C-shaped steel forming machine

A forming machine and C-shaped steel technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of reduced punching accuracy, reduced cutting accuracy, unfavorable steel plate feeding, etc., to achieve improved accuracy, improved stability, improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The embodiment of the present application discloses a C-shaped steel forming machine, which adopts the following technical scheme:

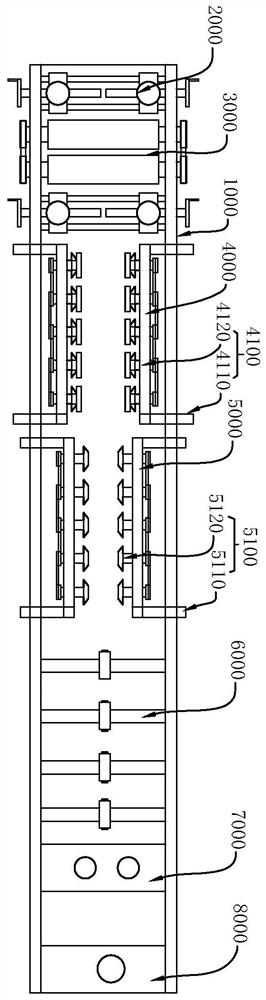

[0055] A C-shaped steel forming machine, refer to figure 1 , including a frame 1000, a guide positioning assembly 2000, a flattening assembly 3000, a side bending assembly 4000, a middle bending assembly 5000, a beading assembly 6000, a punching assembly 7000 and a shearing assembly installed on the frame 1000 in sequence 8000.

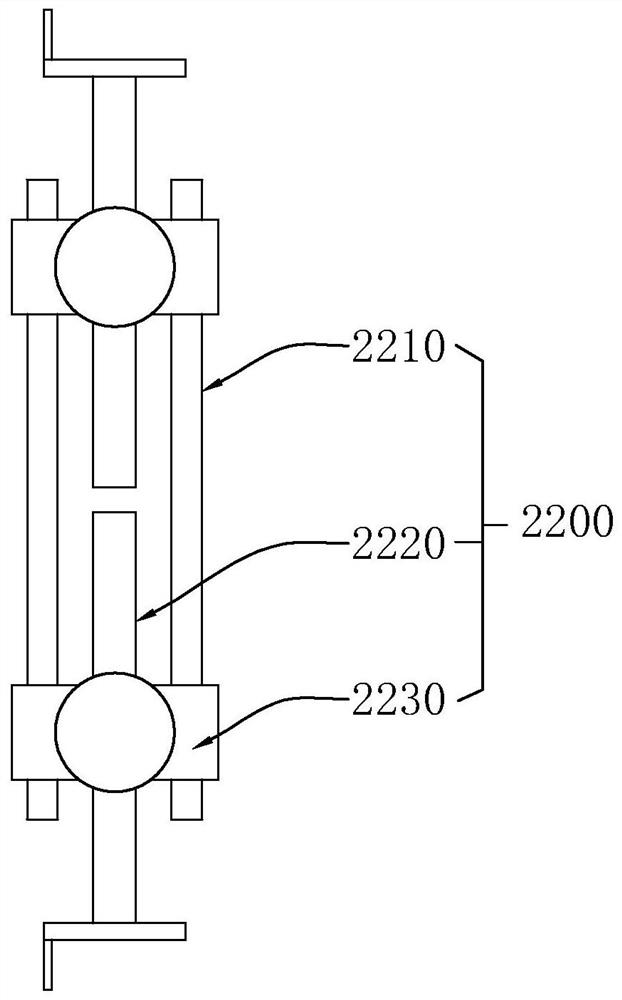

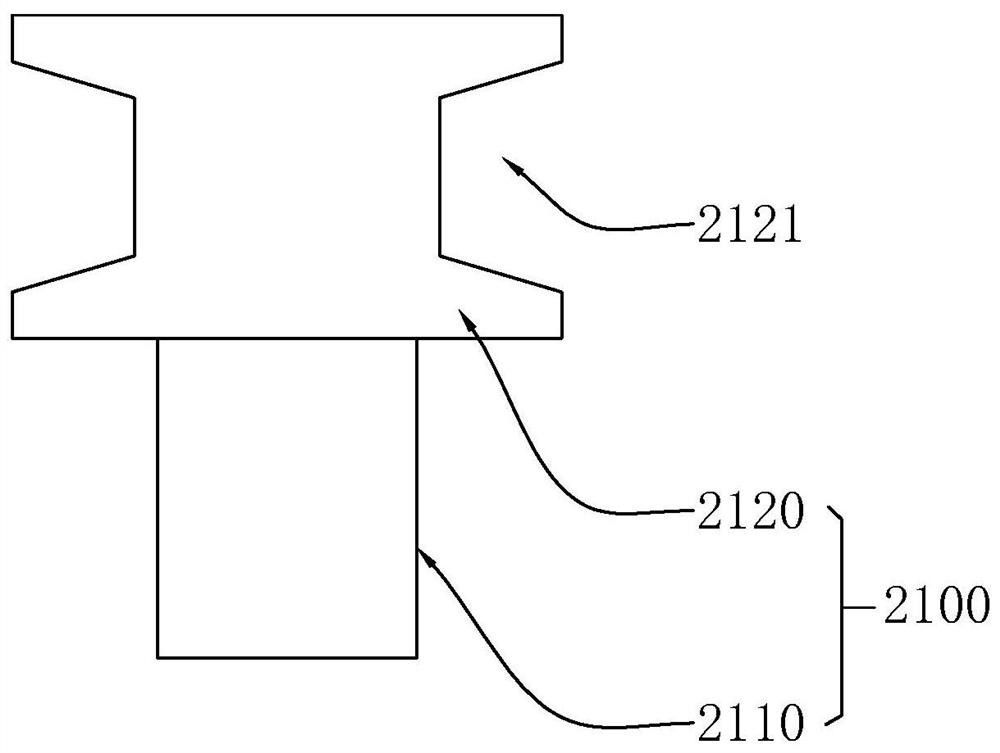

[0056] In this embodiment, a guiding and positioning assembly 2000 is provided on both sides of the flattening assembly 3000, and the guiding and positioning assembly 2000 has at least two opposite guiding and positioning wheels 2100; Guiding and positioning prevents the shift and deformation of the steel plate, improves the stability of the steel plate feeding, and improves the production efficiency; the flattening assembly 3000 includes several groups of pressing rollers 3100 that are rotatably connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com