Punching device and method based on cooperation of nanofluid electro-hydraulic breakdown and infrared thermal radiation

A technology of nanofluid and punching device, which is applied in the direction of mining fluid, safety device, earthwork drilling and mining, etc. It can solve the problems of enhanced permeation of punching liquid, easy blockage, poor punching effect, etc., and achieve the effect of enhanced punching effect , Fast heating speed and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

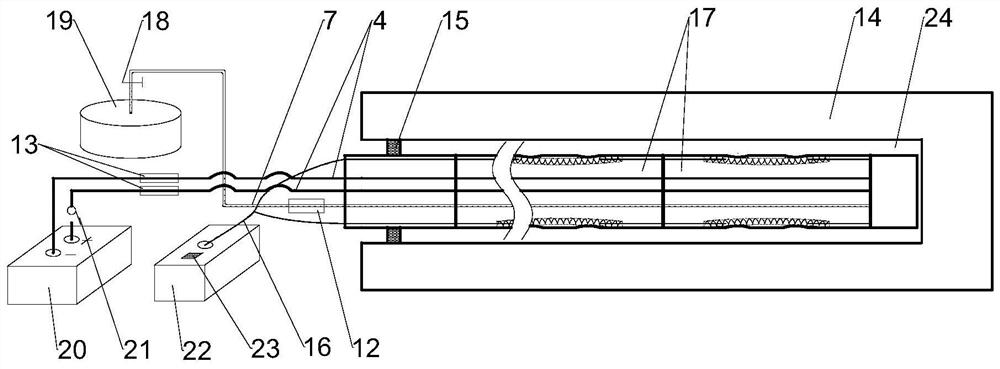

[0042] Next, the present application also provides an implementation method of the above-mentioned punching device based on nanofluid-based liquid-electric breakdown and infrared heat radiation, which specifically includes the following steps:

[0043] The first step is to install the combined drill pipe 17, connect various pipelines, and push the drill pipe 17 into the borehole 24 until the bottom of the borehole 24 after the punching device is installed;

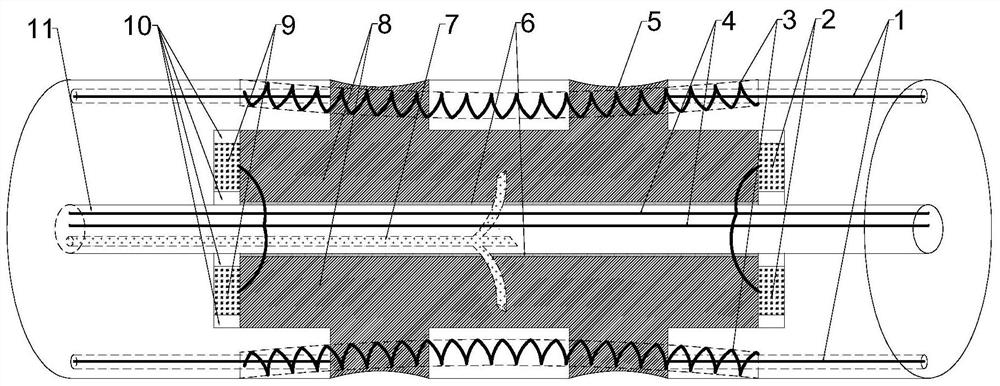

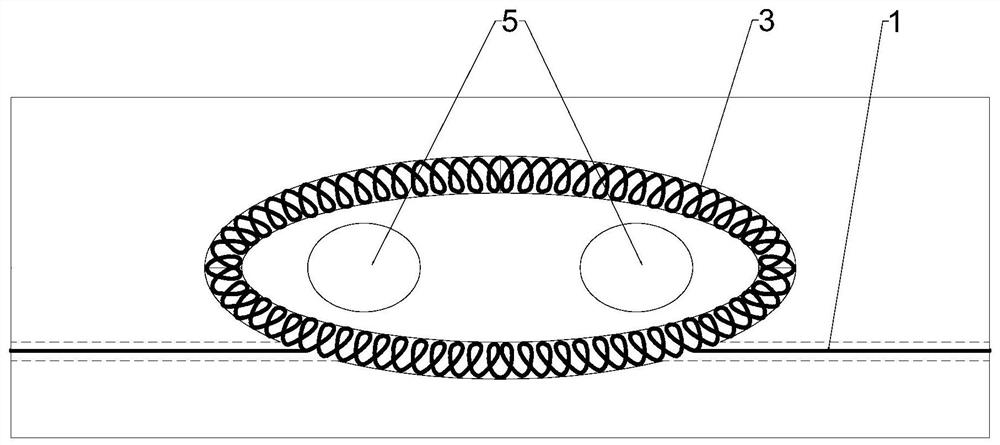

[0044] In the second step, a movable hole sealer 15 is installed at the position of the drill pipe 17 and the hole 24, and the hole 24 is sealed, and the liquid injection pump station 19 is started. Pipe 7 injects AZO nanofluid into injection chamber 8;

[0045] The third step is to start the high-voltage electric pulse generator 20 to charge the positive electrode plate group and the negative electrode plate group (here, the preset charging value is 250V), after the positive electrode plate group and the negative electrod...

Embodiment 2

[0050] The present application also provides a second implementation mode, which specifically includes the following steps:

[0051] The first step is to install the combined drill pipe 17, connect various pipelines, and push the drill pipe 17 into the borehole 24 until the bottom of the borehole 24 after the punching device is installed;

[0052] In the second step, a movable hole sealer 15 is installed at the position of the drill pipe 17 and the hole 24, and the hole 24 is sealed, and the liquid injection pump station 19 is started. The tube 7 injects ZnO nanofluid into the liquid injection chamber 8;

[0053] The third step is to start the high-voltage electric pulse generator 20 to charge the positive electrode plate group and the negative electrode plate group (here the preset charging value is 500KV), after the positive electrode plate group and the negative electrode plate group are charged to the preset voltage of 500KV Turn off the high-voltage power switch 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com