Pyrolysis gasification treatment integration box for garbage

A technology of pyrolysis gasification and integrated box, which is applied in gasification process, moving parts of gasifier, feeding tools of gasification device, etc. The effect of reducing the cracking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

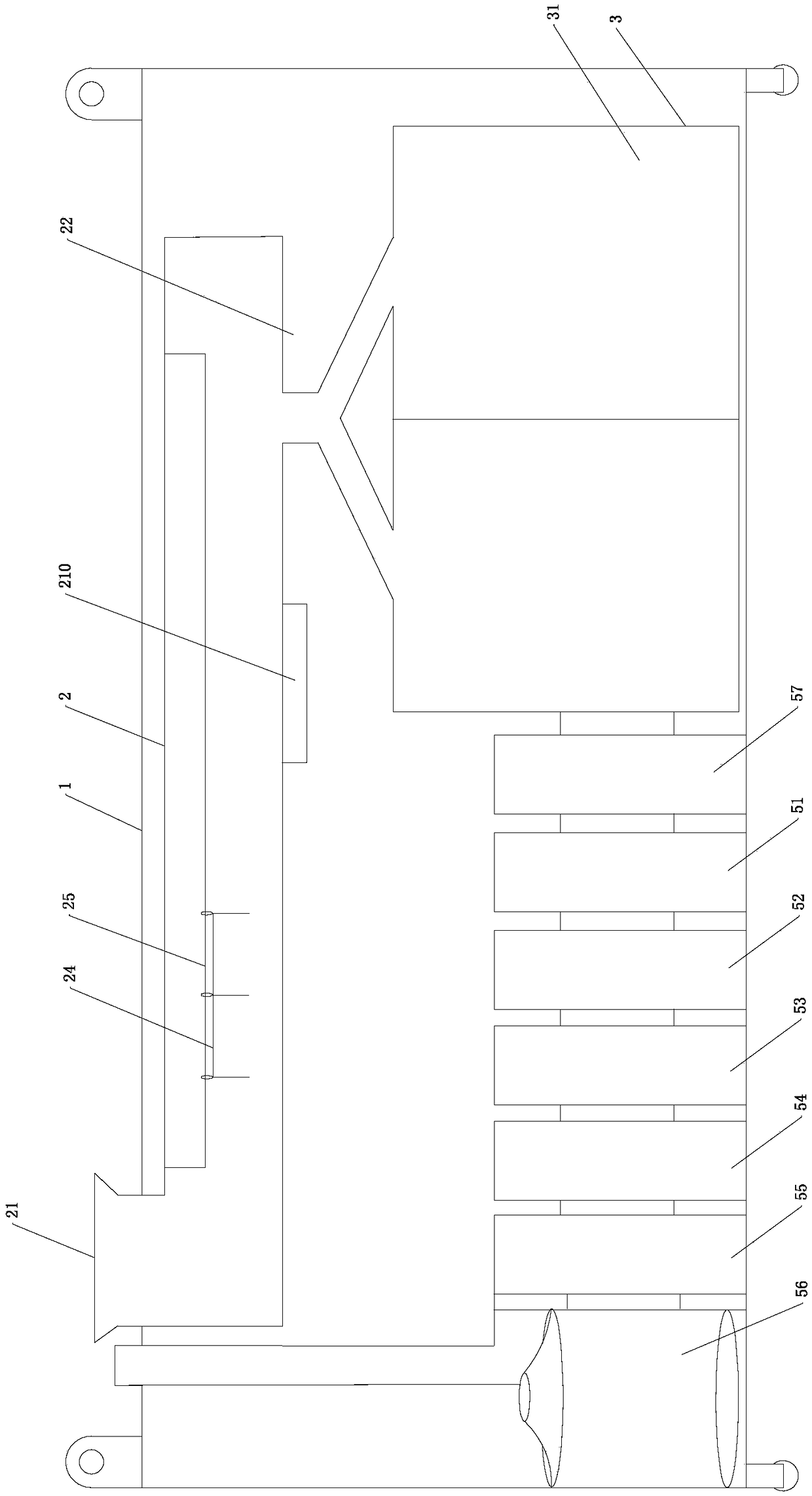

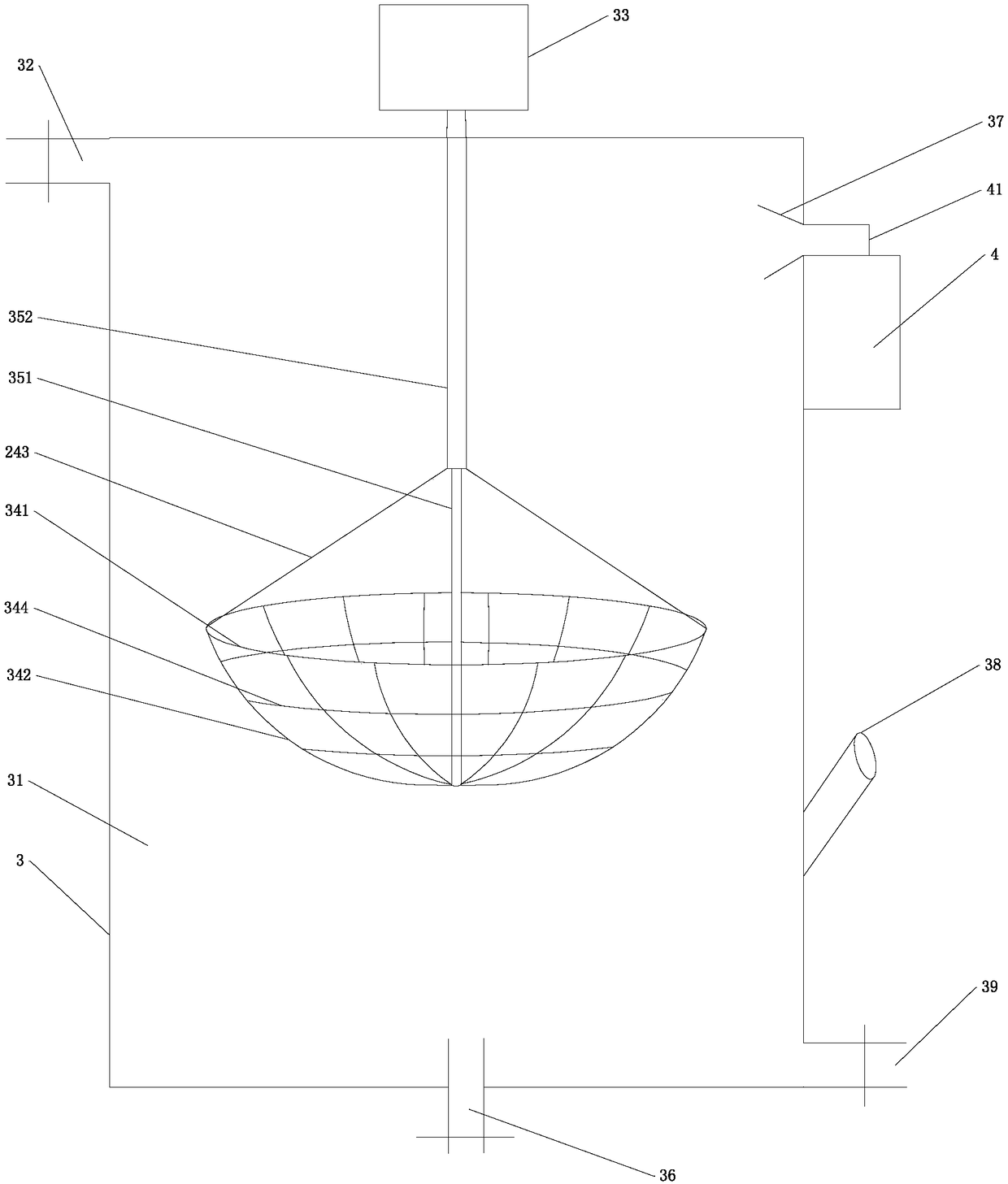

[0023] Such as Figure 1-4 The integrated garbage pyrolysis gasification treatment box shown includes box body 1, feeding system, cracking system, heating system 4, and flue gas purification system;

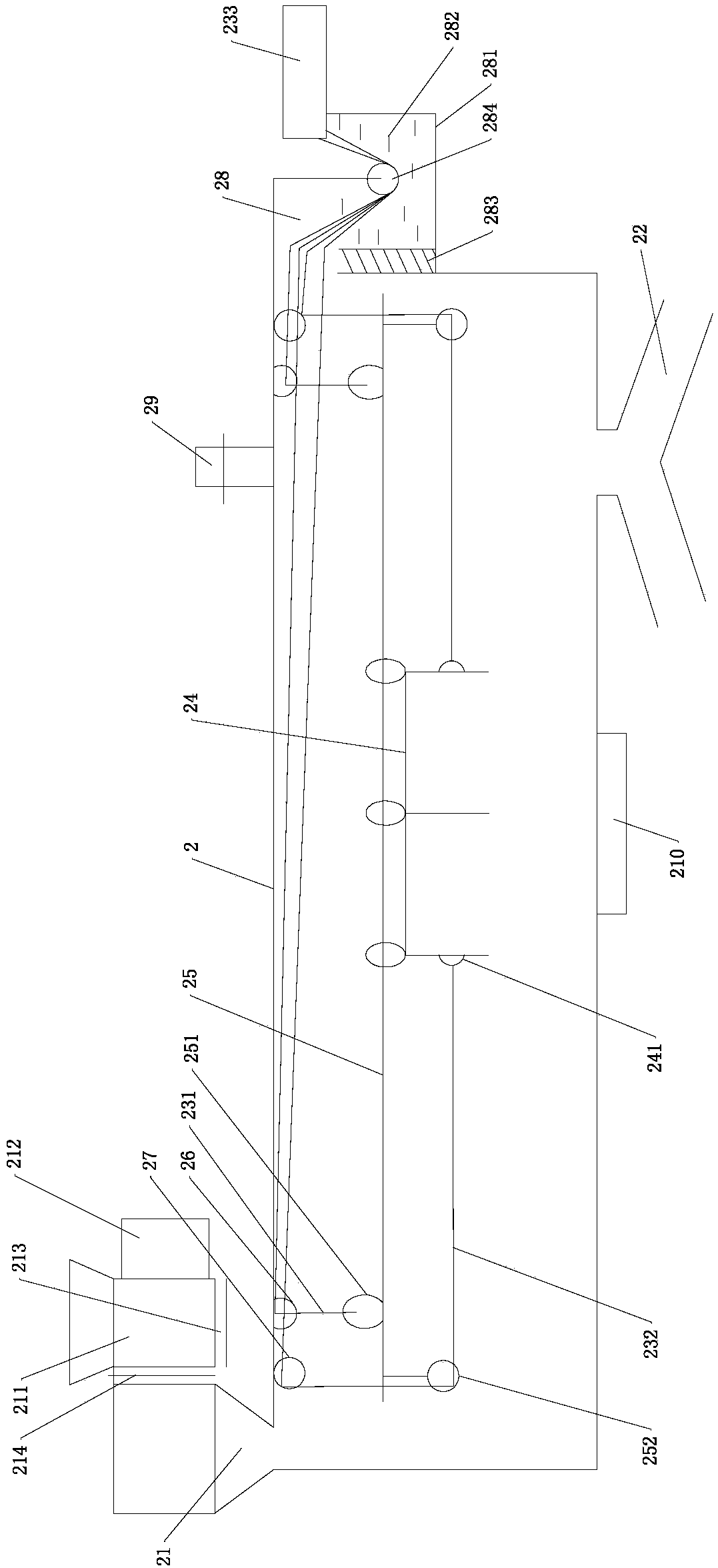

[0024] The feeding system includes a feeding channel 2 located above the inside of the box body 1. The top of the box body 1 is provided with lifting lugs, the bottom of the box body is provided with universal wheels, and the two ends of the feeding channel 2 are respectively provided with a feed port 21 and a discharge port. Port 22, the top of the feeding channel 2 is provided with a gas pipe 29 for feeding gas into the feeding channel 2, the bottom of the feeding channel 2 is provided with a heater 210 for igniting the gas passing into the feeding channel 2, and the feeding port 21 passes through The wall of the box body 1 is located at the top of the box body 1, and a scraping structure capable of driving the garbage is provided in the feed passage 2; a garbage pretreatment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com