Lightweight turnover sleeper

A lightweight, sleeper technology, used in sleeper appliances, railway car body parts, transportation and packaging, etc., can solve the problems of high precision requirements, low anti-vibration performance, and large footprint in the installation process of gas spring brake lines, and achieves flipping. Simple and reliable structure, good dimensional stability, good damping and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

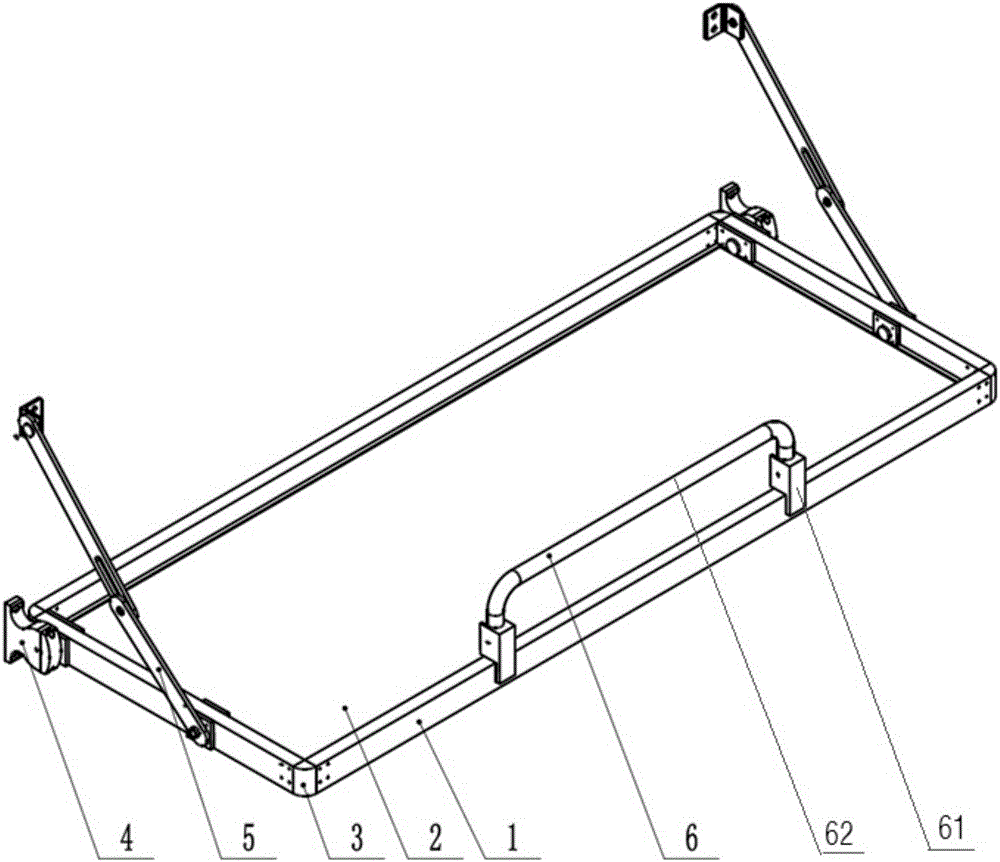

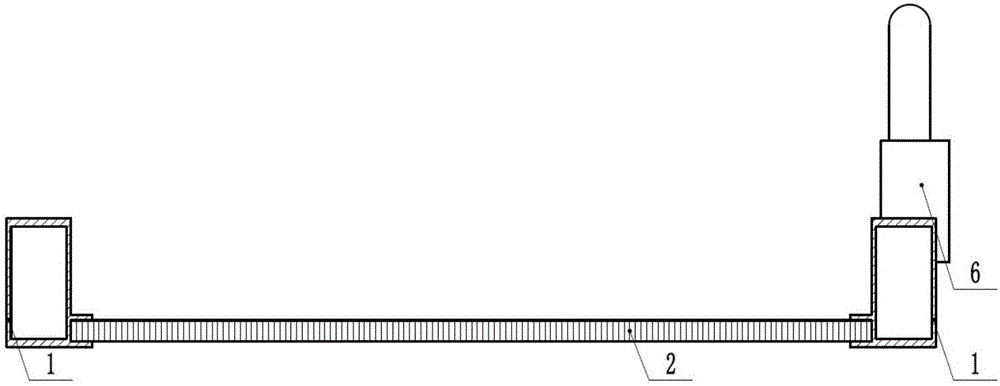

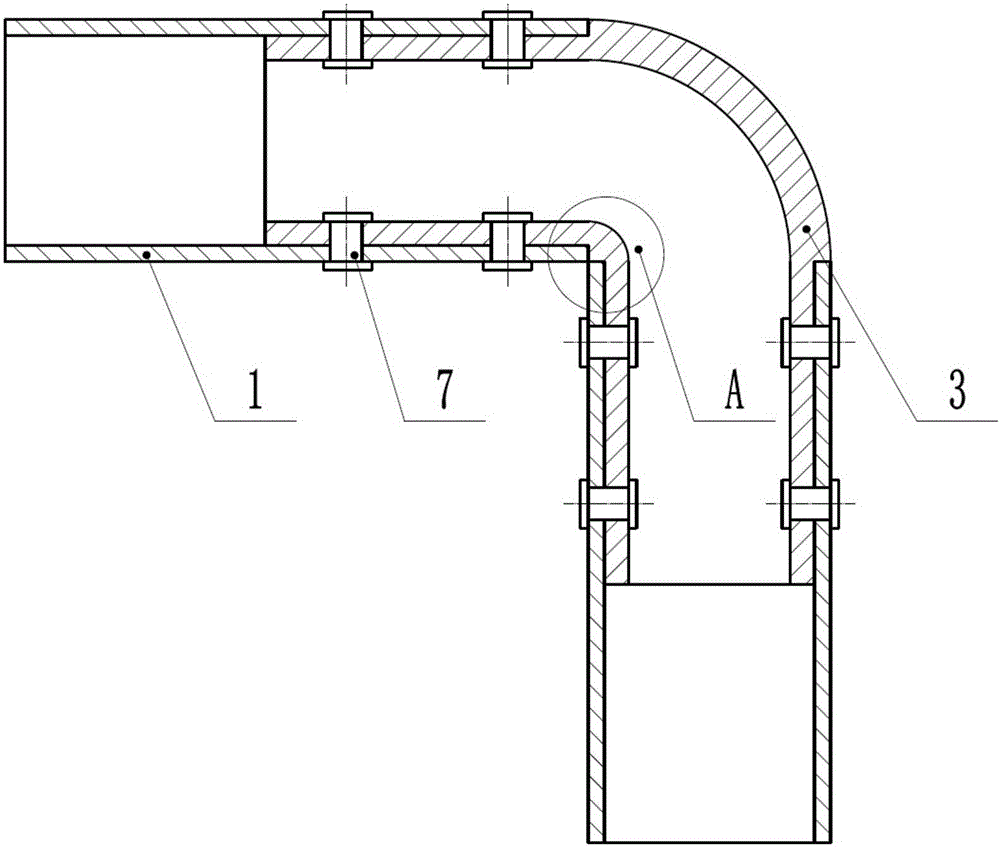

[0038] like figure 1 As shown, the light-weight reversible sleeper disclosed by the present invention includes a bed body, a folding bar 5 and a pendant 4. The bed body includes a sleeper frame and a plank 2 installed on the sleeper frame, and the sleeper frame includes 4 side beams 1, 4 The side beam 1 is connected end to end, and there is a slot on the inner side of the side beam 1 that matches the plank 2, and the plank 2 is installed in the slot; the frame of the sleeper is connected to the side beam 1 in rotation, and one end of the folding rod 5 is connected to the side beam 1 in rotation, and the folding rod The other end of 5 has mounting seat 54, and folding bar 5 is connected with mounting seat 54 in rotation, and the material of paving body, pendant 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com