Gasification-reforming transformation reformer of carbonic materials and method of preparing hydrogen-rich syngas

A reformer and synthesis gas technology, which is used in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

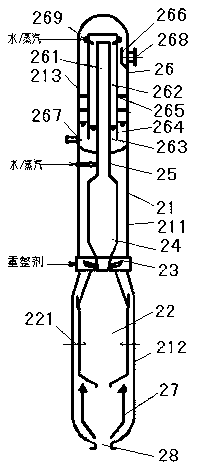

[0034] In order to better understand the present invention, the following will be described in detail through specific implementation cases in conjunction with the accompanying drawings:

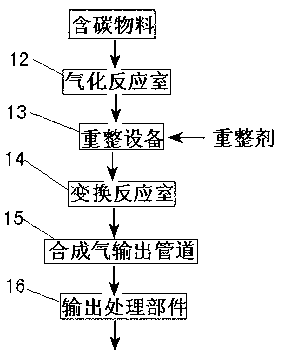

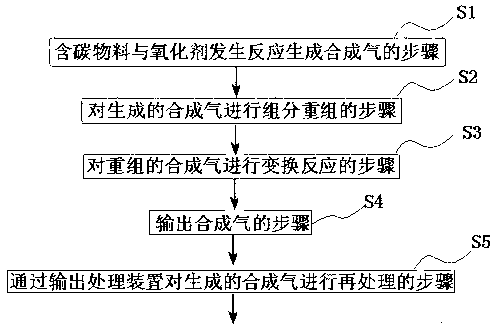

[0035] see figure 1 , figure 1 It is a schematic diagram of the principle of the carbonaceous material gasification-reforming conversion converter of the present invention. The carbonaceous material gasification-reforming conversion conversion furnace of the present invention comprises a coaxially arranged gasification reaction chamber 12, a reforming device 13, a conversion reaction chamber 14, and a synthesis gas output pipeline 15; the gasification reaction chamber is equipped with There is at least one burner; the reforming device is arranged at the output end of the gasification reaction chamber; the shift reaction chamber is arranged at the output end of the reforming device; the synthesis gas output pipe is always tube, connected at the output end of the transformation reaction cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com