Wiper blade nozzle holder

A technology for nozzle brackets and wiper blades, which is applied in the automotive field, and can solve the problems that the washing liquid cannot be sprayed as required, the consumption of washing liquid is too much, and the scraping is not clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

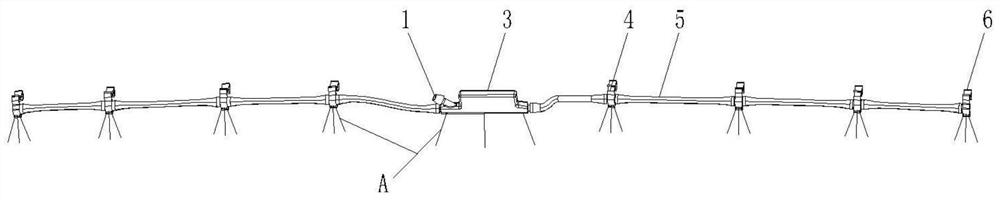

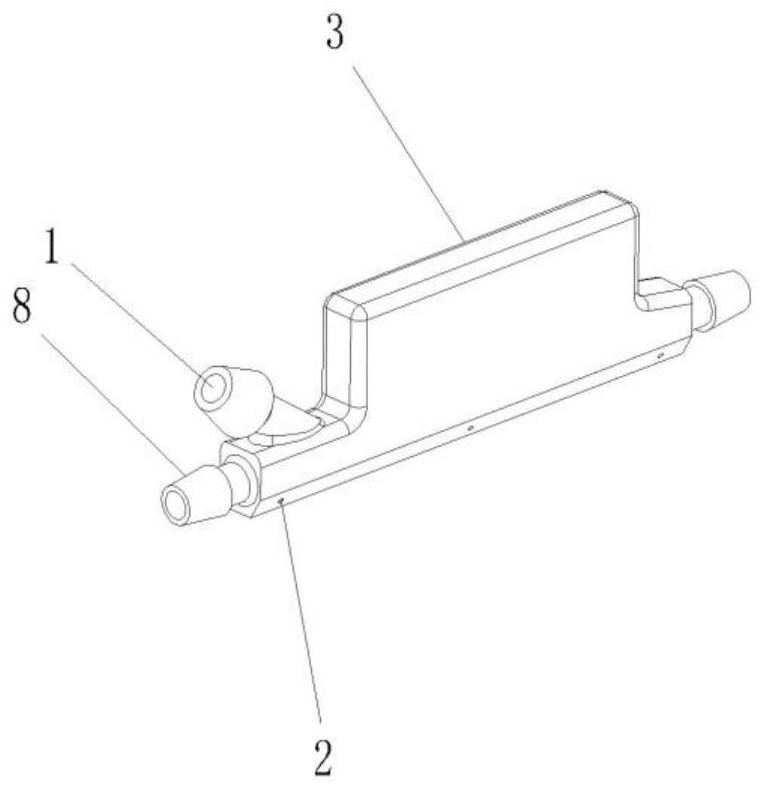

[0024] As shown in the figure: this embodiment provides a wiper blade nozzle bracket, including a wiper bracket for installing a wiper blade, and a liquid inlet hole 1 and a plurality of liquid spray holes 2 are opened on the wiper bracket. The liquid inlet hole is used to guide the washing liquid into the wiper bracket and spray it out through the liquid spray hole, and the liquid spray hole is located on one side of the wiper bracket along the windshield wiping direction.

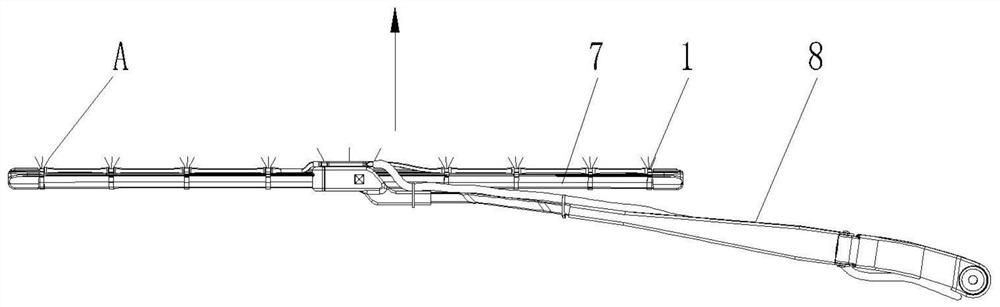

[0025] Such as figure 1 As shown, the wiping direction is the upward side of the wiper bracket along the windshield, and the wiper blade 8 is installed on the wiper bracket, wherein the wiper bracket is installed on the wiper arm 9, and the liquid inlet hole passes through the pipeline and the washing liquid The liquid outlet of the pump is connected. In this embodiment, there is one liquid inlet hole, and each corresponding liquid spray hole is connected with the liquid inlet hole, so that the washing li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com