Manufacturing method for forming three-dimensional grating image-text on concave part of printing product and product made by method

A technology of three-dimensional grating and production method, which is applied in the direction of printing, printing and printing process of producing special varieties of printed matter, can solve the problems of thick material, difficult to bend and form, single image, etc., and achieve accurate nesting and easy bending and forming. , the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

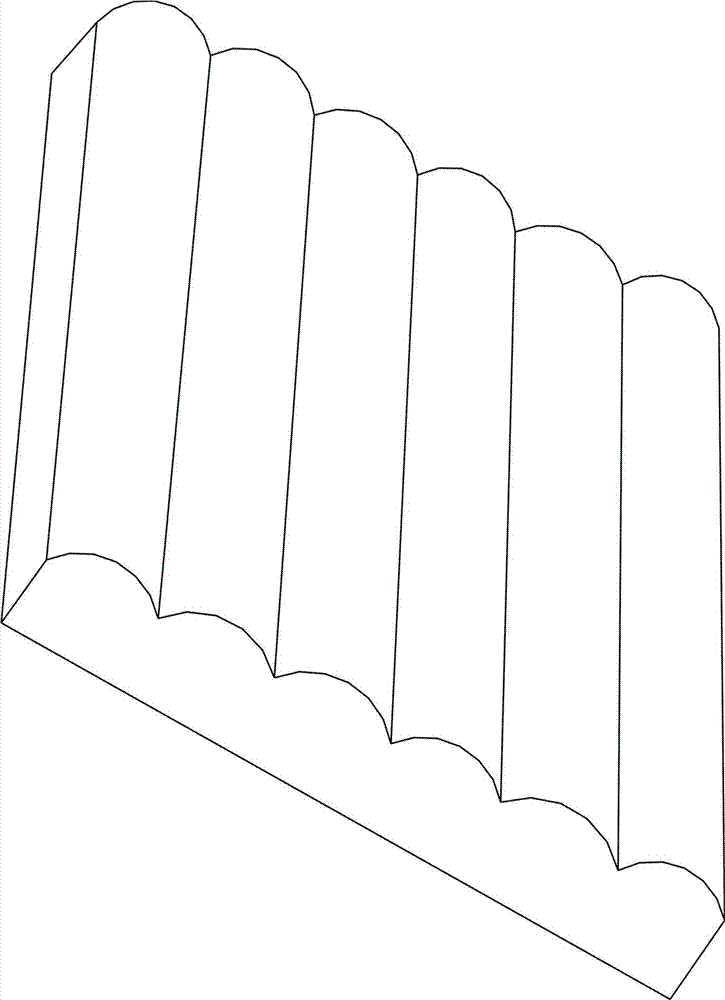

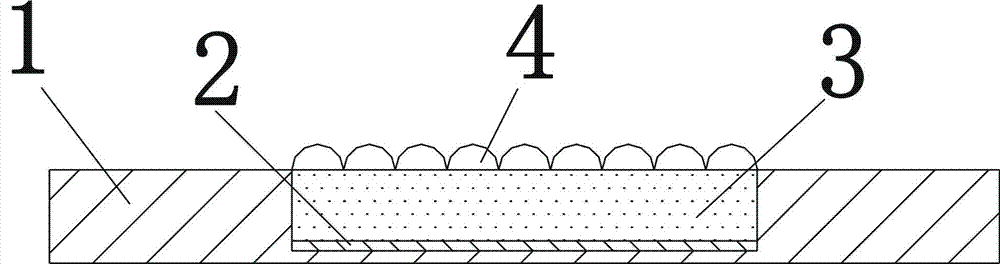

[0031] like figure 2 , 3 As shown, the concave portion of the present invention has a printed product with a three-dimensional grating graphic, and the bottom layer is a white cardboard 1 with a thickness of 1-3 mm, and the white cardboard is embossed to form a concave cavity with a depth of 0.23-0.38 mm; Above the bottom surface in the cavity is an ink layer 2, which adopts three-dimensional printing plate printing to form characters or patterns that can present three-dimensional effects; above the ink layer is a crystal glue layer 3, and the top surface of the crystal glue layer is connected to the cavity. The top surface is flat; on the crystal glue layer is a transparent resin layer 4 with a lenticular lens grating surface structure, and the size of the resin layer corresponds to the size of the top surface of the concave cavity. The production method is: (1) According to the design requirements, use a three-dimensional printing plate to print characters or patterns that...

Embodiment 2

[0033] like Figure 4 , 5As shown, the recess of another structure of the present invention has a three-dimensional lenticular print, the bottom layer is a white cardboard 1 with a thickness of 0.2-0.5mm, and the white cardboard is embossed to form a depth of 0.14-0.2mm. ㎜ concave cavity; above the inner bottom surface of the concave cavity is an ink layer 2a, which is printed by a three-dimensional printing plate to form characters or patterns that can present a three-dimensional effect; above the ink layer is a crystal glue layer 3, the crystal glue layer The top surface is flat with the top surface of the concave cavity; above the crystal glue layer is a transparent resin layer 4 with a lenticular lens grating surface structure, the size of the resin layer corresponds to the size of the top surface of the concave cavity; the white cardboard has no concave cavity Part of the surface of the area has an ink layer 2b, and the ink layer is a character or a pattern formed by pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com