Foamable flame-retarding polyester capable of being used for supercritical CO2 and preparation method and application thereof

A technology of flame retardant polyester and CO2, which is applied in the field of supercritical CO2 foamed flame retardant polyester and its preparation, can solve the problems that it cannot be applied to application fields with high requirements for fire safety, polyester does not have flame retardant properties, and the like, Achieve the effect of high rigidity, light weight and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

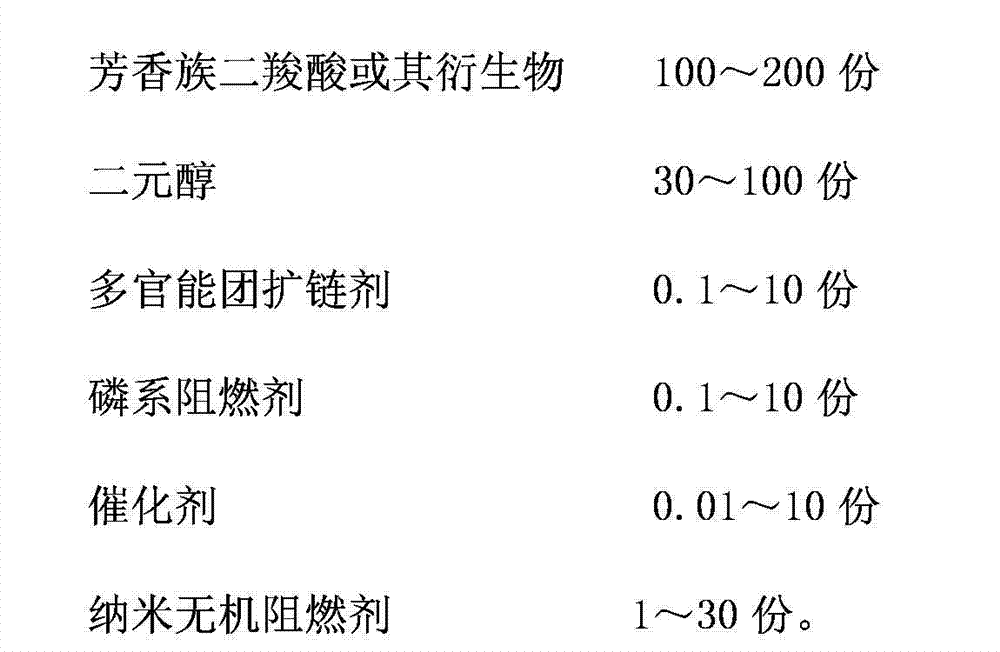

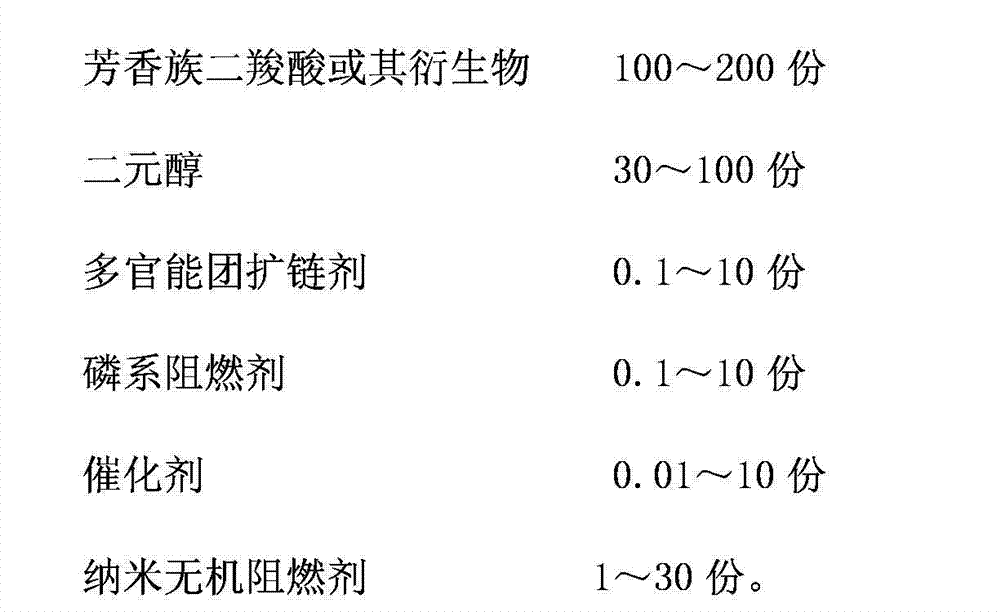

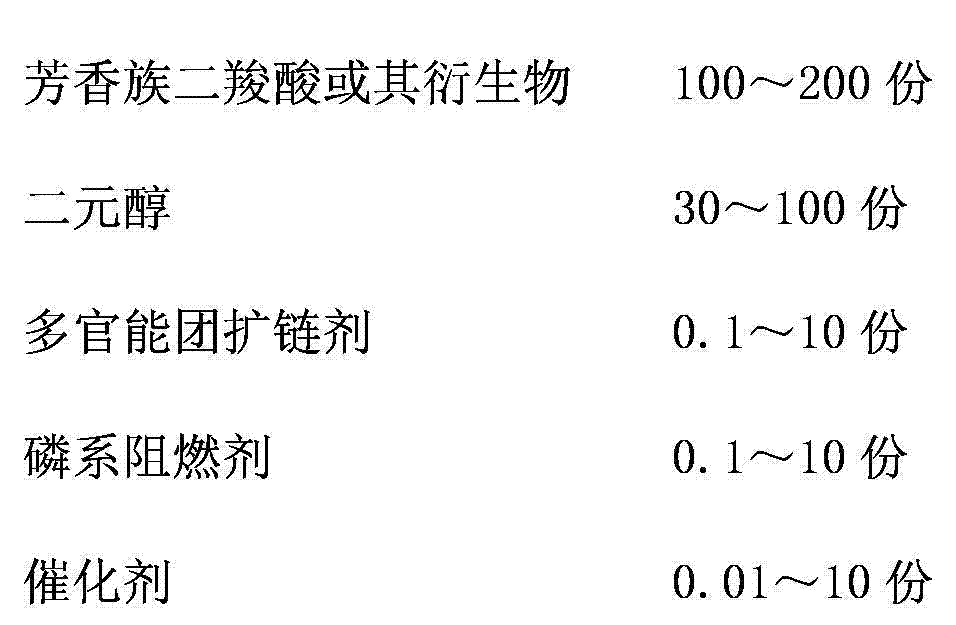

Method used

Image

Examples

Embodiment 1

[0036] In a 2L polyester reactor with a rectification tower, 750g of terephthalic acid, 363.11g of ethylene glycol, 0.94g of pentaerythritol, 7.5g of carboxyethylphenylphosphorous acid, 0.2355g of ethylene glycol antimony and nano-scale The mixture of magnesium hydroxide 7.5 g joins in the reactor, feeds nitrogen, raising temperature, at 230 o C, carry out the esterification reaction under the condition of a pressure of 0.3 MPa, react to the end of the water outlet, then raise the temperature, draw a low vacuum, at 250 o C, 10 4 Under the condition of Pa, react for 1 hour pre-condensation, and then at 280 o C, under the condition of 50Pa, react for 3 hours, final polycondensation reaction, finally feed nitrogen to release the vacuum, discharge the material into ice water and sample in strips.

Embodiment 2

[0038] With the device of embodiment 1, 750g terephthalic acid, 363.11g ethylene glycol, 5.46g glycerol, carboxyethylphenyl hypophosphorous acid 0.75 g, 0.2355g ethylene glycol antimony and nanoscale magnesium hydroxide 0.75 g Add the mixture into the reaction kettle, feed nitrogen, raise the temperature, and react at 230°C and a gauge pressure of 0.3 MPa until the end of the water outlet and the end of the pressurized esterification reaction, then raise the temperature, draw a low vacuum, and °C, 10 4 Pre-condensation under the condition of Pa for 1 hour, and then high vacuum, and the final polycondensation reaction at 280 ° C and 50 Pa for 3 hours, and finally nitrogen gas was introduced to release the vacuum, and the material was discharged into ice water to form strips for sampling.

Embodiment 3

[0040] In an 80L polyester reactor, a mixture of 37kg terephthalic acid, 18kg ethylene glycol, 60.76g pentaerythritol, 37 g carboxyethylphenylphosphorous acid, 13 g ethylene glycol antimony and 37 g nanometer magnesium hydroxide was added Into the reaction kettle, feed nitrogen, raise the temperature, react at 230°C, gauge pressure 0.3MPa until the end of water outlet, then raise the temperature, draw a low vacuum, at 250°C, 10 4 Pre-condensation under the condition of Pa for 1 hour, and then a high vacuum, the final polycondensation reaction at 280 ° C and 50 Pa for 3 hours, and finally nitrogen gas was introduced to relieve the vacuum, and the material was discharged into ice water for sampling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com