Gasification furnace built-in tar gasification circulating system

A technology of tar gasification and circulation system, which is applied in the mechanical details of gasification device, gasification process, moving parts of gasifier, etc., which can solve the problem of less chain safety guarantee of gas production mechanism, poor sustainable gas production capacity, and air pollution and other issues, to achieve the effect of high safety interlocking coefficient and automation degree, strong sustainable gas production capacity, and less smoke and tar emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments and accompanying drawings.

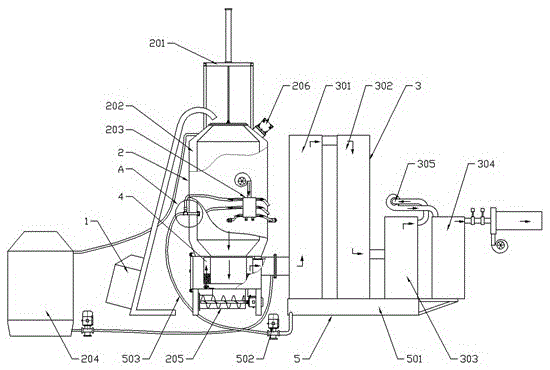

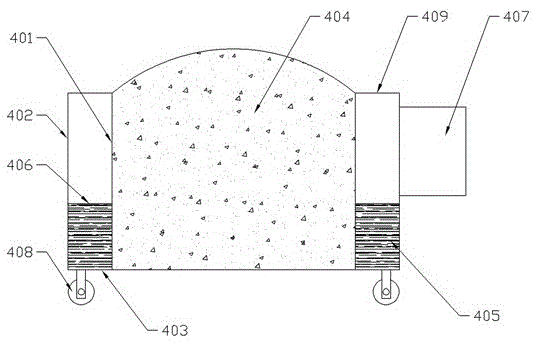

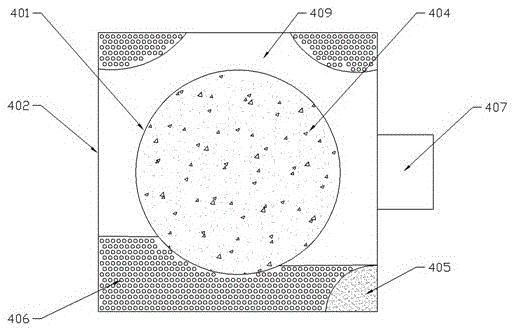

[0022] The implementation method is as follows: Figure 1-6 As shown, the gasification furnace built-in tar gasification circulation system includes a feeding device 1, a gasification device 2, and a separation cooling device 3 connected in sequence. The gasification device 2 includes a furnace body 202, and an automatic switch cover is provided on the top of the furnace body 202. Mechanism 201, a vibrator 206 is provided outside the furnace body 202, an air inlet mechanism 203 and a cooling mechanism 204 are connected outside the furnace body 202, an ash discharge mechanism 205 is provided at the bottom of the furnace body 202, and a tar gasification device is provided above the ash discharge mechanism 205 4. The tar gasification mechanism 4 includes an inner tank 401 and an outer tank 402. The top and bottom of the area between the inner tank 401 and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com