Building climbing frame walk plate machining device

A processing device and walkway board technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reduced product quality, long processing time, low transmission efficiency, etc., to improve the degree of automation, reduce processing time, increase The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

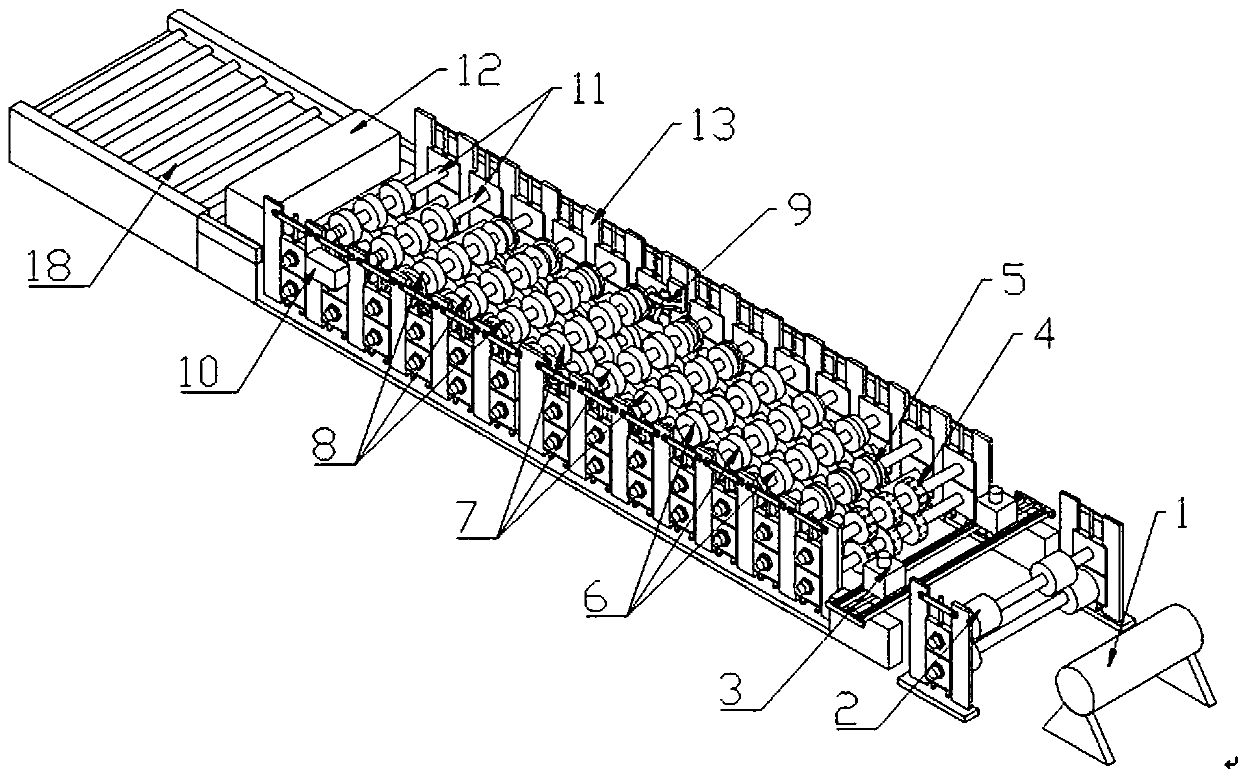

[0033] Example 1 A processing device for building climbing frame walkway slabs

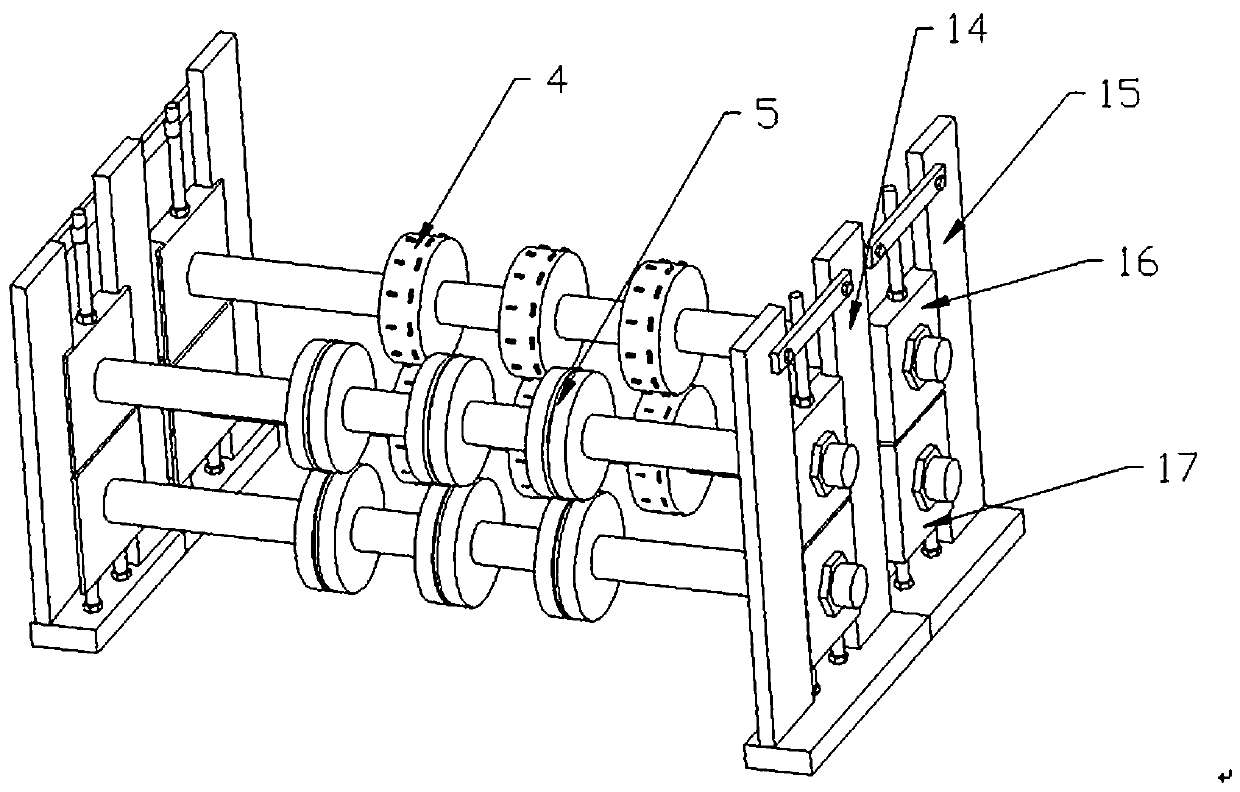

[0034] This example figure 1 As shown, it includes feeding device 1, cutting wheel group 2, punching device 3, embossing wheel group 4 and beading wheel group 5, bending device, welding device 10, conveying wheel group 11 and Cut-off device 12.

[0035] The feeding device 1 includes a feeding support platform, on which a feeding roller is arranged, and the sheet is wound on the feeding roller.

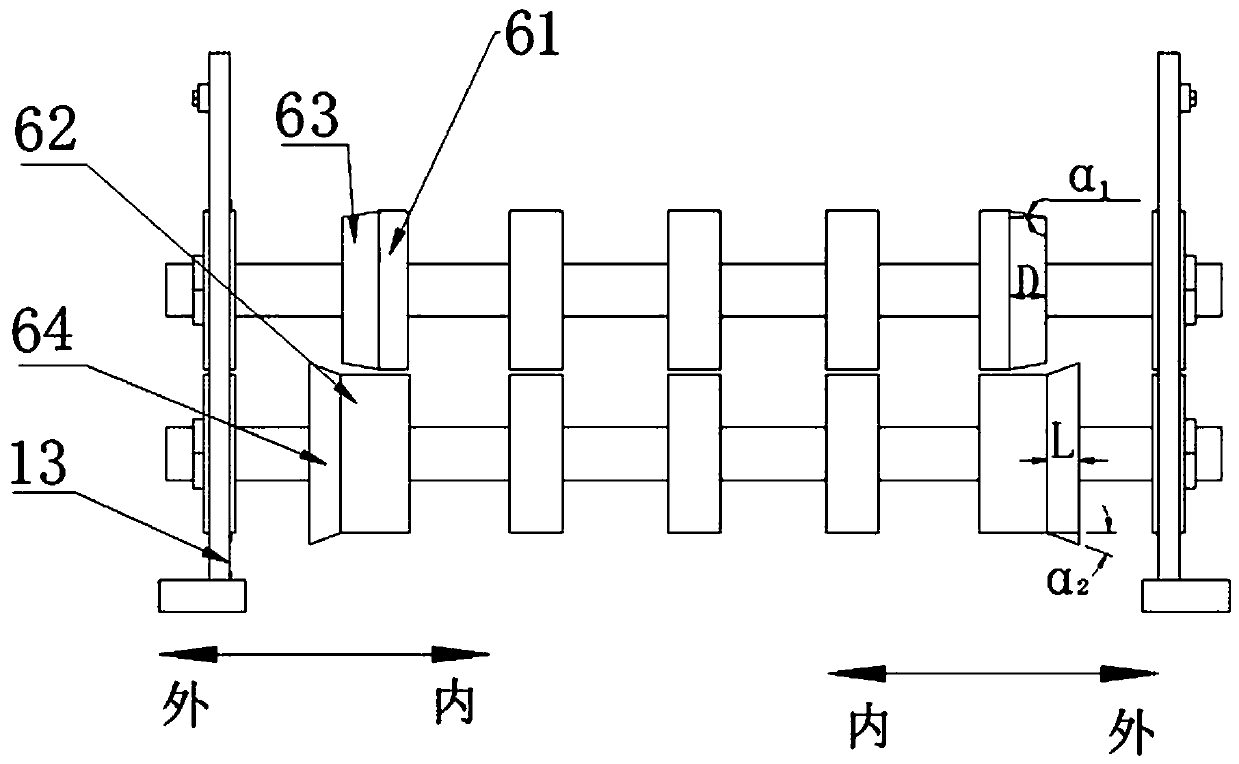

[0036] Cutting wheel group 2, the two ends of cutting wheel group 2 are a pair of cylindrical rollers set up and down facing each other. The extension direction of the upper and lower cylindrical rollers is opposite. The pitch of the cylindrical rollers can get the sheet of required width.

[0037]The punching device 3 is fixed on the two ends of the punching table. Adopt the punching device 3 in the prior art, the hydraulic pump that provides punching power is fixed on the punching table, the punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com