Patents

Literature

38results about How to "Improve component quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

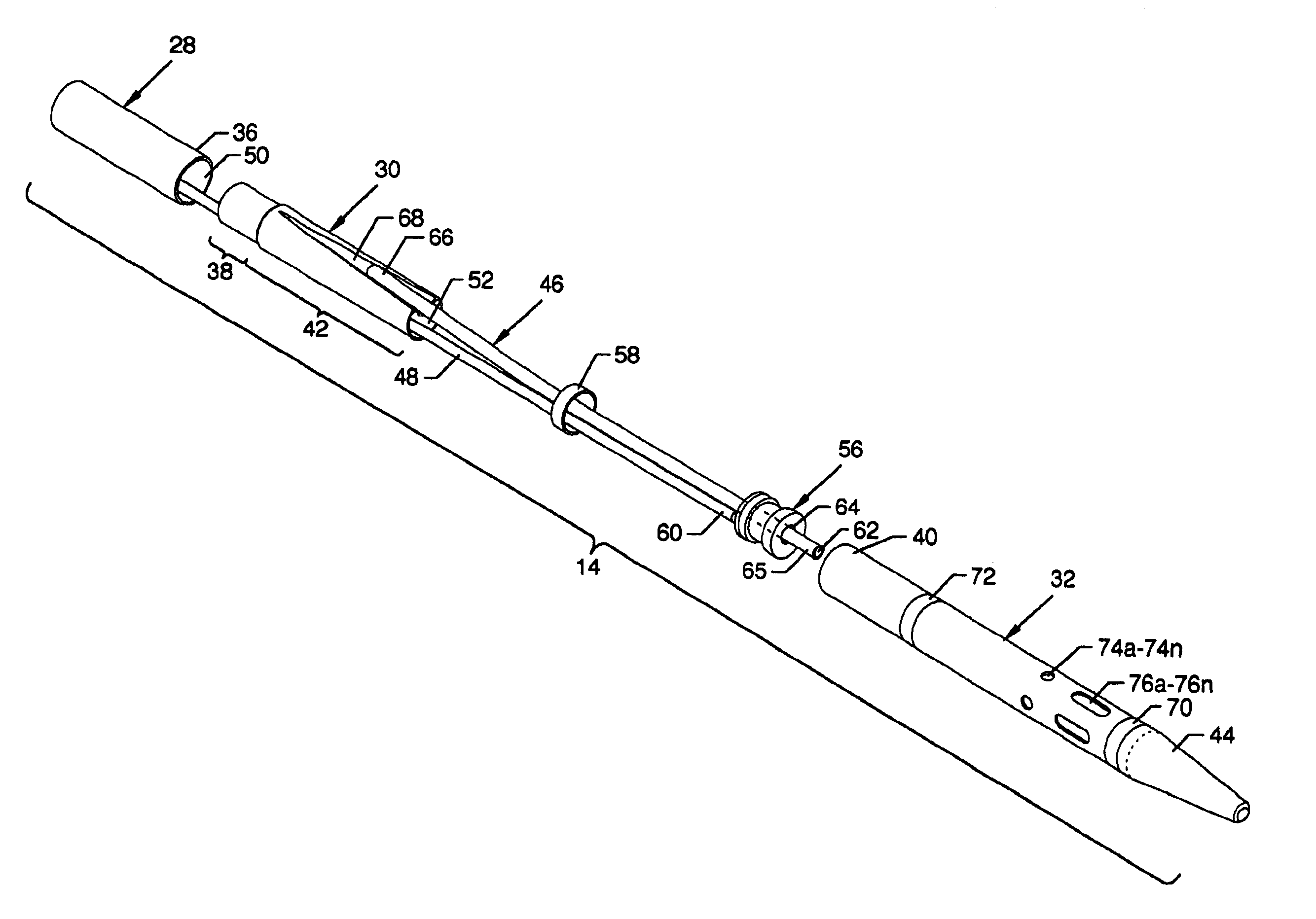

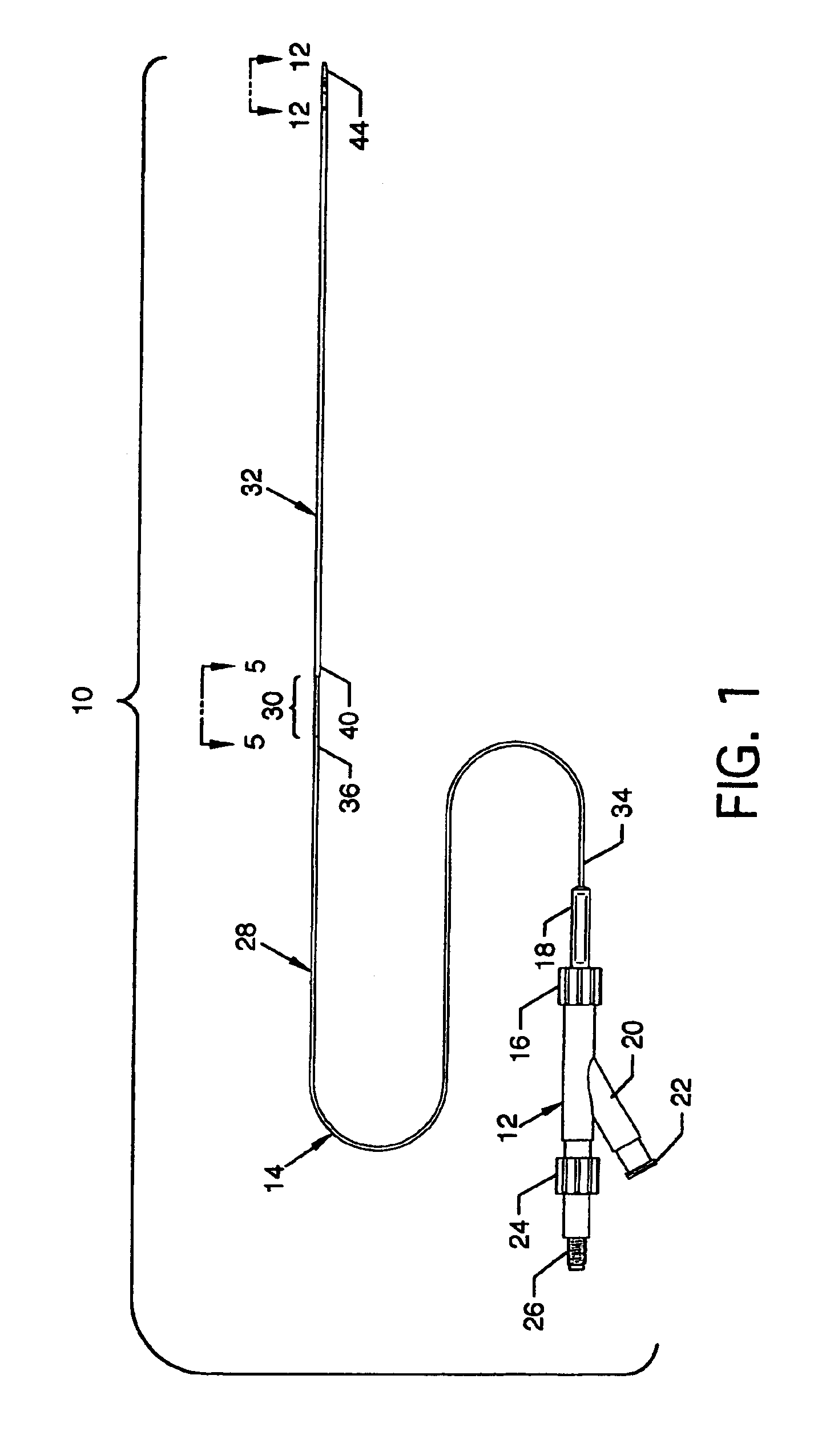

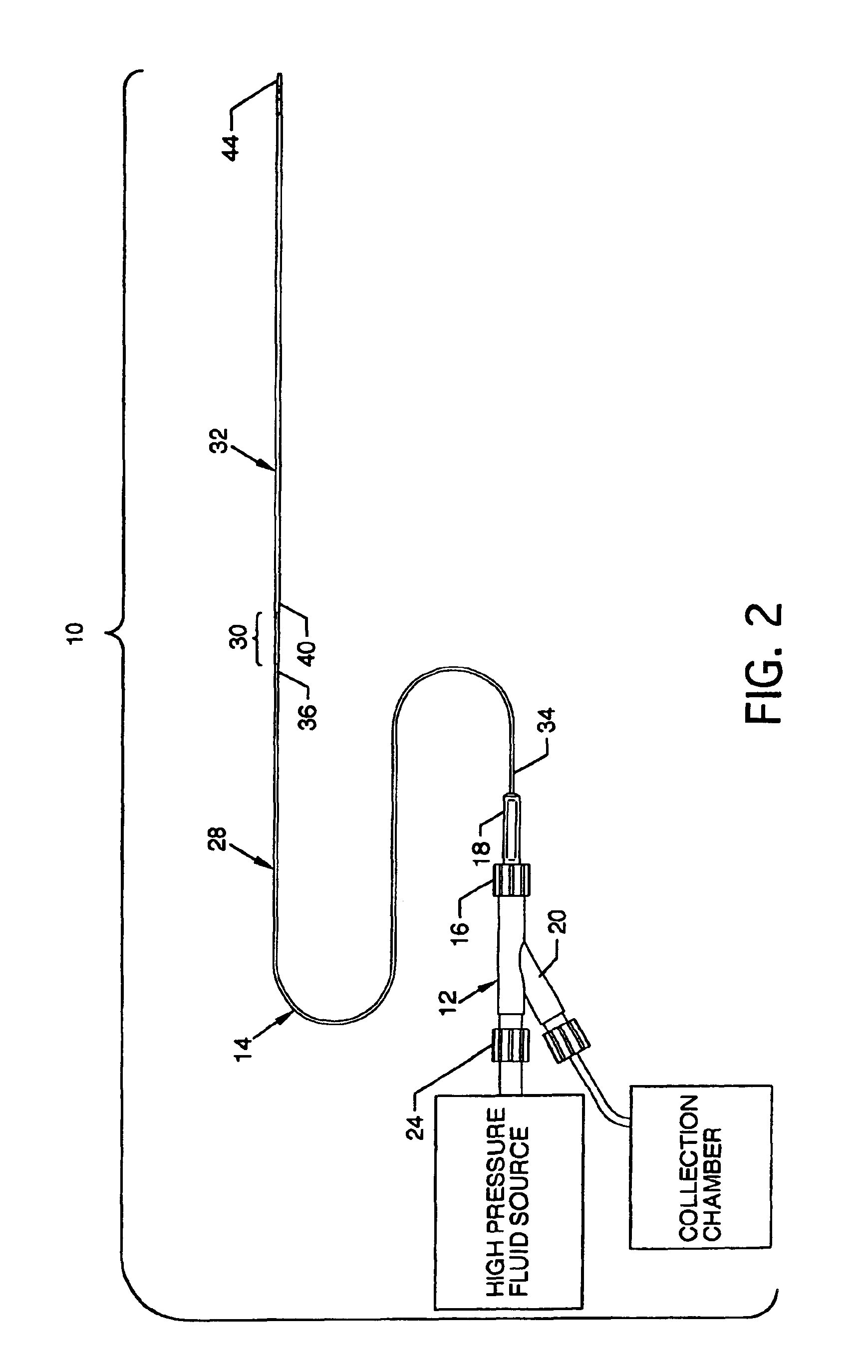

Rapid exchange fluid jet thrombectomy device and method

A rapid exchange fluid jet thrombectomy device for removal of thrombus or unwanted tissue debris from a vein, artery or the like. The device includes a semi-rigid intermediate tube between a proximal and a distal exhaust tube which accommodates a guidewire tube exit located along the catheter at less than one-half the length of the catheter measured from the catheter most distal point. Such a location of the guidewire is convenient for maneuvering and longitudinal advancement of the guidewire, as well as maneuvering and longitudinal advancement of the catheter by one practitioner.

Owner:BOSTON SCI LTD

Plastic component having visible part and light source

ActiveUS20070091614A1Impair impressionImpair qualityNon-electric lightingPoint-like light sourceFiberIn vehicle

The present invention relates to a plastic component having a visible part that is made in one single layer from a plastic molding compound and that comprises a transparent or translucent matrix, and having a light source that comprises one or more lamp elements, situated under the surface of the visible part. The visible part is implemented as essentially opaque in relation to daylight and transparent or translucent in relation to the light emitted by the lamp elements. The visible part also contains admixed effect pigments and defines a surface appearance image which, when the light source is inactive, essentially corresponds to the surface appearance image of the remaining wall of an object in which the plastic component is installed and which, when the light source is active, is essentially determined by the light source activity. The plastic component according to the invention is characterized in that the lamp elements are selected from a group which comprises light-emitting diodes, organic light-emitting diodes, and fiber-optic light systems, the lamp elements at least partially being embedded in the plastic molding compound of the visible part. The manifold uses of this plastic component comprise installation in vehicles, paneling elements, and furniture, as well as in housings of greatly varying devices.

Owner:EMS CHEM AG

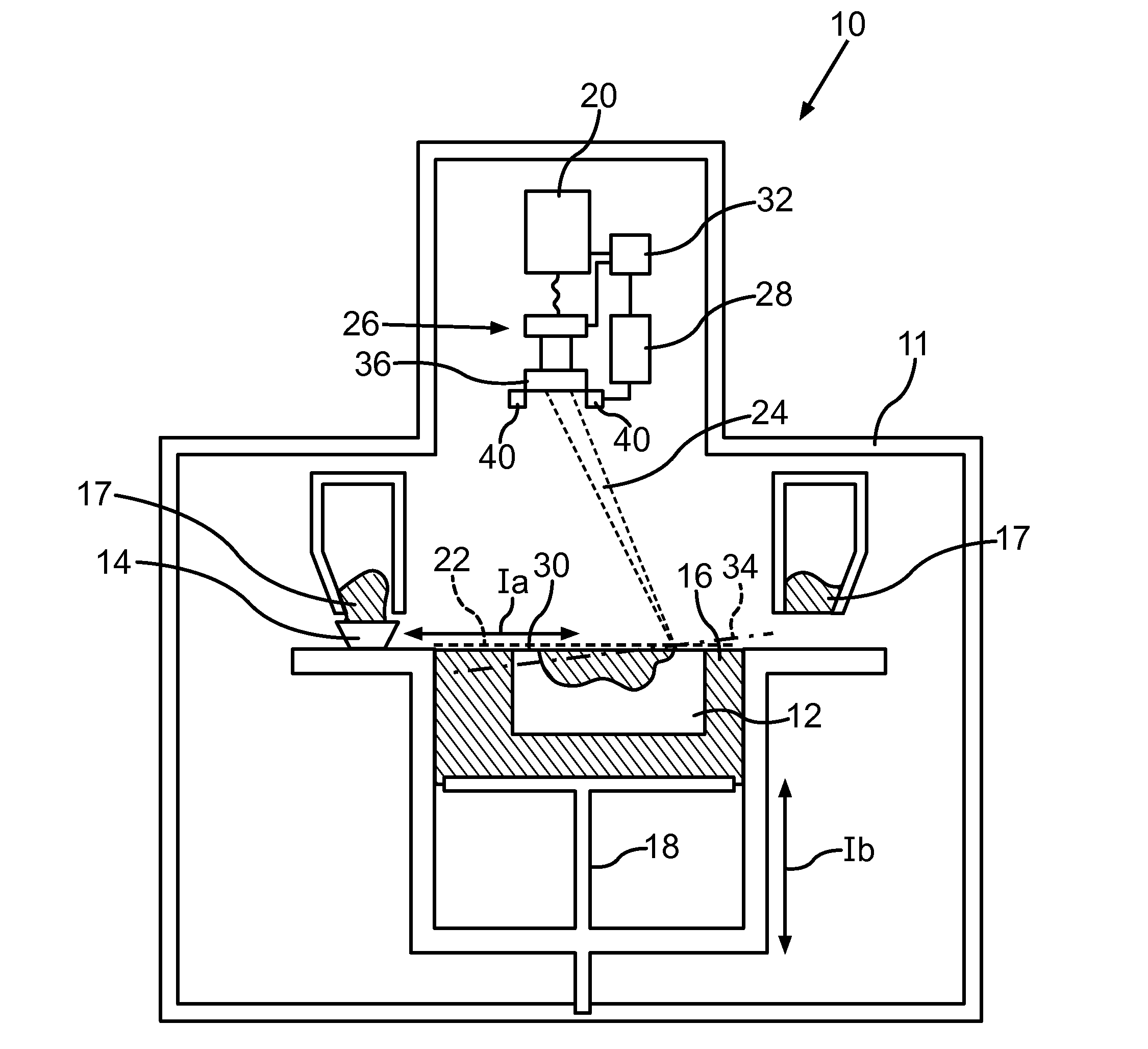

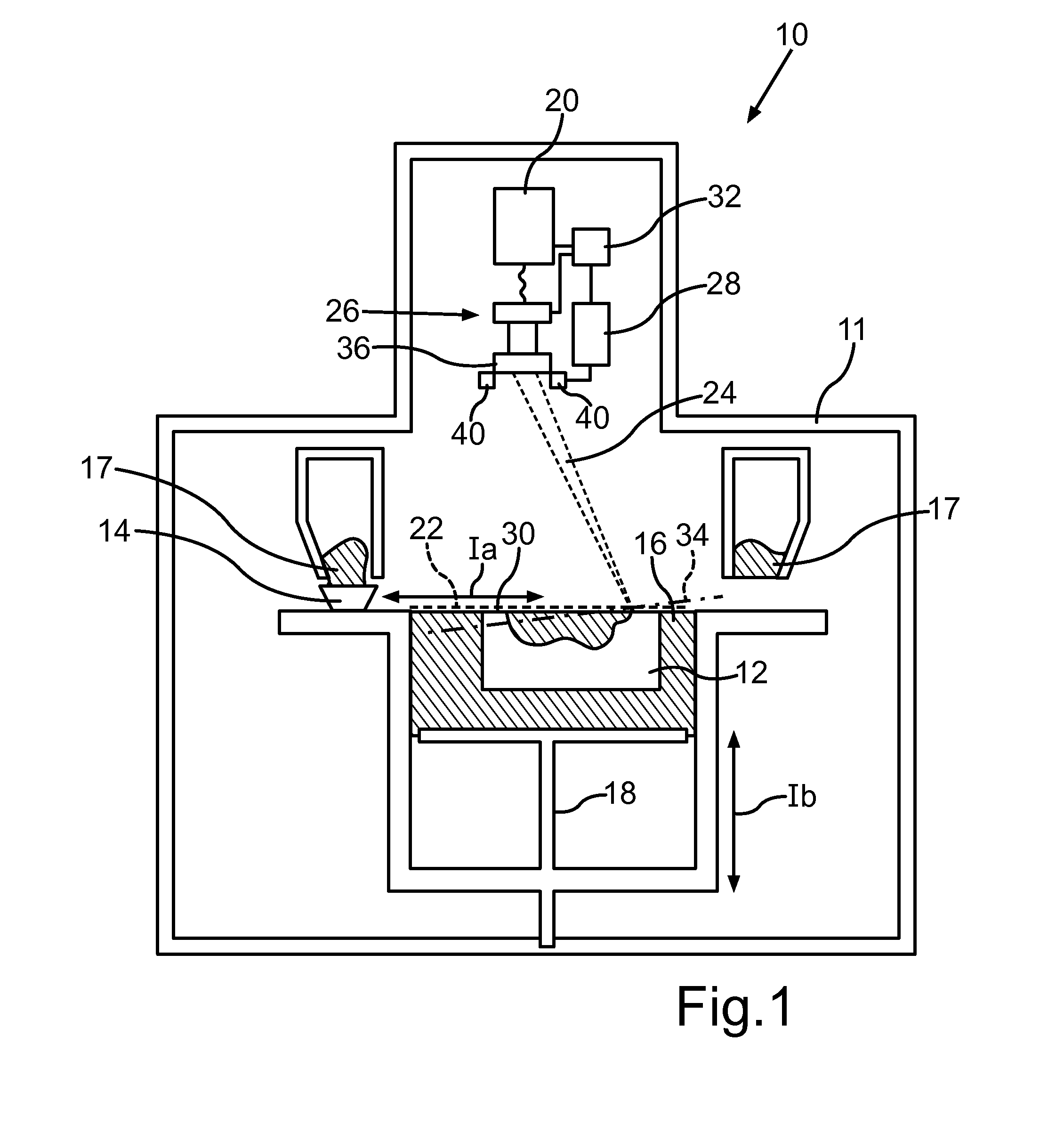

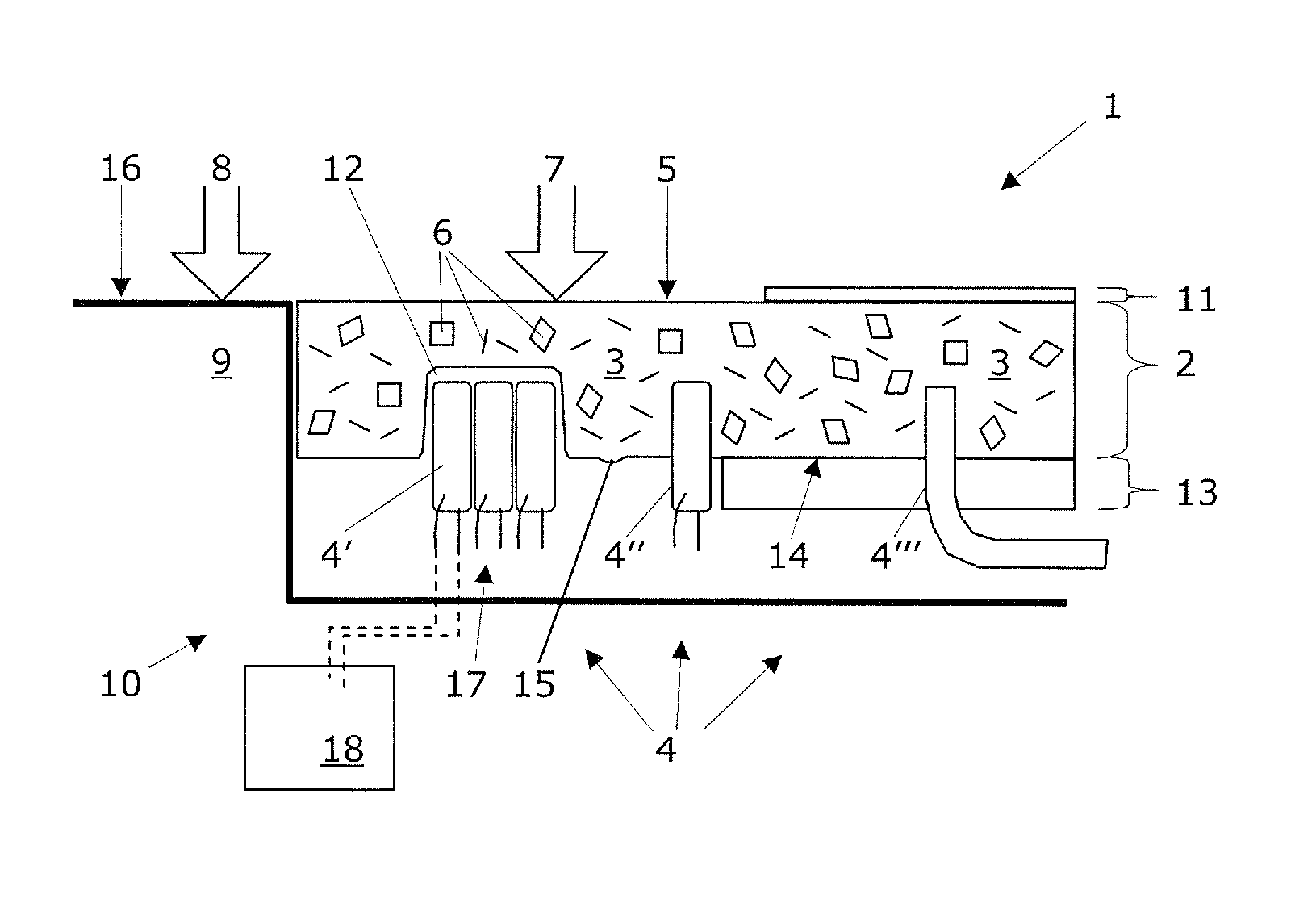

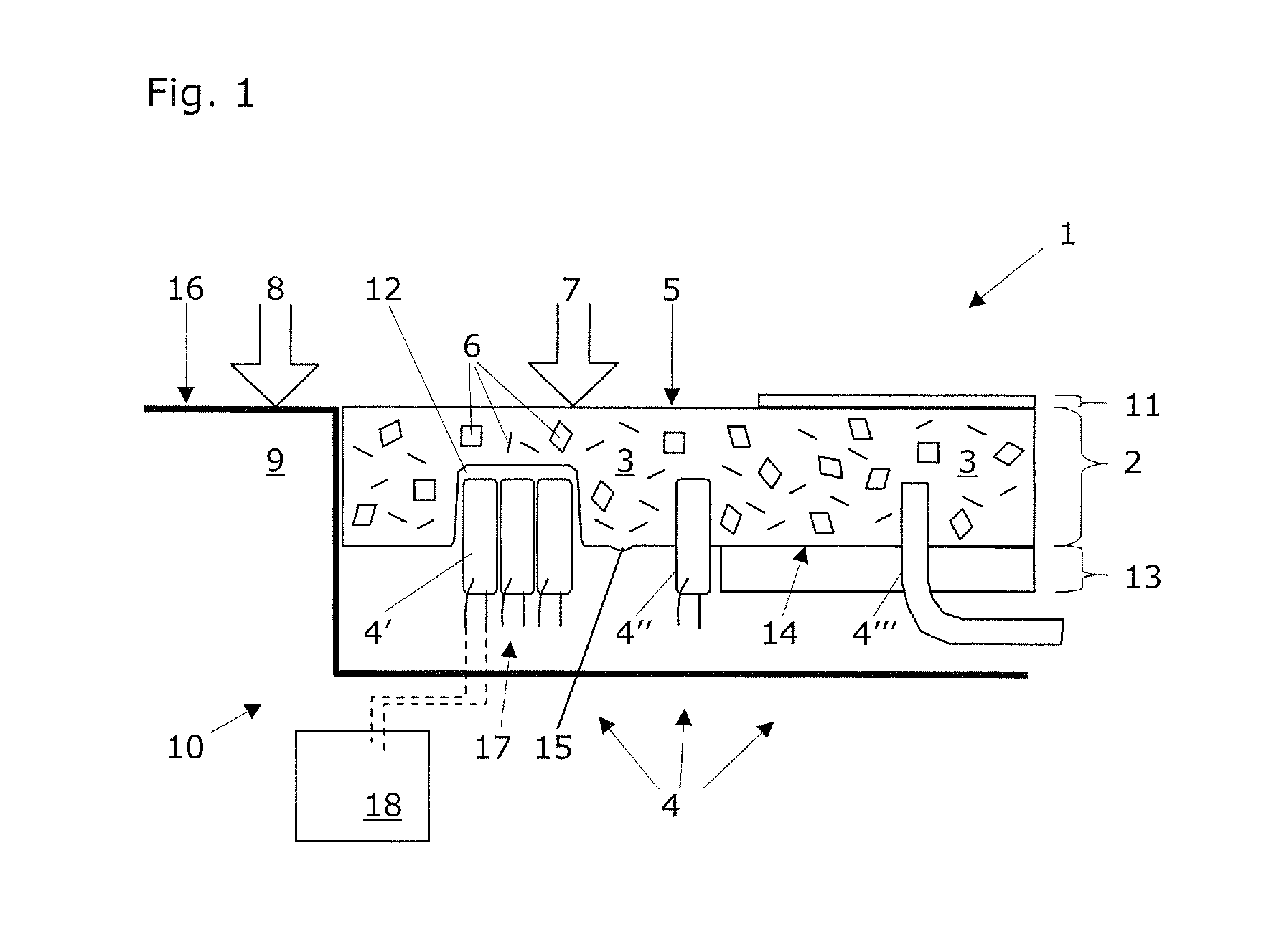

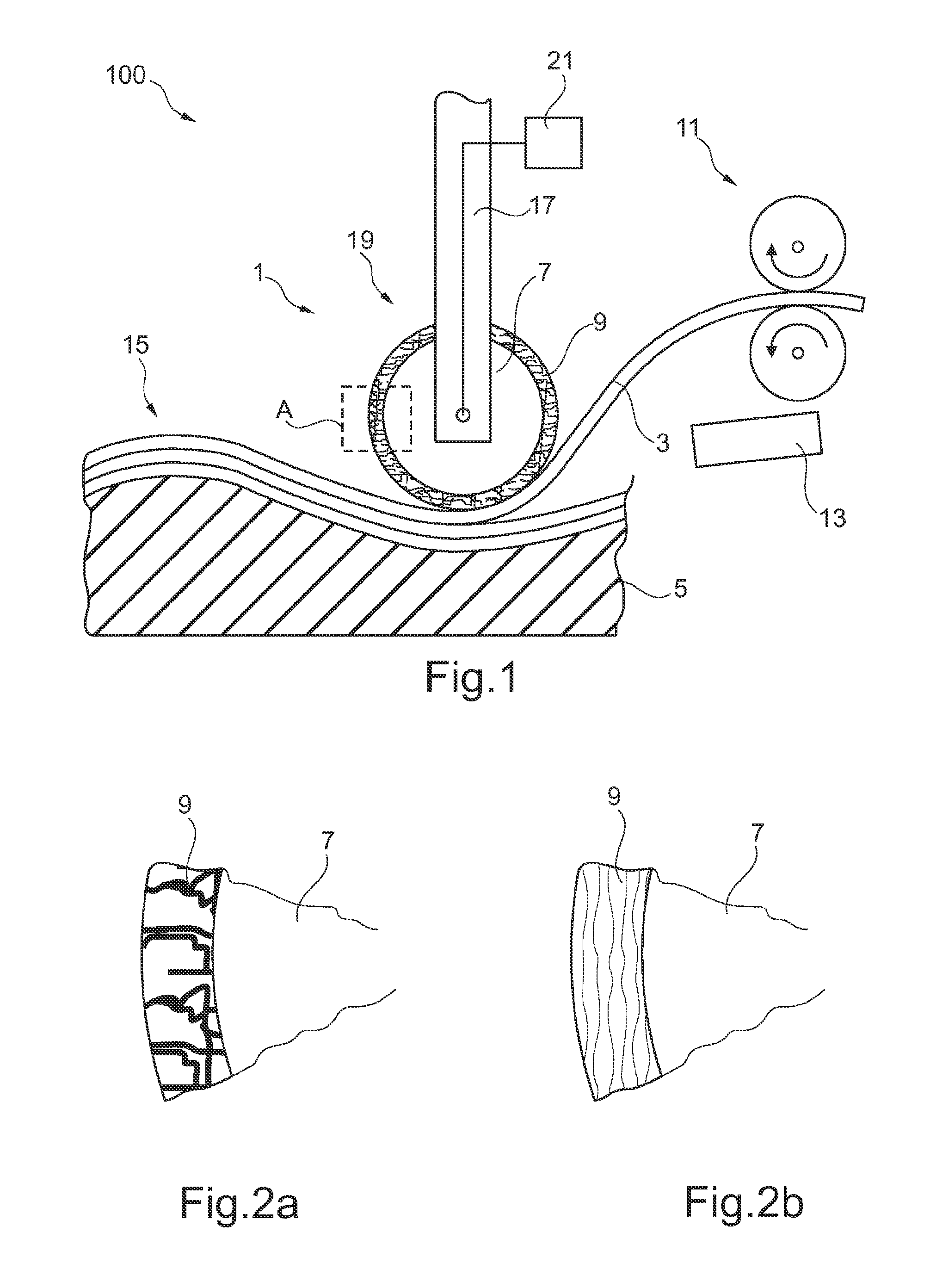

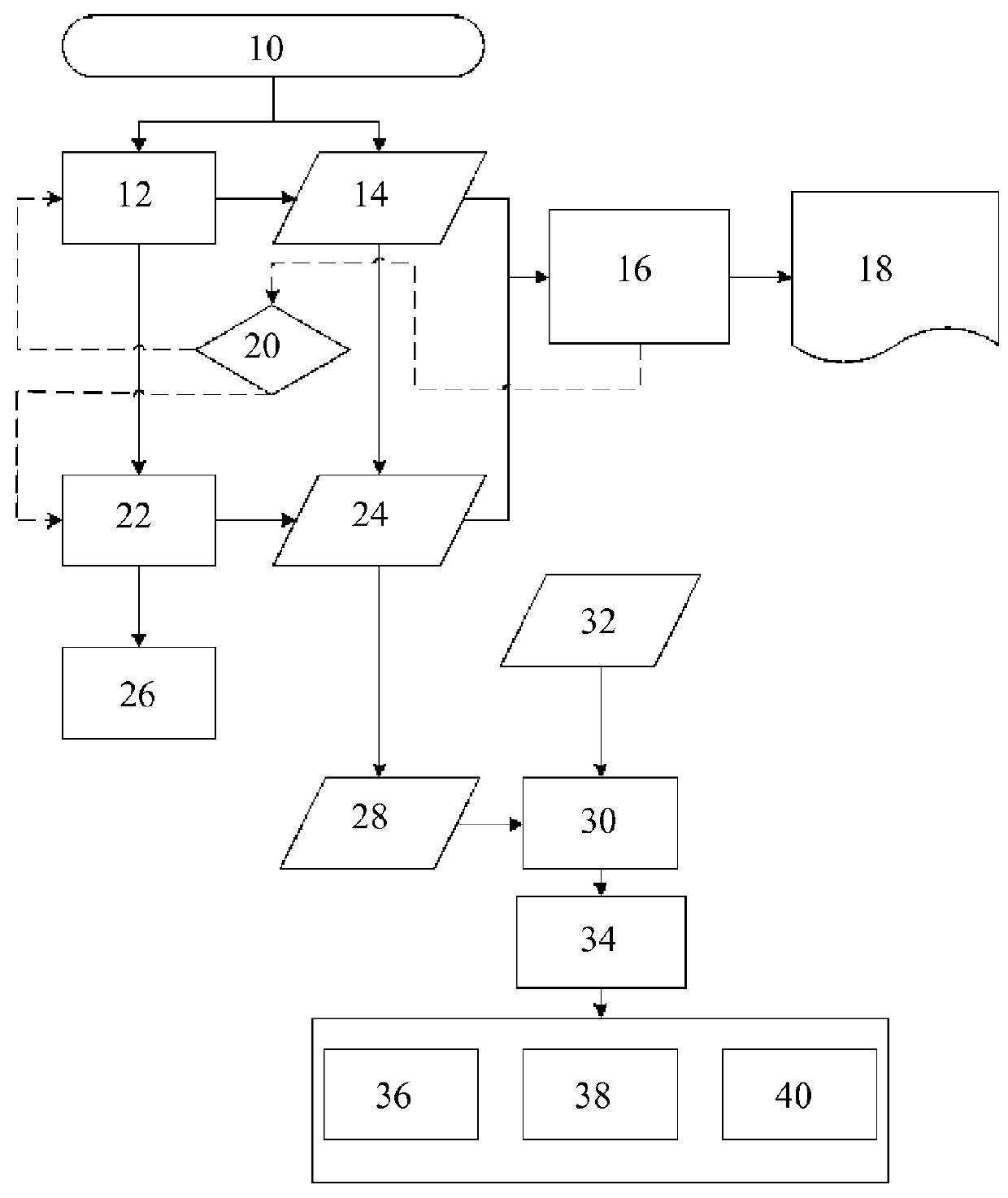

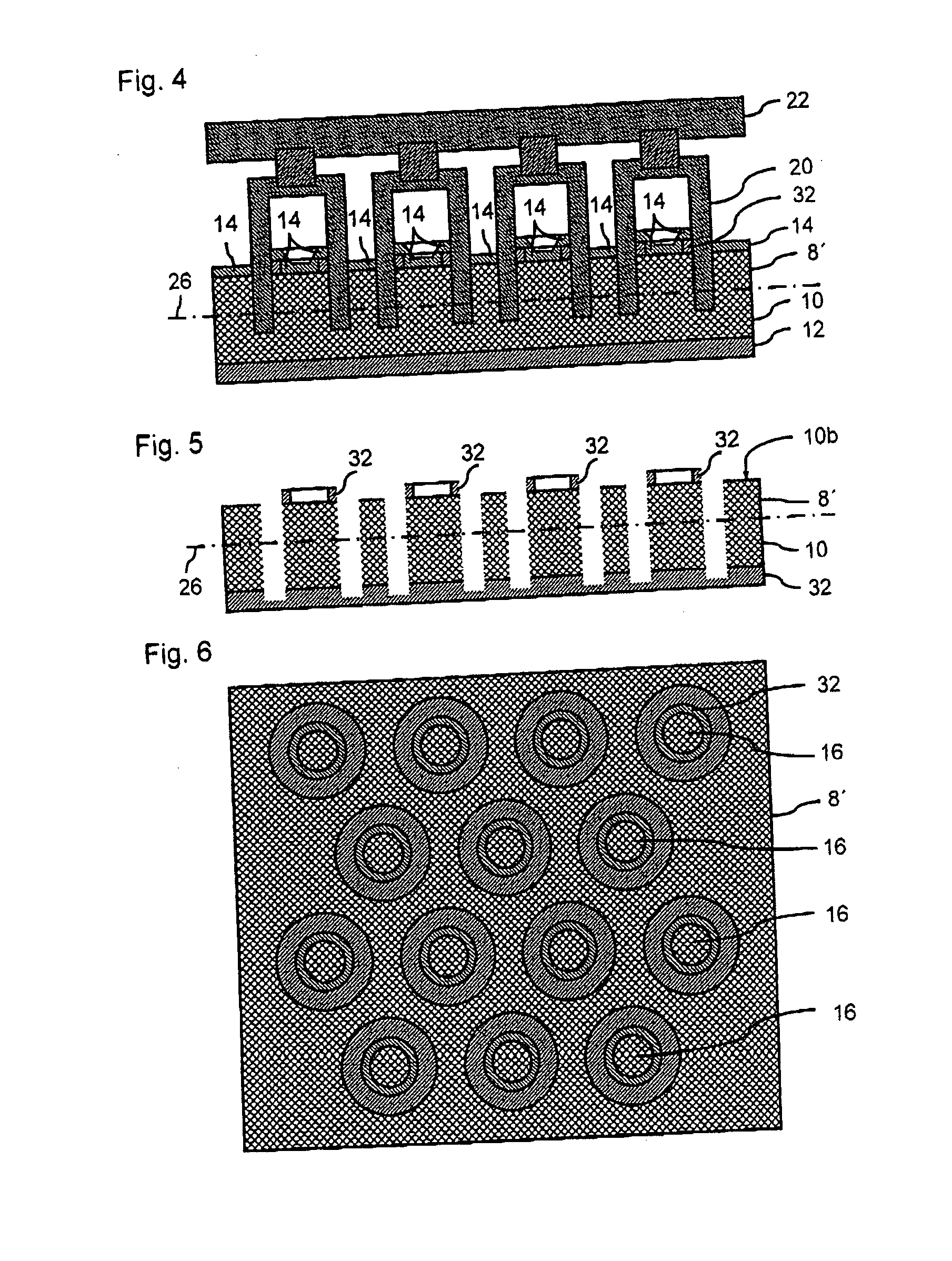

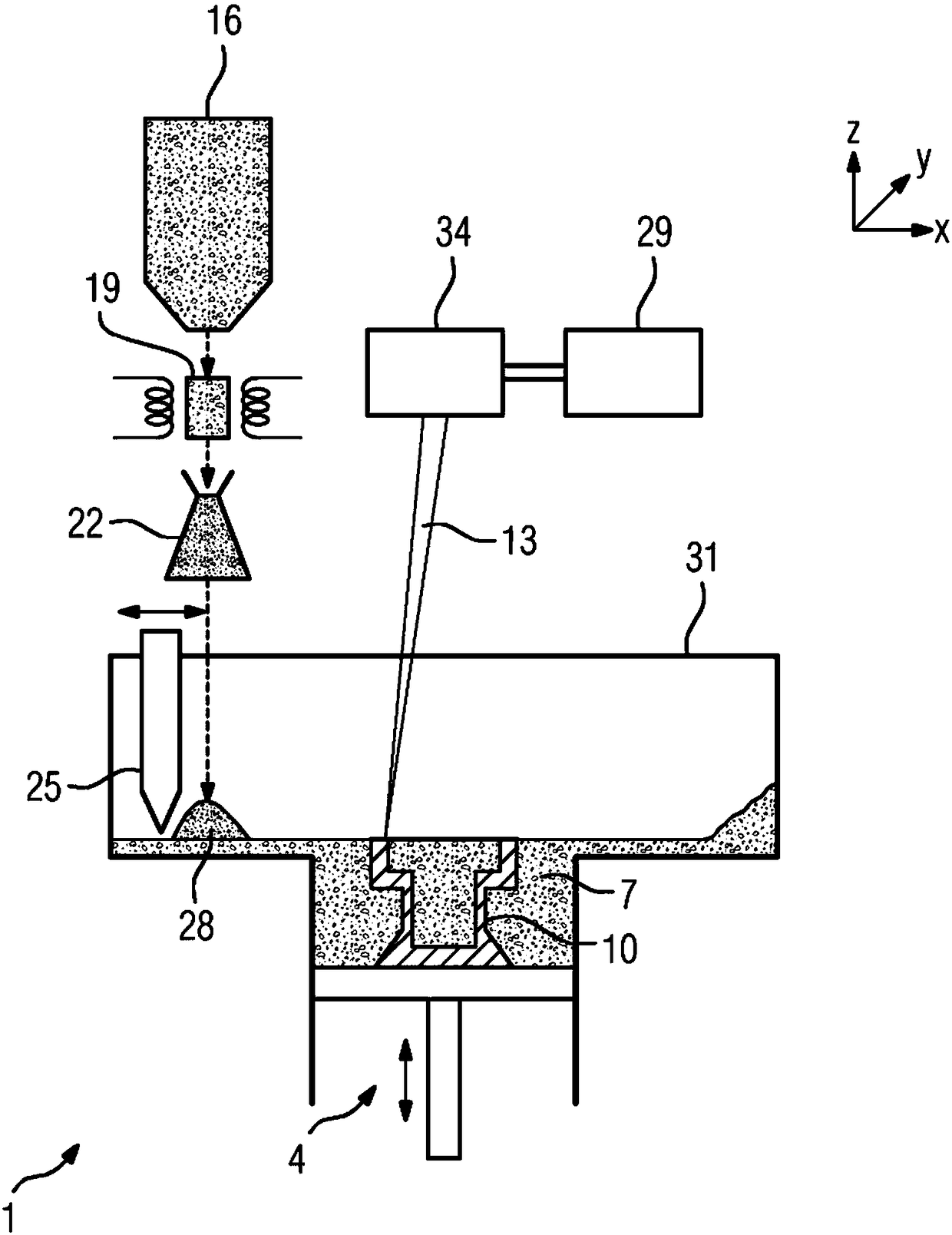

Device for the additive manufacture of a component

InactiveUS20160175935A1Free from damageRapid and simple for determiningAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyHigh energy beam

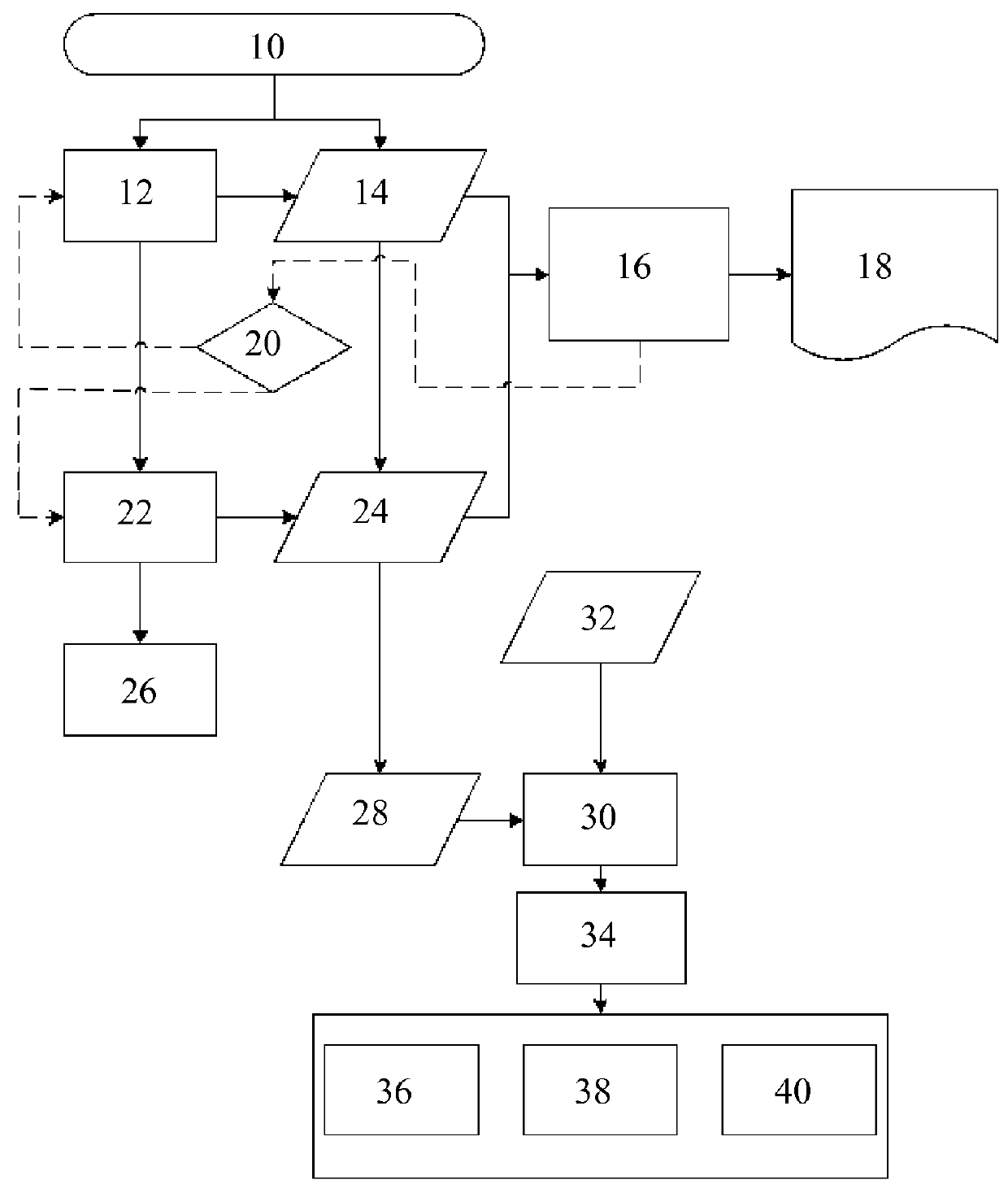

The invention relates to a device (10) for the additive manufacture of a component (12), comprising at least one coating device (14) for producing a powder layer (16) on a construction platform (18); at least one radiation source (20), in particular a laser, for producing a high-energy beam (24), by means of which the powder layer (16) in a construction surface area (22) can be melted and / or sintered locally to form a component layer (30); at least one deflection device (26), by means of which the high-energy beam (24) can be deflected onto different regions of the powder layer (16) and can be focused on the construction surface area (22); at least one measurement system (28), by means of which a cross-sectional geometry of the high-energy beam (24) on the powder layer (16) and / or the component layer (30) can be determined; and at least one equilibration device (32).

Owner:MTU AERO ENGINES GMBH

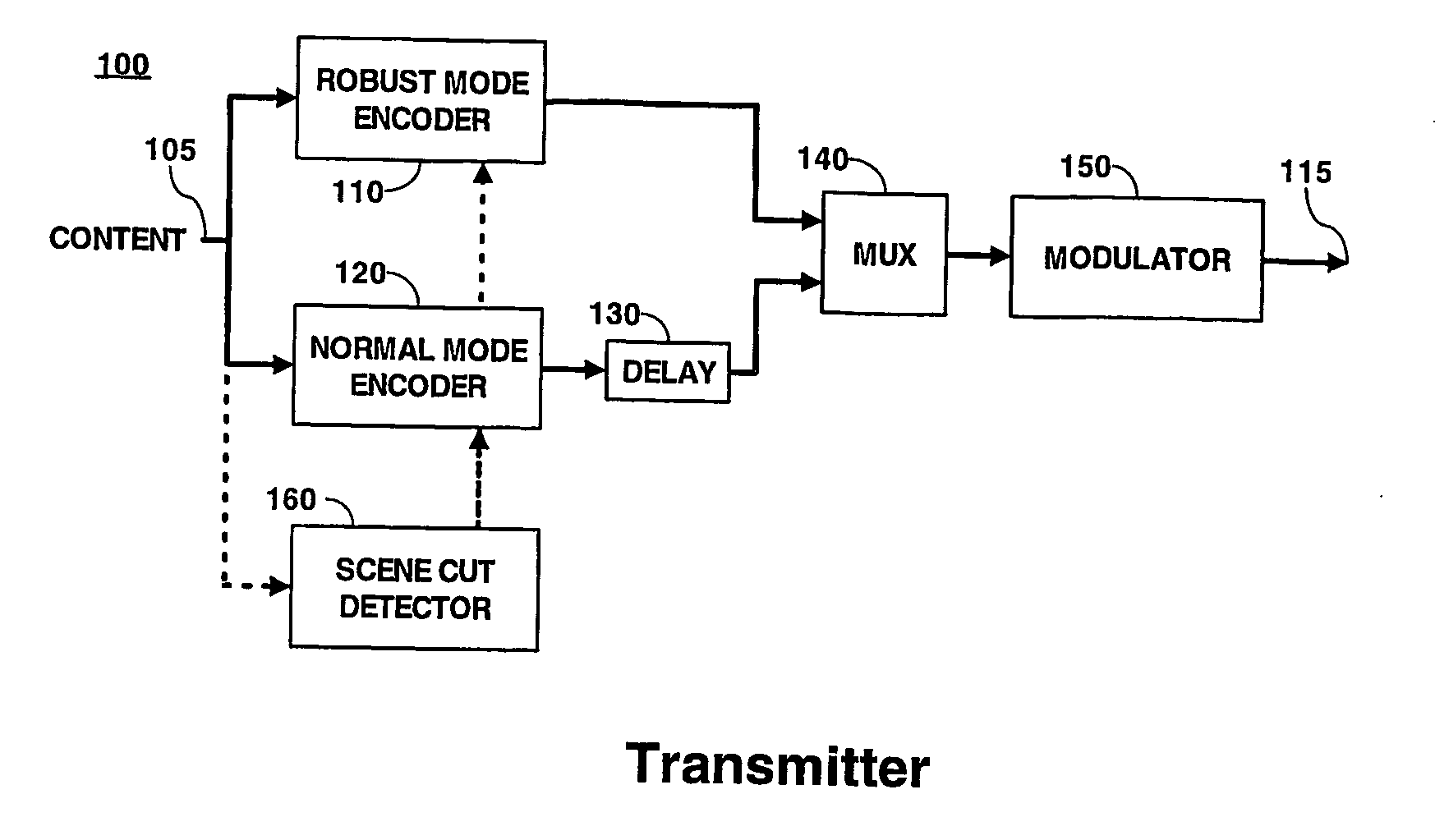

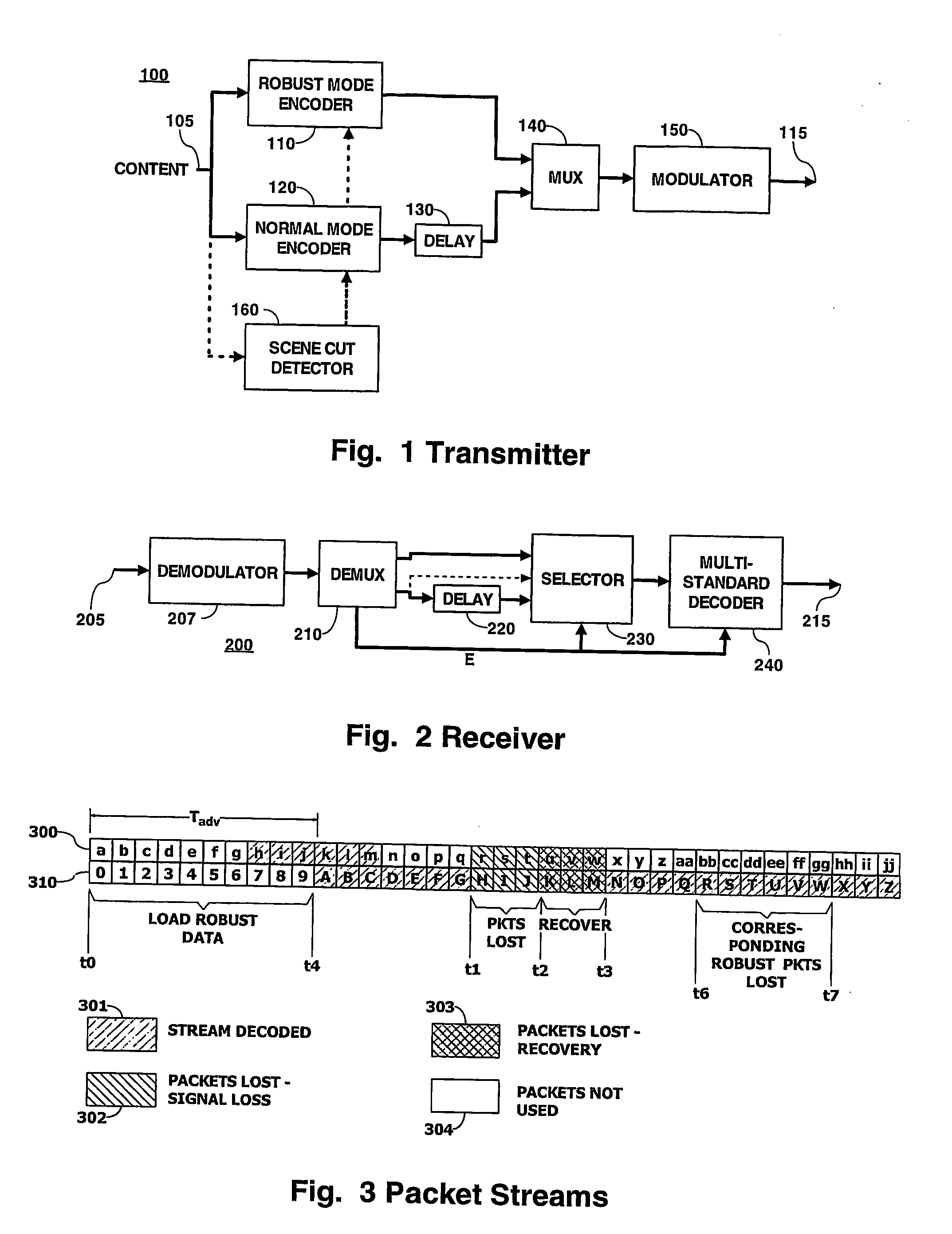

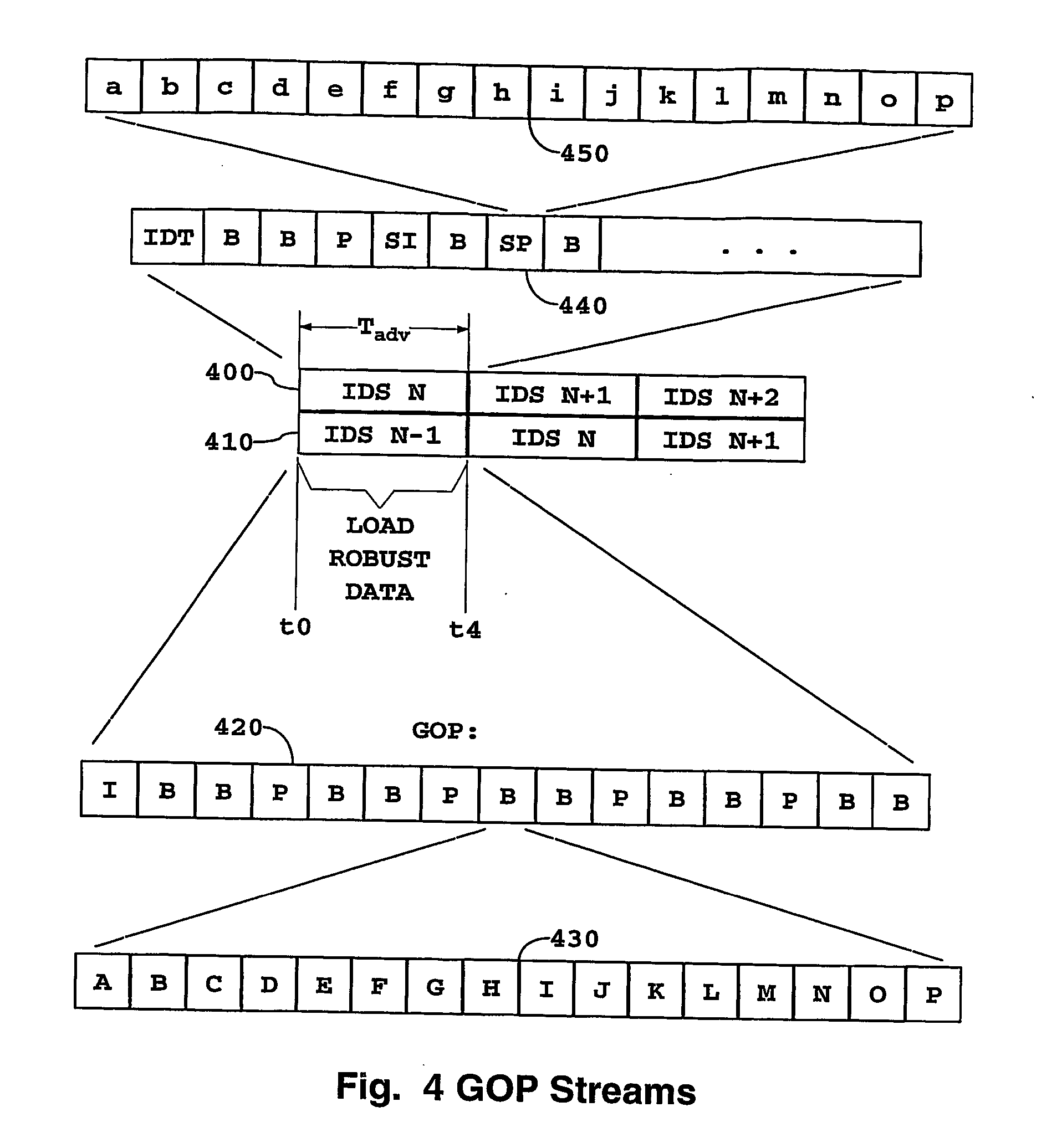

Robust mode staggercasting storing content

ActiveUS20060050781A1Long delayImprove component qualityAnalogue/digital conversionTelevision system detailsBroadcastingComputer science

A method and apparatus for storing staggercasted content includes encoding a set of signals representing content. The set of signals is capable of being decoded to produce a corresponding set of decoded signals, each decoded signal having a quality different from the qualities of the decoded signals corresponding to the other encoded signals. A composite signal comprising the set of encoded signals, staggered in time, is generated. The set of encoded signals is extracted from the composite signal. Errors in the set of extracted encoded signals are detected to produce a subset of available extracted encoded signals which are not erroneous. A content representative signal at a selectable desired quality is decoded. The decoded content representative signal is then stored in a storage device.

Owner:INTERDIGITAL CE PATENT HLDG

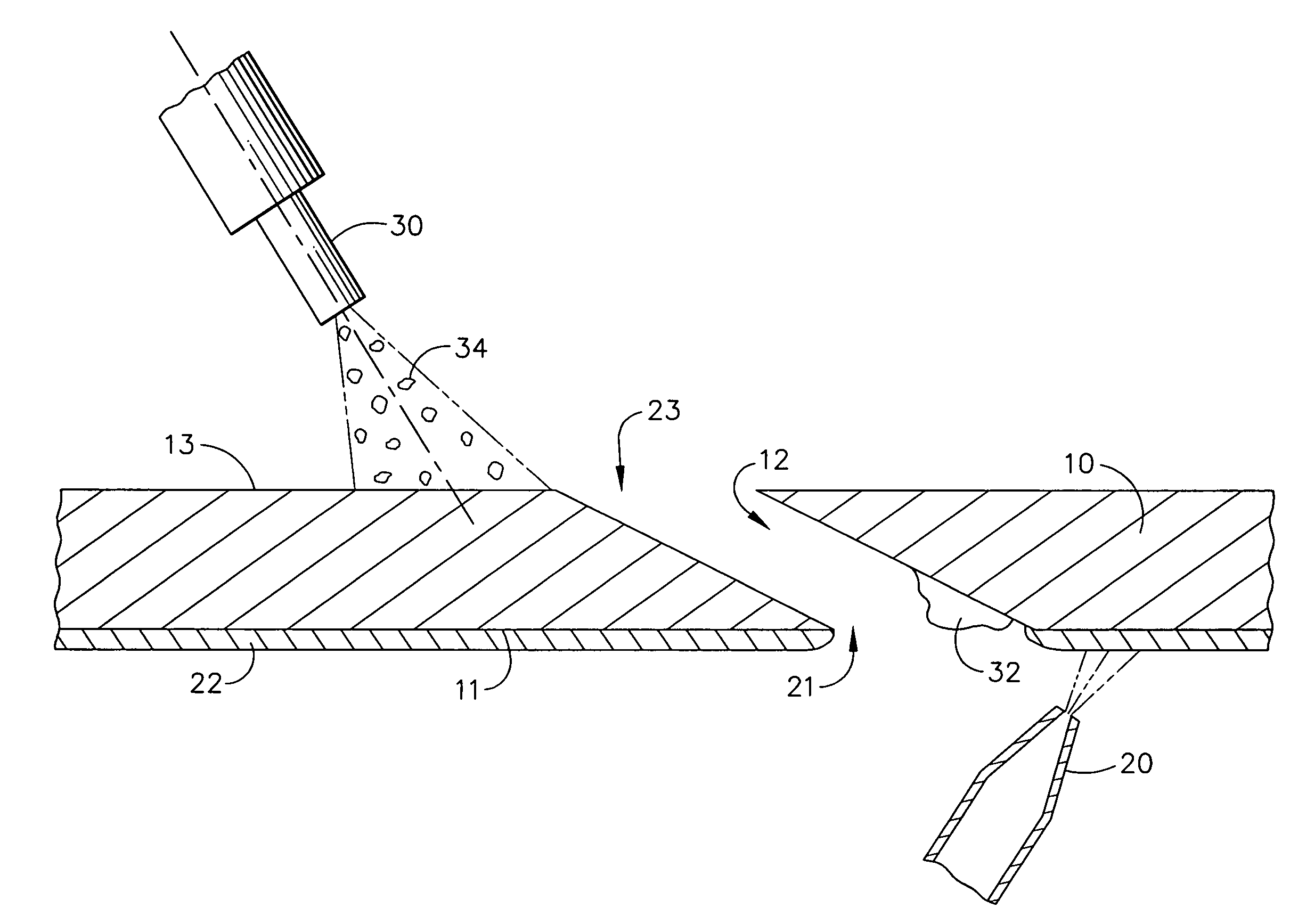

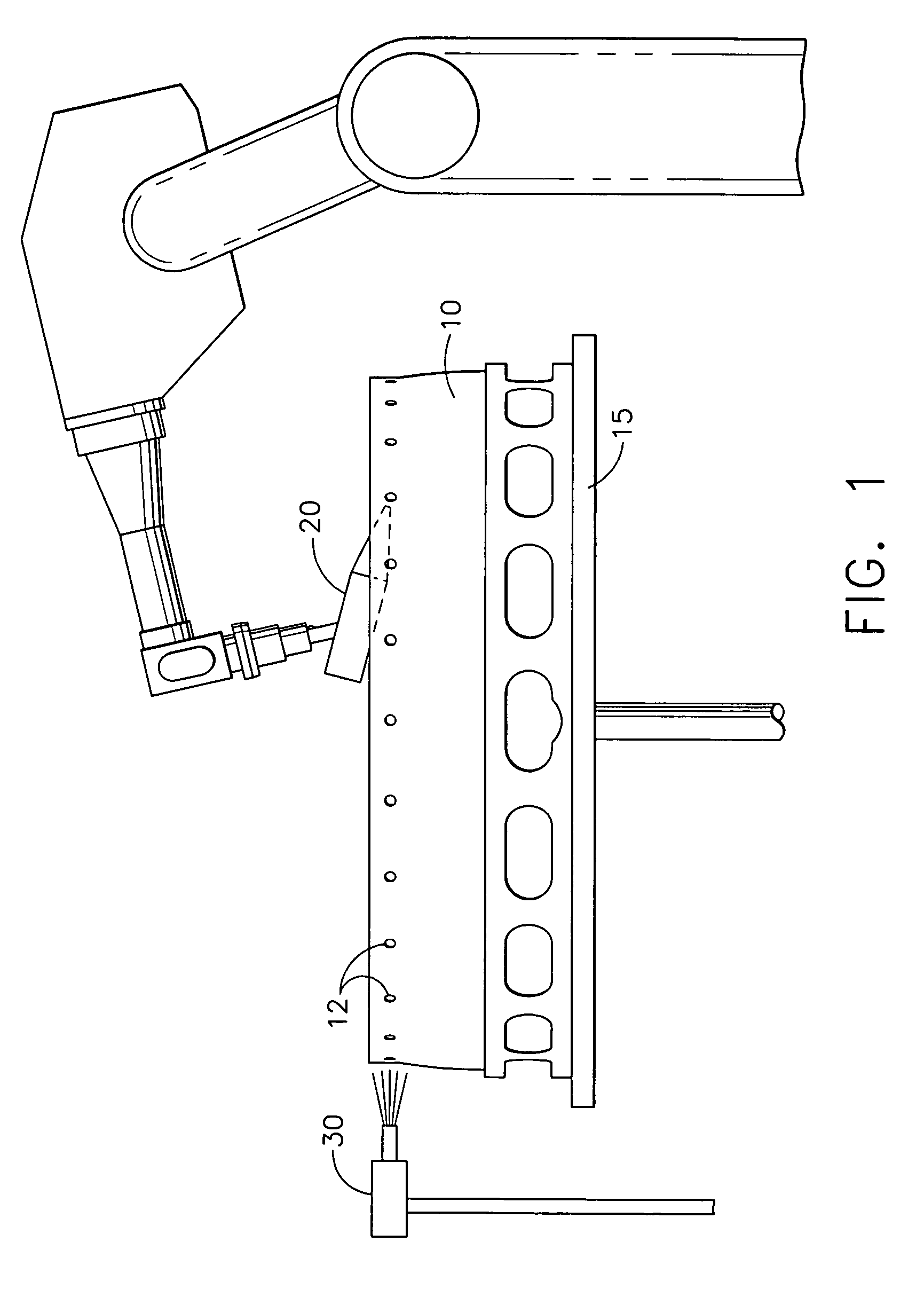

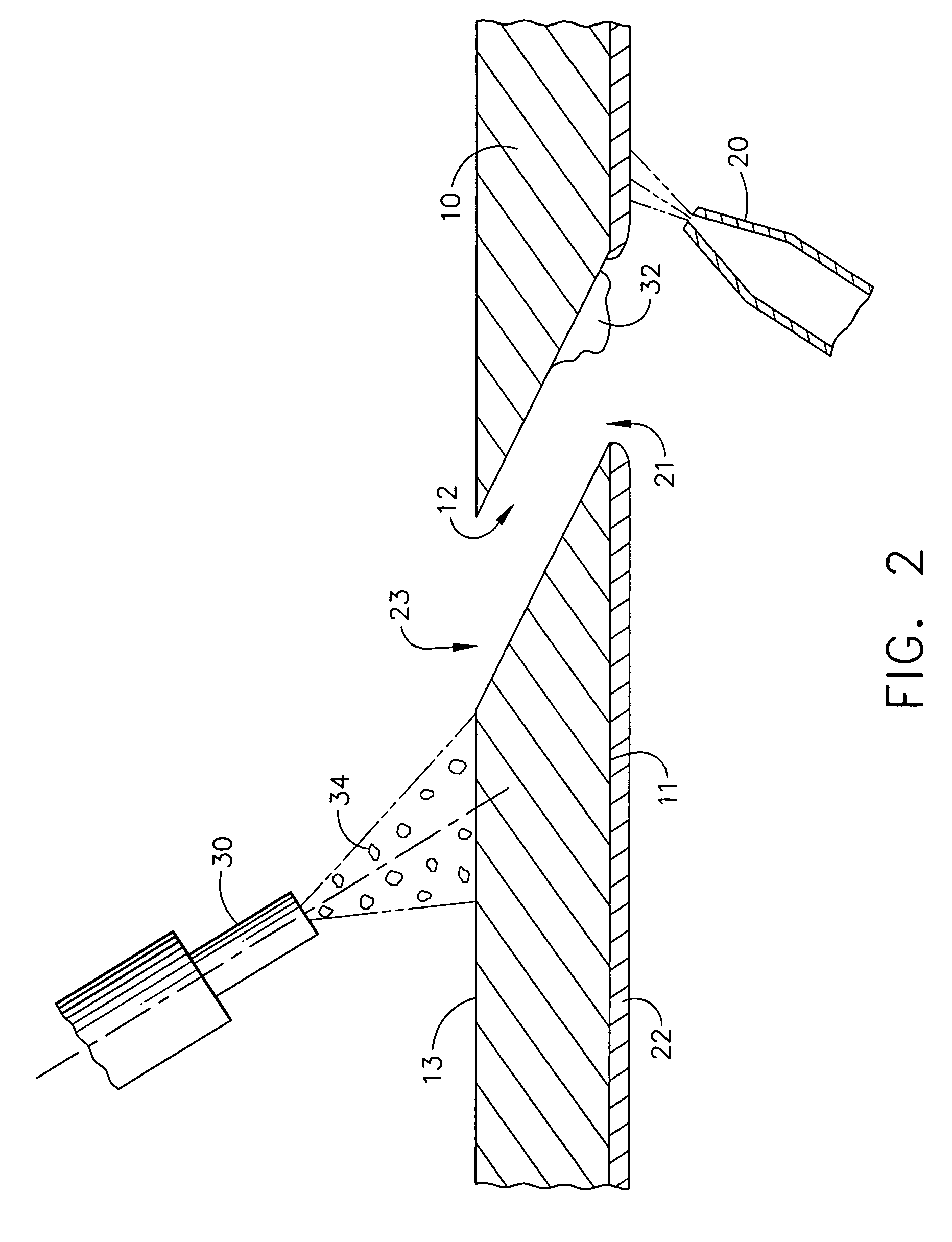

Method for concurrent thermal spray and cooling hole cleaning

ActiveUS7622160B2Improve efficiencyImprove component qualityLiquid surface applicatorsMolten spray coatingThermal sprayingThermal barrier coating

A method for applying a thermal barrier coating to an article having cooling holes and concurrently cleaning obstructions, such as TBC overspray or other debris, from those holes is disclosed. A thermal barrier coating is applied to a first surface of an article having cooling holes. Concurrently therewith, a plurality of particles are projected against a second surface of the article, such that at least some of the particles pass through the cooling holes, strike the overspray constituents prior to cooling, knocking at least some of the obstructions out of the cooling hole.

Owner:GENERAL ELECTRIC CO

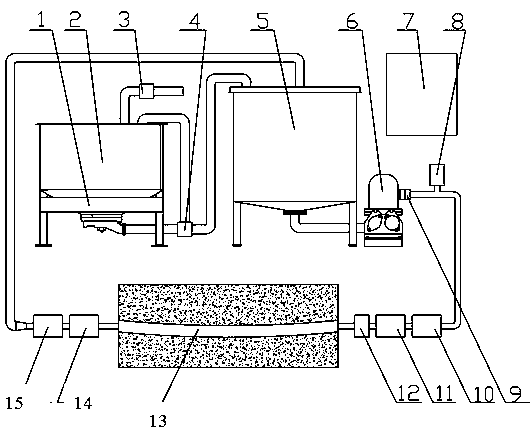

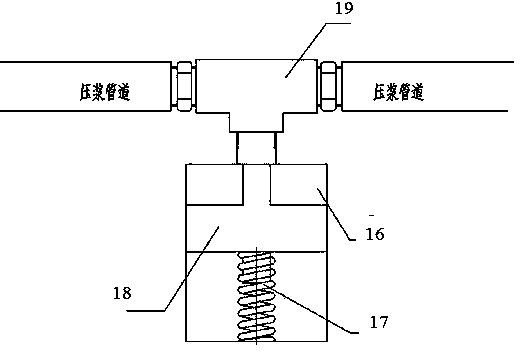

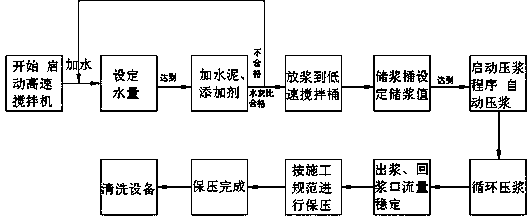

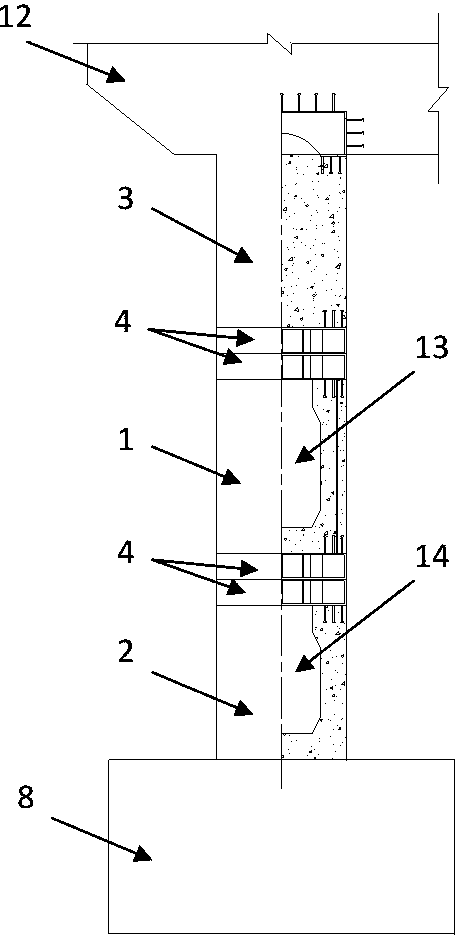

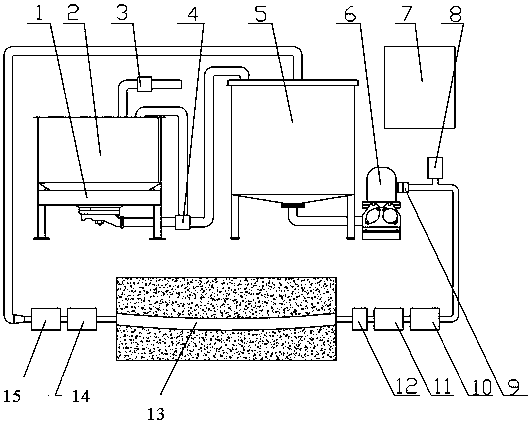

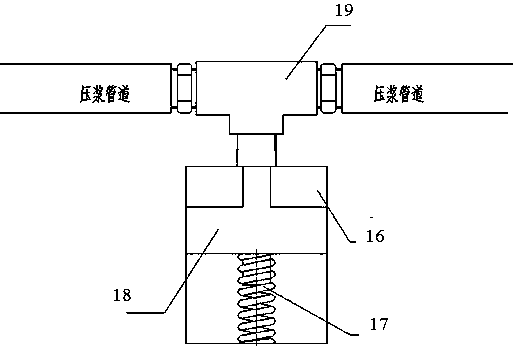

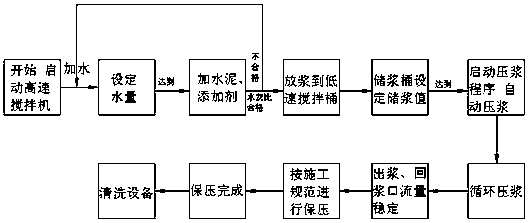

Intelligent circulating prestress mud jacking system and control method thereof

ActiveCN104074143AStable pressureDensified groutBridge erection/assemblyBuilding material handlingLower limitPre stress

The invention discloses an intelligent circulating prestress mud jacking system and a control method thereof. A pressure compensation device is arranged on a mud jacking pipeline between a mud jacking pump and a mud inlet and comprises a piston and an elastic mechanism, wherein the end of the piston is communicated with the mud jacking pipeline, and the elastic force of the elastic mechanism drives the end of the piston to be pressed into the mud jacking pipeline. Pressurizers are arranged at the positions of the mud inlet and a mud outlet respectively to control the quantity of mud entering the duct of a beam component and the quantity of mud discharged from the duct of the beam component respectively. Electromagnetic flowmeters are arranged at the positions of the mud inlet and the mud outlet respectively to acquire flow signals of the mud inlet and the mud outlet. Two sets of mud jacking pump plungers are arranged to achieve mud jacking alternately, water and cement ratio control is achieved in a closed-loop control mode, and an effective circulation pressure value, a dwell pressure value, a lower dwell pressure limiting value and an upper dwell pressure limiting value and a dwell time value are set to control components and mud. The system has the advantages that mud pressure is stable, jacked mud is dense, and the quality of components is high.

Owner:柳州市桥厦科技发展有限公司

Plastic component having visible part and light source

InactiveUS7985008B2Impair impressionImpair qualityNon-electric lightingPoint-like light sourceFiberIn vehicle

The present invention relates to a plastic component having a visible part that is made in one single layer from a plastic molding compound and that comprises a transparent or translucent matrix, and having a light source that comprises one or more lamp elements, situated under the surface of the visible part. The visible part is implemented as essentially opaque in relation to daylight and transparent or translucent in relation to the light emitted by the lamp elements. The visible part also contains admixed effect pigments and defines a surface appearance image which, when the light source is inactive, essentially corresponds to the surface appearance image of the remaining wall of an object in which the plastic component is installed and which, when the light source is active, is essentially determined by the light source activity. The plastic component according to the invention is characterized in that the lamp elements are selected from a group which comprises light-emitting diodes, organic light-emitting diodes, and fiber-optic light systems, the lamp elements at least partially being embedded in the plastic molding compound of the visible part. The manifold uses of this plastic component comprise installation in vehicles, paneling elements, and furniture, as well as in housings of greatly varying devices.

Owner:EMS CHEM AG

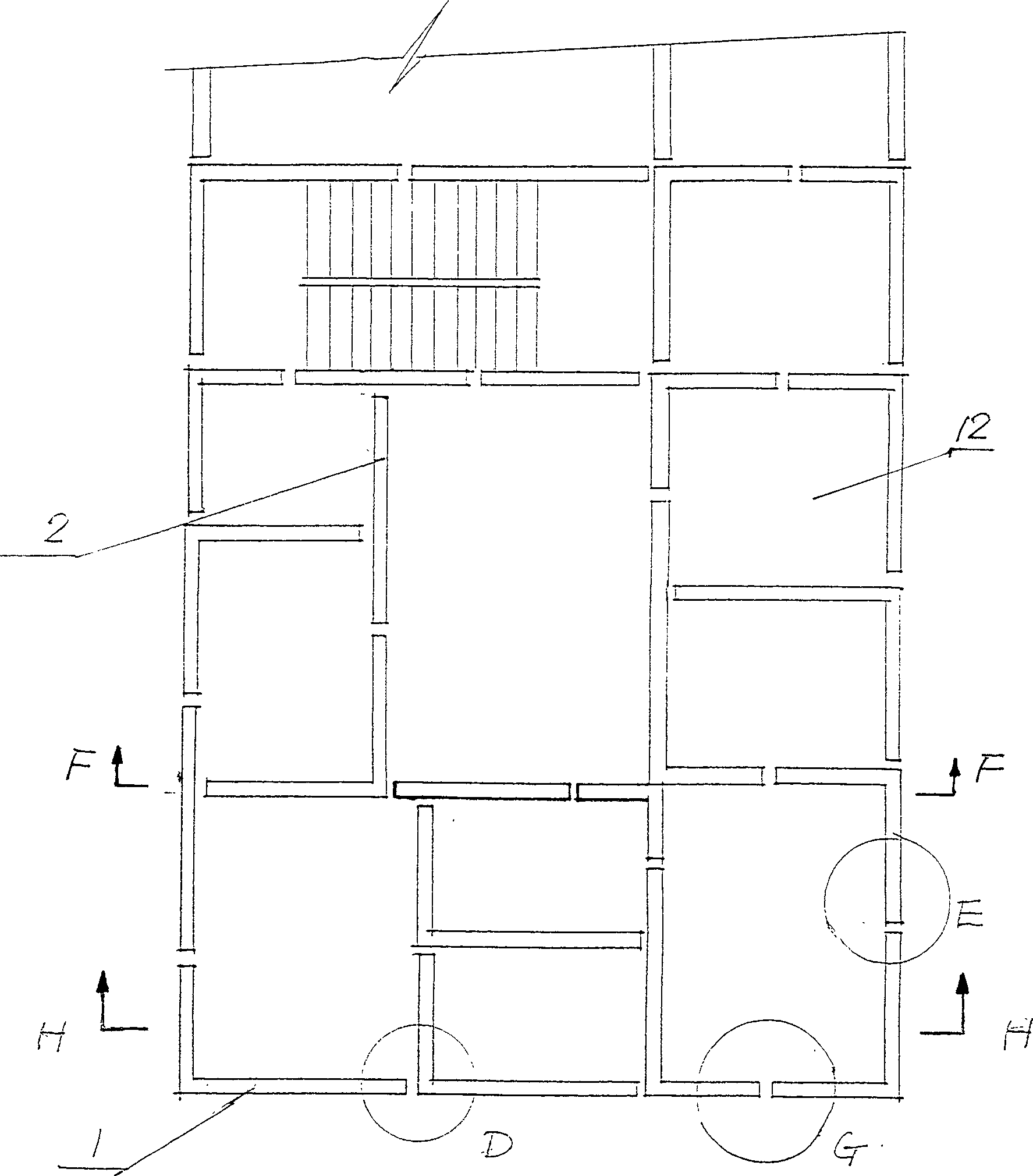

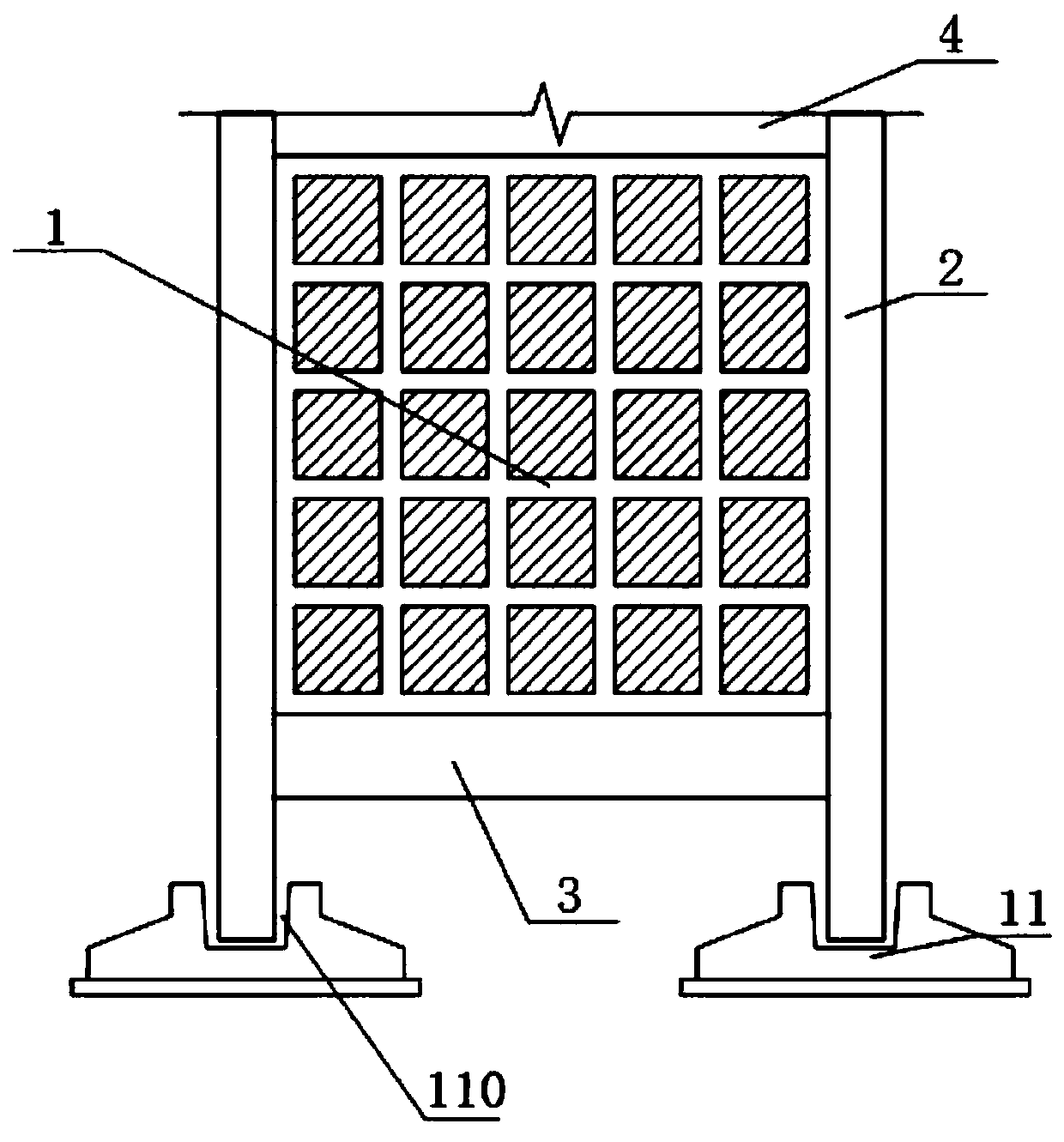

Prefabricated concrete shear wall building structure and its construction method

The present invention relates to building structure and construction method. It includes one wall structure comprising rigid net frame with shaped steel and steel wire member and planar sandwich layer with foamed glass; integrally cast floor board connected via steel wire net; combined construction process of assembling prefabricated members and site casting;a nd movable and easy-to-connect wall for variable bay and fitting setting. The present invention has high integral performance, short construction period and low building cost.

Owner:朱维高

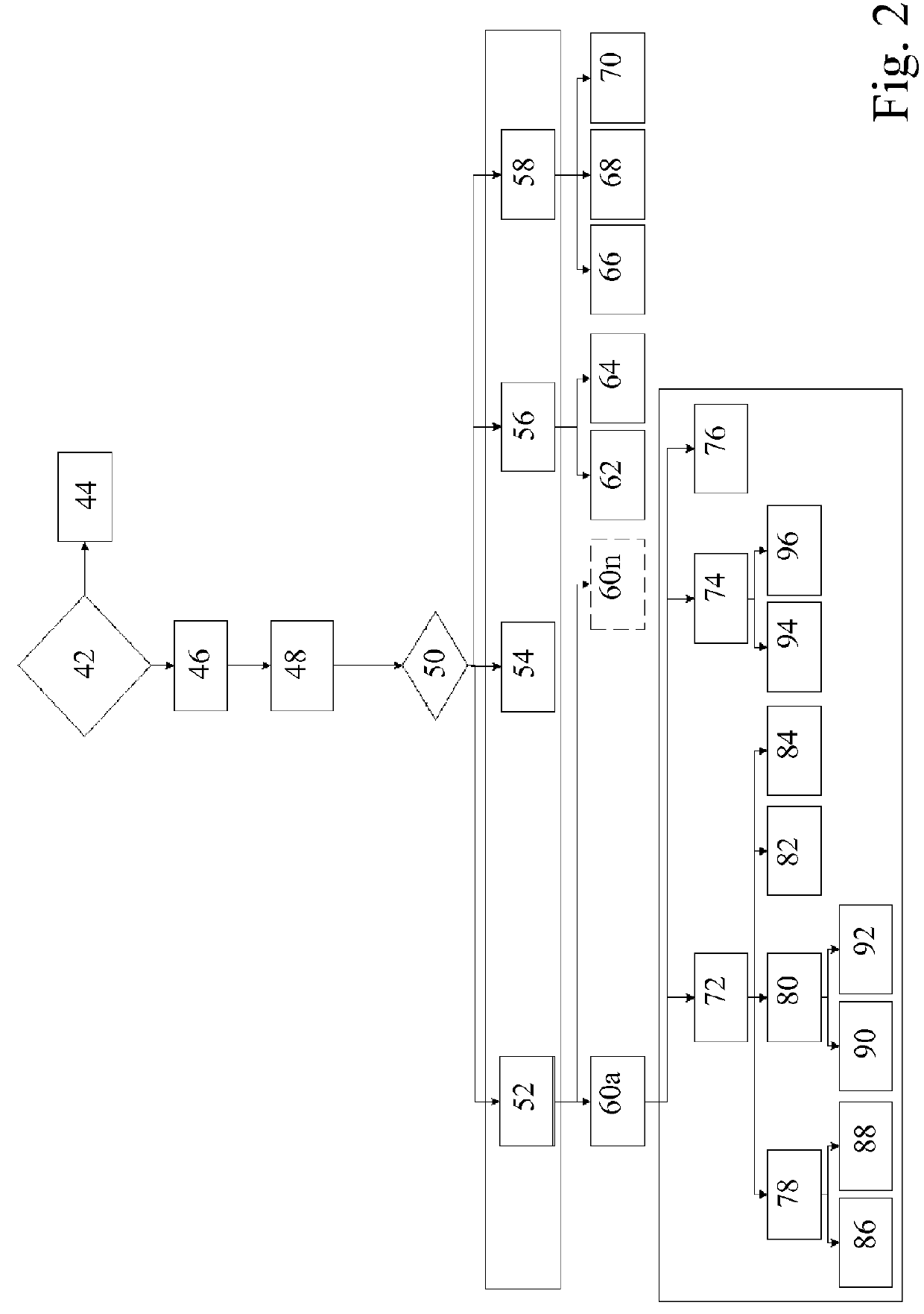

Method for the quality assessment of a component produced by means of an additive manufacturing method

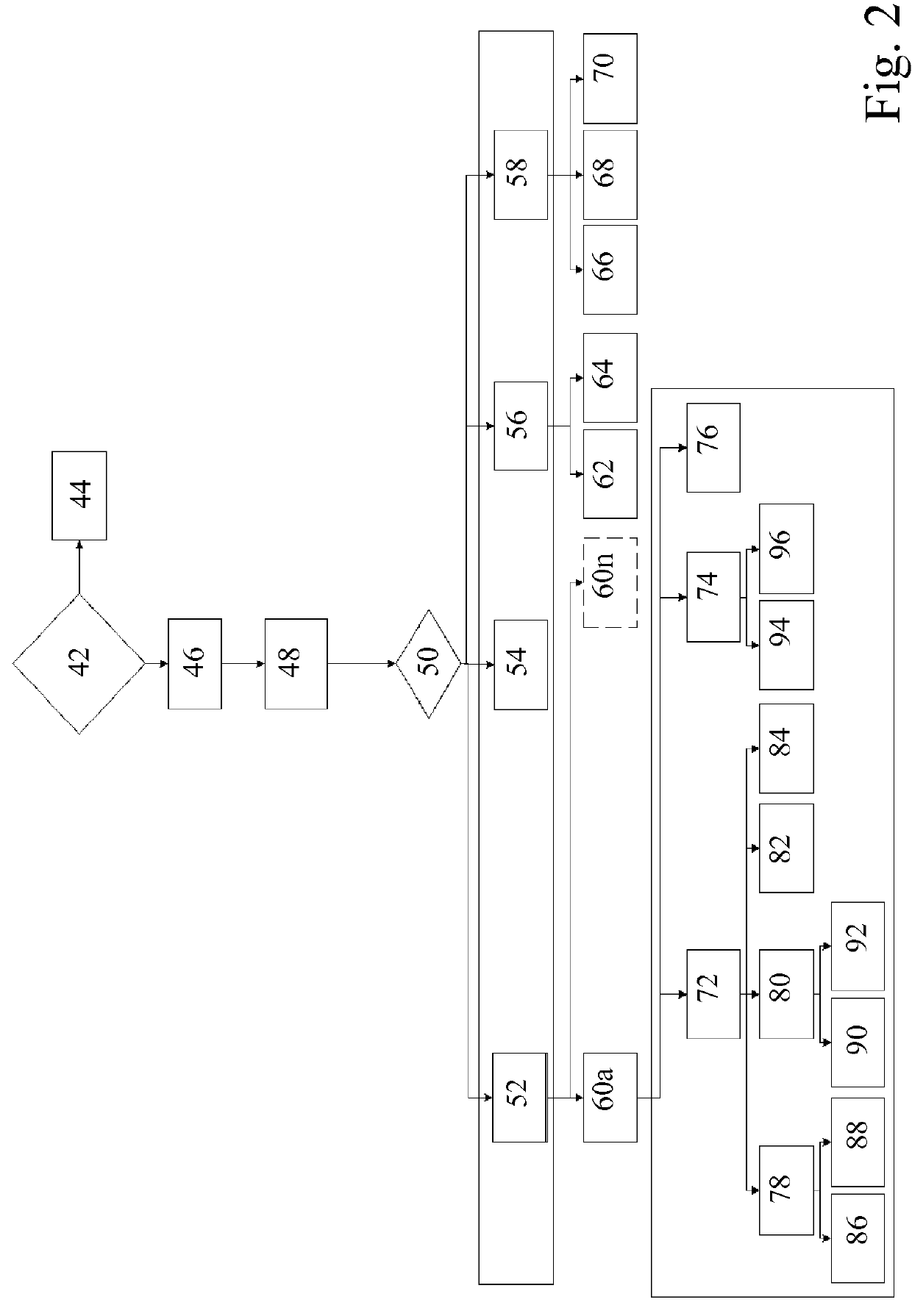

ActiveUS20160054231A1Fast and accurate determinationImprove component qualityProgramme controlOptically investigating flaws/contaminationQuality assessmentAdditive layer manufacturing

The invention relates to a method for the quality assessment of a component produced by means of an additive manufacturing method. In the course of the method, it is checked first of all whether the component violates predetermined absolute limits in order to rule out the existence of serious malfunctions in the additive manufacturing process. Subsequently, a component-dependent targeting process is determined. On the basis of this targeting process, the limits for deviations are established and deviating actual values of the component are isolated and assessed by means of various parameters.

Owner:MTU AERO ENGINES GMBH

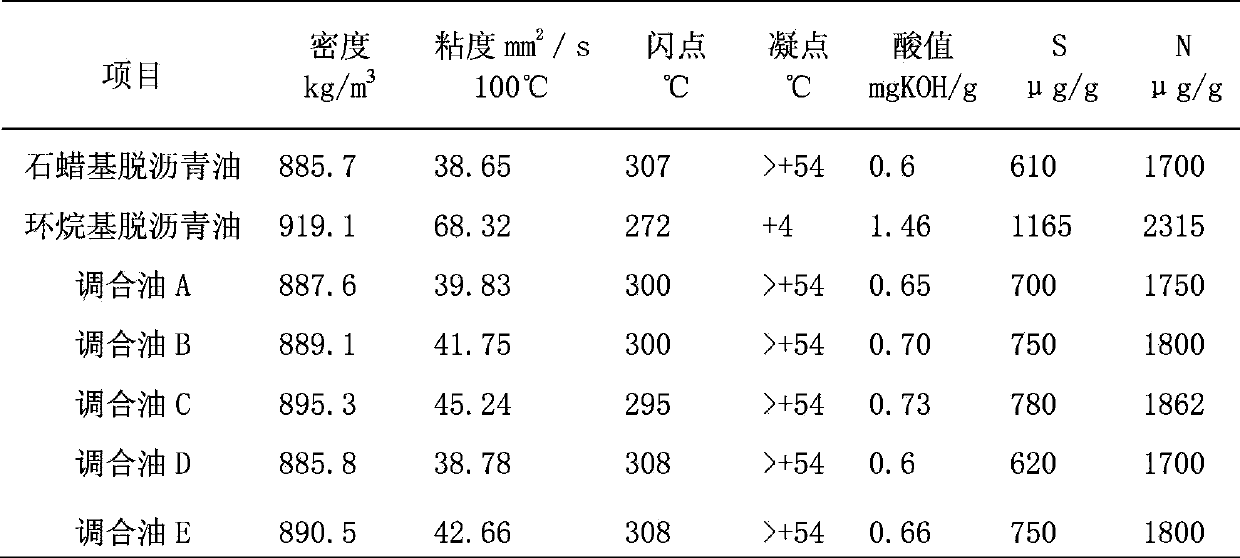

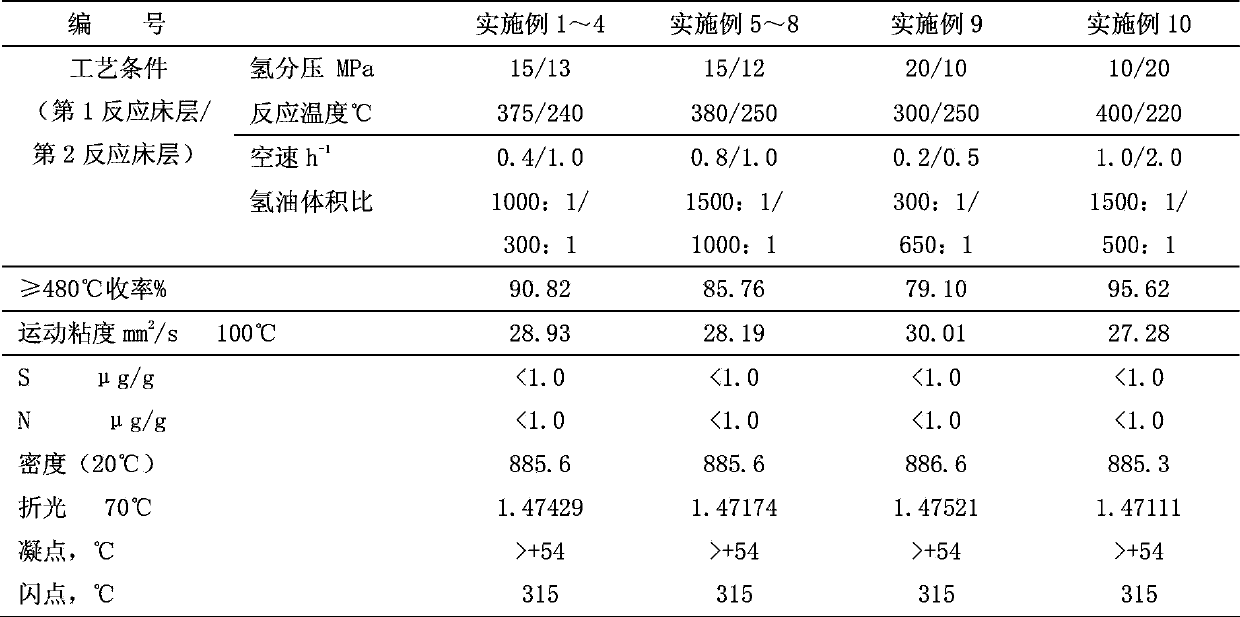

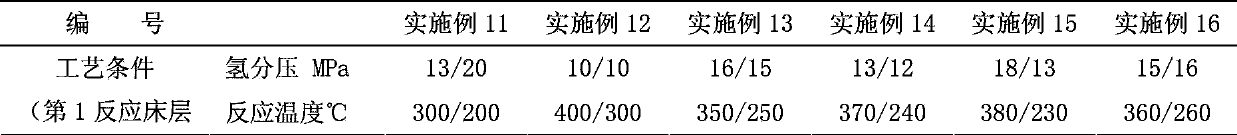

Preparation method of food-grade microcrystalline wax

InactiveCN103865580AExtended service lifeChange the rate of the hydrogenation reactionPetroleum wax refiningMicrocrystalline waxSlag

The invention relates to a preparation method of food-grade microcrystalline wax. The preparation method comprises the following steps that blended oil comprising paraffin-based slag-reduced deasphalted oil and naphthenic base slag-reduced deasphalted oil is used as a raw material, is fed into a first reaction bed layer and then undergoes a hydrotreatment modification reaction; the reaction product is fed into a stripping tower and the stripped product is fed into a second reaction bed layer and undergoes a hydrofining reaction to produce hydrofined product oil; the hydrofined product oil is cut by atmospheric and vacuum fractionation equipment to form a heavy lubricant component having a temperature of 480-750 DEG C; the heavy lubricant component and an acetone-benzol dewaxing solvent are mixed; the mixture is cooled to below -15 DEG C; the cooled mixture is filtered so that dewaxed filtrate and deoiled wax are obtained; the deoiled wax is mixed with carclazyte by stirring; and the mixture is filtered so that the carclazyte is removed and the food-grade microcrystalline wax is obtained. The food-grade microcrystalline wax has Seybolt color number greater than +25, a drop melting point of 67-92 DEG C, a needle penetration degree of 15-35(1 / 10mm), oil content of 0.85-3.0%, sulfur and nitrogen content less than 1 microgram per gram and heavy metal and arsenic content less than 1mg / kg.

Owner:PETROCHINA CO LTD

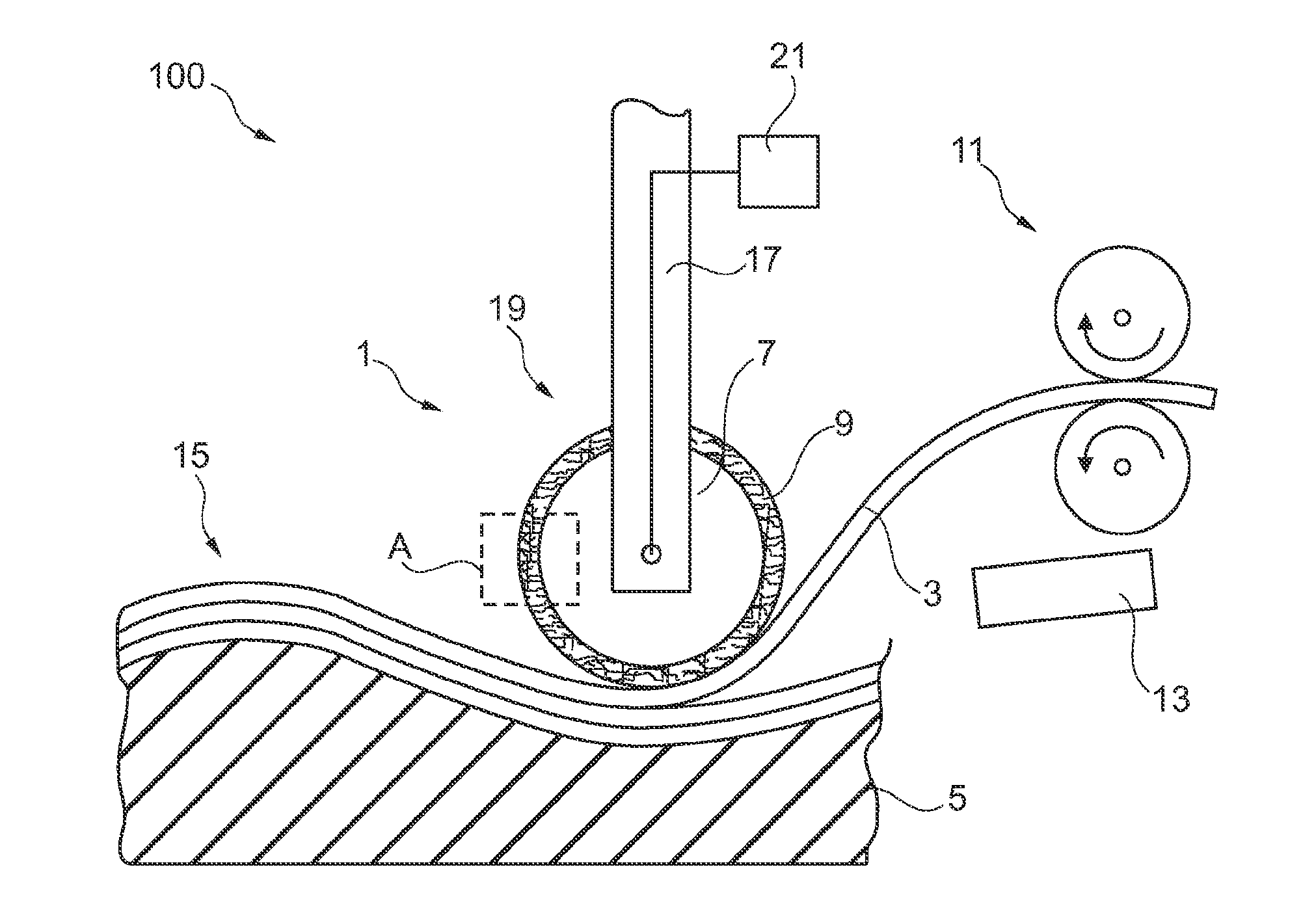

Pressing-on device for pressing on fiber-reinforced thermoplastic materials, fiber arranging device, and method for arranging a fiber-reinforced thermoplastic material

InactiveUS20120073749A1Maintain propertiesImprove insulation effectAdhesive processesPaperhangingHeat resistanceInorganic materials

A pressing-on device for pressing fiber-reinforced thermoplastic materials onto a mold is described. The pressing-on device has a main body and a pressing-on layer provided on a surface of the main body. The pressing-on layer is implemented in this case using an inorganic material, preferably a ceramic material, and has a flexibility because of its structure which allows it to adapt itself to the contour of a mold. Increased heat resistance of the pressing-on device and improved properties of the processed fiber-reinforced thermoplastic material can be achieved.

Owner:AIRBUS OPERATIONS GMBH

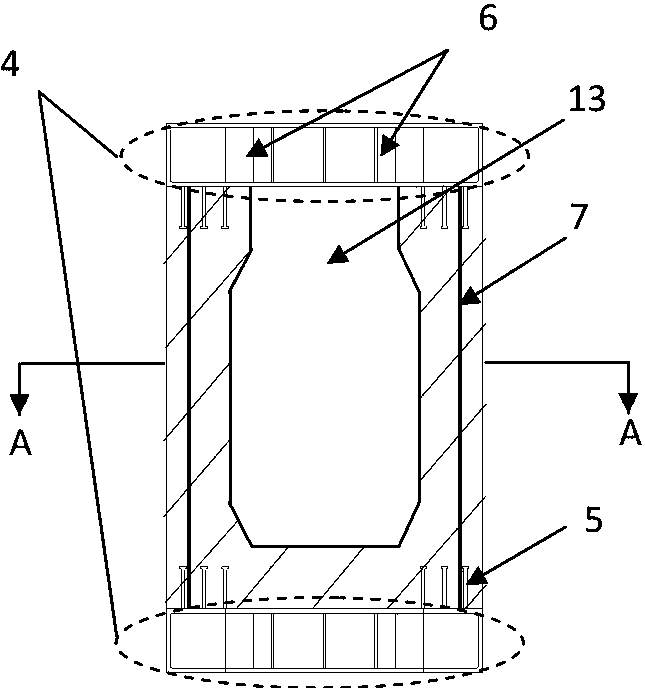

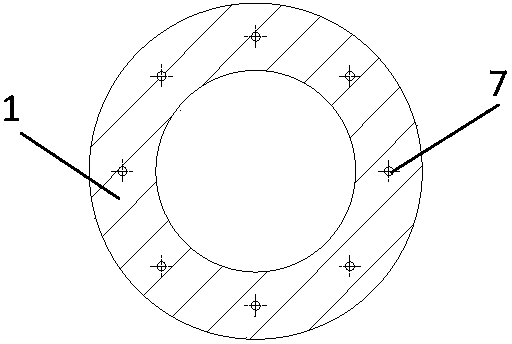

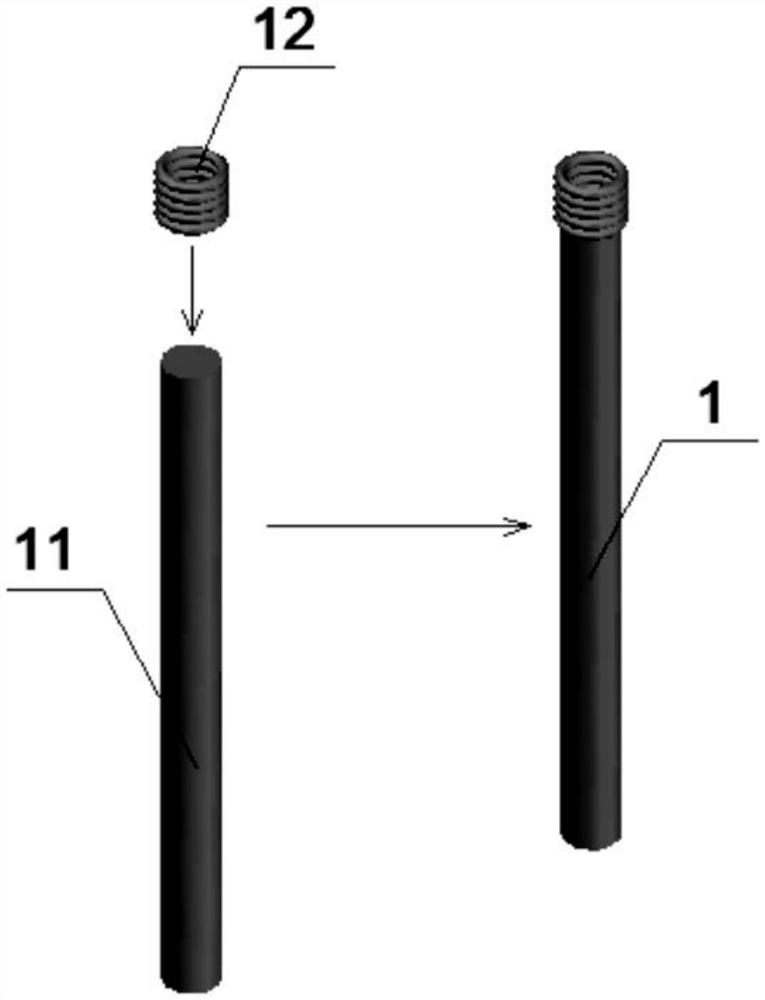

Tubular concrete bridge pier

ActiveCN103628403ALess materialShorten the construction periodBridge structural detailsReinforced concretePre stress

The invention provides a tubular concrete bridge pier in order to overcome the defects of an existing reinforced concrete bridge pier. The tubular concrete bridge pier is composed of a pier column lower end joint section body, more than one pier column standard joint section body and a pier column upper end joint section body. The pier column lower end joint section body is placed on a foundation, the upper end of the pier column lower end joint section body is connected with the lower end of the pier column standard joint section body, and the upper end of the pier column standard joint section body is connected with the lower end of the pier column upper end joint section body. The tubular concrete bridge pier has the advantages that the using amount of concrete is reduced compared with the using amount of the concrete of a traditional solid bridge pier, the economy is improved, and meanwhile the demand for energy conservation and emission reduction is met; a pre-tensioning method prestress component is used, so that the anti-cracking performance of pier columns is effectively improved; steel components are used between bridge pier joint sections, and the safety of bridge pier structures under the earthquake action can be effectively improved.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

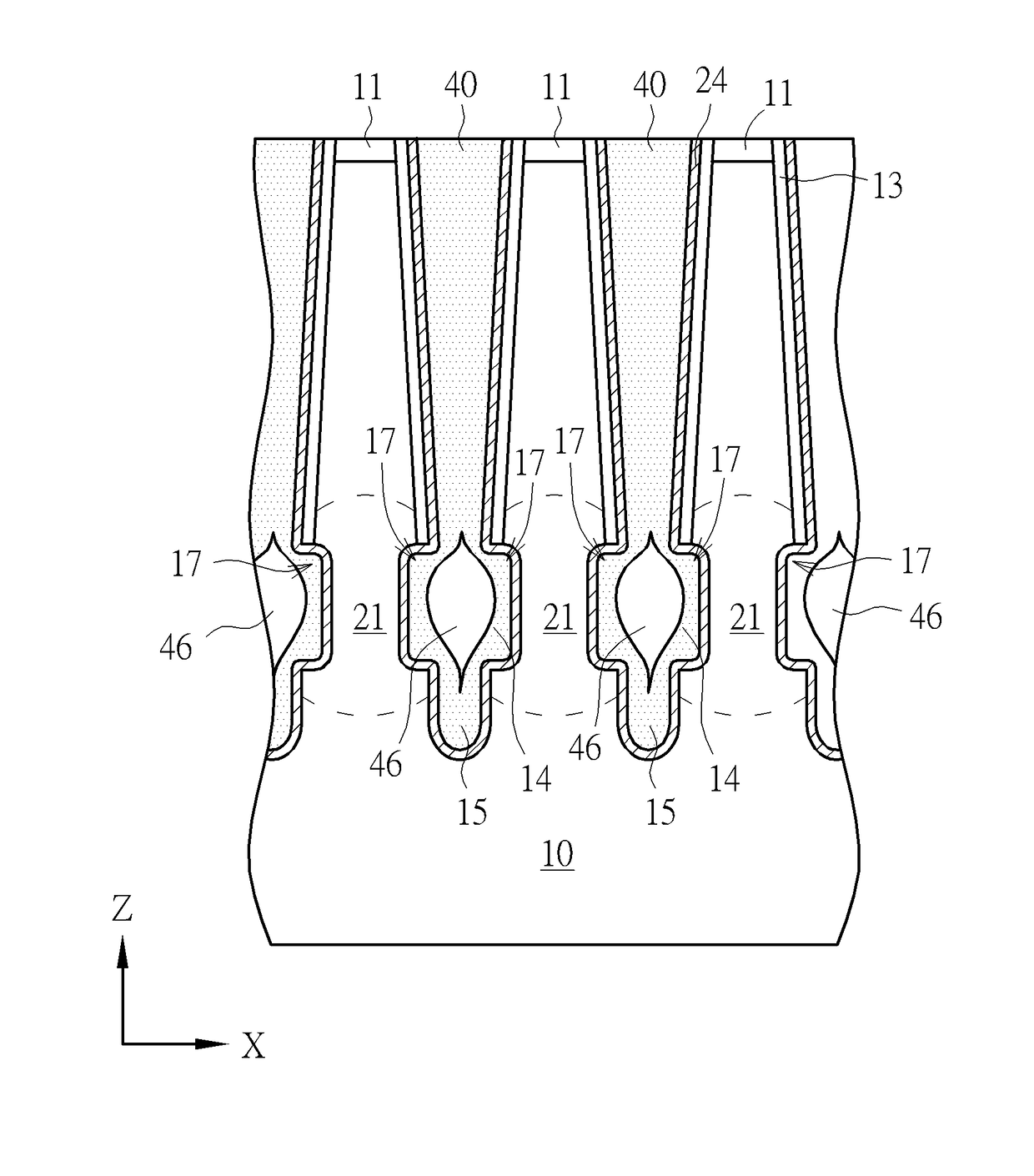

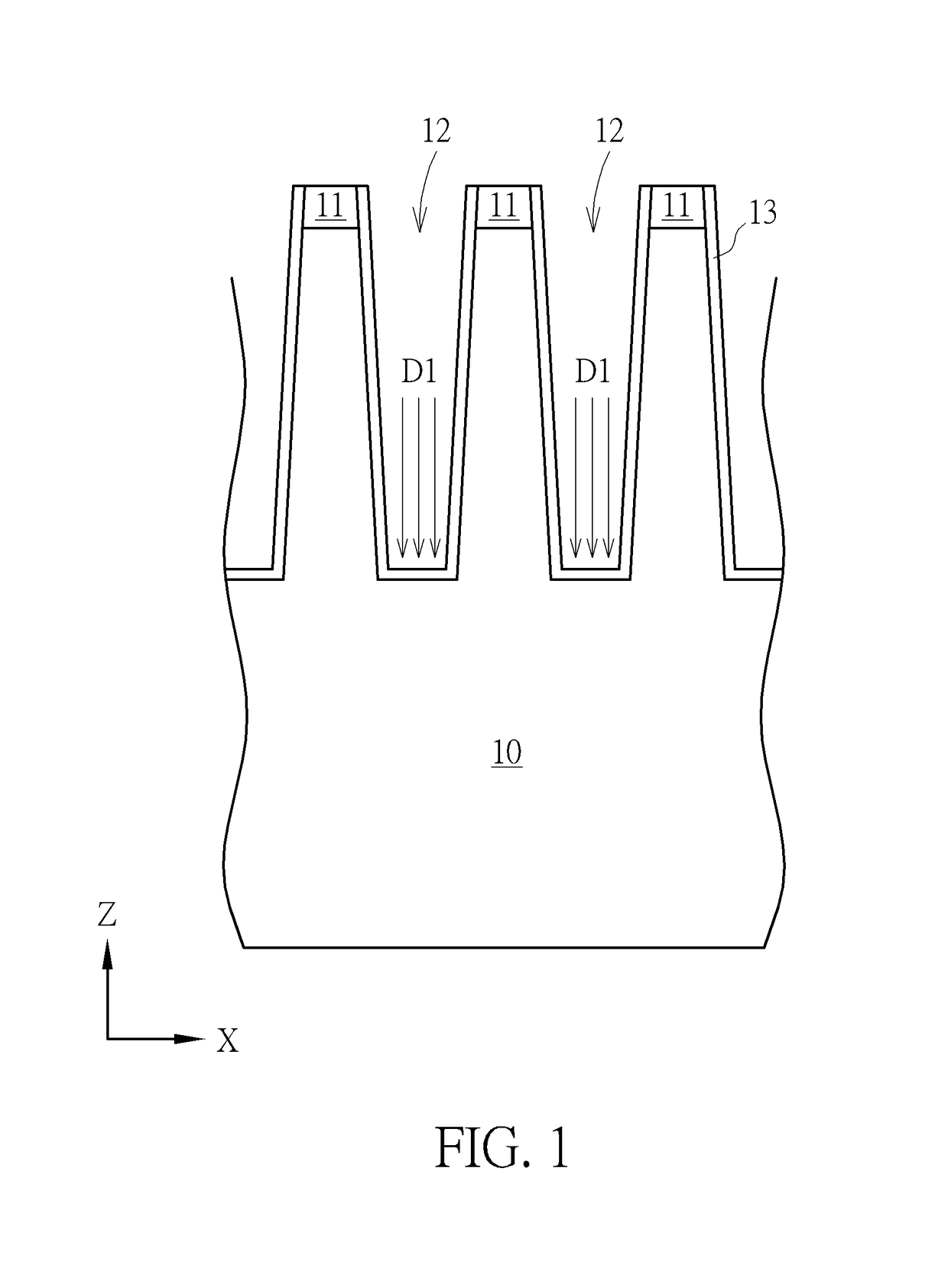

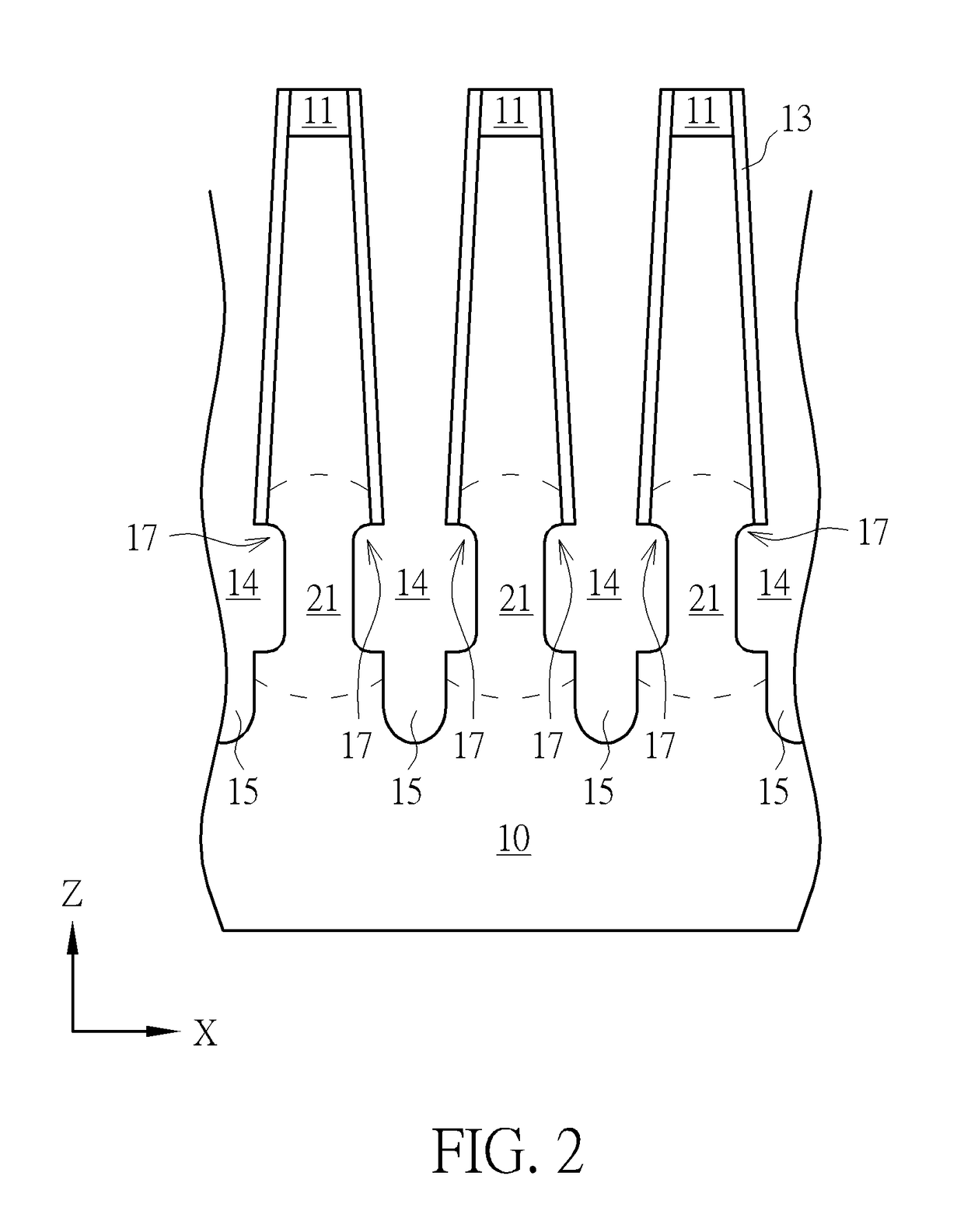

Silicon buried digit line access device and method of forming the same

ActiveUS9691773B2Improve component qualityReduce capacitanceTransistorSemiconductor/solid-state device detailsFilling materialsEngineering

An access device includes a plurality of first digit lines (DL) trenches extending along a first direction, buried digit lines between each DL trench, second and third trenches separating the digit lines, a filling material filling the digit line trenches comprising airgaps in each second trench, a plurality of word line (WL) trenches extending along a second direction, metal word lines deposited on the walls of the word line trenches, a filling material filling the word line trenches.

Owner:NAN YA TECH

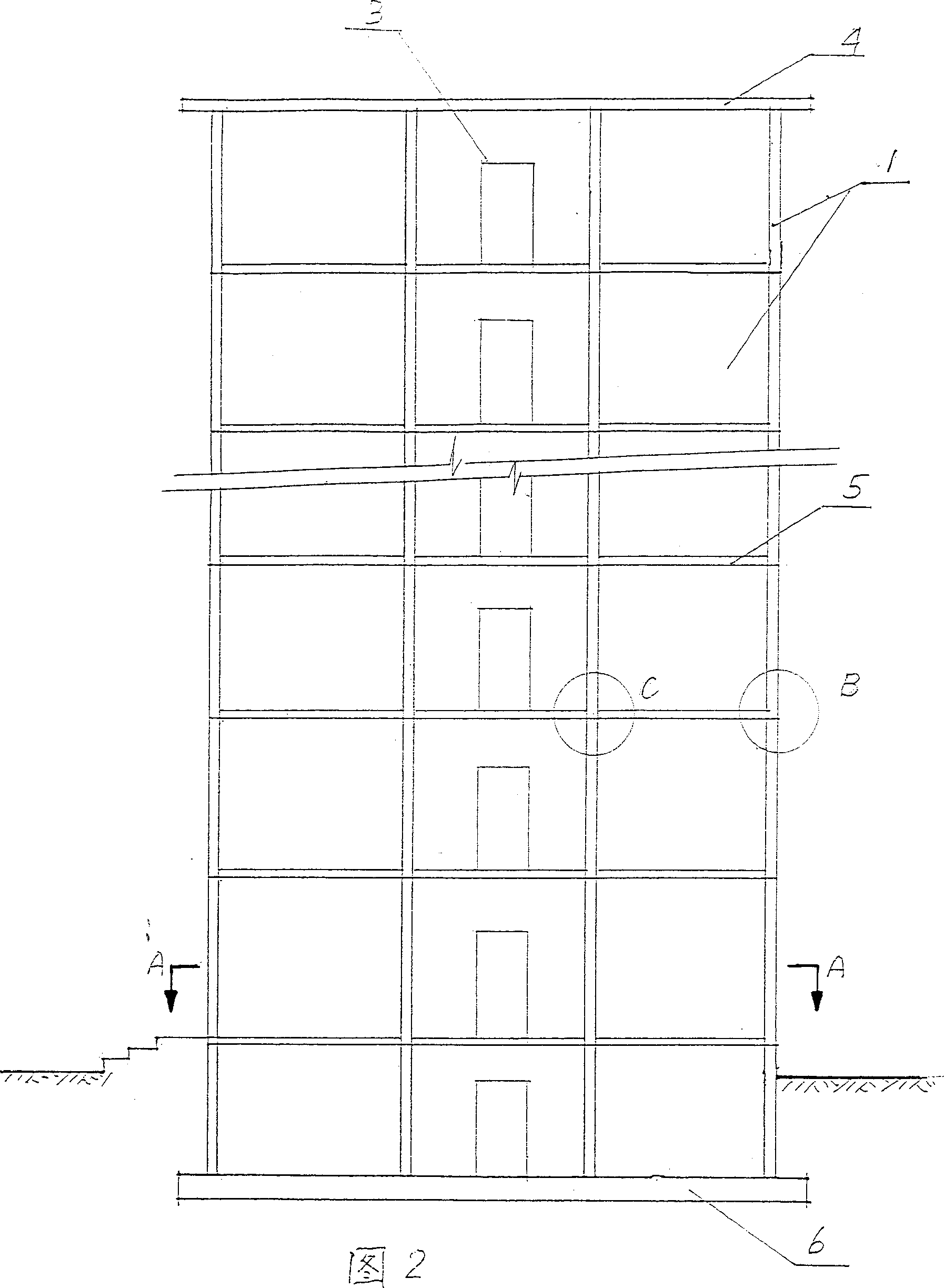

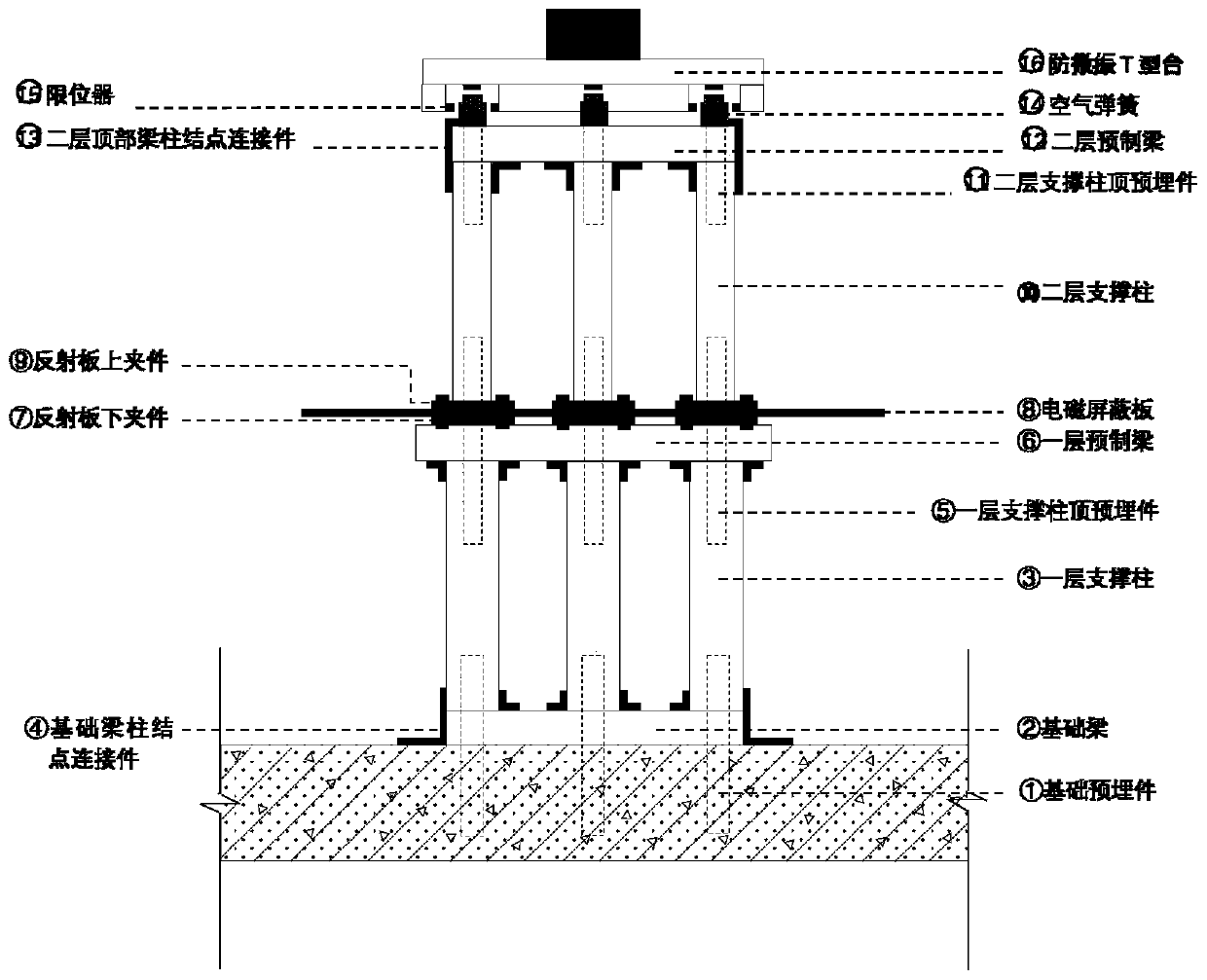

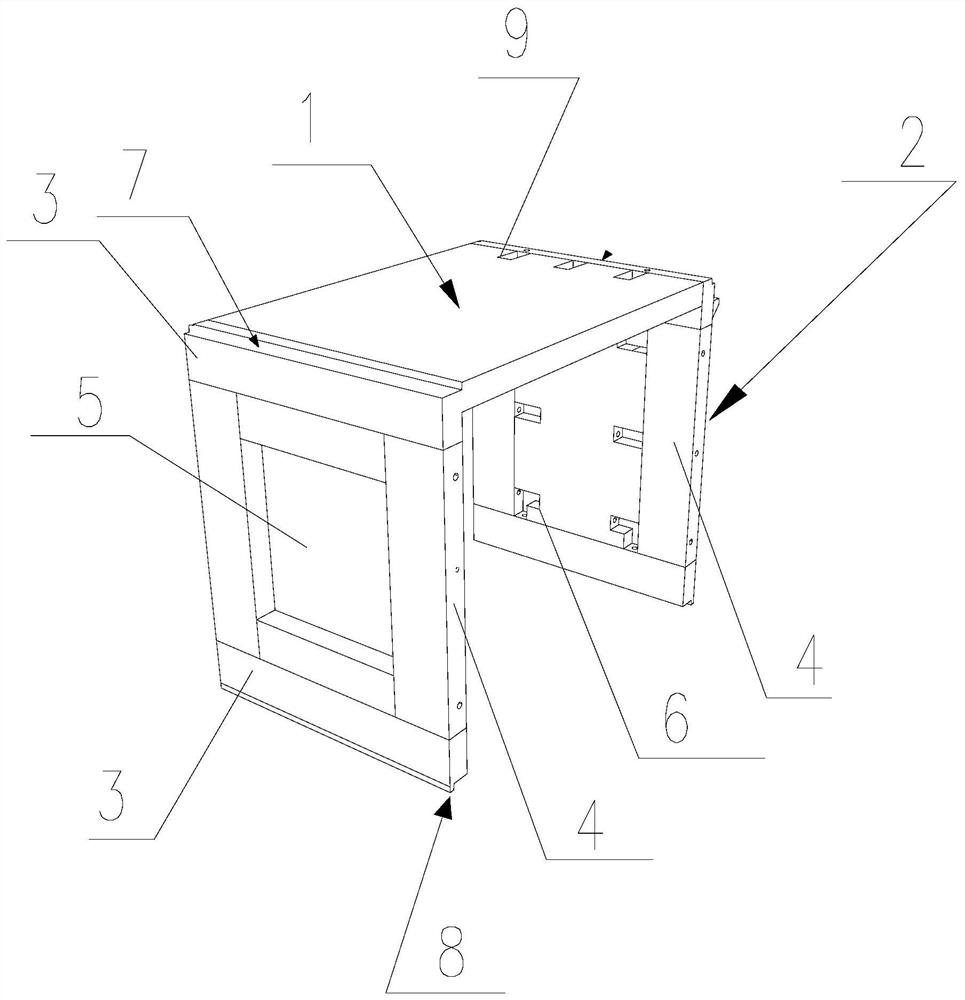

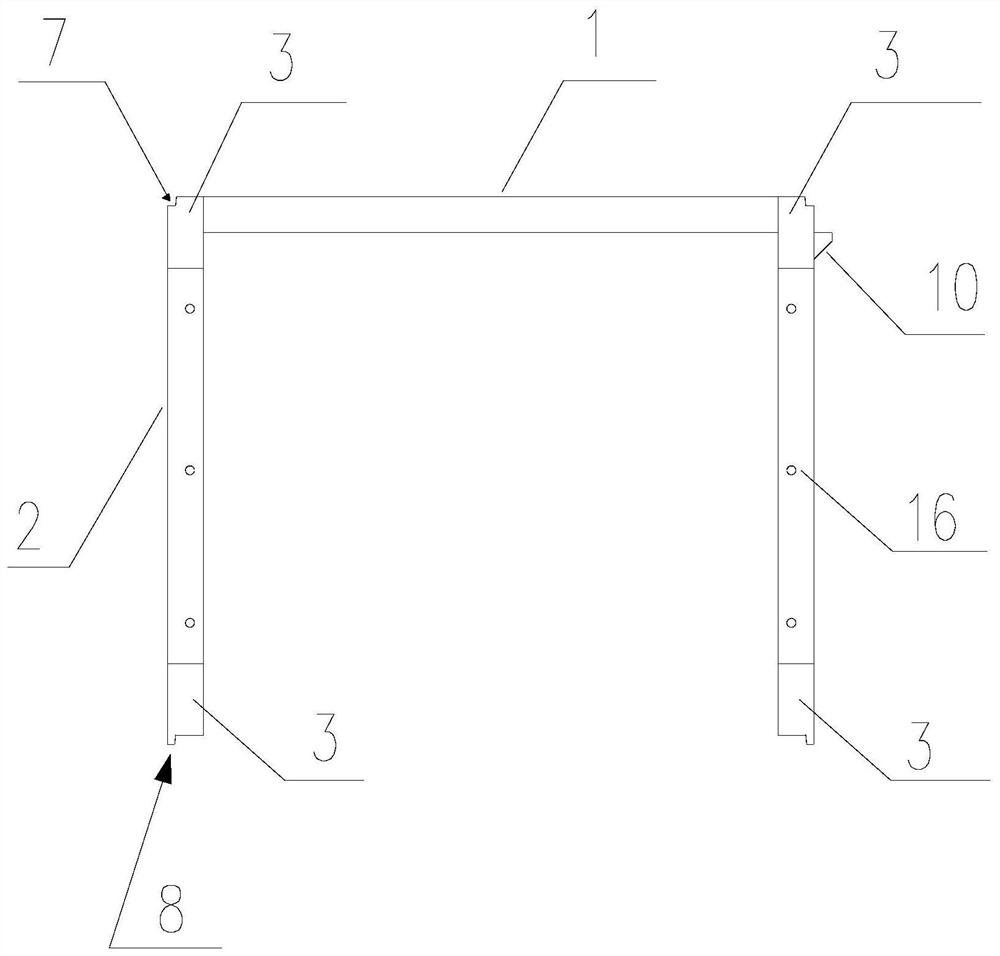

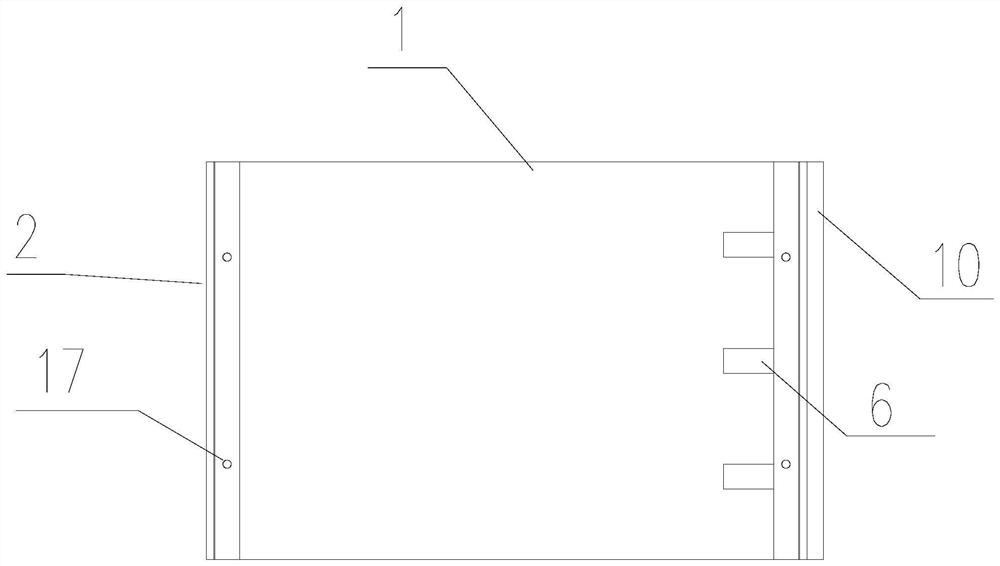

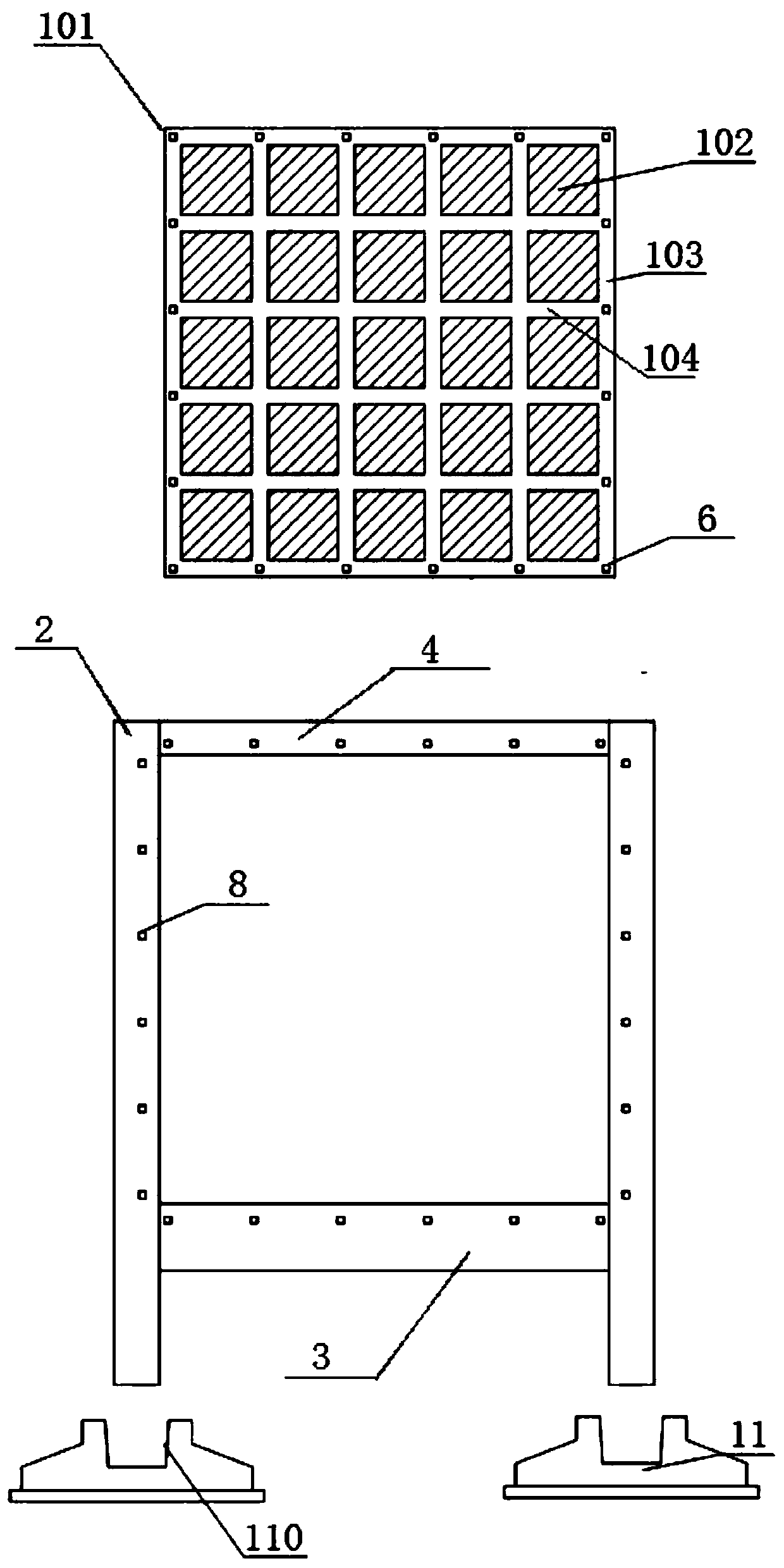

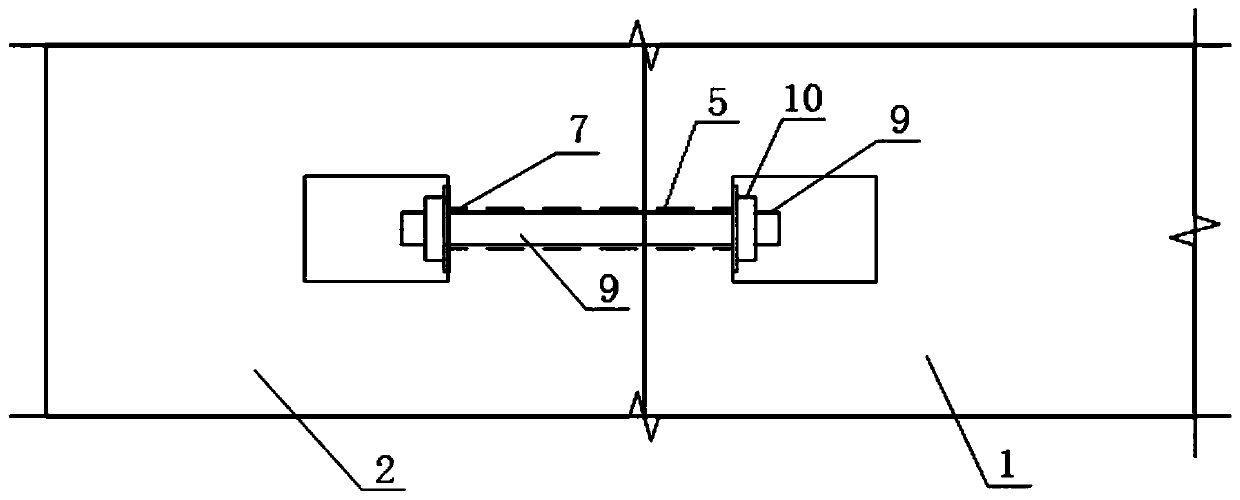

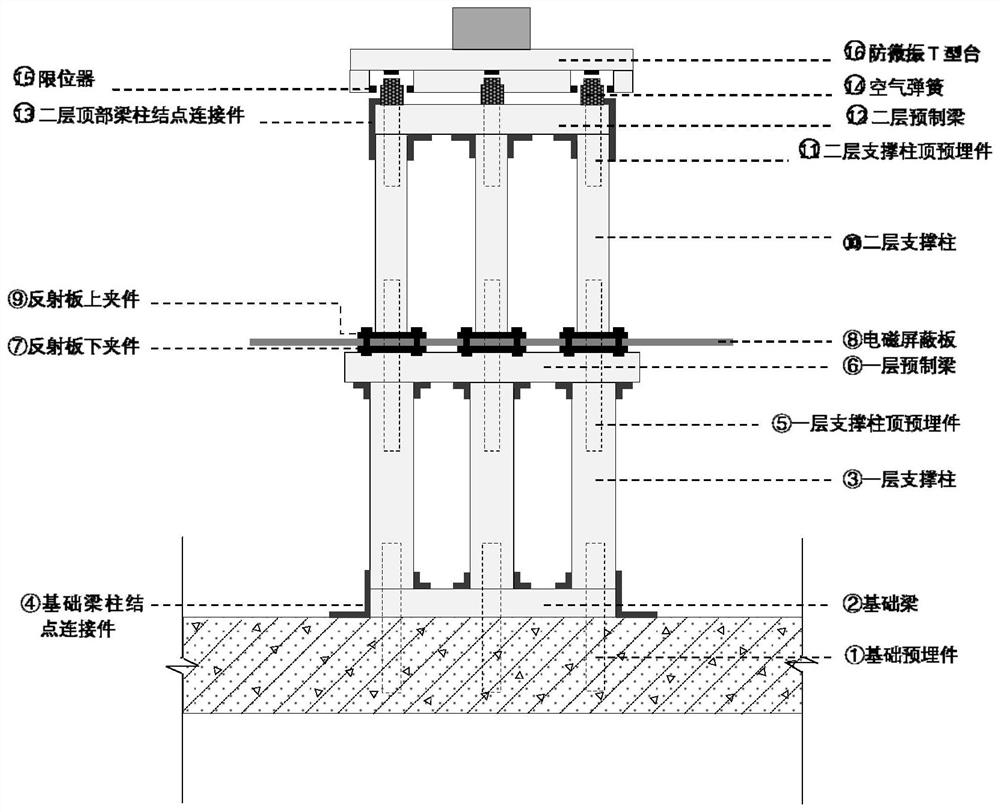

High-rise type suspension type micro-vibration equipment construction structure and construction structure

ActiveCN109827033AFulfill design requirementsEasy to disassembleFoundation engineeringSpecial foundation layoutControl systemAir spring

The invention provides a high-rise type suspension type micro-vibration equipment construction structure. The structure comprises a rigid supporting structure, an air floatation control system and ananti-micro-vibration T-shaped table (16); the rigid supporting structure comprises a foundation beam structure, a first-layer supporting structure and a second-layer supporting structure, wherein a foundation beam is connected with the first-layer supporting structure through first-layer supporting columns (3), the first-layer supporting structure and the second-layer supporting structure are connected through second-layer supporting columns (10), the first-layer supporting columns (3) are connected with the foundation beam, and the six circular-section concrete stand columns are arranged in total; the air floatation control system comprises an air floatation system (14) and a limiter (15); the air floatation system (14) is an independent air spring structure and is composed of a mechanical height valve, a main air chamber, an additional air chamber, an air inlet and an air outlet; the limiter (15) is arranged between the anti-micro-vibration T-shaped table (16) and the air floatationsystem (14); and the anti-micro-vibration T-shaped table (16) provides a supporting platform structure with a certain balance weight and a rigid body characteristic for the air floatation system (14),and radar detection equipment is placed on the anti-micro-vibration T-shaped table (16). The invention further provides a corresponding equipment construction method.

Owner:SINOMACH

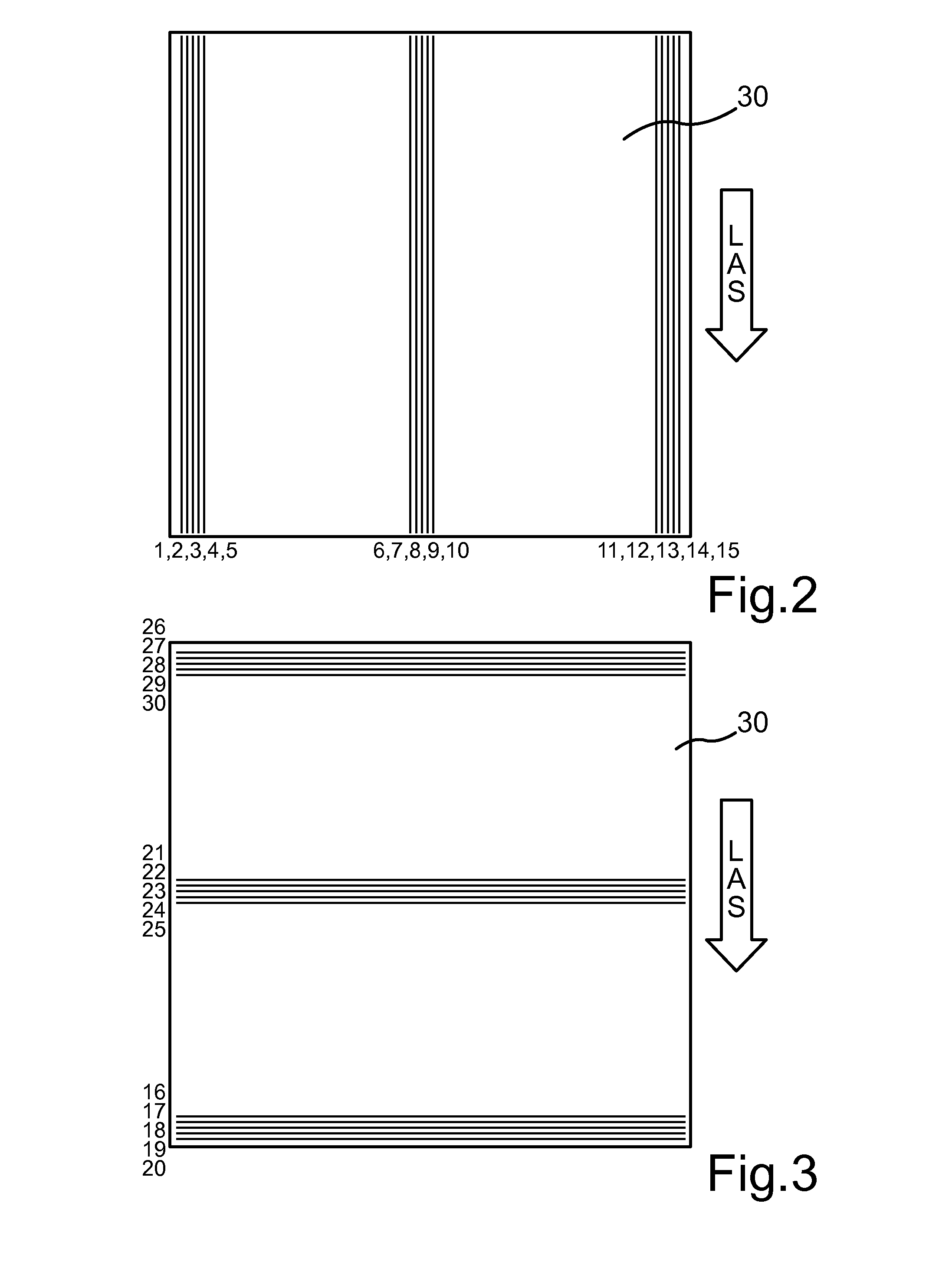

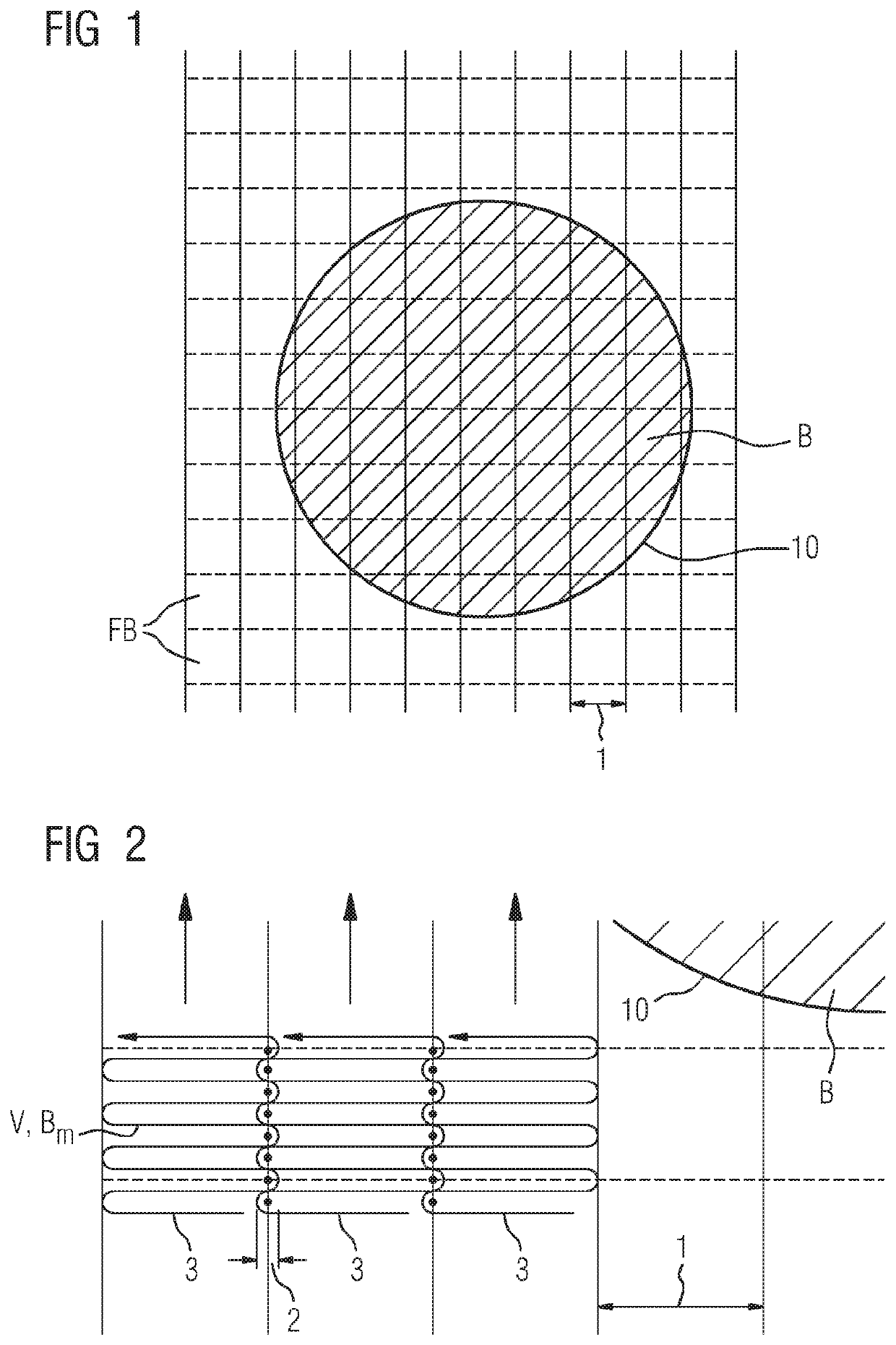

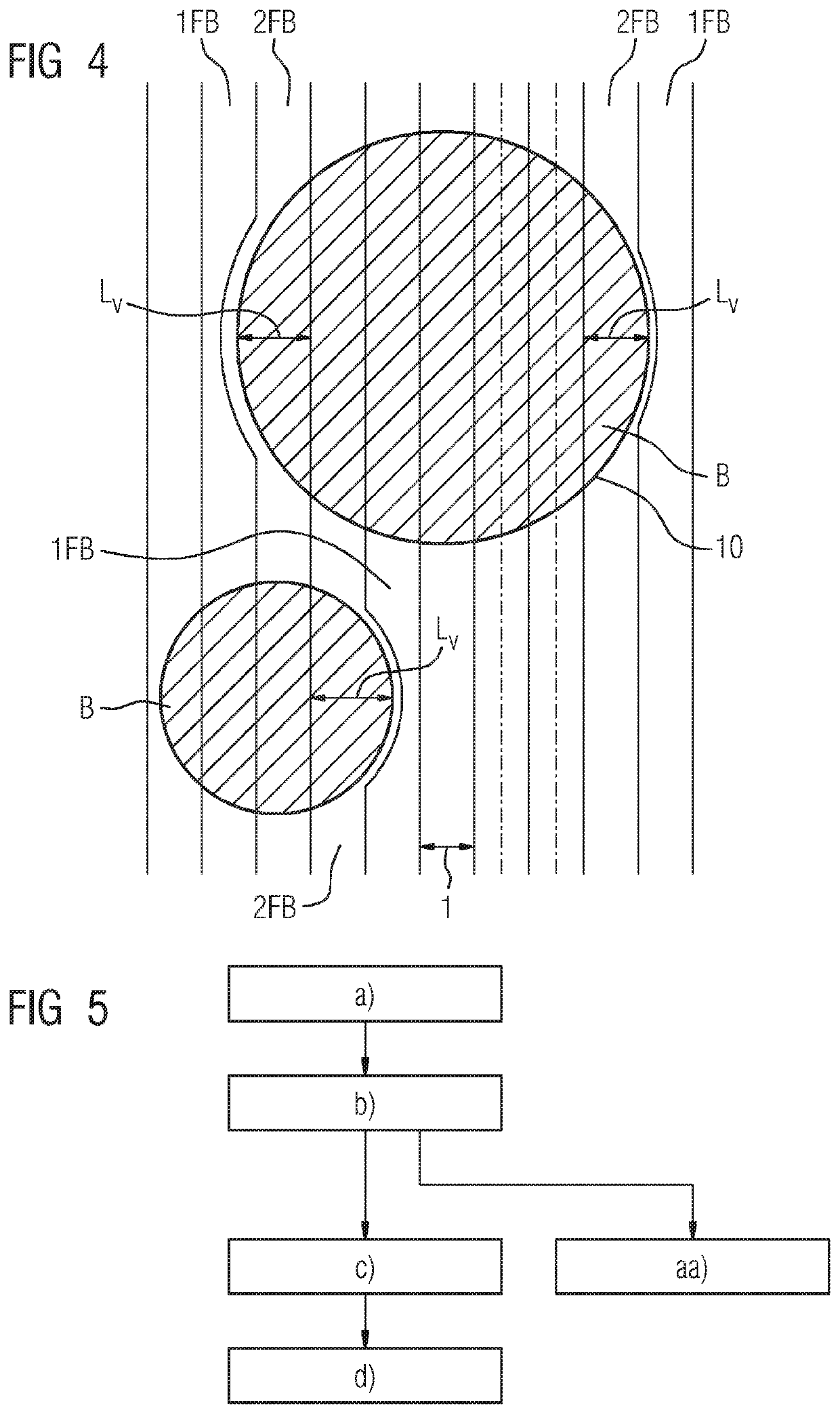

Method for selectively irradiating a material layer, production method, and computer program product

PendingUS20210079796A1Improve component qualityHigh dimensional accuracyTurbinesAdditive manufacturing apparatusManufacturing engineeringMechanical engineering

A method for selectively irradiating a material layer in additive manufacturing, the method includes: providing a predetermined component geometry which contains geometrical information of individual layers of a component to be manufactured additively; and defining layer by layer an irradiation pattern in areas of a layer to be constructed for the manufacturing of the component, the irradiation pattern comprising irradiation vectors in each area; and, if a predefined irradiation vector length is not reached in a first area, lengthening irradiation vectors in a second area of the layer adjacent to the first area as far as a component contour.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

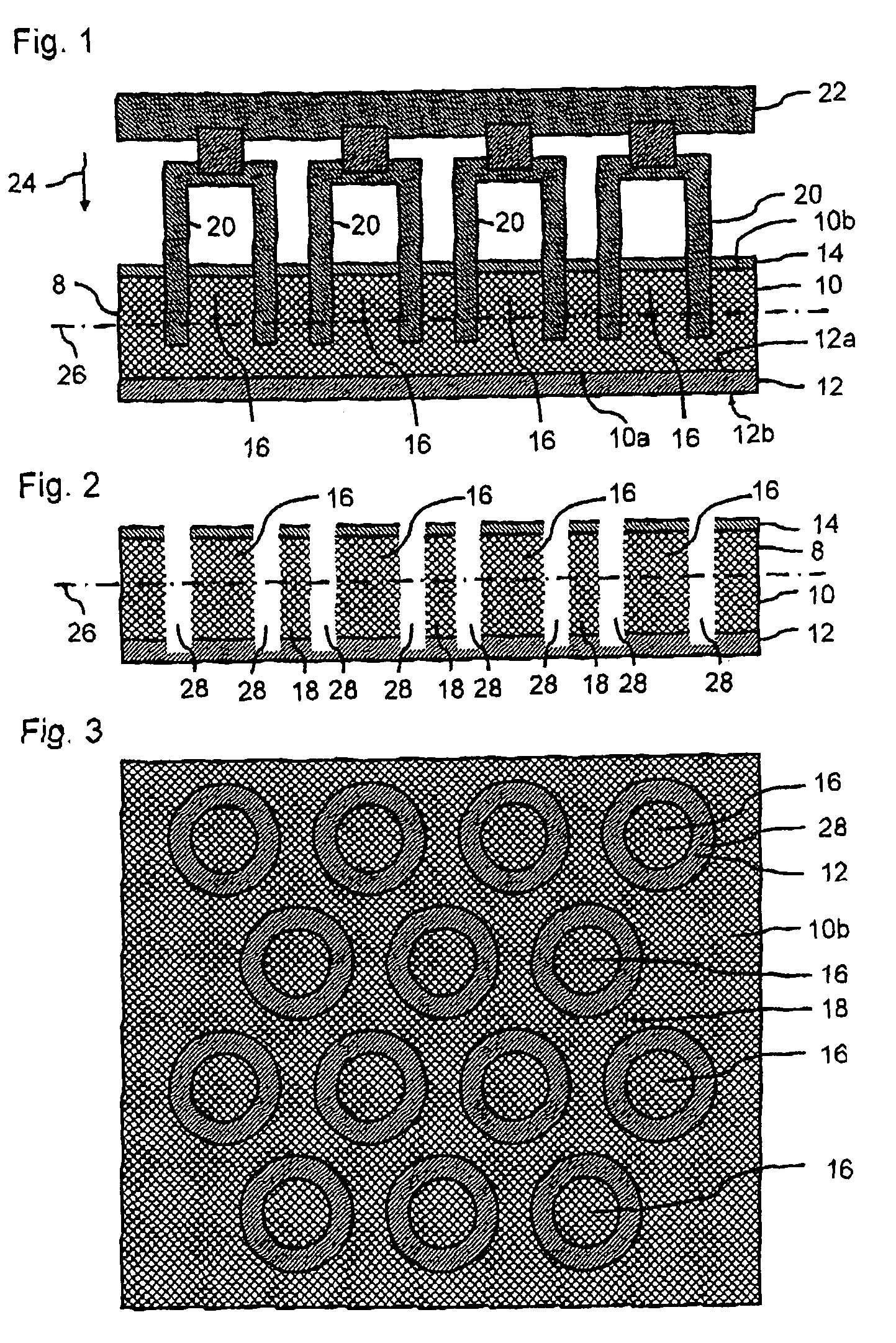

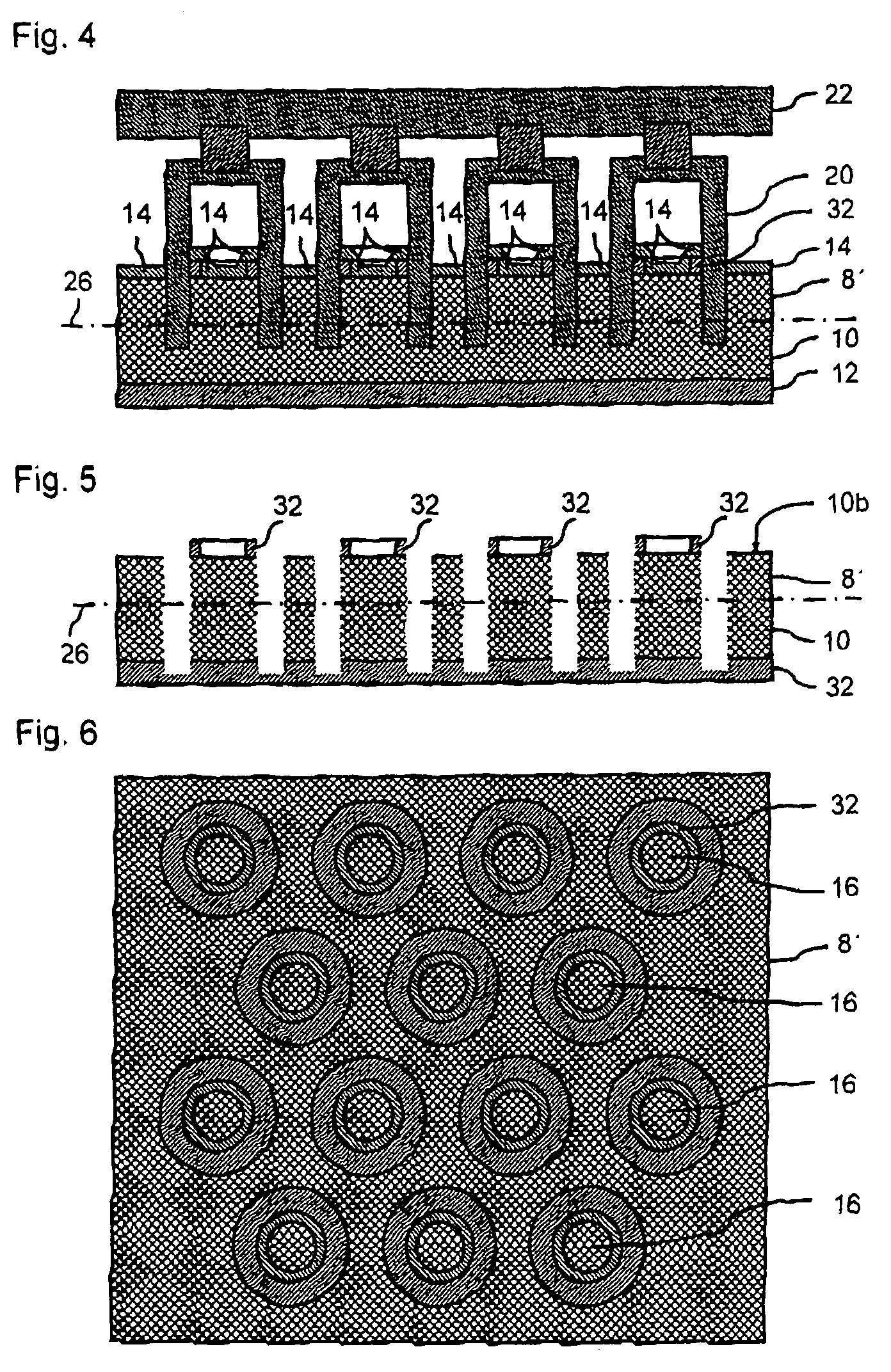

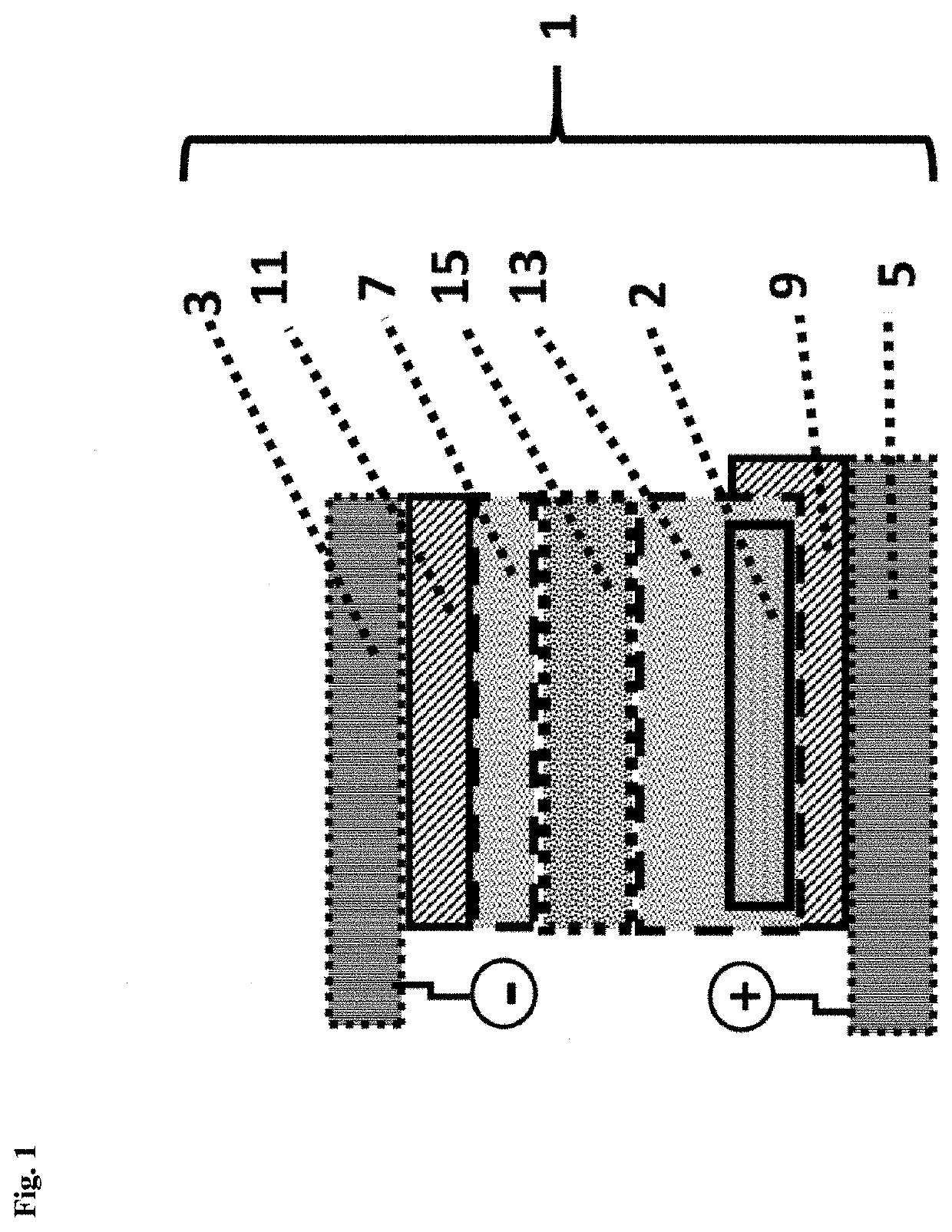

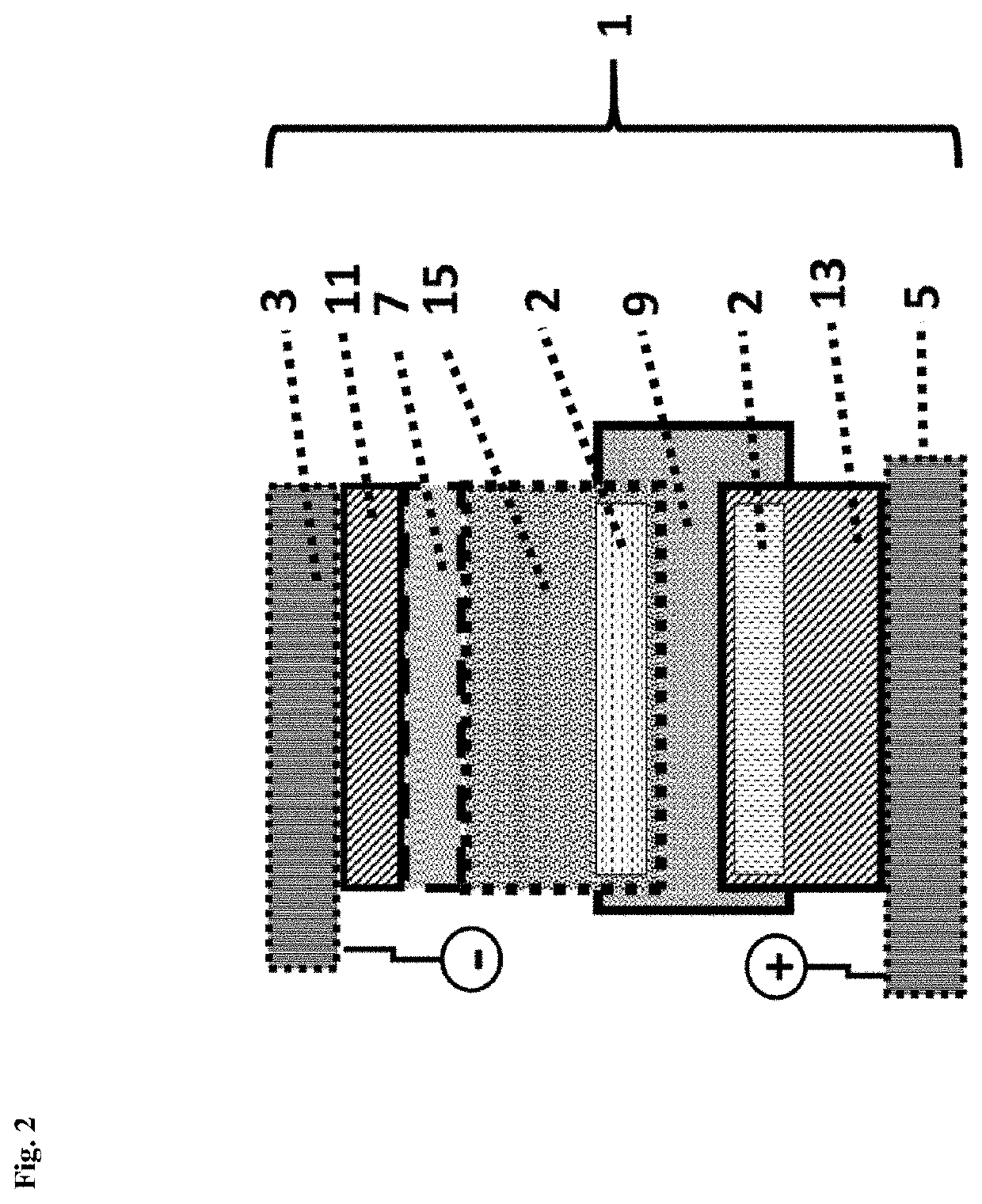

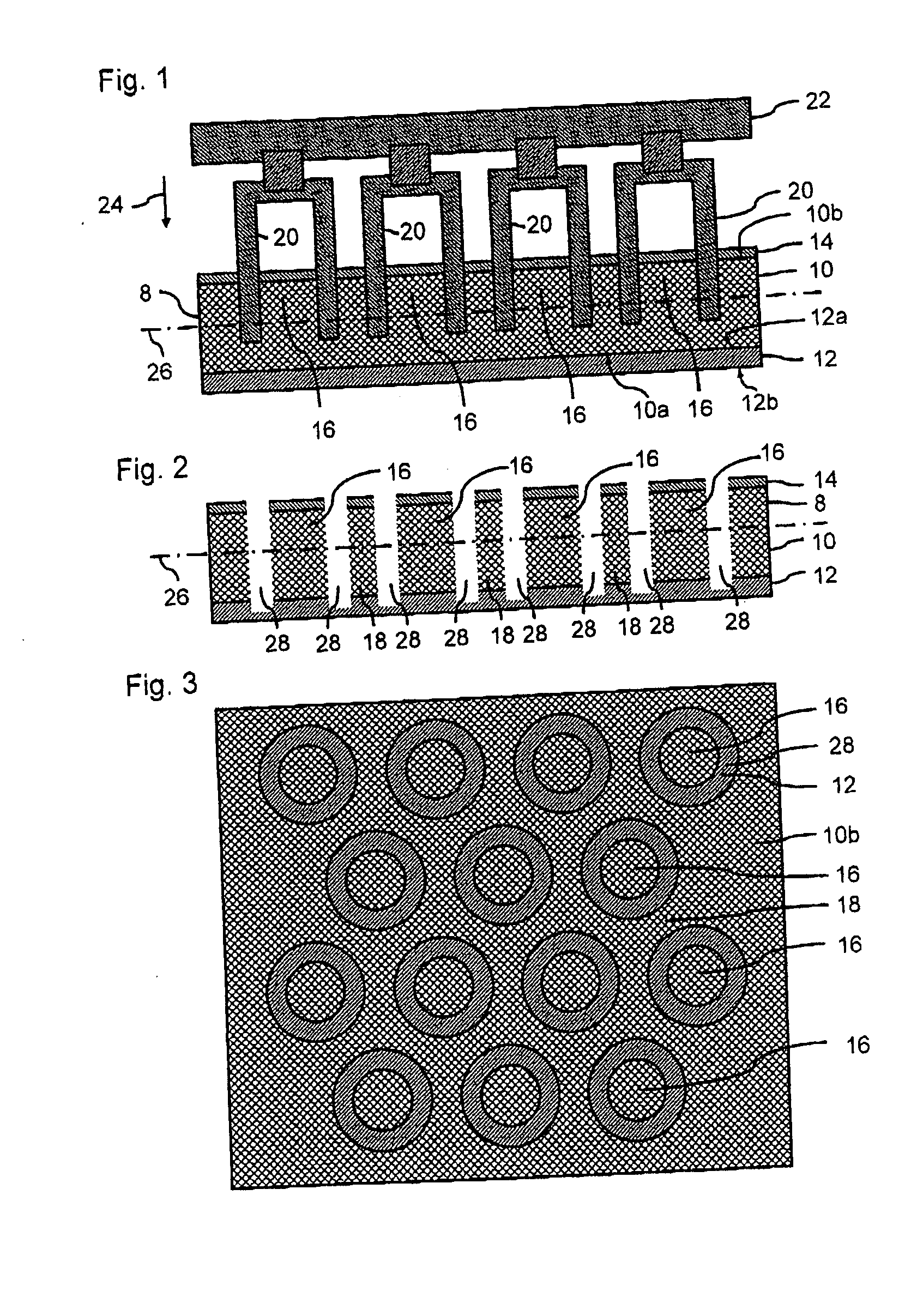

Process for producing components

ActiveUS7736995B2Improve component qualityImprove surface qualitySemiconductor/solid-state device manufacturingFine working devicesEngineeringGlass sheet

The invention relates to a process for producing components, in particular small glass plates such as windows for optical caps for optical components. The process includes providing a substrate, providing a carrier, joining a first surface of the substrate to a first surface of the carrier, machining the components out of the substrate, and detaching the components from the carrier in order to separate the components.

Owner:SCHOTT AG

Method for the quality assessment of a component produced by means of an additive manufacturing method

ActiveUS9964496B2Fast and accurate determinationImprove component qualityOptically investigating flaws/contaminationTotal factory controlQuality assessmentAdditive layer manufacturing

The invention relates to a method for the quality assessment of a component produced by means of an additive manufacturing method. In the course of the method, it is checked first of all whether the component violates predetermined absolute limits in order to rule out the existence of serious malfunctions in the additive manufacturing process. Subsequently, a component-dependent targeting process is determined. On the basis of this targeting process, the limits for deviations are established and deviating actual values of the component are isolated and assessed by means of various parameters.

Owner:MTU AERO ENGINES GMBH

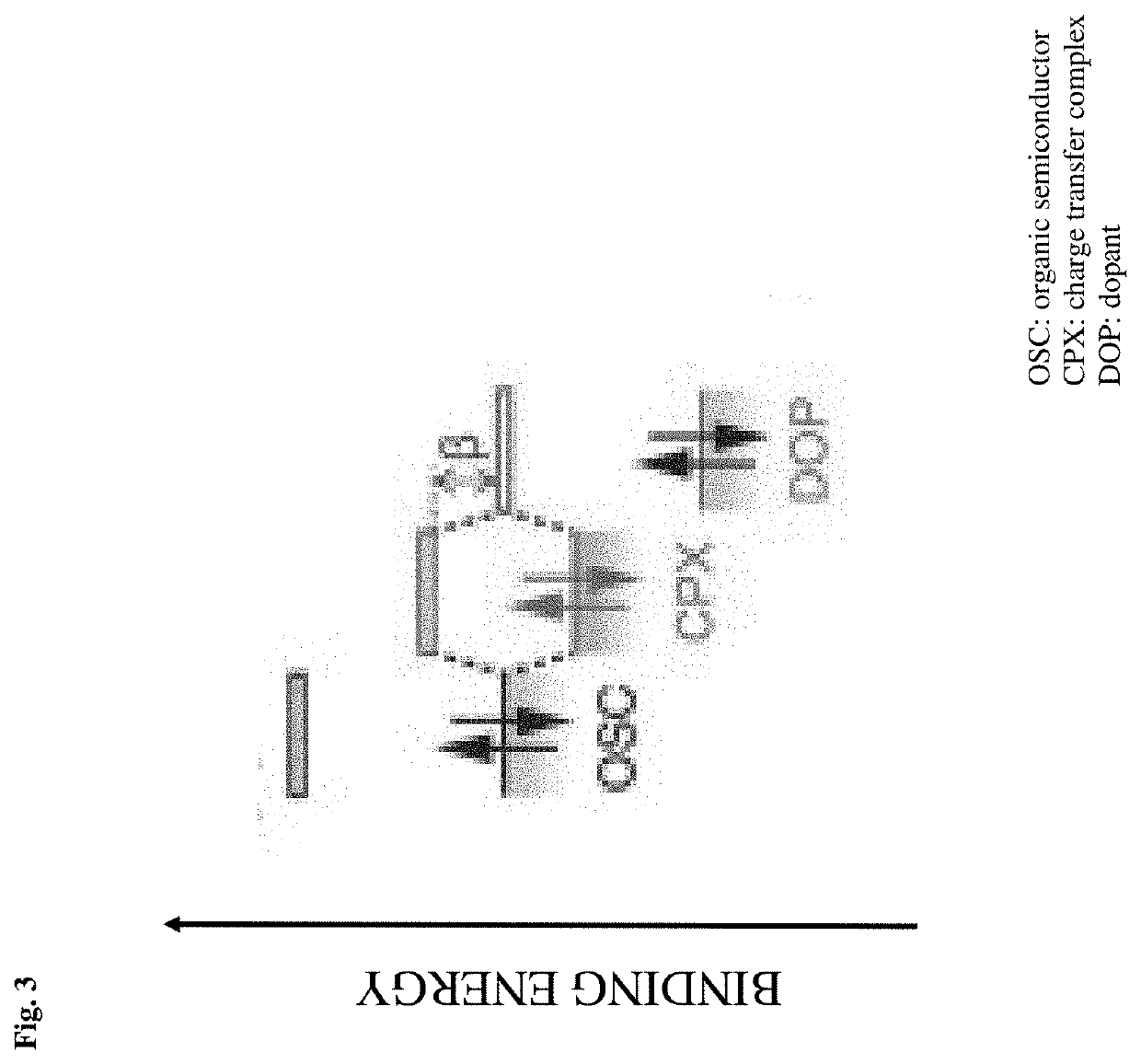

Inductively doped mixed layers for an optoelectronic component, and method for the production thereof

ActiveUS20200020871A1Long useful lifeShorten the timeFinal product manufactureSolid-state devicesSemiconductor materialsActive layer

An optoelectronic component with a cathode and an anode and a layer system between the cathode and the anode is provided. The optoelectronic component having multiple electroactive layers, wherein the component can be produced by a method in which an inductively doped mixed layer is generated between at least two layers made of semiconductor materials.

Owner:INURU GMBH

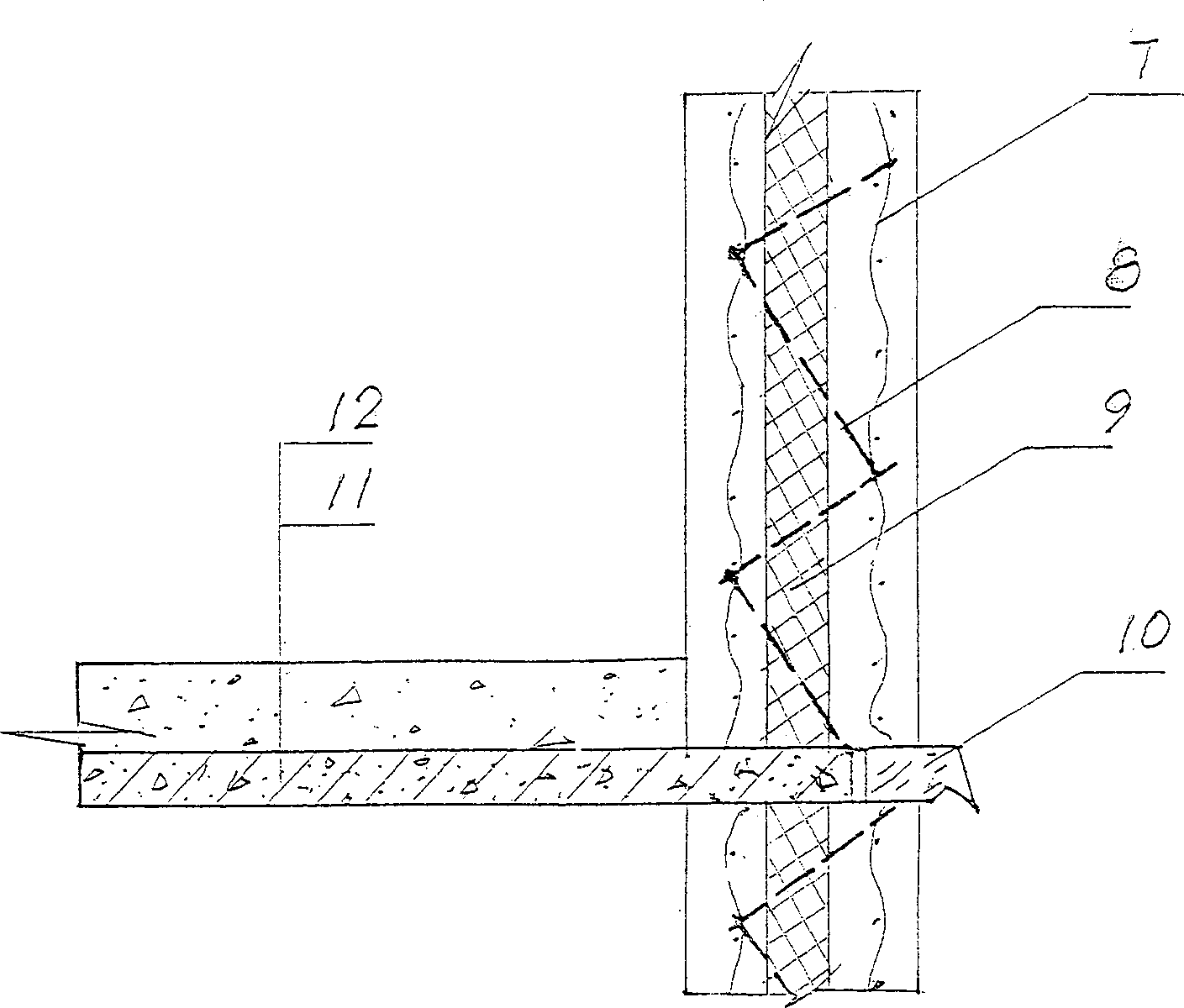

Basic module for building and low-rise and multi-rise modular building structure system

PendingCN112523545AMeet shipping requirementsMeet the requirements of energy saving and environmental protectionSpecial buildingPortal frameStructural system

The invention discloses a basic module for building. The basic module for the building comprises a top plate and two side plates which are integrally formed, the two side plates are connected to the top plate to form a concrete portal frame, embedded columns are arranged on the two vertical side edges of the side plates, hidden beams are arranged on the top sides and the bottom sides of the side plates, a plurality of reserved hole channels are formed in at least one side plate, the reserved hole channels comprise horizontal hole channels and vertical hole channels, the multiple horizontal hole channels are horizontally formed in at least one embedded column of the side plates, the multiple vertical hole channels are vertically formed in at least one hidden beam of the side plates, and a corbel support is arranged on the outer side surface, away from the top plate, of the hidden beam of the at least one side plate. According to the basic module for the building and the low-rise and multi-rise modular building structure system, the modular building structure system comprises at least two basic modules, at least one horizontal module and an expansion connecting assembly, wherein thetwo basic modules arranged at intervals are connected together through the horizontal module, the bottom side faces of the two ends of the horizontal module are placed on the corbel support, a plurality of installing grooves are formed in the edges of the two sides of the horizontal module, and the extension connecting assembly are fixed in the installing grooves of the top plate and the installing grooves of the horizontal modules.

Owner:筑友智造科技产业集团有限公司

Ecological composite wall body and construction process thereof

PendingCN109811933AEasy constructionShort construction periodWallsBulk storage containerRebarWall plate

The invention discloses an ecological composite wall body and a construction process thereof. The ecological composite wall body comprises an ecological composite wall plate, frame columns, a ground beam and a frame beam; the frame columns are arranged on the two sides of the ecological composite wall plate; the ground beam is arranged at the bottom end of the ecological composite wall plate; theframe beam is fixed at the top end of the ecological composite wall plate; the ecological composite wall plate comprises a steel reinforcement skeleton and a concrete building block; and the concretebuilding block is arranged in a cavity of the steel reinforcement skeleton and is subjected to casting molding through concrete. The ecological composite wall body is high in construction speed and high in efficiency, has excellent heat-insulating property, reduces the use amount of concrete and improves seismic resistance and anti-seismic property.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Steel for cold forging and manufacturing method thereof

ActiveUS11111568B2Improve machinabilityImprove component qualityFurnace typesHeat treatment furnacesChemical compositionPhysical chemistry

Owner:NIPPON STEEL CORP

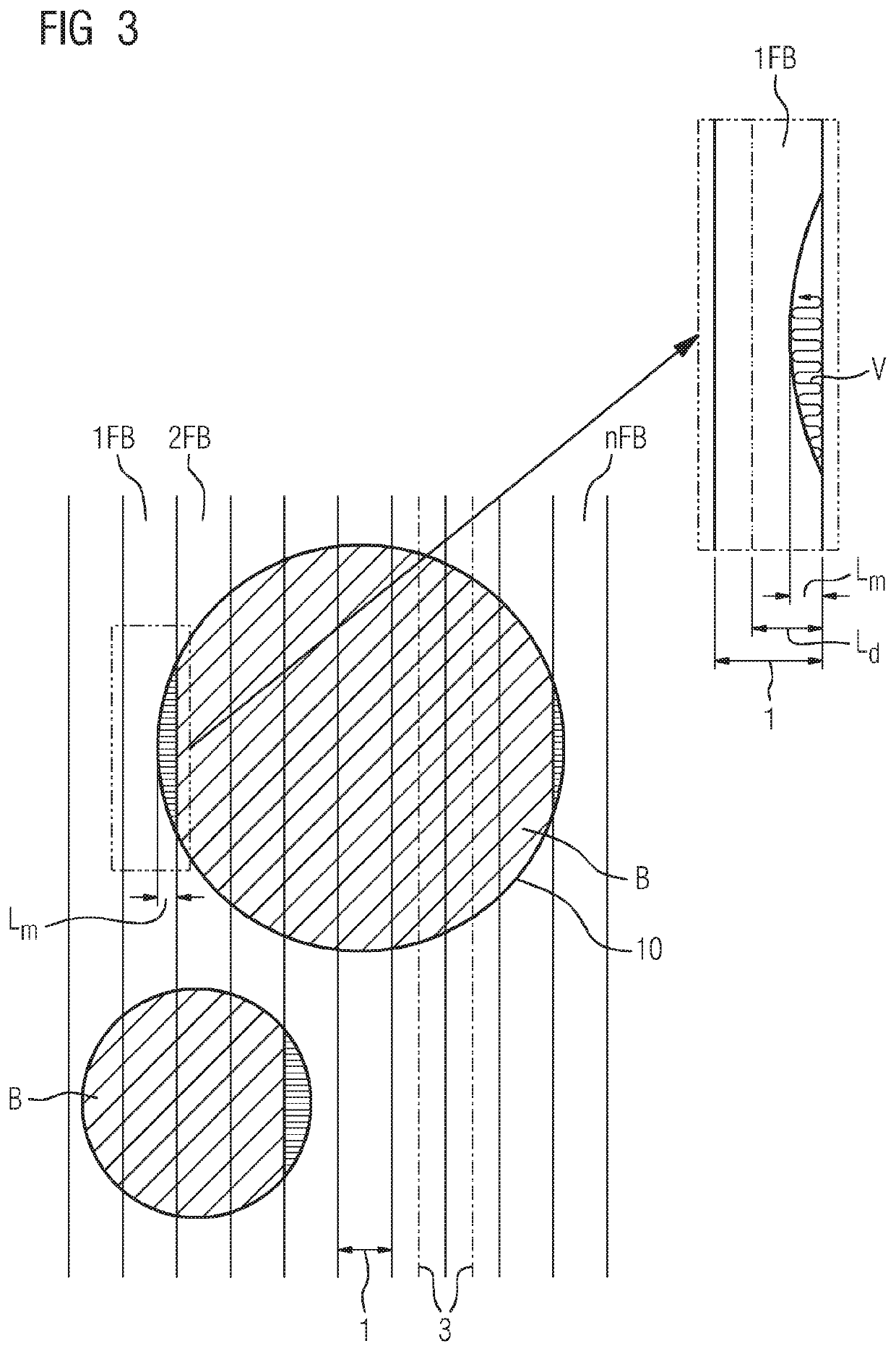

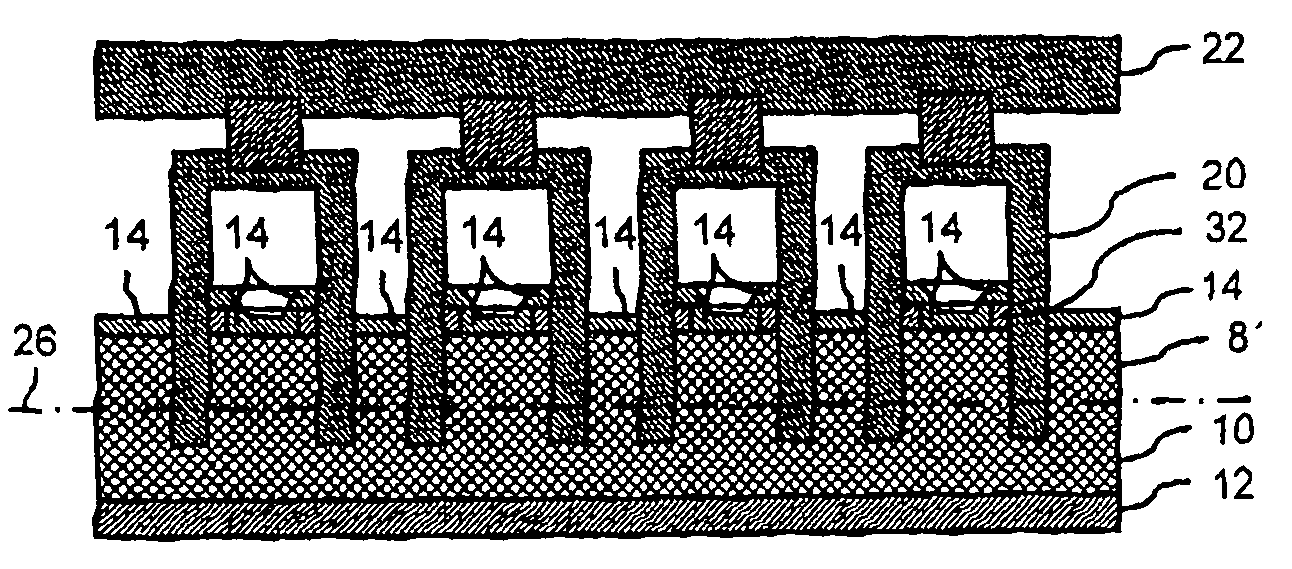

Process for producing components

ActiveUS20070170597A1High machining qualityCost reductionSemiconductor/solid-state device detailsSolid-state devicesEngineeringHigh surface

The invention relates to a process for producing components, in particular small glass plates, for example as windows for optical caps for optical components. It is an object to provide an inexpensive process which ensures a high surface quality of the components. The process according to the invention comprises the steps of: providing a substrate (10), providing a carrier (12), joining a first surface (10a) of the substrate (10) to a first surface (12a) of the carrier (12), for example by laminating on a carrier film, machining the components (16) out of the substrate (10), for example by means of ultrasonic vibratory lapping or sand-blasting, with the components (16) being held together by the carrier (12) at least immediately after the machining-out step, and detaching the components (16) from the carrier (12) in order to separate the components (16).

Owner:SCHOTT AG

A towering suspended micro-vibration equipment construction structure and its construction method

ActiveCN109827033BFulfill design requirementsEasy to disassembleFoundation engineeringSpecial foundation layoutAir springRadar detection

The present invention provides a towering suspended micro-vibration equipment construction structure, including: a rigid support structure, including a foundation beam structure, a first-floor support structure and a second-floor support structure, the foundation beam and the first-floor support structure pass through a first-floor support beam ( 3) Connection. The support structure on the first floor is connected to the support structure on the second floor through the support beams (10) on the second floor, and the support columns (3) on the first floor are connected to the foundation beams. There are six concrete columns with circular cross-sections in total; the air flotation control system includes air Float system (14) and limiter (15), air flotation system (14) is an independent air spring structure composed of mechanical height valve, main air chamber, additional air chamber, air inlet and exhaust port, limiter (15) installed between the anti-microvibration T-stage (16) and the air flotation system (14); and the anti-microvibration T-stage (16), which provides a certain counterweight for the air flotation system (14) and has rigid body characteristics The supporting platform structure and place the radar detection equipment. Corresponding equipment construction methods are also provided.

Owner:SINOMACH

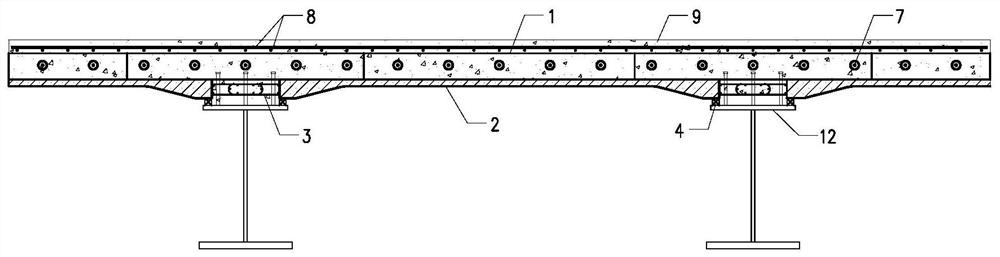

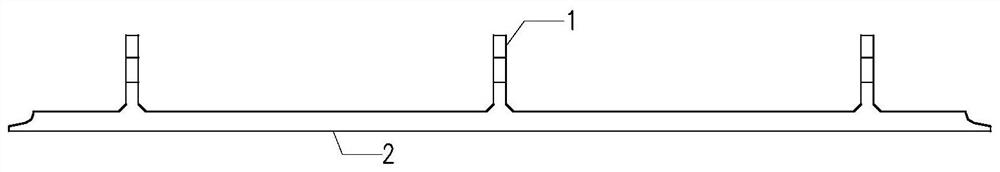

UHPC-NC combined bridge deck slab structure with stiffening ribs and construction method of UHPC-NC combined bridge deck slab structure

PendingCN114438879AOptimizing the Bridge Deck StructureReduce engineering costsBridge structural detailsBridge erection/assemblyRebarBridge deck

The invention relates to a UHPC-NC combined bridge deck structure provided with stiffening ribs and a construction method thereof.The combined bridge deck structure comprises a plurality of UHPC components provided with the UHPC stiffening ribs, a UHPC connecting layer, bridge deck steel bars and an NC post-pouring layer, the UHPC components are hoisted on a main beam, the UHPC connecting layer is poured between every two adjacent UHPC components, and the NC post-pouring layer is connected with the UHPC components. The bridge deck slab reinforcing steel bars are laid on the tops of the stiffening ribs, and the NC post-pouring layer is poured on the UHPC components and the bridge deck slab reinforcing steel bars. By using the construction method provided by the invention, the UHPC-NC combined bridge deck slab structure of the stiffening ribs can be obtained. Compared with the prior art, the method has the advantages that the bridge deck structure is optimized, the engineering cost is reduced, the operation and maintenance cost of the whole life cycle is reduced, construction is convenient, the speed is high, quality is good, and safety is high.

Owner:SHANGHAI PUDONG ARCHITECTURAL DESIGN & RES INST

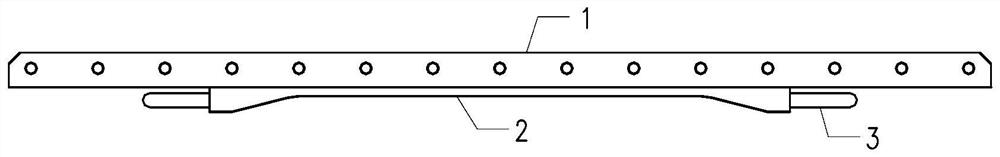

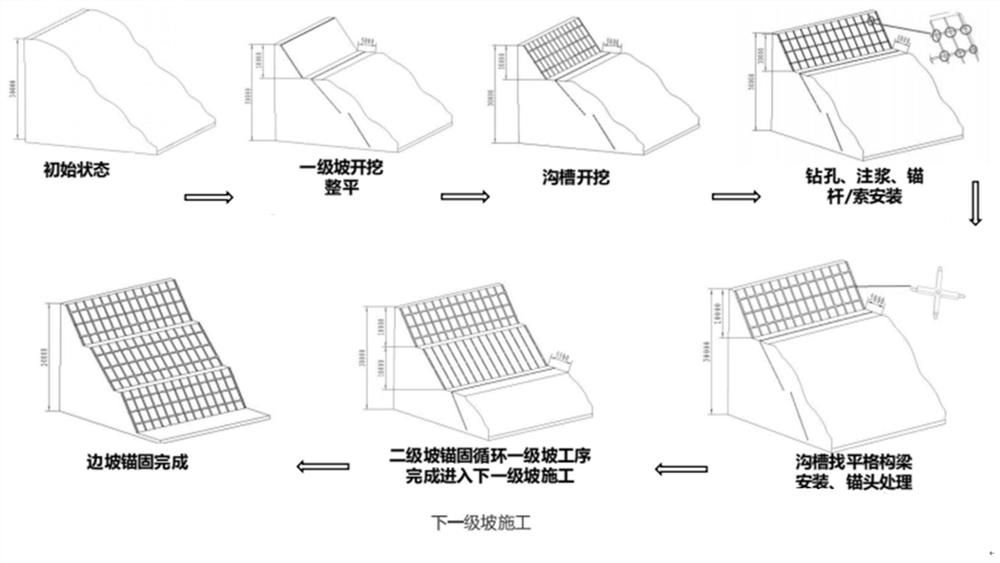

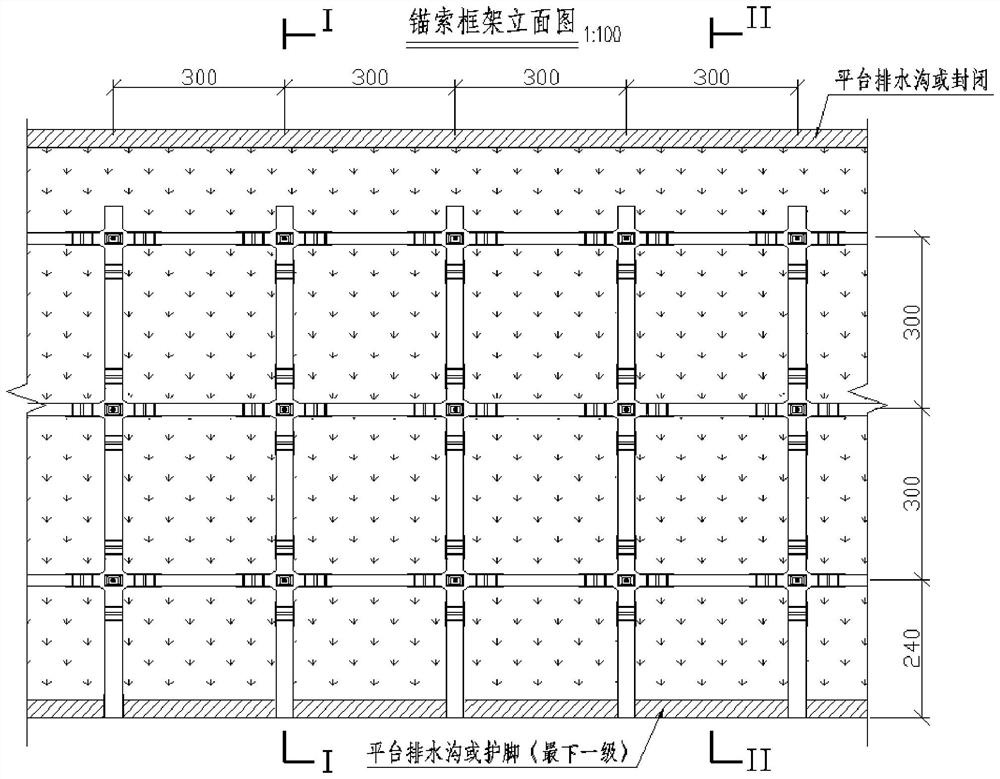

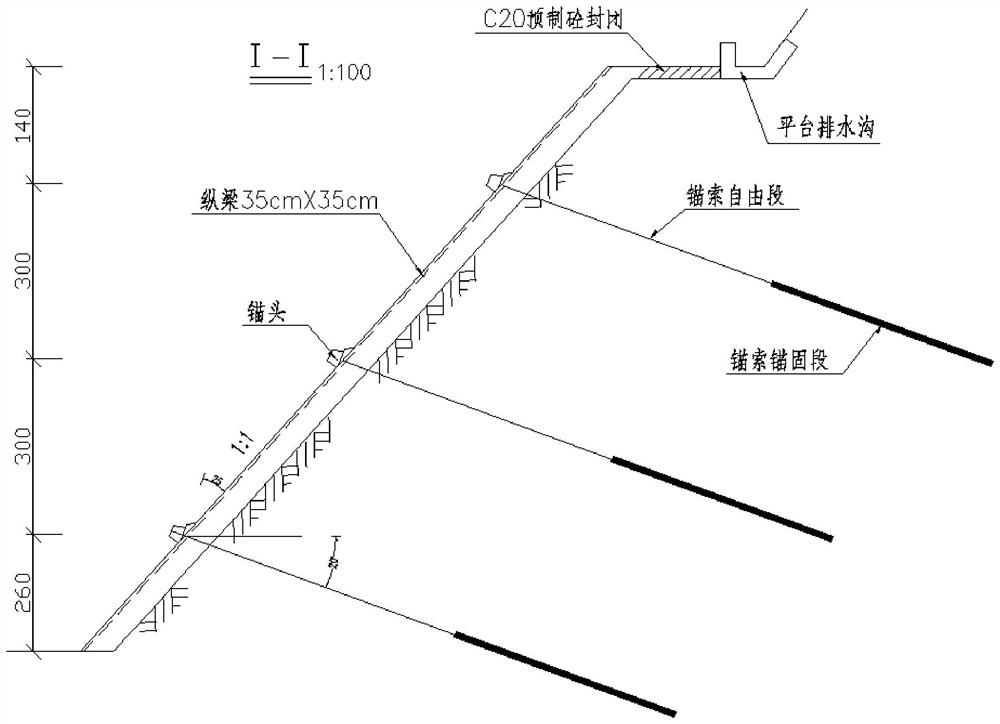

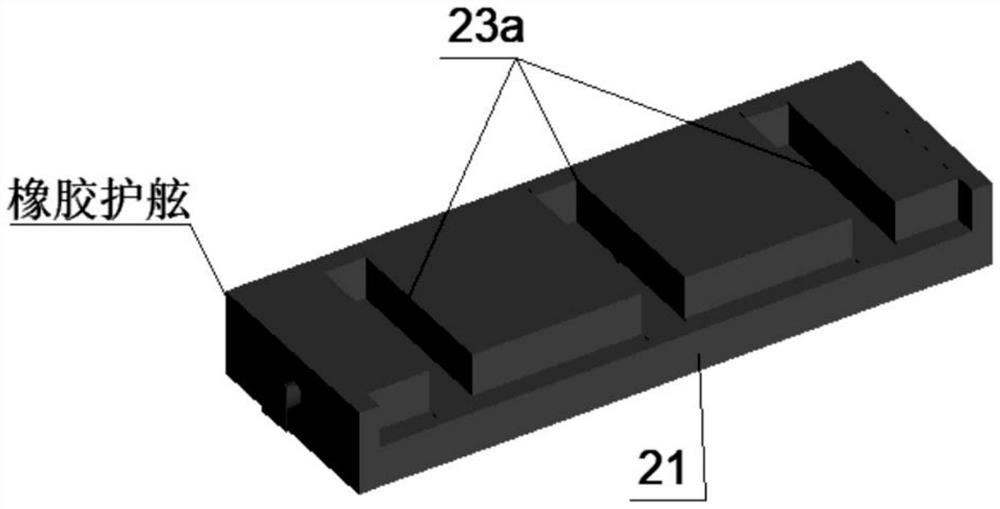

Mechanical construction method for side slope anchoring

InactiveCN114396062AFast constructionContinuous constructionExcavationsBulkheads/pilesArchitectural engineeringEconomic benefits

The invention discloses a side slope anchoring mechanical construction method which comprises the following steps: excavating and leveling a primary slope, and supporting the bottom of the slope; grooving operation is conducted on the first-level slope; after grooving operation is completed, the slope surface at the position of the frame beam is cleaned; drilling, grouting and anchor rod / cable mounting operation are carried out on the slotted primary slope; after the grooves are leveled, prefabricated lattice transverse beam concrete prefabricated parts and prefabricated lattice longitudinal beam concrete prefabricated parts are installed, and anchor head treatment is conducted; and the steps are cycled for construction of the next stage of slope until side slope anchoring is completed. According to the side slope anchoring mechanical construction method, grooving, drilling, grouting and bolt / cable anchoring are integrated, the construction speed is high, construction is continuous, an operation platform is not needed, the drilling efficiency is high, the lattice beams adopt the prefabrication technology, the component quality is high, grooving of the lattice beams adopts mechanical construction, the construction cost is low, and the construction efficiency is high. The grooving depth and flatness can be guaranteed, concrete is saved, continuous construction is achieved, the lower slope can be excavated in time, and economic benefits are good.

Owner:中铁一局集团(广州)建设工程有限公司 +1

Device and method for additive manufacturing

InactiveCN108348999AShort processing timeShort cooldownTurbinesTransportation and packagingMechanical engineeringAdditive layer manufacturing

A device and a method by means of which the powder to be applied to another layer that is to be coated is preheated, allow the time to carry out the method to be significantly shortened.

Owner:SIEMENS AG

Steel for cold forging and manufacturing method thereof

ActiveUS20190264305A1Excellent in cold forgeabilityImprove machinabilityFurnace typesHeat treatment furnacesChemical compositionSulfide

A steel for cold forging has a predetermined chemical composition, satisfies d+3σ≤10.0 and SA / SB<0.30, includes 1200 / mm2 or more of sulfides having an equivalent circle diameter of 1.0 to 10.0 μm in a microstructure, and has an average distance between the sulfides of less than 30.0 μm. Here, d is an average value of equivalent circle diameters of sulfides having an equivalent circle diameter of 1.0 μm or more, σ is a standard deviation of the equivalent circle diameters of the sulfides having an equivalent circle diameter of 1.0 μm or more, SA is the number of sulfides having an equivalent circle diameter of 1.0 μm or more and less than 3.0 μm, and SB is the number of the sulfides having an equivalent circle diameter of 1.0 μm or more.

Owner:NIPPON STEEL CORP

Prestressed intelligent circulation grouting system and its control method

ActiveCN104074143BStable pressureDensified groutBridge erection/assemblyBuilding material handlingLoop controlClosed loop

A prestressed intelligent circulating grouting system and its control method, the grouting pipeline between the grouting pump and the grouting port is provided with a pressure compensation device, the pressure compensating device includes a piston and an elastic mechanism, and the piston end The head is connected with the grouting pipeline, and the elastic force of the elastic mechanism is to drive the piston end to press into the grouting pipeline; the pressure maintaining devices are respectively installed at the slurry inlet and the slurry outlet, and respectively control the amount of slurry entering the channel of the beam member and the discharge The amount of slurry in the channel of the beam member; the electromagnetic flowmeter is respectively installed at the slurry inlet and the slurry outlet to measure the flow signals of the slurry inlet and the slurry outlet; The grouting action, the water-cement ratio control step adopts closed-loop control, and the effective cycle pressure value is set; the holding pressure value: the lower limit value of the holding pressure; the upper limit value of the holding pressure; the holding time value controls the component slurry control. Its advantages are stable slurry pressure, compact grouting and good component quality.

Owner:柳州市桥厦科技发展有限公司

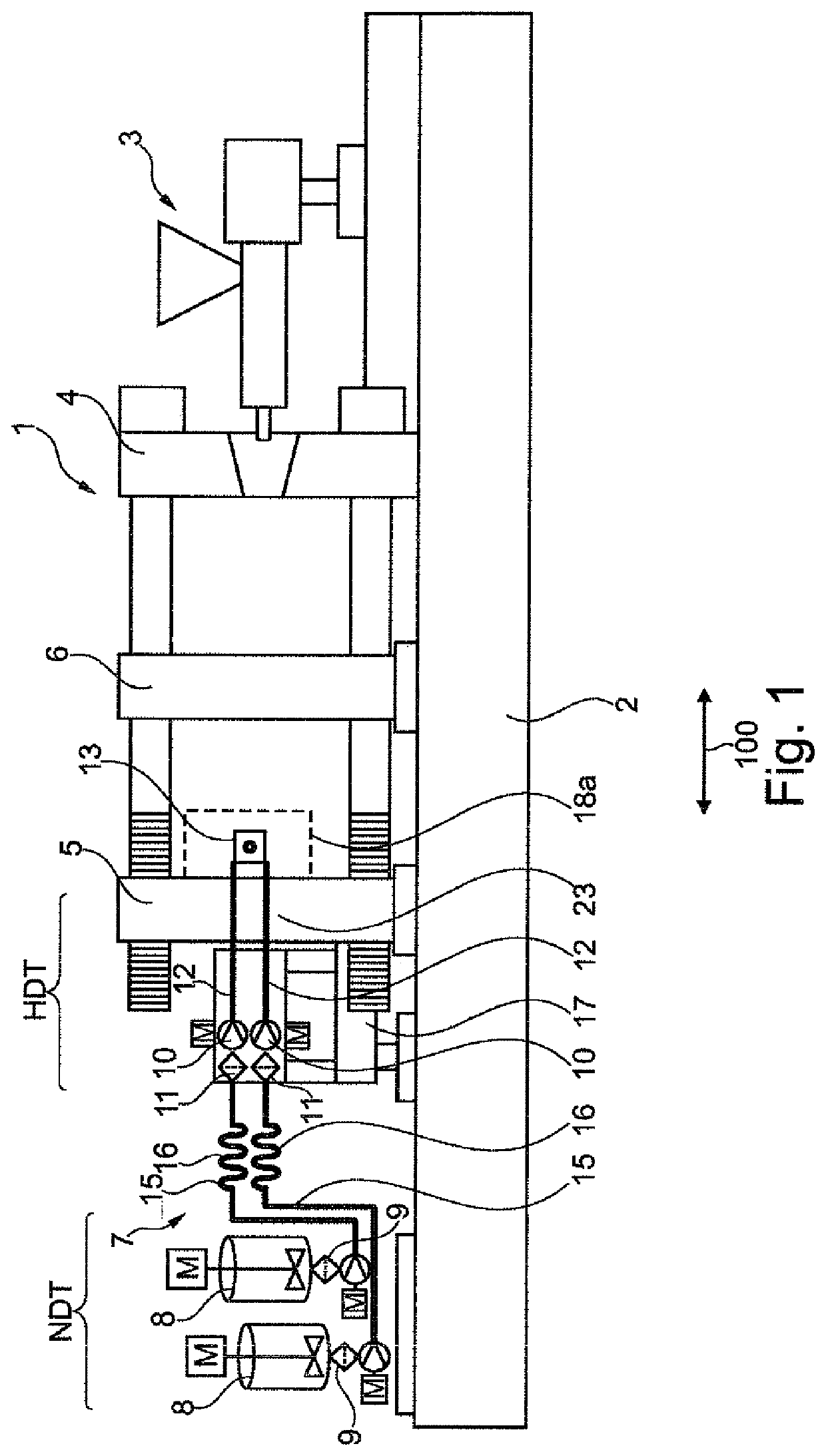

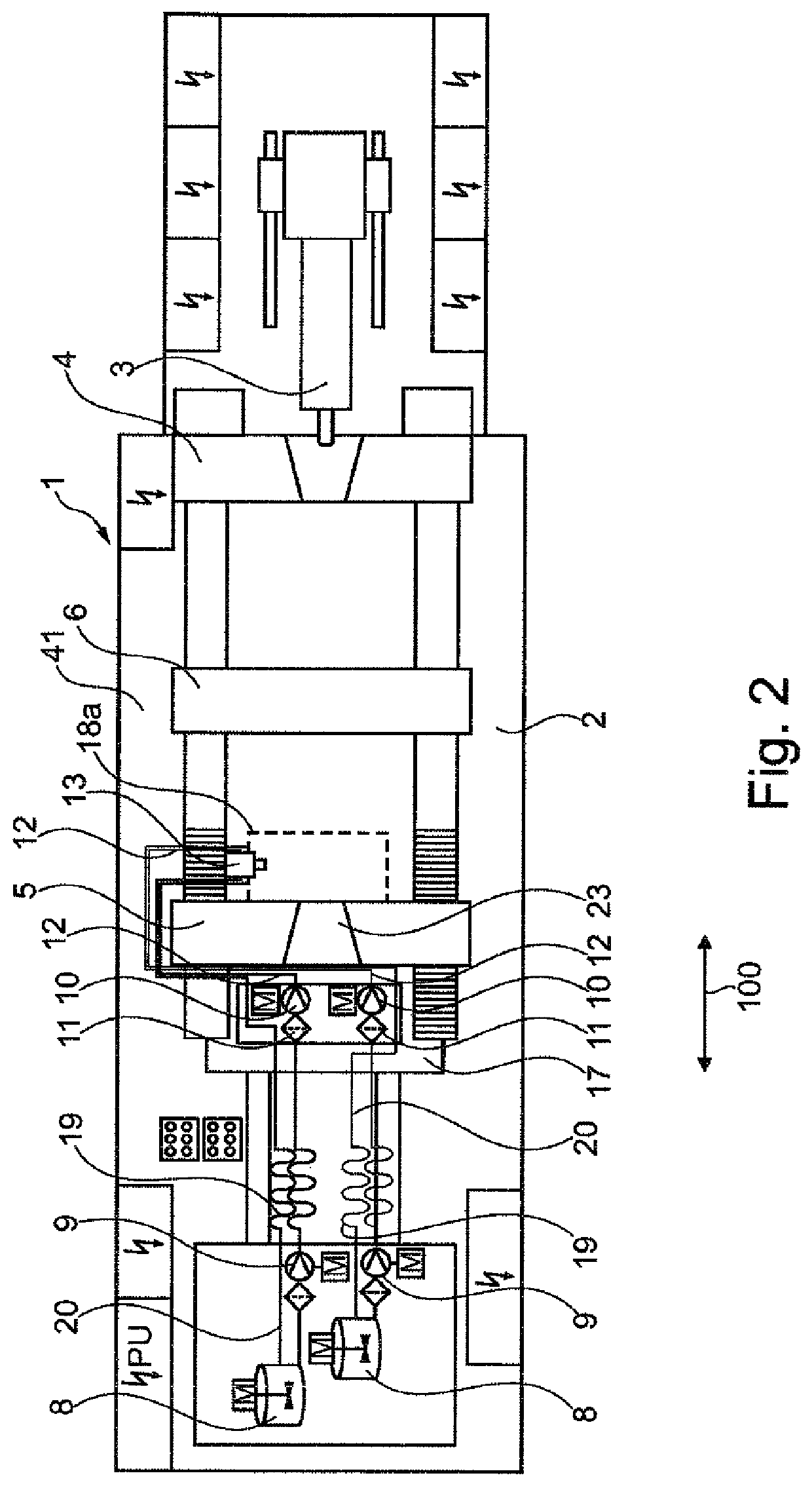

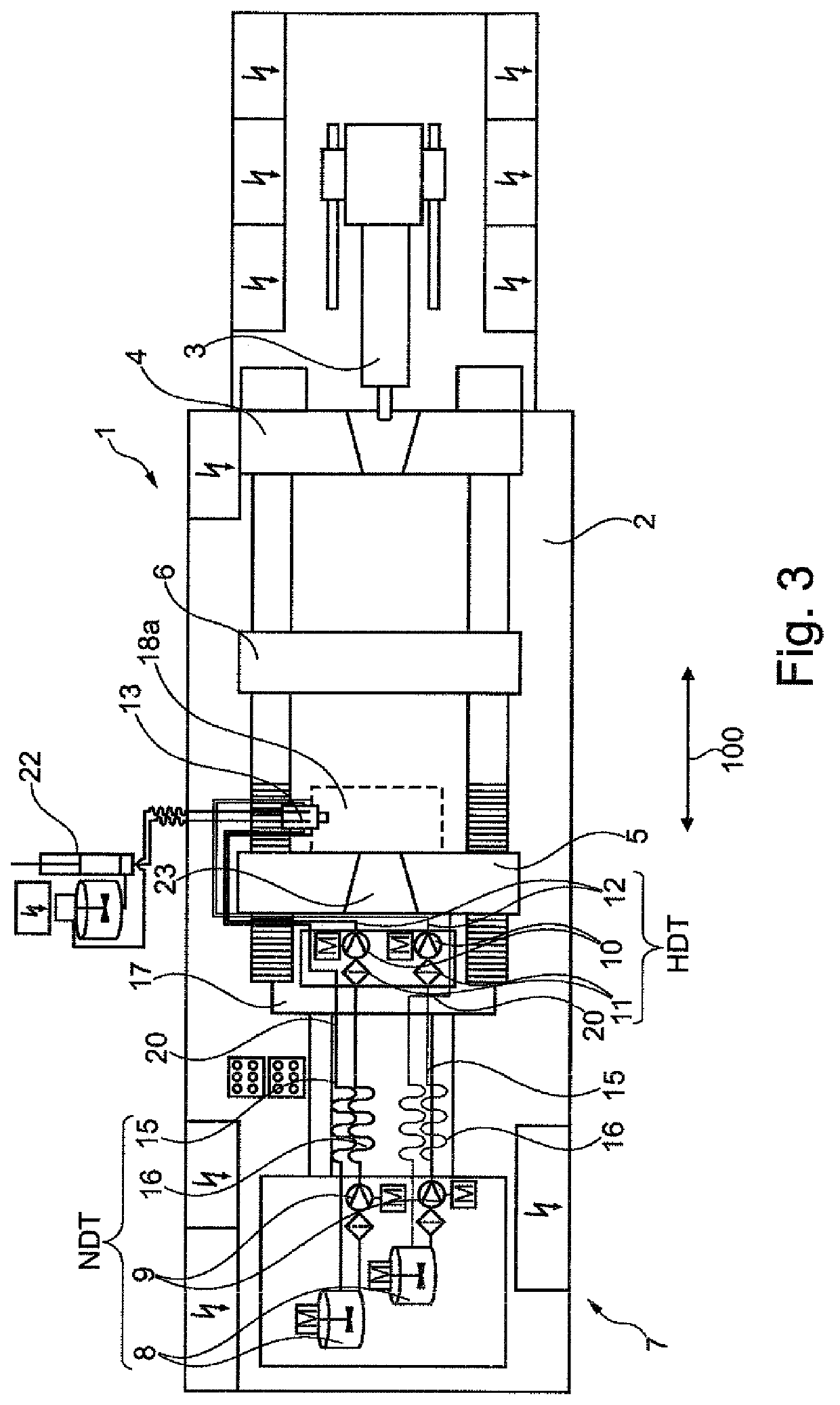

Injection moulding machine having a coating installation

ActiveUS11020882B2Increase doseImprove component qualityCoatingsInjection molding machineInjection moulding

The invention relates to an injection moulding machine having a coating installation, wherein the injection moulding machine has at least one fixed platen and one movable platen for the fastening of mould tool halves of at least one mould tool, and the coating installation has first pressure-generating and / or first pressure-conducting means for coating components at a first, relatively low pressure level and second pressure-generating and / or second pressure-conducting means for the coating components at a second, relatively high pressure level, wherein at least all second pressure-generating and all second pressure-conducting means are coupled to the movable platen so as to be jointly movable along a movement path of the movable platen.

Owner:KRAUSSMAFFEI TECH GMBH

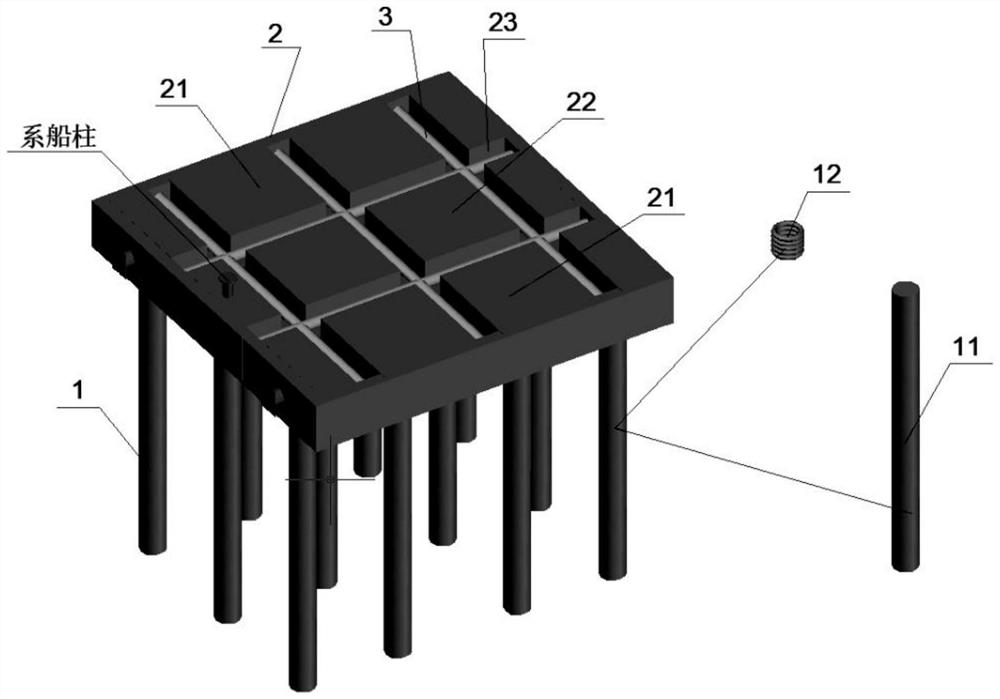

Fabricated abutment structure for wharf engineering and use method of fabricated abutment structure

PendingCN114775516AImprove component qualitySpeed up the construction progressBreakwatersQuaysSteel tubeAbutment

The invention discloses an assembly type abutment structure for wharf engineering and a using method of the assembly type abutment structure. The assembly type abutment structure structurally comprises pile foundations, slotting type modular abutments, connecting steel frames and subsidiary facilities. The pile foundation is connected with the lower end of the slotted modular abutment, the connecting steel frame is located in a notch in the upper end of the slotted modular abutment, and the subsidiary facility is prefabricated on the slotted modular abutment; the slotted modular abutment comprises a berthing module and a mooring module, the notches are located at the joint of the berthing module and the mooring module, each notch is composed of a berthing module prefabricated notch and a mooring module prefabricated notch, and the notches are evenly distributed in the slotted modular abutment; the pile foundation comprises a steel pipe pile and a corrugated steel pipe, and the corrugated steel pipe is welded to the top of the steel pipe pile. Different modules are connected into a whole through the connecting steel frames and the notch post-cast strips, the integrity and the force transmission effectiveness of the abutment structure are ensured, and the component quality and the construction progress are improved through the prefabrication mode.

Owner:CCCC THIRD HARBOR CONSULTANTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com