Soaking pressing method and apparatus

A pressurizing device and heat-soaking technology, applied in presses, lighting and heating equipment, presses for material forming, etc., can solve problems such as difficult temperature distribution, difficult temperature control of processed products, and increased temperature fluctuations of processed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

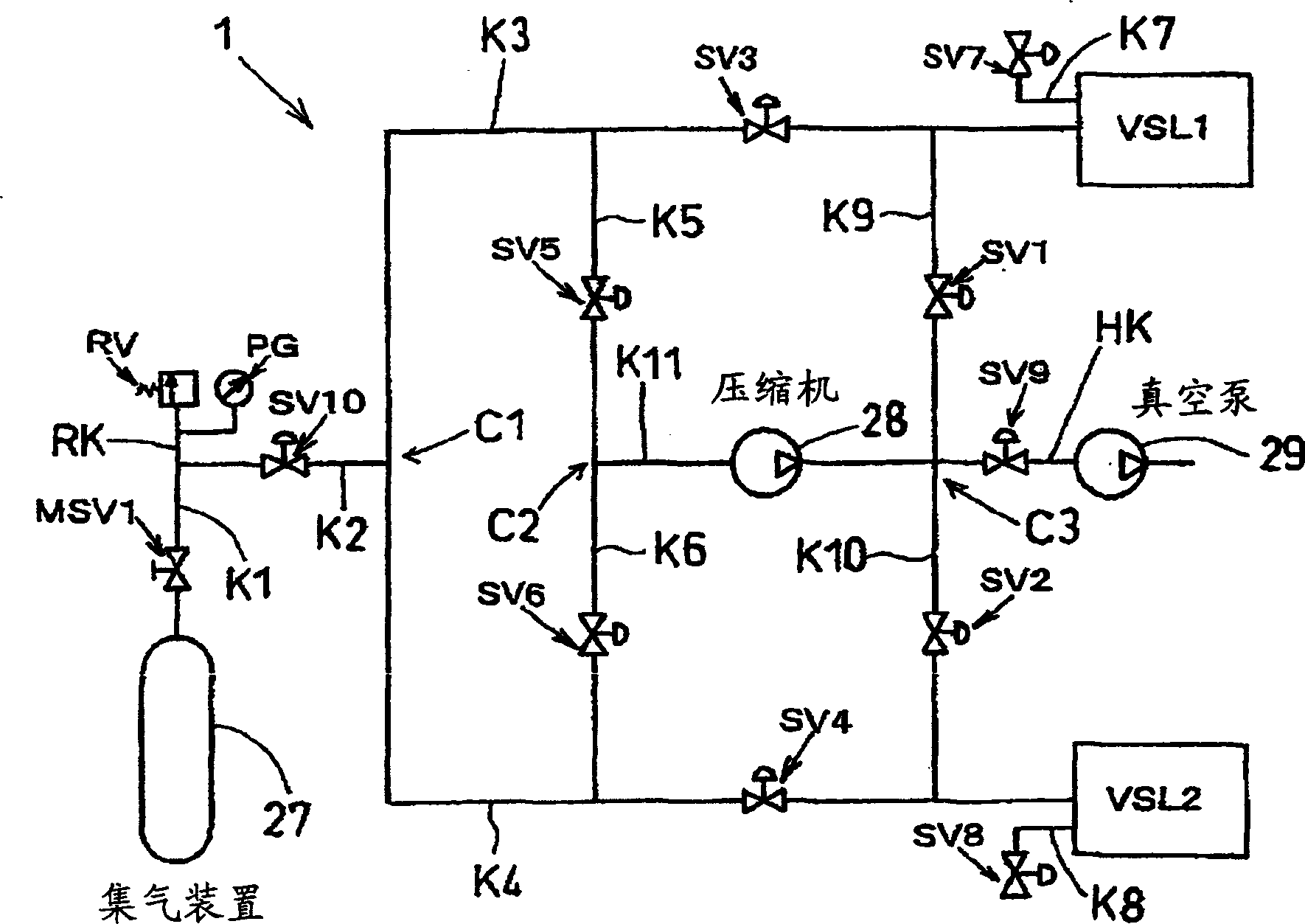

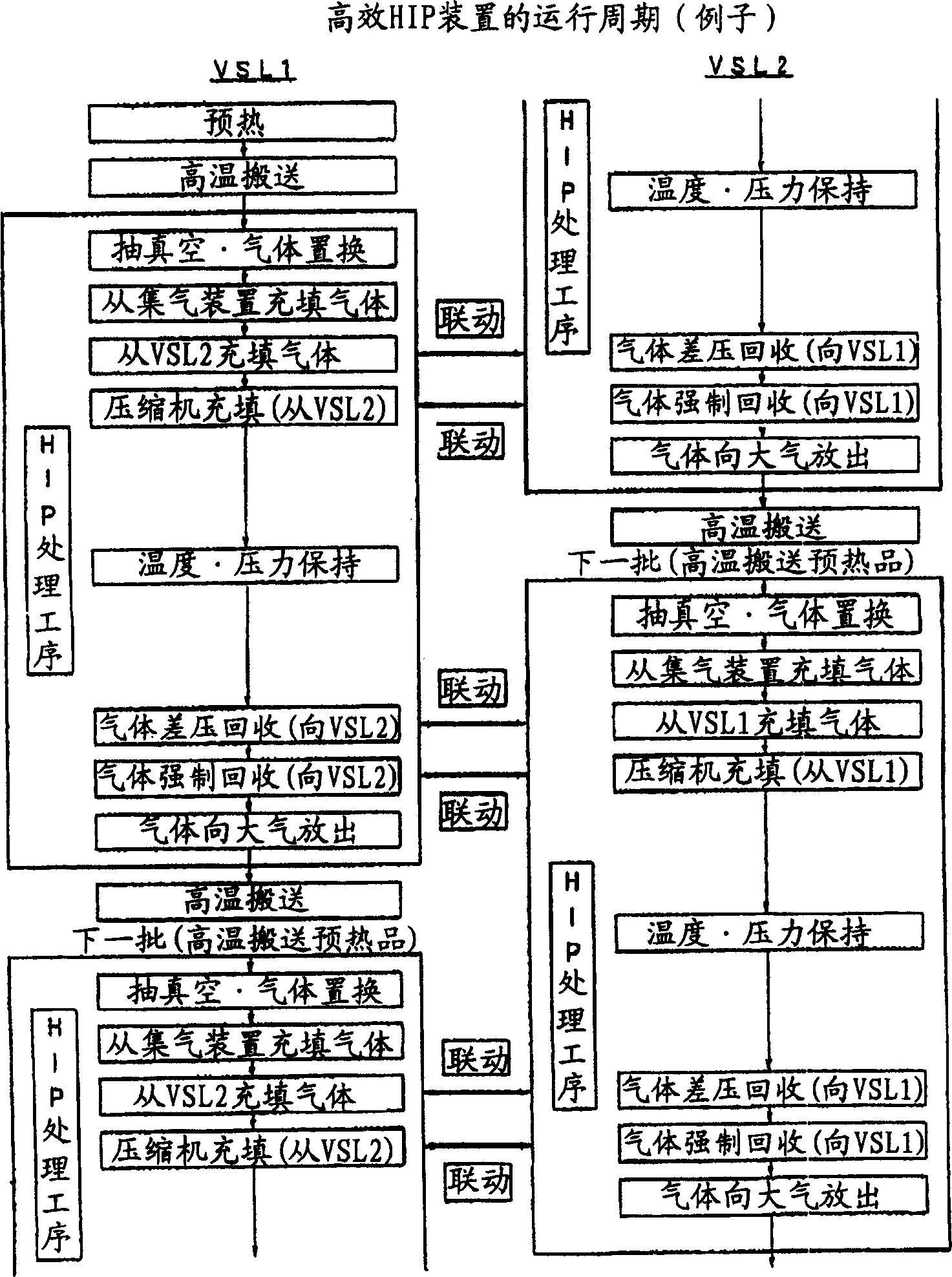

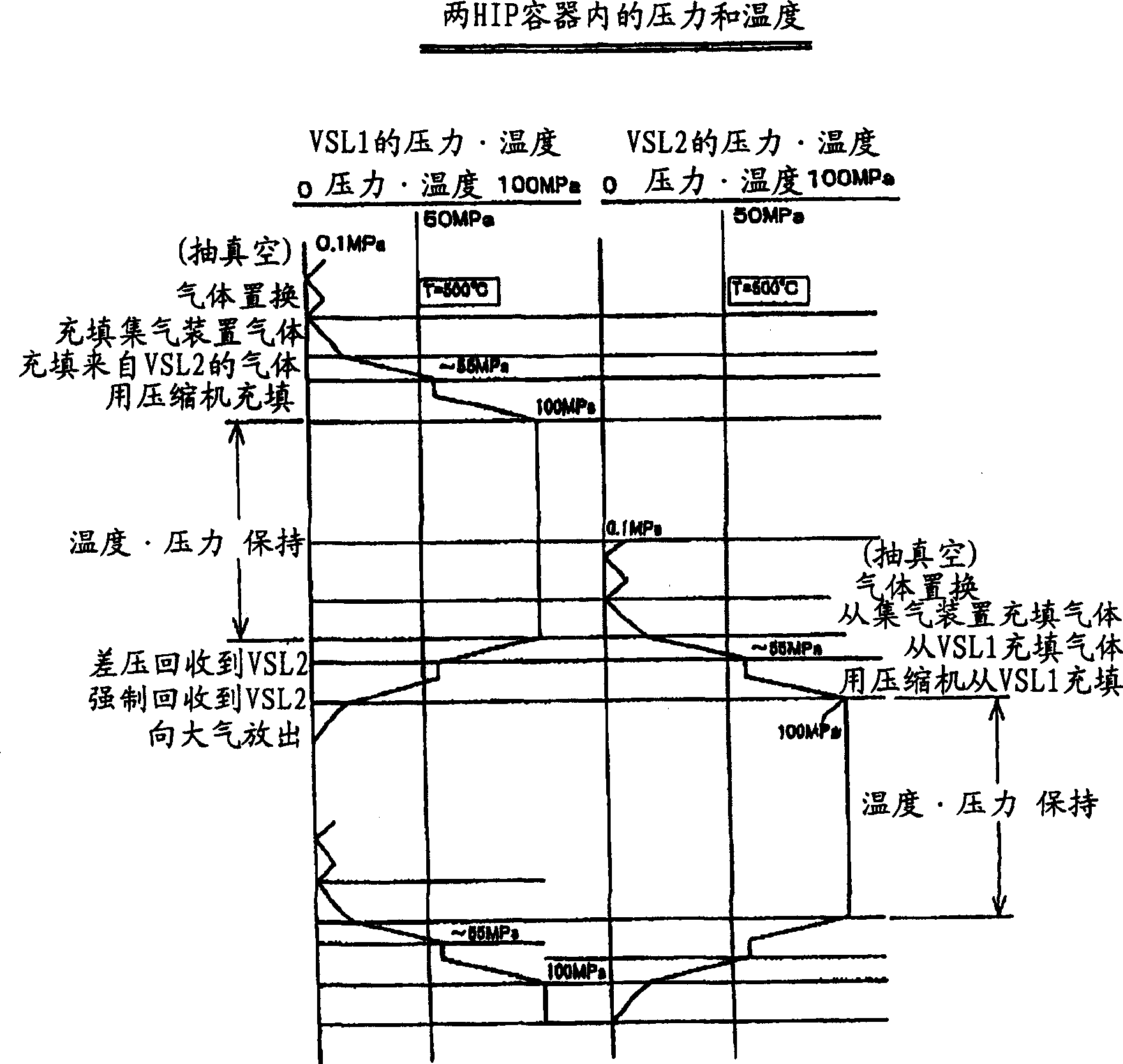

[0031] Embodiments of the present invention will be described below with reference to the drawings.

[0032] Figure 4 It is a figure which shows an example of the high-pressure container 2 and the electric furnace 3 of the main part of the soaking pressurization apparatus (HIP apparatus) 1 of this invention, and the HIP apparatus 1 is the processing chamber 4 in the electric furnace 3 accommodated in the high-pressure container 2 It is a device that heats the processed product 5 inside, injects a pressurized medium gas into the high-pressure vessel 2 and raises the pressure, and heats and pressurizes the processed product 5 (HIP treatment).

[0033] The high-pressure container 2 is composed of a high-pressure cylinder 6 with an axis and an opening up and down, an upper cover 7 that blocks the upper opening of the high-pressure cylinder 6, and a lower cover 8 that blocks the lower opening of the high-pressure cylinder 6. The load applied to the upper and lower covers 7 and 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com