A device and method for testing the bending strength of bamboo slices by ultrasonic motor

A technology of ultrasonic motor and bending strength, which is applied in the electrical field, can solve the problems of waste, large margin of glue pressure, etc., and achieve the effects of energy saving, heating temperature and pressure time reduction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

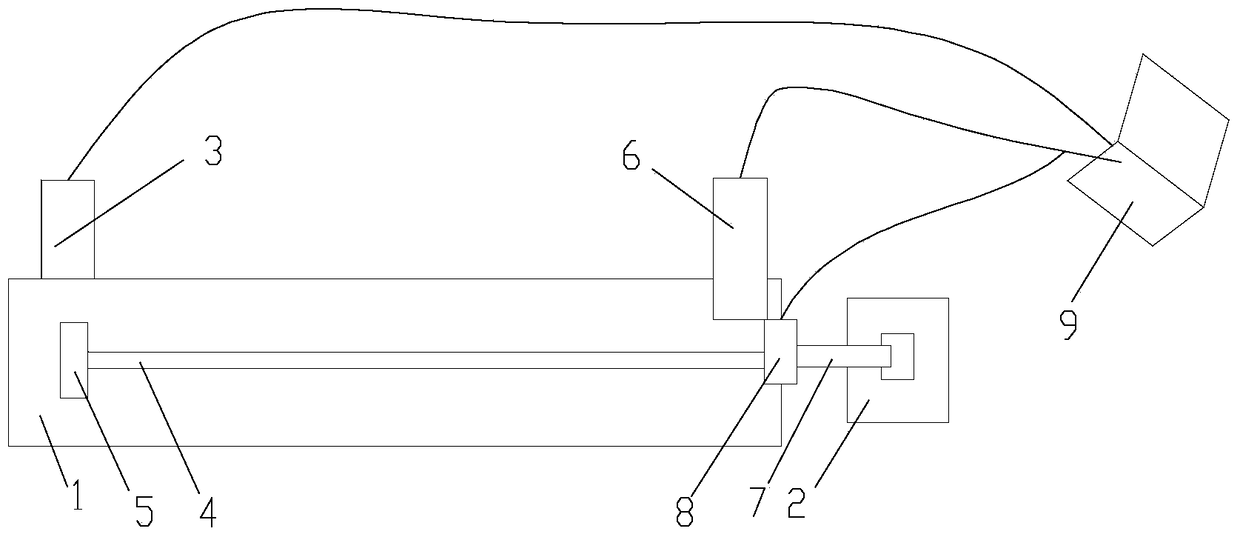

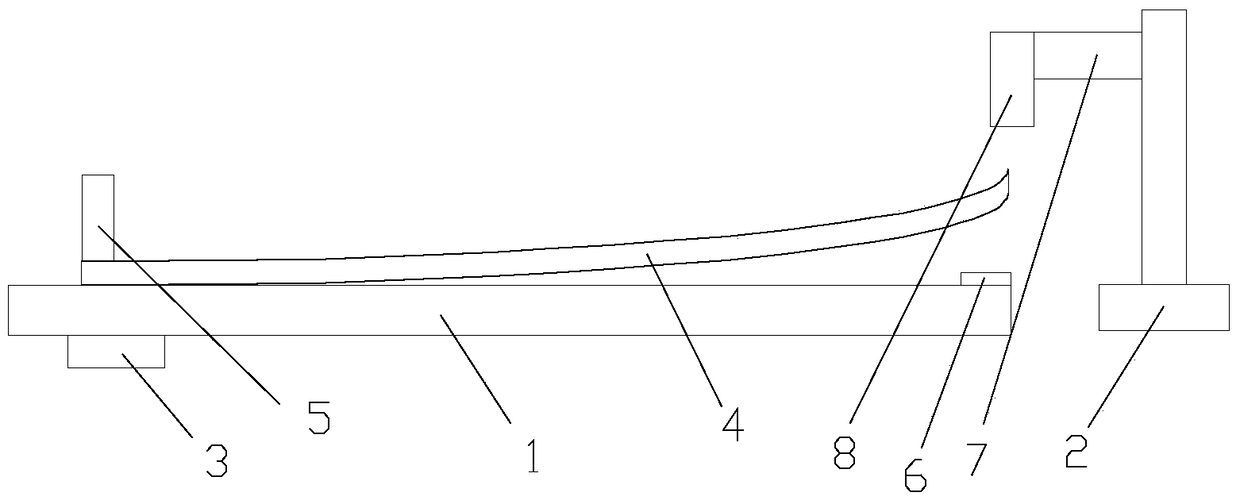

[0021] Such as figure 1 and figure 2 A device for testing the bending strength of bamboo slices by an ultrasonic motor as shown, comprising a test platform 1 and an ultrasonic motor 2, one end of the test platform 1 is provided with an in-position sensor 3 and a pressure block 5 for fixing one end of the bamboo slice 4, and the other end of the test platform 1 One end is provided with a level sensor 6; the mover 7 of the ultrasonic motor 2 is provided with a test head 8, and a force sensor is provided on the test head 8; the in-position sensor 3, the level sensor 6 and the test head 8 are connected with intelligent control equipment. The intelligent control device is preferably a computer 9 . Ultrasonic motor 2 has a fast response speed, which can improve the test accuracy to a limited extent without adding other mechanisms; compared with ordinary electromagnetic motors, when the level sensor detects that the bamboo piece is attached to the platform, the motor can stop quick...

Embodiment 2

[0025] A method for testing the bending strength of bamboo slices by an ultrasonic motor, comprising the steps of:

[0026] Step 1, using a pressing block 5 to fix one end of the bamboo sheet 4 on the test platform 1;

[0027] Step 2, the mover 7 of the ultrasonic motor 2 drives the test head 8 to press down the other end of the bamboo slice 4 until the level sensor 6 detects that the other end of the bamboo slice 4 is attached to the upper surface of the test platform 1;

[0028] Step 3, the intelligent control device obtains the straightening strength of the bamboo slices 4 through the force sensor.

[0029] The bamboo slices 4 are transported to the test platform 1 through the automatic transmission belt; at this time, the position sensor 3 detects the bamboo slices, and after measuring the straightening strength, the automatic transmission belt transports the bamboo slices 4 to the corresponding storage box.

[0030] The intelligent control device is preferably a computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com