A process for cogeneration of electricity, charcoal and heat by fluidized bed gasification of straw

A technology of fluidized bed gasification and fluidized bed gasification furnace, which is applied in gasification process, chemical industry, granular/powdered fuel gasification, etc. It can solve the problems of poor economic benefit, single process product, and reduced efficiency , to achieve the effect of facilitating large-scale production, improving economic benefits, and stably improving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

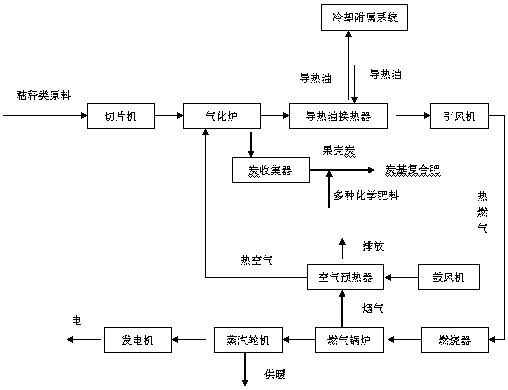

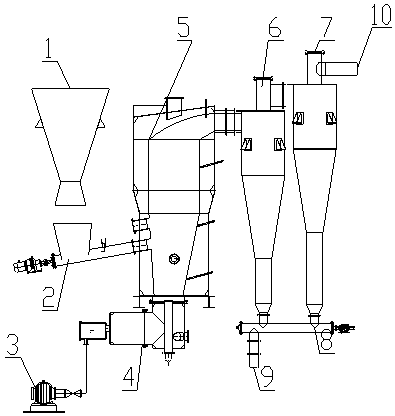

[0041]3MW and more than 3MW straw fluidized bed gasification power generation co-generation process of electricity, charcoal and heat: After the straw biomass is collected, it is cut into 20-30mm length by a slicer, and the dry moisture content is less than 20%. Belt conveying, hopper in front of the furnace, and spiral feeding into the fluidized bed gasification furnace for cogeneration of charcoal and gas, gasification at 750°C under the action of hot air blown by the blower, and gasification produces combustible gas (the calorific value of combustible gas is 1100- 1200Kcal, temperature about 600℃), the hot gas is cooled by the heat transfer oil heat exchanger, the temperature of the cooled combustible gas is about 350 degrees, and it is sent to the boiler with a burner by a high temperature resistant induced draft fan for combustion, and steam is generated to drive the steam turbine For power generation, the waste heat of steam exhausted by the steam turbine is used for heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com