Auto-controlled gas liquid two purpose leakage detector

A leak detector, a dual-purpose technology, applied in the direction of measuring the increase and decrease rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of not being able to detect liquid, internal valve damage, affecting accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

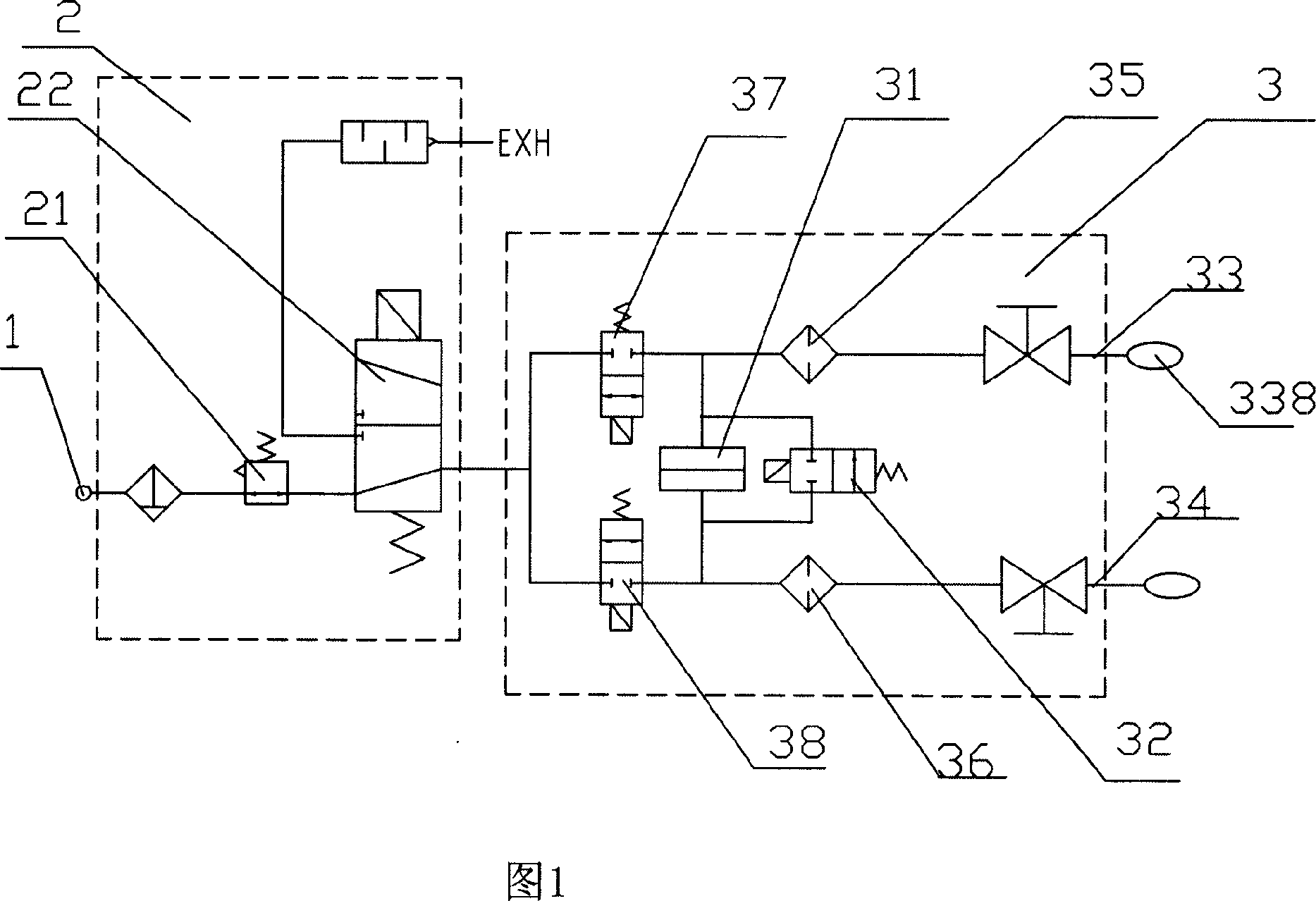

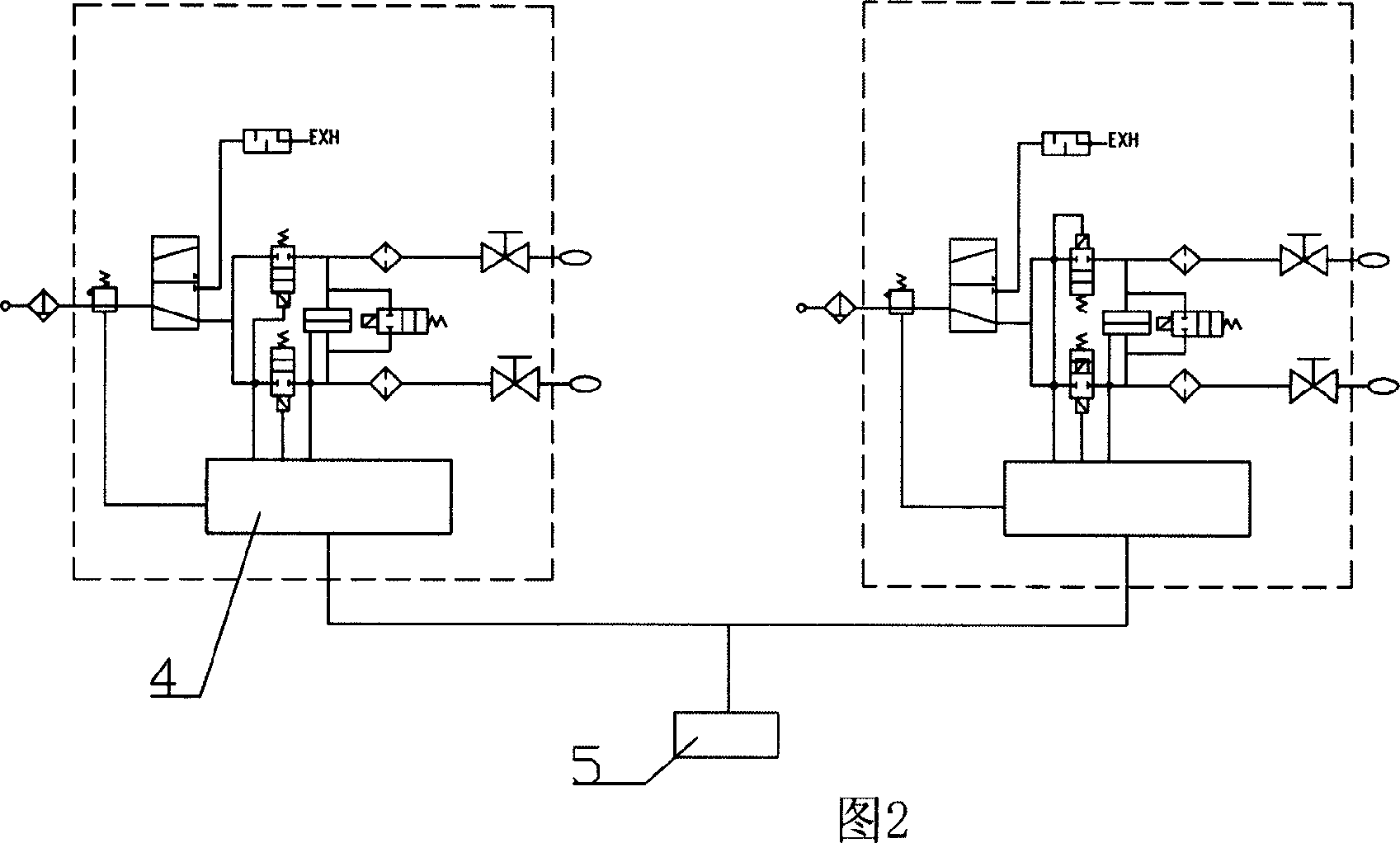

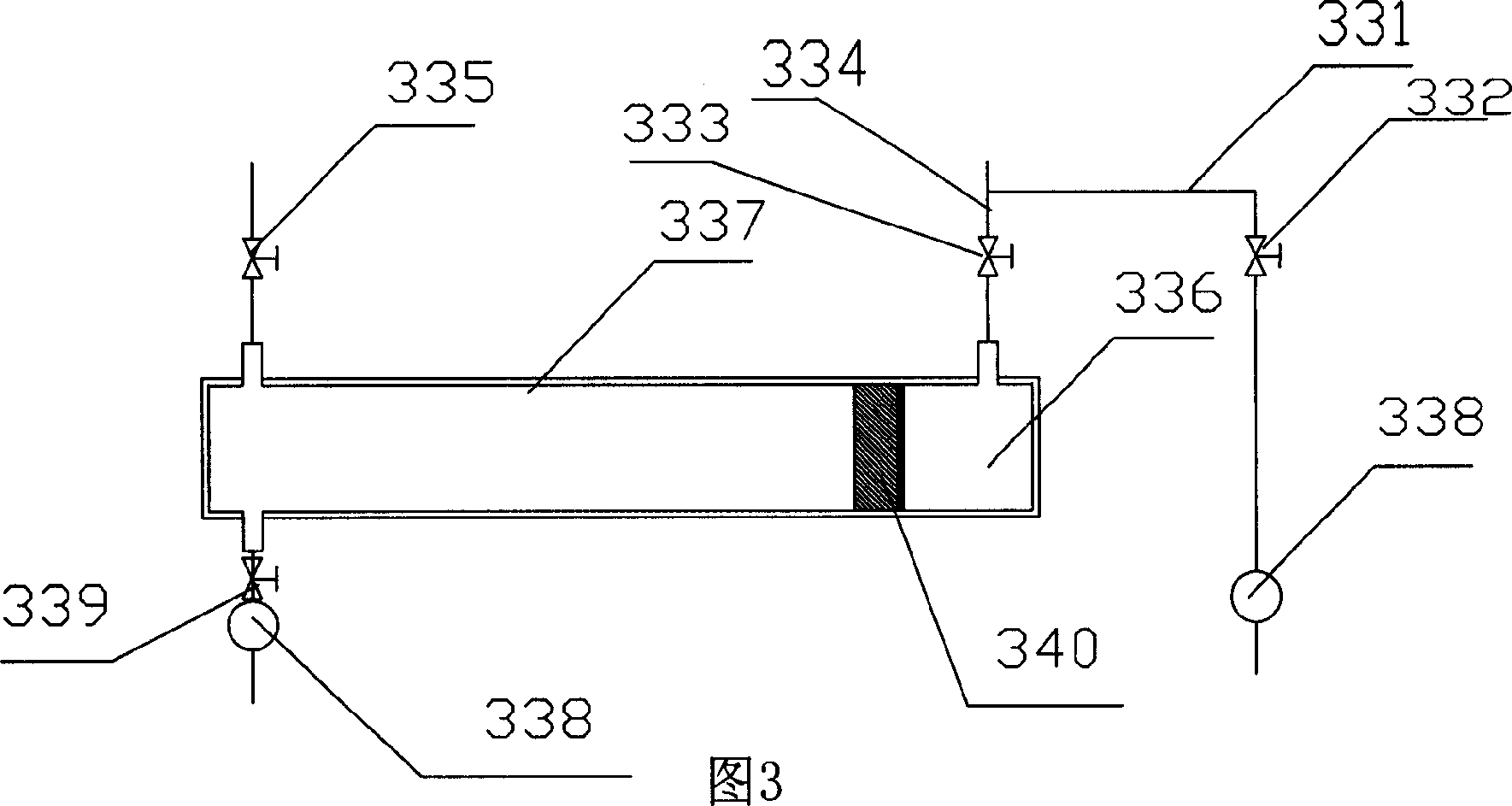

[0027] An automatic control gas-liquid dual-purpose leak detector, as shown in Figure 1 and Figure 2, includes a gas source 1, a pressure adjustment part 2, a differential pressure detection part 3, and a pressure adjustment part 2 and a differential pressure detector connected in series in sequence. The pressure detection part 3 is connected to the control part 4, and the differential pressure detection part 3 includes an SM5852-001-D-3-L digital differential pressure sensor 31, a first filter 35, a second filter 36, and a first two-way valve 37 , the second two-way valve 38, the pressure protection valve 32 and the probe 33 and the standard part 34 arranged in parallel, the pressure adjustment part 2 is provided with a SAM-APU-01 type electric control valve 21 and a three-way valve 22, and the control part 4 is provided with The output terminal (not shown) that can be connected with the remote control system 5, as shown in Figure 3, the probe 33 includes a gas detection pipel...

Embodiment 2

[0029] Other structures are different from Embodiment 1, as shown in FIG. 4 , the pressure sensor 340 provided between the air chamber 336 and the liquid chamber 337 is provided with two piston assemblies, and an oil chamber is arranged between the two piston assemblies. 341, the oil chamber 341 is provided with an oil inlet 342 and an oil outlet 343.

Embodiment 3

[0031] An automatic control gas-liquid dual-purpose leak detector, as shown in Figure 1 and Figure 2, includes a gas source 1, a pressure adjustment part 2, a differential pressure detection part 3, and a pressure adjustment part 2 and a differential pressure detector connected in series in sequence. The pressure detection part 3 is connected to the control part 4, and the differential pressure detection part 3 includes an SM5852-001-D-3-L digital differential pressure sensor 31, a first filter 35, a second filter 36, and a first two-way valve 37 , the second two-way valve 38, the pressure protection valve 32 and the probe 33 and the standard part 34 arranged in parallel, the pressure adjustment part 2 is provided with a SAM-APU-01 type electric control valve 21 and a three-way valve 22, and the control part 4 is provided with The output terminal (not shown) that can be connected with the remote control system 5, as shown in Figure 5, the gas-liquid dual-purpose detection devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com