Method for producing fine coal, pyrite concentrate and building sand by using high-sulfur coal refuses

A technology for high-sulfur coal gangue and construction sand, which is applied in the field of sulfur fine sand and construction sand, and high-sulfur coal gangue to produce clean coal, can solve the problems of furnace extinguishing and calorific value reduction, and achieves reduction of investment and production cost. , the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for producing clean coal, sulfur concentrate sand and construction sand from high-sulfur coal gangue, comprising the following steps:

[0025] a, prepare slurry: get 1 ton of coal gangue, crush it to a particle size of 80-120 mesh, add water until the mass percentage content of coal gangue is 30% (that is: the mass percentage content of coal gangue is 30%, and the remainder is water), Send it into the adjustment tank, and then add No. 2 oil of flotation agent (or No. 2 mineral processing oil, No. 2 mineral processing agent oil, terpineol oil for mineral processing, etc.) Shanshan Chemical Co., Ltd.; Hangzhou Tonglu Tianmu Pine Oil Refinery Plant; Gansu Baiyin Company Mineral Processing Pharmaceutical Factory, etc.) 60 grams, kerosene 1000 grams (manufacturer: PetroChina refineries; Sinopec refineries), mixed to make slurry; No. 2 oil is a foaming agent, and kerosene is a collector for coal;

[0026]b. Preparation of clean coal by flotation separation: the slur...

Embodiment 2-8

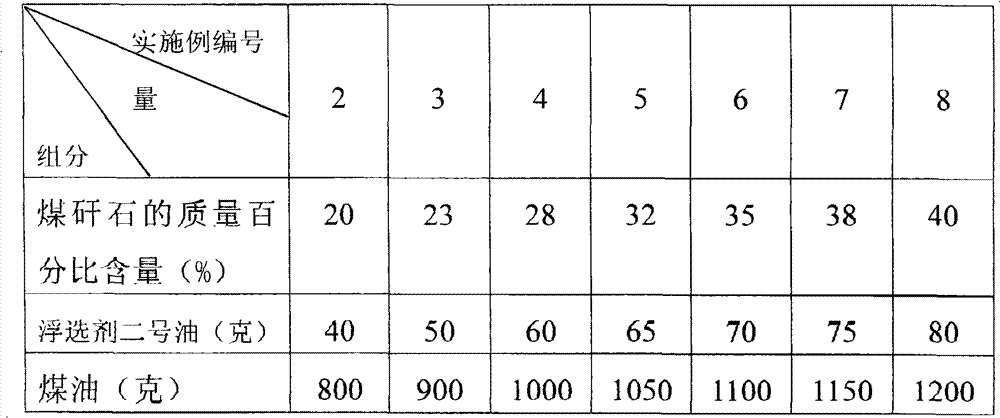

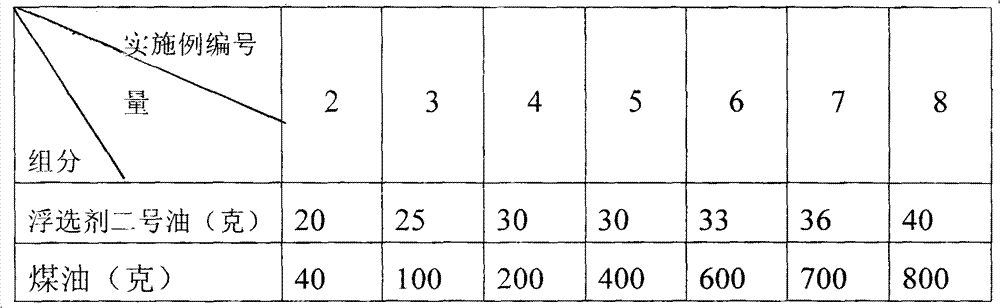

[0032] A method for producing clean coal, sulfur concentrate sand and construction sand from high-sulfur coal gangue, comprising the following steps:

[0033] a, prepare slurry: get 1 ton of coal gangue, crush it to a particle size of 80-120 mesh, add water until the mass percentage content of coal gangue is 20-40% (that is: the mass percentage content of coal gangue is 20-40%, and the remaining is water), sent to the adjustment tank, and then added No. 2 oil of flotation agent (or called No. 2 mineral processing oil, No. 2 mineral processing agent oil, pine alcohol oil for mineral processing, etc.) ; Zibo Boshan Chemical Co., Ltd.; Hangzhou Tonglu Tianmu Pine Oil Refinery Plant; Gansu Baiyin Company Mineral Processing Pharmaceutical Factory, etc.) 40-80 grams, kerosene 800 grams-1200 grams (manufacturers: PetroChina refineries; Sinopec refineries) , made into a slurry by stirring and mixing; No. 2 oil is a foaming agent, and kerosene is a collector for coal;

[0034] In each...

Embodiment 9

[0044] The method for producing clean coal, sulfur concentrate sand and construction sand from high-sulfur coal gangue comprises the following steps:

[0045] a. Prepare slurry;

[0046] b. Preparation of clean coal by flotation separation;

[0047] c, hydraulic gravity separation and separation to prepare sulfur concentrate: the step c hydraulic gravity separation to prepare sulfur concentrate is replaced by: sending the sulfur-containing and water-containing tailings into the spiral chute (the manufacturer of the spiral chute equipment has: Jiangxi Shicheng County Mine Machinery factory, Henan Fangda Industrial Co., Ltd., Hebei Kenaite FRP Co., Ltd., etc., carry out hydraulic gravity separation in the same prior art), and the separated heavy slurry enters the shaker again (the manufacturer of this equipment: Mining Machinery in Shicheng County, Jiangxi Province; Hengfu Mining Machinery Manufacturing Co., Ltd. in Yunnan Province; Nonferrous Mining Machinery Factory in Shiche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com