Intelligent circulating prestress mud jacking system and control method thereof

A prestressing and intelligent technology, which is applied in the processing of building materials, construction, bridge construction, etc., can solve the problems of accelerated steel strand corrosion, effective prestress reduction, weakening the bonding force of tendons, etc., and achieve grouting density , Stable pressure and good component quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

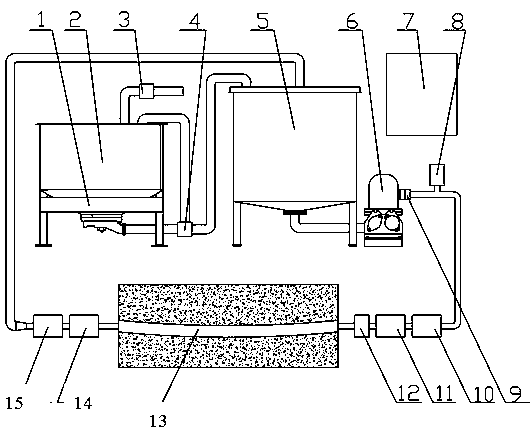

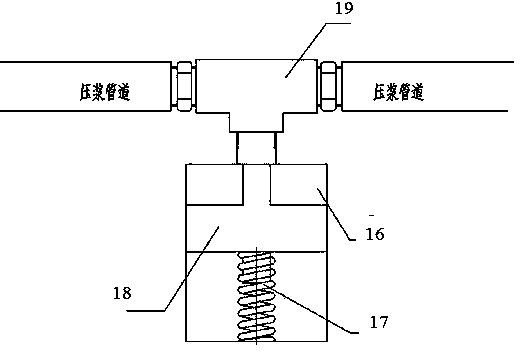

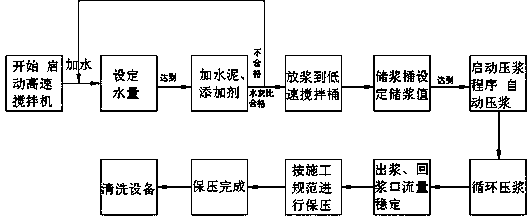

[0029] Such as figure 1 As shown, the prestressed intelligent circulation grouting system of the present invention includes a high-speed mixer 2, an electric control box 7, a low-speed pulp storage tank 5, a grouting pump 6, a pressure sensor 12, an electromagnetic flowmeter 11 at a pulp inlet, and a pulp outlet Electromagnetic flowmeter 14, water inlet valve 3, load cell 1, air compressor, slurry inlet pressure maintaining device 10, slurry outlet pressure maintaining device 15, set in the grouting pipeline between the grouting pump and the grouting inlet There is a pressure compensating device 8, and the pressure compensating device 8 includes a piston 18 and an elastic force mechanism, the end of the piston 18 communicates with the grouting pipeline, and the elastic force of the elastic force mechanism drives the end of the piston to press into the grouting pipeline.

[0030] Such as figure 2 As shown, the elastic force mechanism includes a spring 17 arranged in the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com