Adhesive and use thereof

A technology of adhesives and compositions, applied in the direction of adhesive types, adhesives, polyurea/polyurethane adhesives, etc., can solve problems such as the adverse effect of curing speed on the performance of cured products and adherends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0106] Preparation of the three-component adhesive

[0107] [043] In one embodiment, the three-component adhesive of the present invention is prepared as follows: A component contains one or more polyol resins, including polyester polyol, polyether polyol or a combination thereof, and simultaneously formulates It is made by mixing appropriate substances at a certain temperature and under the action of dispersing equipment; component B contains isocyanate curing agent, which includes TDI and its derivatives, MDI and its derivatives, or their combination; group C It contains general-purpose polyurethane curing catalyst and appropriate substances, mixed at a certain temperature and under the action of dispersing equipment.

[0108] Use of three-component adhesives

[0109] [044] In one embodiment, the present invention provides a method of using a three-part adhesive comprising a first part comprising one or more polyols at different temperatures a second component containi...

Embodiment 1

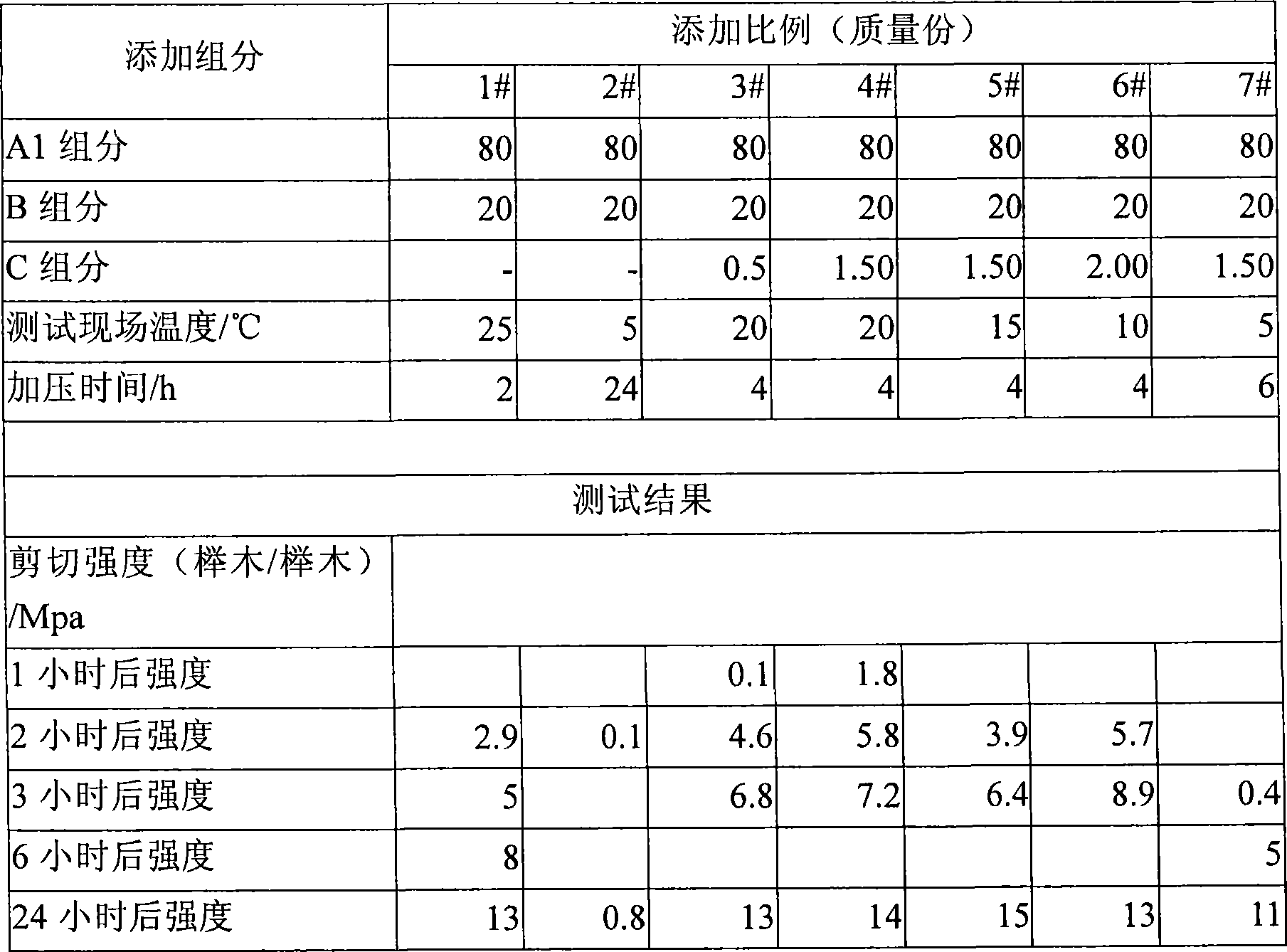

[0137] Example 1. Preparation of three-component adhesive 1

[0138] [054] Three-component polyurethane adhesives of different formulations (see Table 1 below) were prepared according to the following procedure. To prepare the first component (component A1), 60% by weight of the weight of component A1 of German Bayer polyether polyol 1380BT was poured into a clean stirred tank and the composition was mixed thoroughly. And pour 39wt% of quartz powder and 1wt% of auxiliary agents such as defoamers into the stirring tank respectively and stir. Stirring was continued for 60 minutes after all ingredients were added, vacuum and heat were applied to the stirred tank, and vacuum was maintained for 1 hour after the stirred tank contents reached 110°C. Then, after the vacuum was stopped, the contents of the stirred tank were discharged into another clean container and cooled to room temperature. At this point, component A1 is ready for use in the three-component adhesive. The secon...

Embodiment 2

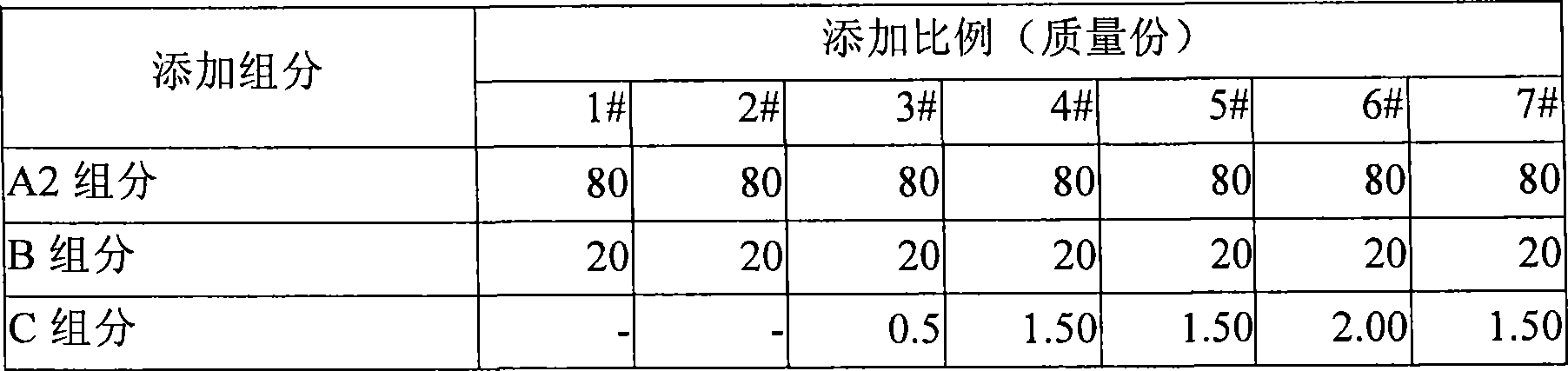

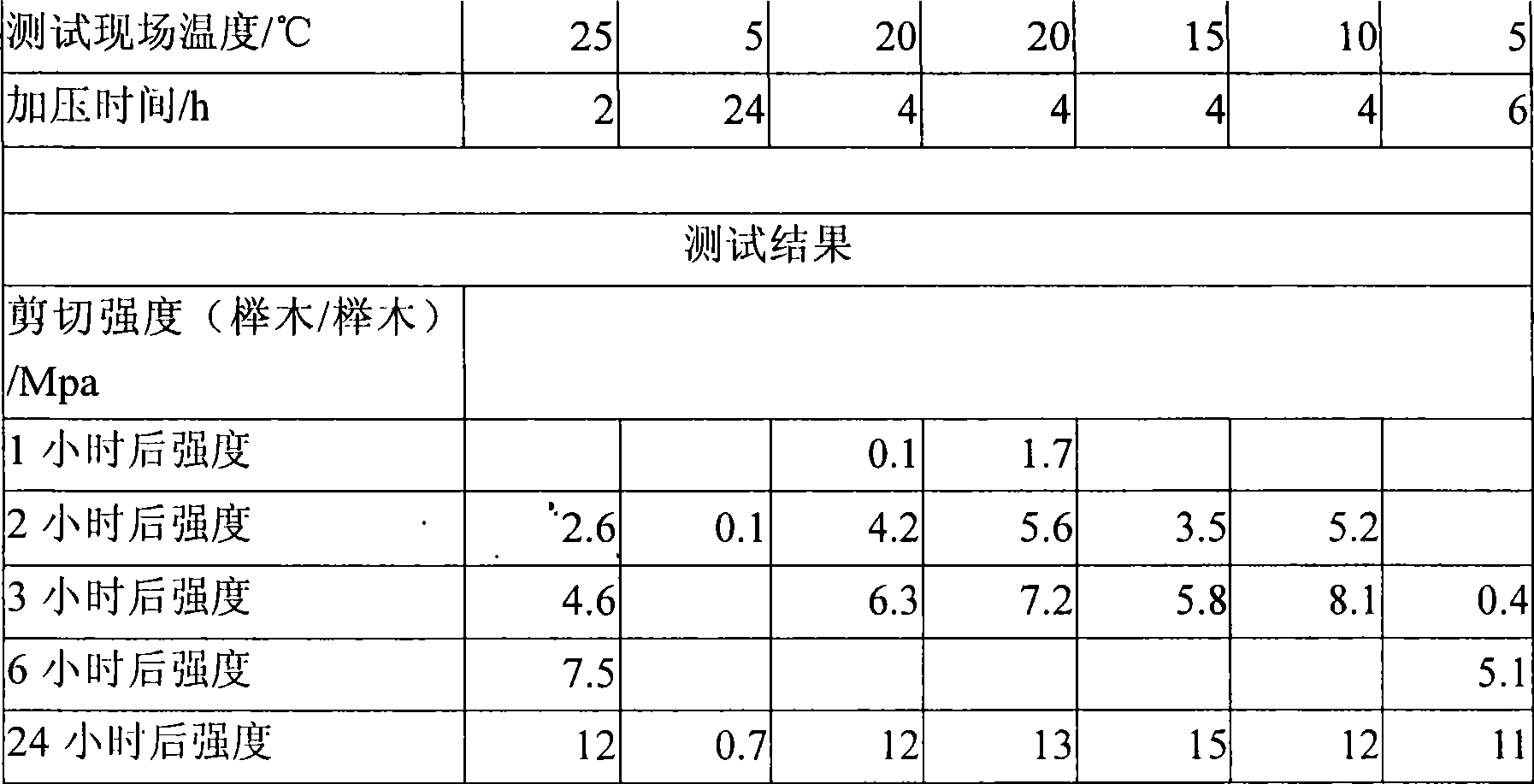

[0139] Example 2. Preparation of three-component adhesive 2

[0140] [055] Three-component polyurethane adhesives of different formulations (see Table 2 below) were prepared according to the following procedure. To prepare the first component (component A2), pour 40wt% German Bayer polyether polyol 1380BT and 20wt% polyethylene adipate diol (PEA3000) into a clean Stir in the kettle and mix the composition thoroughly. And pour 39wt% of quartz powder and 1wt% of auxiliary agents such as defoamers into the stirring tank respectively and stir. Stirring was continued for 60 minutes after all ingredients were added, vacuum and heat were applied to the stirred tank, and vacuum was maintained for 1 hour after the stirred tank contents reached 110°C. Then, after the vacuum was stopped, the contents of the stirred tank were discharged into another clean container and cooled to room temperature. At this point, component A2 is ready for use in the three-component adhesive. The secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com