A simple aluminum-plastic plate heater and hot bending process

An aluminum-plastic panel and heater technology, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inconvenient operation by operators, inability to meet process requirements, and small rolling arc spacing, and achieve significant economic benefits. Beautiful appearance and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

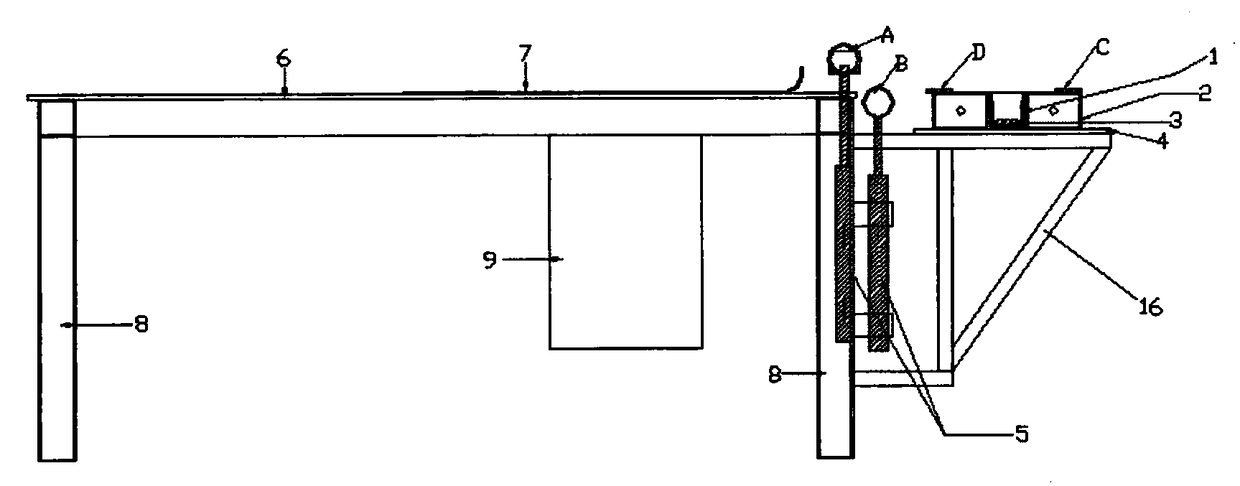

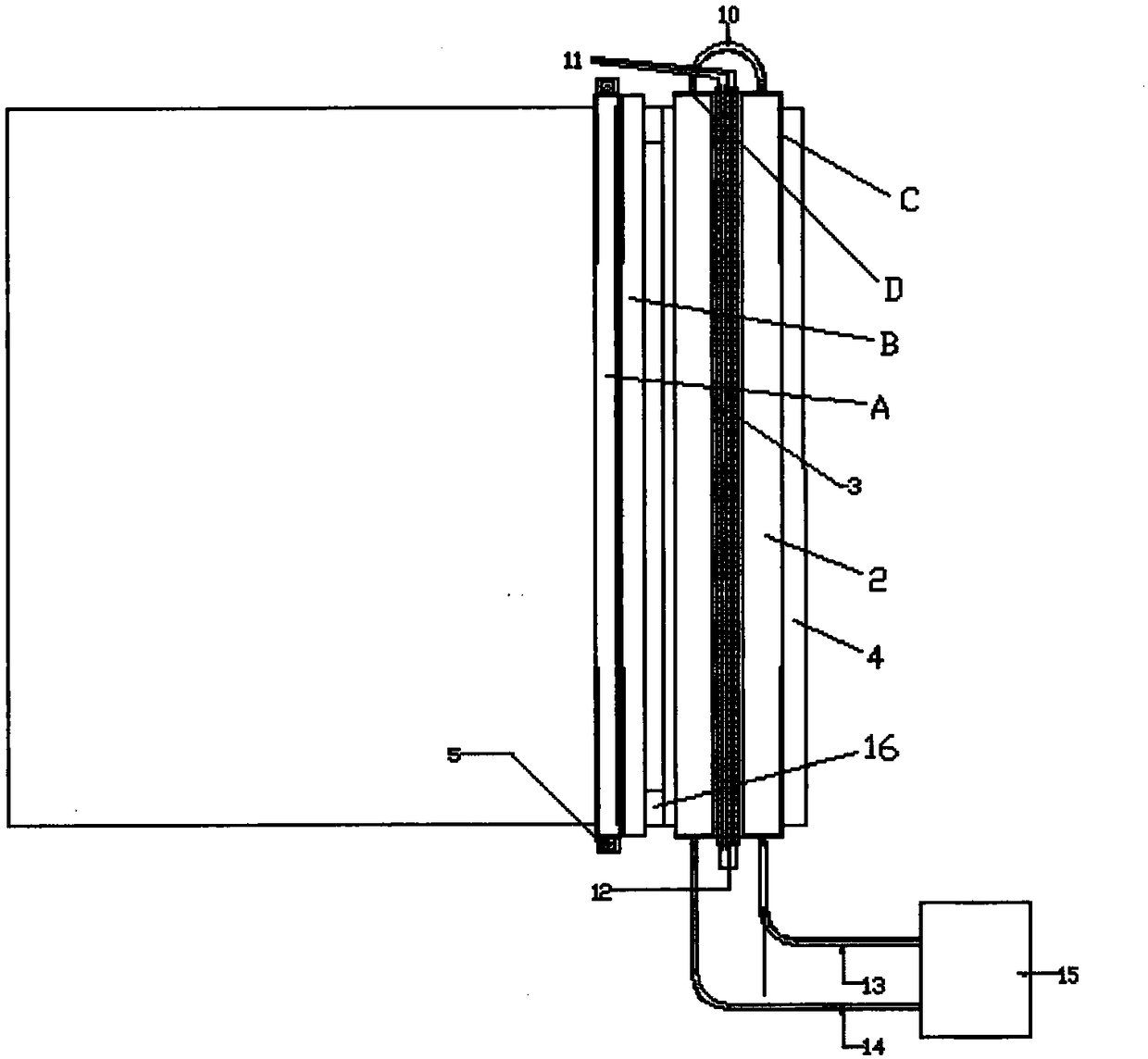

[0027] Such as figure 1 , 2 As shown, a simple aluminum-plastic plate heater provided by the present invention includes a platform 6 with platform pillars 8, a round tube crossbar A is arranged on one side of the platform 6, and a round tube is arranged on the outside of the side. Cross bar 2 B, round pipe cross bar 1 A, and round pipe cross bar 2 B are respectively fixed on the output ends of two groups of cylinders 5, each group of cylinders 5 is connected and fixed with platform 6, and round pipe cross bar 1 A is set on two sets of cylinders 5. On the first cylinder 5, two cylinders 5 are located at the two ends of the circular tube cross bar A, so that the aluminum-plastic plate 7 can pass between the two cylinders 5 at the bottom of the circular tube cross bar A, and the circular tube cross bar two B Be located on three cylinders 5, each one at both ends and the center. The other side of the circular pipe cross bar 2B is provided with a heater, and the heater is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com