Method for heating a high temperature winkler gasifier

a gasifier and high-temperature technology, applied in the field of high-temperature winkler gasifier heating, can solve the problems of gasifiers that cannot be fully heated, cannot be immediately ignited, and personnel involved in the dismounting process are exposed to a corresponding level of heat, so as to achieve the effect of simplified heating of high-temperature winkler gasifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

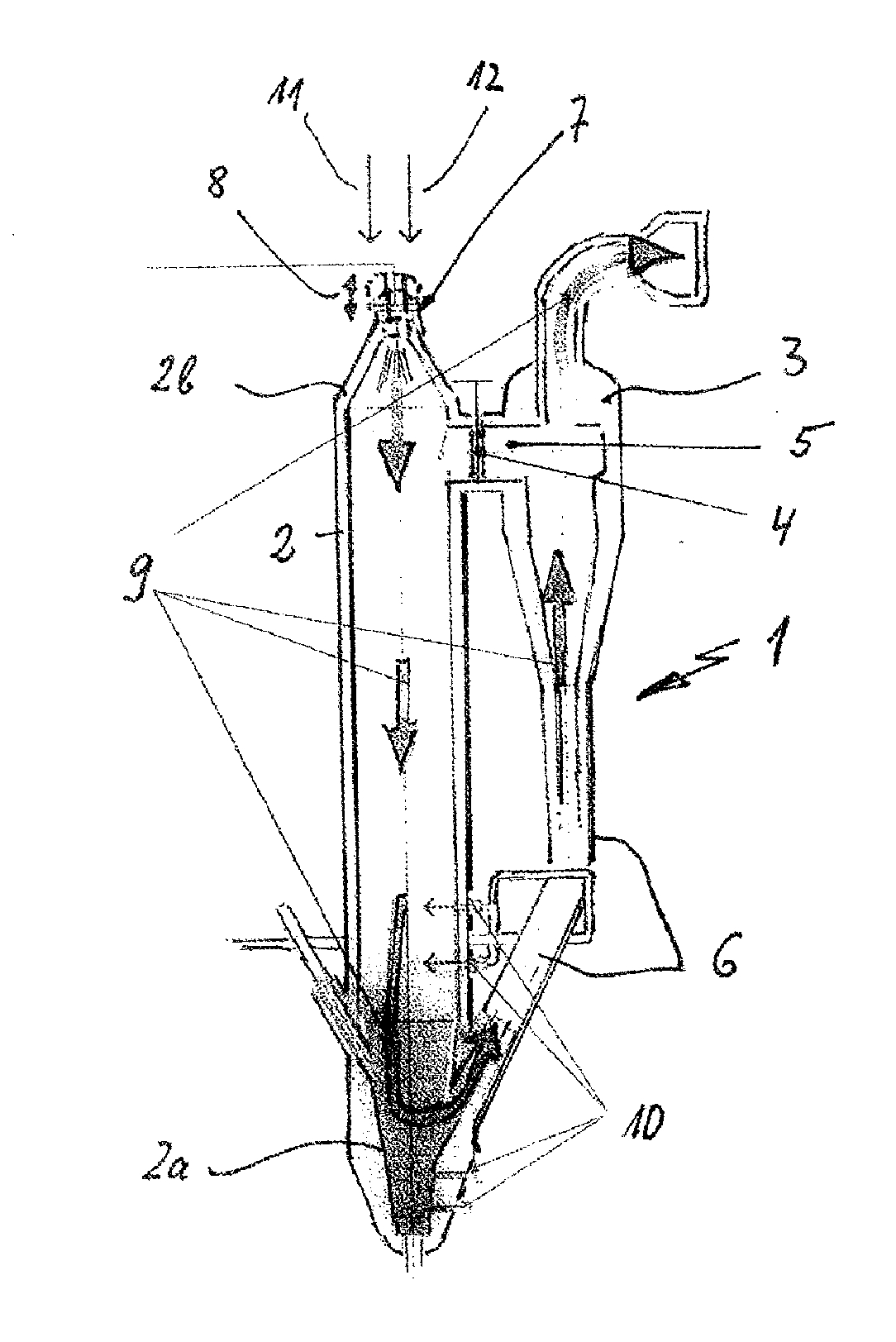

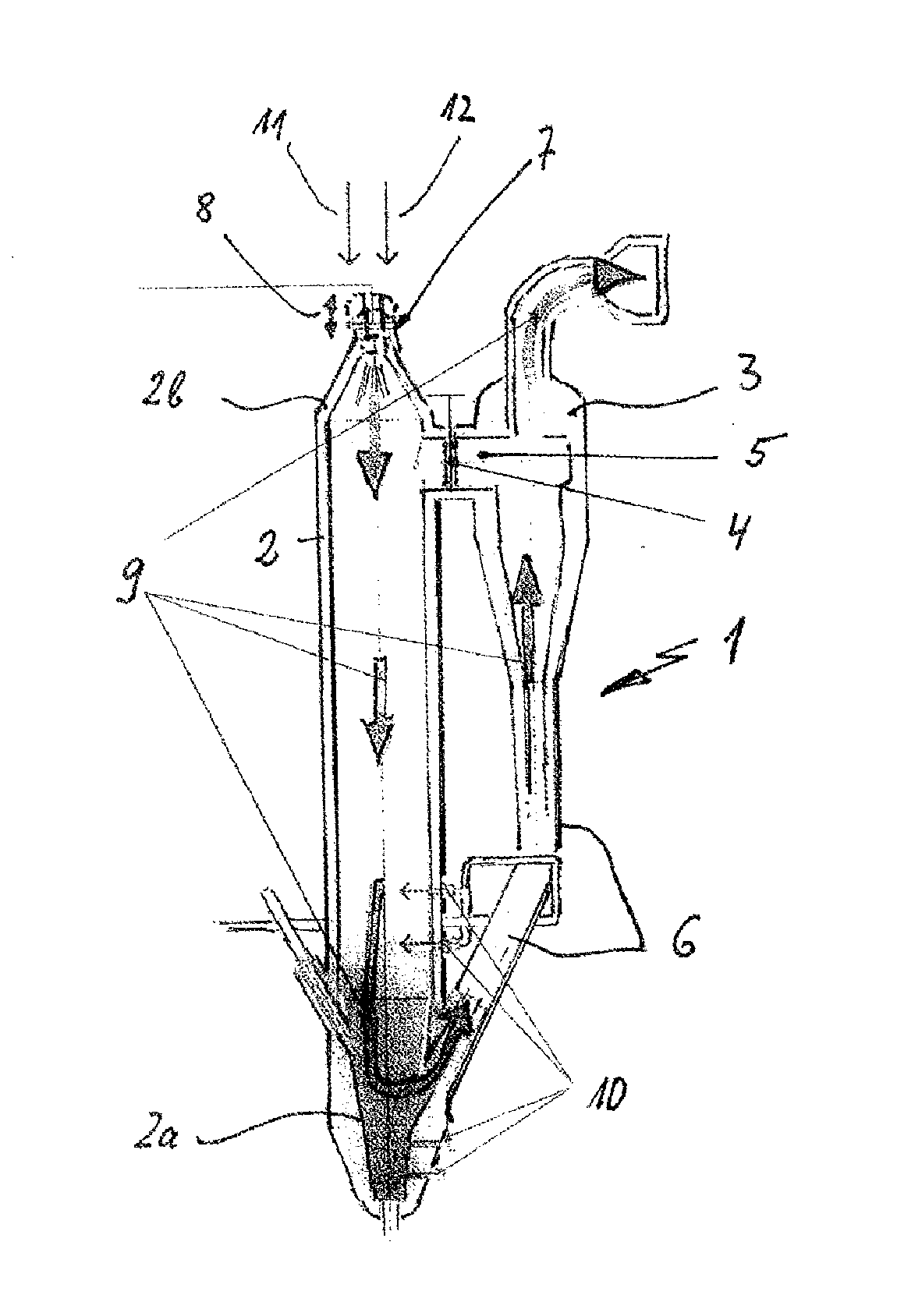

[0011]With a method of the type referred to in the introduction, use is made of at least one burner which is installed in the head region of the gasifier and which acts downward into the interior of the gasifier, wherein a gas flow is generated in the reverse direction through the return conduit of the cyclone.

[0012]With this method implementation, that is to say, with the use of a burner in the gasifier head and a reversal of the flow conditions that prevail during operation in the gasifier, optimum heating of the gasifier is realized with relatively simple means, wherein the need for mounting and dismounting the burner just for the heating process is eliminated.

[0013]Refinements of the method implementation according to the invention will emerge from the following description. Here, it may be provided that the burner is operated stoichiometrically or substoichiometrically.

[0014]A further refinement consists in that, during substoichiometric operation of the burner, combustion air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com