Hollow glass spacing section bar

A glass, fixed-distance technology, applied in parallel glass structure, wing frame and other directions, can solve the problems of poor bending and shaping performance, cumbersome process, poor thermal insulation performance, etc., and achieve the effect of avoiding moisture absorption

Inactive Publication Date: 2008-10-15

SHANDONG NATERGY ENERGY TECH CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aluminum, stainless steel and other metal hollow spacers are easy to bend and form. After forming, they are better shaped and easy to process, but have poor heat insulation performance; polymer plastic spacer profiles have low thermal conductivity and good heat insulation effect, but poor bending and setting performance. In order to make an integral partition frame, it has to be cut into strips, and then assembled with corner connectors, which is a cumbersome process; pre-mixed with porous materials and molecular sieve desiccants, and then compounded with sealing materials and reinforcing materials, the manufacturing process is complicated. high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

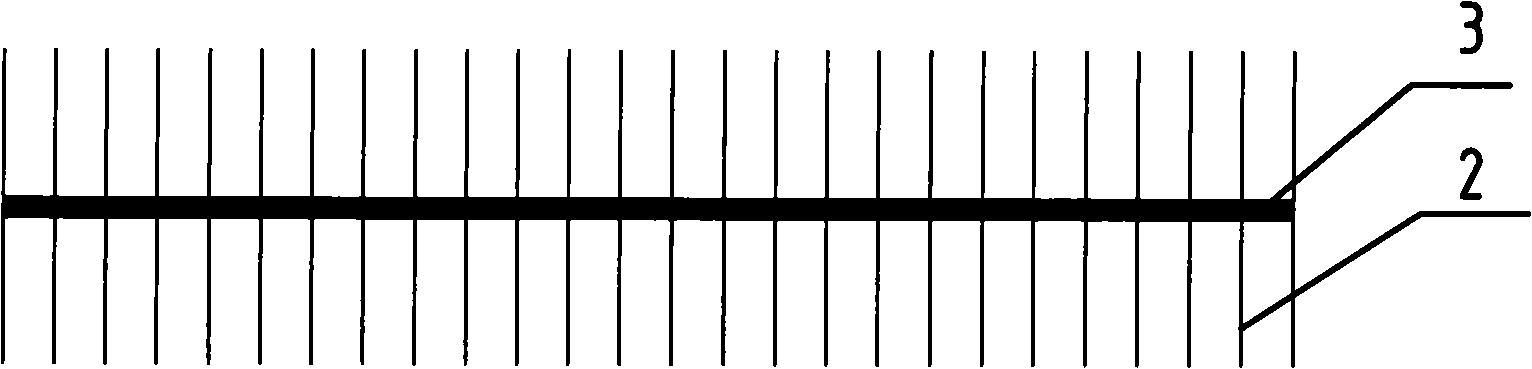

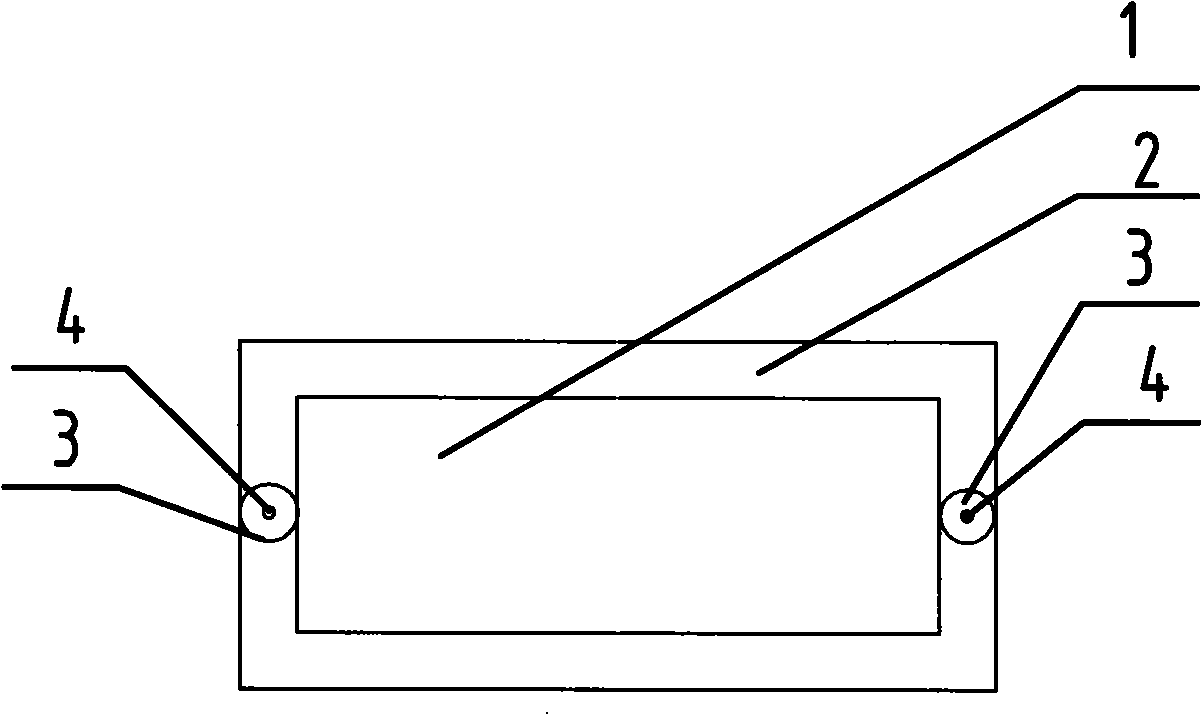

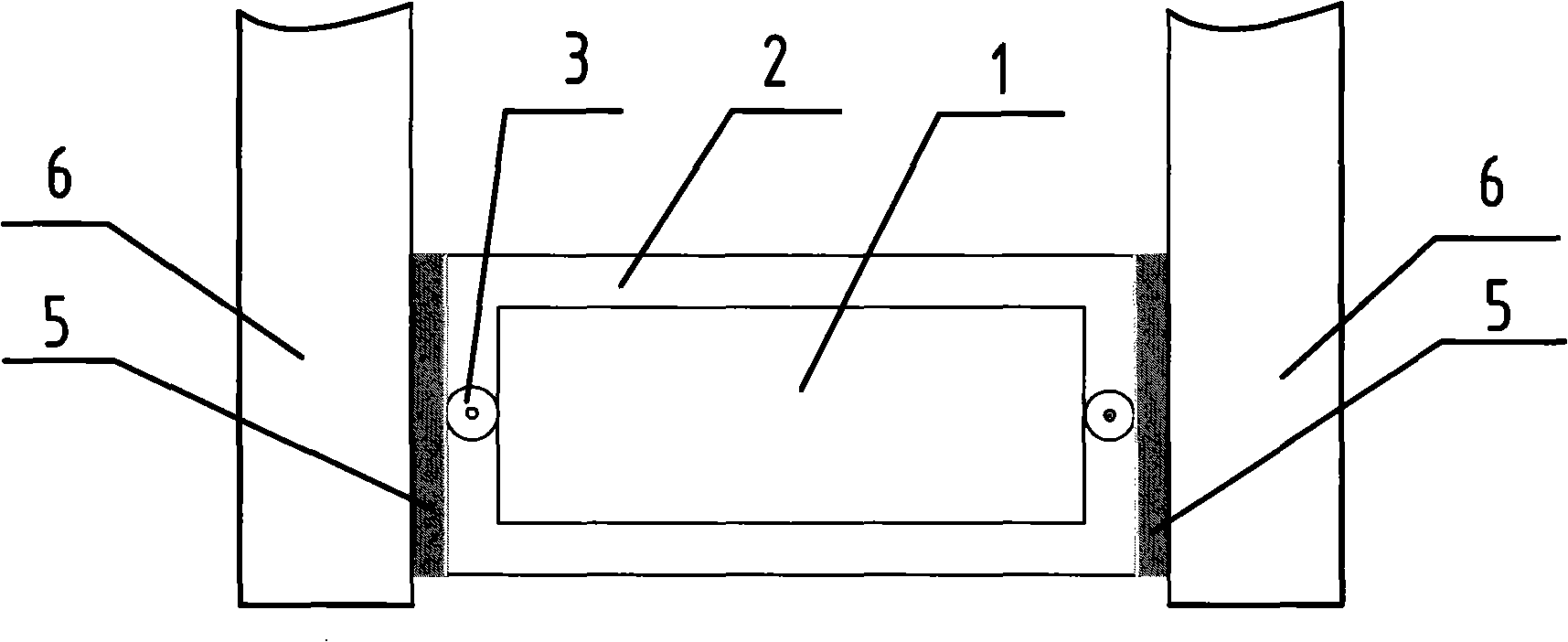

The invention provides a hollow glass spacing profile, relating to a hollow glass spacing-closing material, in particular to a hollow glass spacing profile with cold-bent shaped integral bulkhead. The hollow glass spacing profile comprises a corrugated hollow pipe (2) which is processed and molded with thermoplastic macromoleclar polymer as raw material and has a cross section basically as a rectangular frame, as well as two thermoplastic macromoleclar polymer reinforcing ribs (3) with built-in rigid metal wires (4). The reinforcing ribs (3) are perpendicular to ripples and are arranged along the center lines of two glass support sides of the corrugated hollow pipe (2). The invention provides the hollow glass spacing profile which is good in heat-sound insulation effect, easy to bend and shape, simple in manufacture process, low in cost, capable of being coiled, convenient for storing, transporting and processing operation, and suitable for the application in a plurality of aspects, such as the manufacture of hollow glass doors and windows for houses, vehicles, ships and aircrafts.

Description

Insulating glass spacer profile technical field The invention relates to a hollow glass fixed-distance interval profile, which relates to a hollow glass fixed-distance closing material, in particular to a hollow glass fixed-distance interval profile with a cold-bending and shaped integral partition frame. Background technique Compared with single-layer glass, insulating glass has the advantages of heat insulation, sound insulation, and energy saving, and is widely used in many aspects such as home furnishing, vehicle, ship, and aircraft door and window manufacturing. The spacer material used for insulating glass components plays a vital role in giving full play to the superior performance of insulating glass. Aluminum, stainless steel and other metal hollow spacers are easy to bend and form. After forming, they are better shaped and easy to process, but have poor heat insulation performance; polymer plastic spacer profiles have low thermal conductivity and good heat insul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E06B3/24E06B3/66

Inventor 刘昂峰

Owner SHANDONG NATERGY ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com