Connecting method for solar cell array front and back face circuits

A solar cell array and connection method technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large connection thickness, affecting the gathering volume, etc., and achieve the effect of small connection thickness, improved reliability, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with embodiments and accompanying drawings.

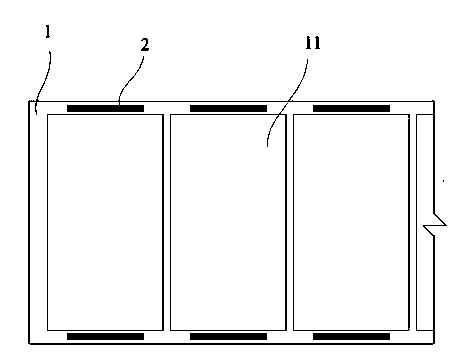

[0026] Such as figure 1 As shown, a plurality of sheet-shaped solar cell soldering pads 2 are laid on the front surface of the substrate 1, and both ends of the solar cell string 11 pasted on the front surface of the substrate are connected to the solar cell soldering pads 2 respectively. In order to facilitate welding, the solar cell welding pad 2 should be arranged on the edge of the base plate 1. The solar cell welding plate 2 is made of a metal material that is easy to weld, has low resistance, is soft, and has good toughness, preferably silver, copper or a valveable alloy, and the thickness does not exceed 0.5 mm.

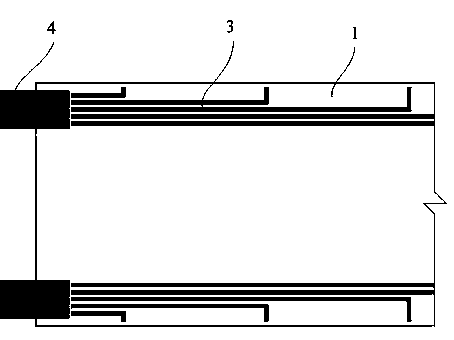

[0027] Such as figure 2 As shown, a sheet-like cable 3 is laid on the back of the substrate 1. The cable 3 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com