Technology for shells downdraft fixed bed gasification power generation and co-production of active carbon and heat

A fixed-bed gasifier, a technology for producing activated carbon, applied in fixed-bed gasification, gasification process, gasifier moving parts, etc., can solve the problems of insufficient standardization, high noise of gas generators, and large number of generators, etc. To achieve the effect of being conducive to large-scale production, stable improvement of equipment, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

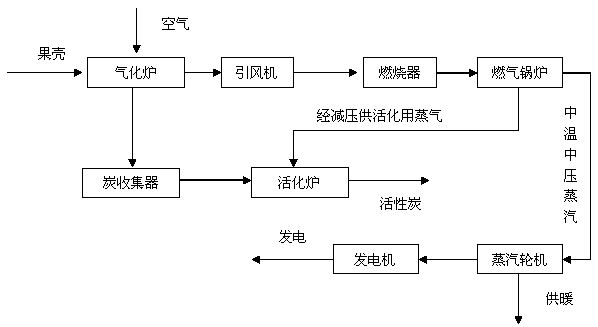

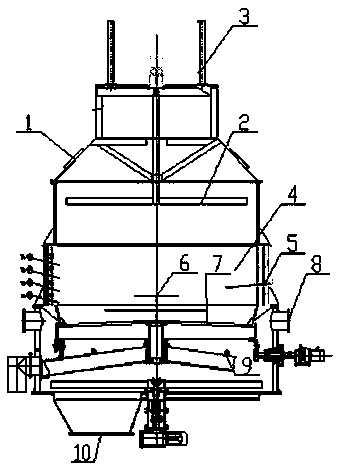

[0042] 3MW and more than 3MW, a kind of husk type downdraft fixed-bed gasification power generation co-production process of activated carbon and heat: After the husk biomass is collected, the water content should be less than 20% (if the water content exceeds 20%, use a roller to dryers and other drying equipment to dry to less than 20%), through the belt conveyor, the hopper in front of the furnace, and into the gas-char cogeneration fixed-bed gasifier, using air as the gasification agent, at a temperature of 600°C-800°C Gasification (gas production 1.7-2.5m 3 / kg, charcoal yield 20-30%), hot gas will be produced after gasification (calorific value of hot gas is 950-1300Kcal), the temperature of hot gas is about 350°C (the tar contained in hot gas is gaseous at about 350°C, hot gas There is still a small amount of dust), the hot gas is sent into the burner through the high-temperature induced draft fan to burn in the boiler, and produces medium-temperature and medium-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com