process of the method for testing using the device described in Embodiment 1 is as follows:

[0059] (1) Asphalt concrete specimens 71 with a diameter not less than 100mm and not more than 155mm obtained by indoor preparation or on-site core drilling on the road surface;

[0060] (2) Fill the cylindrical open container 62 with the same outer diameter as the asphalt concrete specimen 71 and with a sensor installation hole on one side with the crushed stones sieved by a standard square hole sieve of 13.2 mm to 16 mm, and then fill it with water;

[0061] (3) Glue the bottom of the asphalt concrete specimen 71 and the top open circular part of the cylindrical open container 62 filled with gravel with adhesive 101, and coat the circumference of the side wall of the asphalt concrete specimen 71 with adhesive 101 And make it flow naturally until the adhesive 101 is coated on the outer sidewall of the asphalt concrete specimen 71 and the ...

Embodiment 3

[0073] The specific process of the method for testing using the device described in Embodiment 1 is the same as in Embodiment 2, except that the control process adopted in this embodiment is as follows:

[0074] The first air intake control valve 41 is controlled by the programmable controller 1 to open for 0.25s, and the second air intake control valve 42 is opened for 0.25s at 0.15s. Apply pressure to the asphalt concrete specimen 71 within 0.1s when the gas control valve 42 is opened at the same time; at 0.25s, the first exhaust control valve 45 is opened for 0.25s to exhaust the pressure vessel 63 to atmospheric pressure; at 0.1s, the fourth The air intake control valve 44 is opened for 0.25s, and the third air intake control valve 43 is opened for 0.25s at 0.25s; the second exhaust control valve 46 is opened for 0.3s at 0.35s to exhaust the pressure vessel 66 to atmospheric pressure; except for the second exhaust control valve 46 at an interval of 0.1s, the other control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com