Graphite mold for casting and assembling method thereof

A graphite mold and mold technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor overall wear resistance of bucket teeth, reduced casting production efficiency, uneven structure of bucket teeth, etc., and achieves easy demoulding. Low manufacturing cost and the effect of being beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

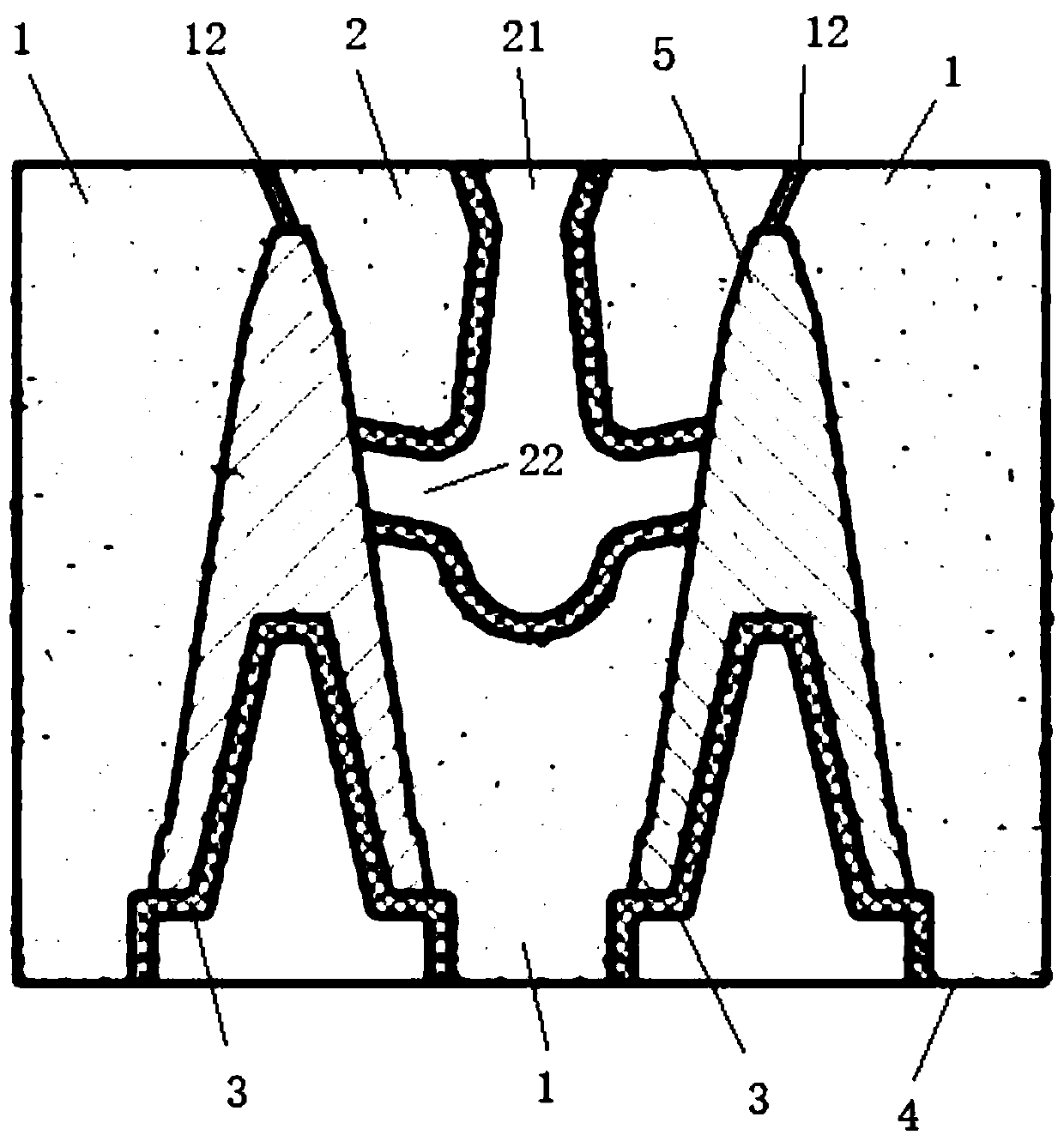

[0060] Such as figure 1 Shown is a schematic view of the longitudinal section of the graphite mold in the present invention.

[0061] The structure of the graphite mold includes: a mold body 1, a first sandbox 2, a second sandbox 3, and a mold case 4. The mold body 1 is provided with two cavities 11, and the top of the cavities 11 is provided with an exhaust hole 12; the first sandbox 2 is located between the two cavities 11, and the first sandbox 2 is provided with a connected branch runner 22 And the main runner 21, the opening of the main runner 21 is located at the top of the first sandbox 2; one end of the branch runner 22 is connected to the middle of the cavity 11, and the other end is connected with the main runner 21; the second sandbox 3 is located in the cavity The lower part of 11. The assembled mold b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com