Material testing device under high-pressure hydrogen environment based on ionic liquids and operation method

A technology for ionic liquid and material testing, which is applied in the field of material testing devices under high-pressure hydrogen environment based on ionic liquid, can solve the problems of low measurement sensitivity of load sensitive components, low test efficiency, and corresponding flow reduction, so as to avoid the hidden danger of hydrogen leakage , Improve the safety of the device, and the effect of corresponding traffic increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

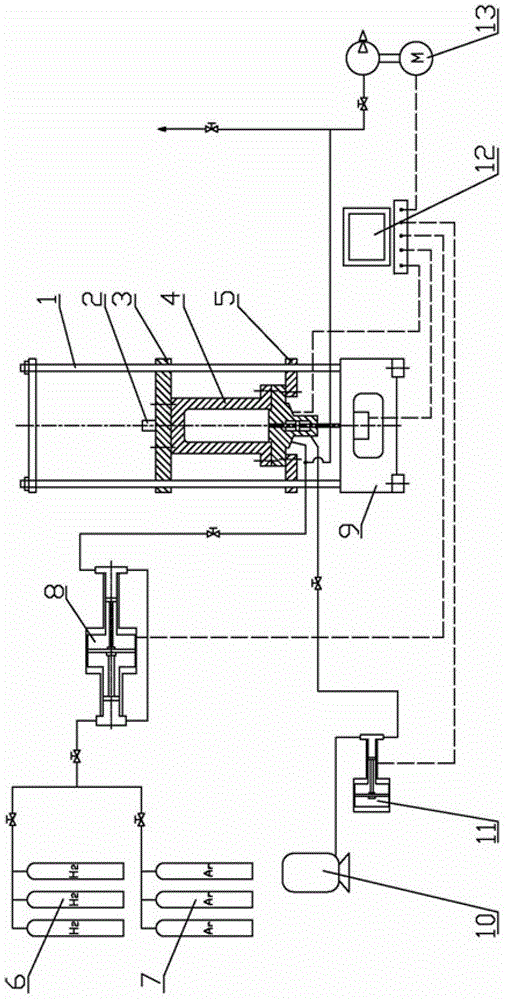

[0033] In this embodiment, the material test device based on the high-pressure hydrogen environment of ionic liquid, such as figure 1As shown, it includes a high-pressure hydrogen environment box 4, a main engine 9 with power output, a hydrogen cylinder set 6 for providing high-pressure hydrogen, a pneumatic hydrogen booster pump 8, an ionic liquid storage device 10 for providing high-pressure ionic liquid, and a pneumatic liquid booster pump 11 , a vacuum pump 13 for vacuuming in the high-pressure hydrogen environment box 4, an argon cylinder set 7 for replacement, and a control system 12 for the entire test device, etc. The high-pressure hydrogen environment box 4 is fixedly supported by the environment box support plate 5, and its opening and closing are jointly realized by the environment box lifting hydraulic cylinder 2, the upper guide ring plate 3 and the guide column 1.

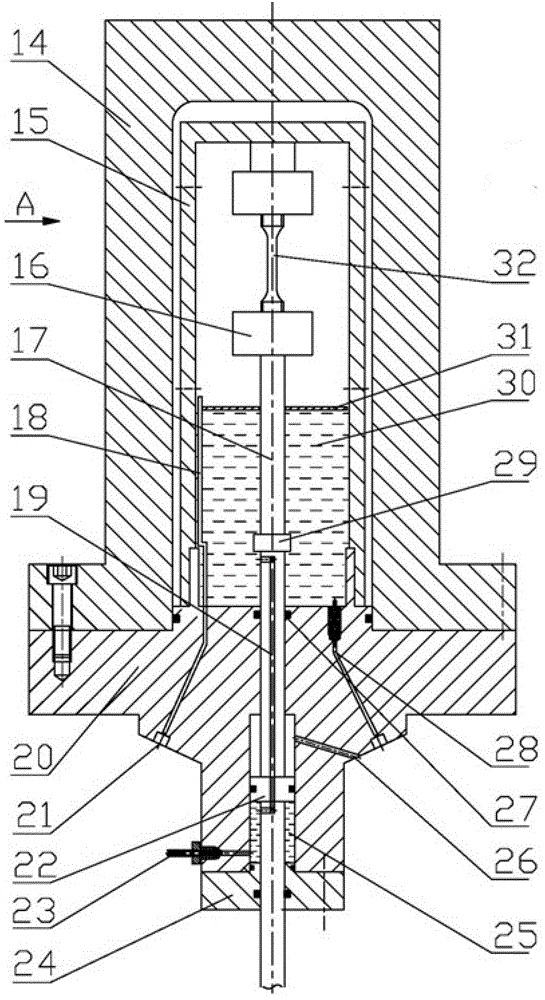

[0034] like figure 2 As shown, the high-pressure hydrogen environment box 4 is composed of an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com