Arc laminated wood component forming method based on wood plasticity

A molding method, a technology of glulam, applied in the joining of wooden veneers, wood processing appliances, chemical instruments and methods, etc. Reliable, high-quality components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

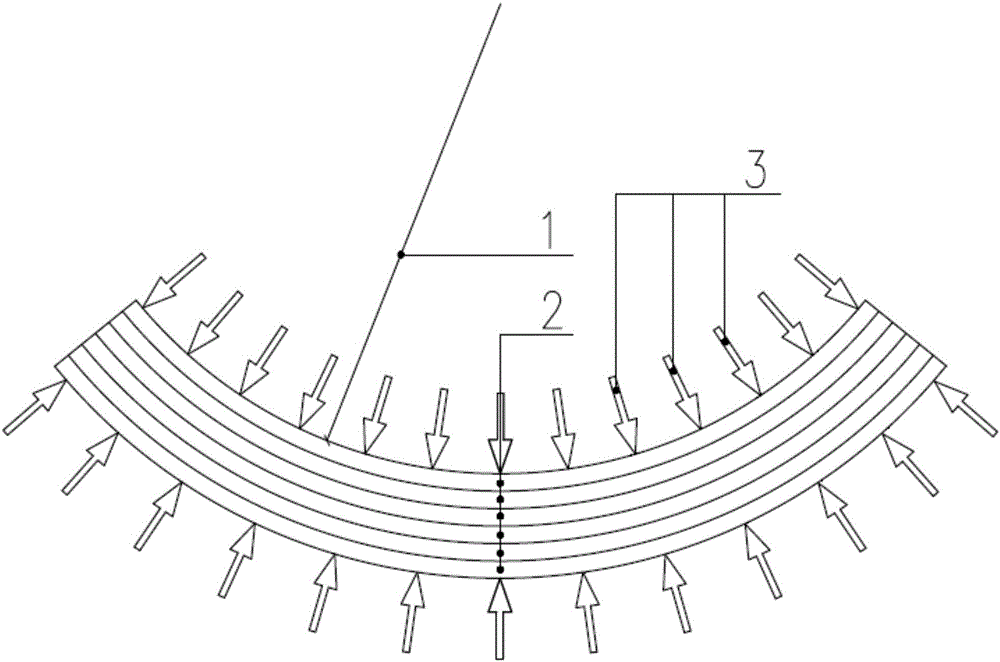

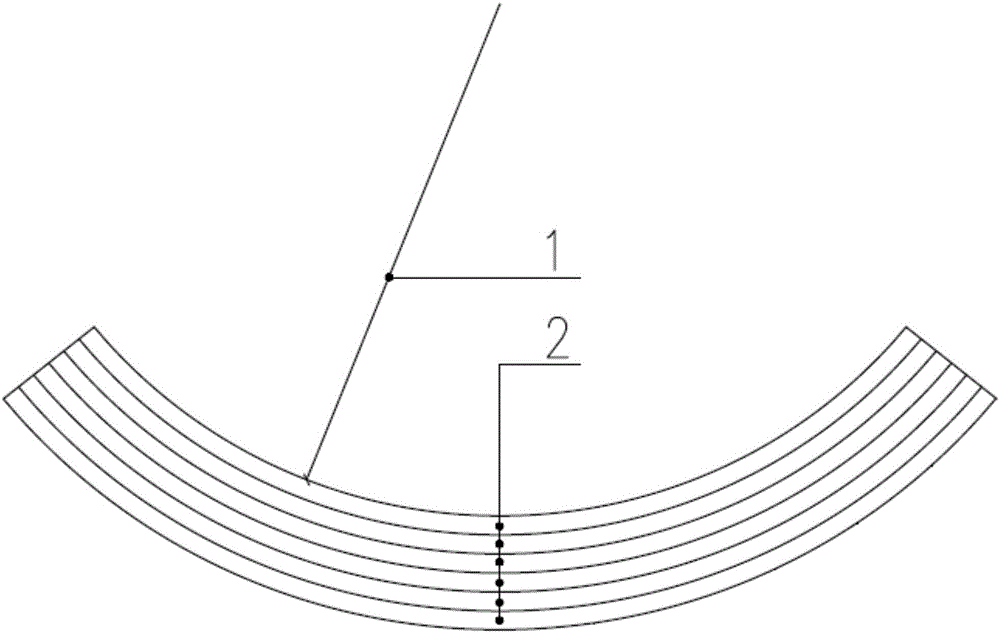

[0031] The molding method of arc-shaped glued wood components based on wood plasticity, including five processes of wood moisture content adjustment, wood plywood gluing, profiling, pressurization and pressure relief maintenance, among which wood moisture content adjustment, wood plywood gluing, leaning The four processes of molding and pressurization are all completed under the environmental conditions that the temperature is 30° C. and the relative humidity is 80%.

[0032] The moisture content of the wood is 16%, the design radius of curvature of the curved glulam member is 6000mm, the section height of the member is 600mm, the number of wooden laminates is 16, and the thickness of each layer of wooden laminates is 37.5mm, then the curved glulam member The radius of curvature of the preparation is 6000mm.

[0033] The glue coating on the wooden laminate is 300g / m2 on one side 2 , the glue pressing time is 5.0h, and the number of wooden laminates is 16 layers, such asfigure...

Embodiment 2

[0038] The molding method of arc-shaped glued wood components based on wood plasticity, including five processes of wood moisture content adjustment, wood plywood gluing, profiling, pressurization and pressure relief maintenance, among which wood moisture content adjustment, wood plywood gluing, leaning The four processes of molding and pressurization are all completed under the environmental conditions that the temperature is 32° C. and the relative humidity is 85%.

[0039] The moisture content of the wood is 18%, the design radius of curvature of the curved glulam member is 18000mm, the section height of the member is 800mm, the number of wooden laminates is 22, and the thickness of each layer of wooden laminates is 36.3mm, then the curved glulam member The radius of curvature of the preparation is 18000mm.

[0040] The glue coating of the wooden laminate is 350g / m2 on one side 2 , the glue pressing time is 6.0h, and the number of wooden laminates is 22 layers, such as fi...

Embodiment 3

[0044] The molding method of arc-shaped glued wood components based on wood plasticity, including five processes of wood moisture content adjustment, wood plywood gluing, profiling, pressurization and pressure relief maintenance, among which wood moisture content adjustment, wood plywood gluing, leaning The four processes of molding and pressurization are all completed under the environmental conditions that the temperature is 35° C. and the relative humidity is 90%.

[0045] The moisture content of the wood is 20%, the design radius of curvature of the curved glulam member is 10000mm, the section height of the member is 1200mm, the number of wooden laminates is 33, and the thickness of each layer of wooden laminates is 36.3mm, then the curved glulam member The radius of curvature of the preparation is 10000mm.

[0046] The glue coating of the wooden laminate is 380g / m2 on one side 2 , the glue pressing time is 5.5h, and the number of wooden laminates is 33 layers, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com