Circulating fluidized bed and pyrolysis bed combined gasification process and device

A circulating fluidized bed, pyrolysis gasification technology, applied in the direction of gasification process, gasification device details, gasifier moving parts, etc., can solve the problems of increasing transportation labor costs, reducing coal utilization rate, and low thermal efficiency of raw coal , to achieve the effect of high raw coal gasification rate, high conversion rate and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

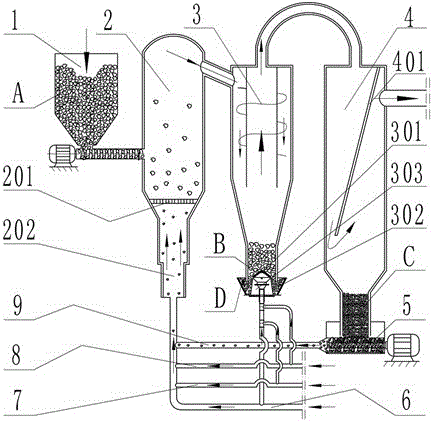

[0023] As shown in the drawings, the raw coal hopper 1 and the circulating fluidized bed gasifier 2 are connected through a coal delivery pipeline, and the upper part of the circulating fluidized bed gasifier 2 and the upper part of the cyclone separator 3 It is connected through a gas pipeline, and the top of the cyclone separator 3 is connected with the top of the precipitation chamber 4 through a gas pipeline; raw coal A is set in the raw coal hopper 1, and the upper part of the circulating fluidized bed gasifier 2 is In the gasification furnace cavity, an air distributor 201 is installed in the middle, and a mixed air distribution chamber 202 is located in the lower part. The upper part of the cyclone separator 3 is provided with a central cylinder, the bottom is provided with a slag pan 302, and the conical air distribution body 301 is arranged in the upper part of 302. The cyclone separator 3 floats on the slag pan 302, and a water seal is set between the slag pan 302 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com