Lost foam-graphite chilling-antigravity casting process for railway cast-steel wheels

A technology of anti-gravity casting and lost foam casting, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc. It can solve the secondary oxidation of molten steel, the low recycling rate of water glass sand, and the impact of waste sand discharge on the surrounding ecological environment, etc. problems, to achieve the effect of reducing consumption and discharge of waste sand, and reducing the impact on the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

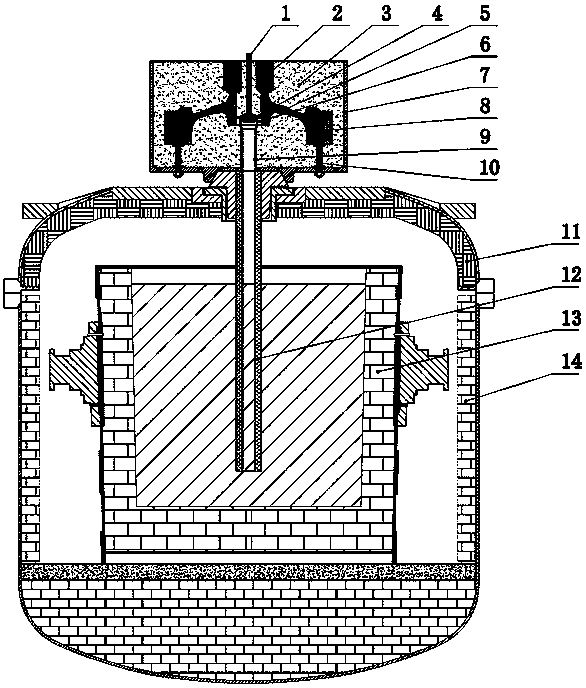

[0016] The lost foam graphite chilled anti-gravity casting process for railway cast steel wheels combines the advantages of lost foam casting technology, graphite chilled process and anti-gravity casting technology. In the sand box 7, the molded riser foam pattern 2, the wheel foam pattern 5 and the assembly of the inner runner 6, the pouring tube 9, the plug head 4 and the plug rod 1 are bonded together, and then placed on the graphite ring 8 and fill dry sand 3 into the lost foam casting sand box 7, after vibration, connect the negative pressure system, place the sand box on the top of the prepared pressure tank cover 11, and assemble it on the pressure tank cover 11 The riser pipe 12 communicates with the pouring pipe 9, and a ladle 13 is placed in the pressure tank body 14, and the riser pipe 12 is inserted into the ladle 13, and air or inert gas is pressed into the pressure tank to cast the wheels.

[0017] In this example, in figure 1 Among them, the thread roots at bot...

specific Embodiment 2

[0018] This embodiment is further described on the basis of specific embodiment 1. The graphite ring 8 is located on the outer surface of the corresponding wheel rim, and the formed riser foam pattern 2 is distributed above the wheel hub, and the formed wheel foam pattern 5 is designed in the hub hole. It is in the shape of a through hole to reduce the machining allowance of the axle hole of the wheel blank. The assembly of the plug head 4 and the plug rod 1 is fixed at the center of the hub hole through the inner runner 6, and the pouring tube 9 is also located at the center of the hub hole.

specific Embodiment 3

[0019] This embodiment is based on specific embodiment 1 to further illustrate the pouring process. Air or inert gas is pressed into the pressure tank, and the molten steel in the ladle 13 flows along the riser pipe 12, The pouring pipe 9 and the inner runner 6 are injected, the wheel foam pattern 5 and the riser foam pattern 2 are gasified after meeting molten steel, the gas is sucked away by the vacuum pump connected to the lost foam casting sand box 7, and the molten steel replaces the space of the foam pattern, and the molten steel is When the mold is filled to the set riser height, take down the plug rod 1, the plug head 4 blocks the pouring pipe 9, the pressure tank is released, and the poured mold is removed. The molten steel in the riser continues to feed the wheel body. The wheel rim is rapidly solidified under the chilling effect of the graphite ring 8 to form a dense structure. At the same time, under the action of the riser, the sequential solidification from the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com