Integrated type biomass self-operated cyclone gasification combustion furnace

A biomass and integrated technology, applied in the direction of solid fuel combustion, gasification process, combustion equipment, etc., can solve the problems of inability to produce biomass coke, serious environmental pollution, etc., and achieve easy promotion, low pollution emissions, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

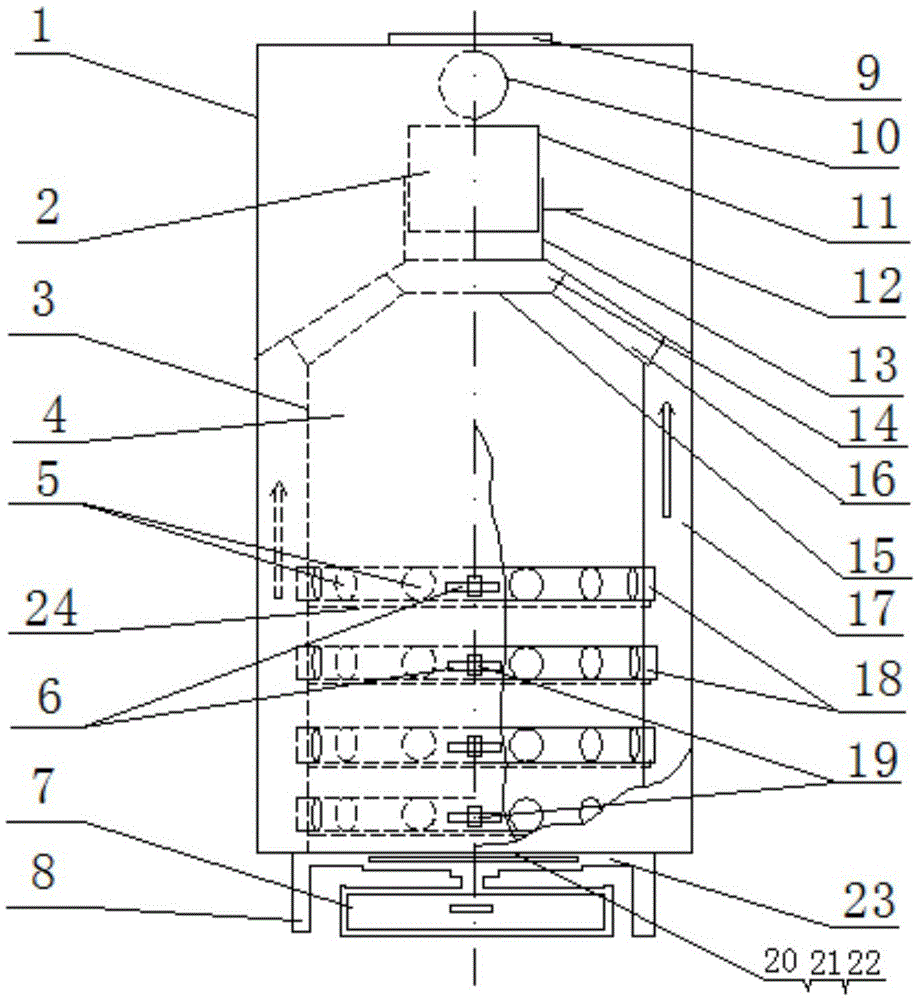

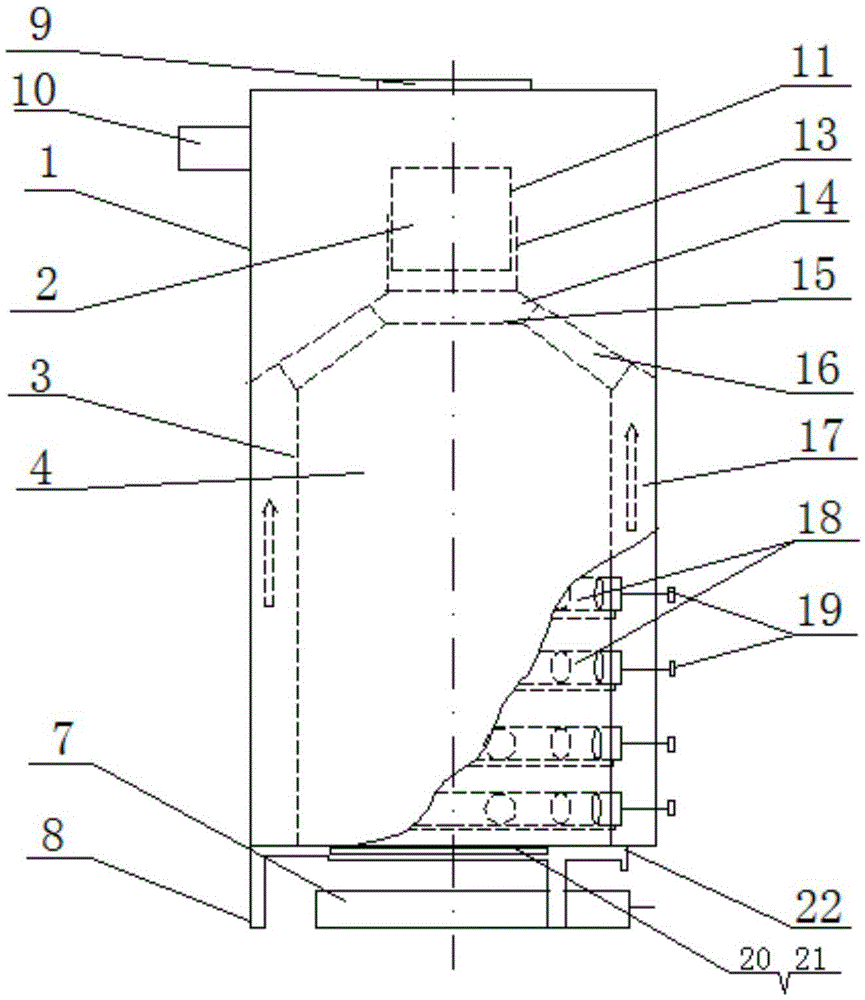

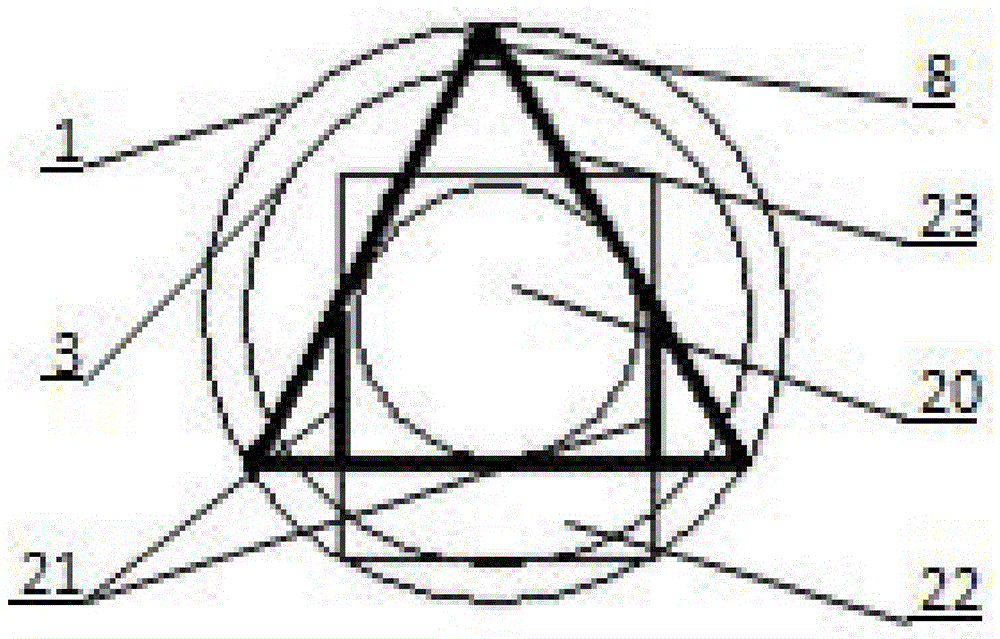

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0019] Such as Figure 1~4 As shown, the integrated biomass self-powered cyclone gasification combustion furnace in this embodiment includes a shell 1, a furnace foot 8, a furnace ring cover 9, a flue 10, a furnace door 20, a slot 21, a slot 22 and Furnace seat frame 23, wherein: it also includes an inner tube 3, 3 to 5 rows of primary air inlet holes 5, 3 to 5 primary air regulating slots 6, a coke bucket 7, a combustion chamber 11, a combustion chamber 13, Secondary air inlet 14, 8-10 guide vanes 16, 3-5 primary air adjustment rings 18, 3-5 primary air adjustment buttons 19 and 3-5 retaining strips 24; shell 1 is a bottomless cylinder , the inner cylinder 3 is composed of a cylinder and a cone, the lower end of the cone is connected to the upper end of the cylinder, the gasification chamber port 15 is set at the top of the cone, the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com