Fabricated abutment structure for wharf engineering and use method of fabricated abutment structure

A prefabricated and pier technology, which is applied in the direction of basic structure engineering, pier, quay wall, etc., can solve the problems of difficult prefabricated pier lifting and installation, continuous laying of steel bars is impossible, and the plane scale of pier is large, so as to improve the accuracy and construction safety, superior construction convenience, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

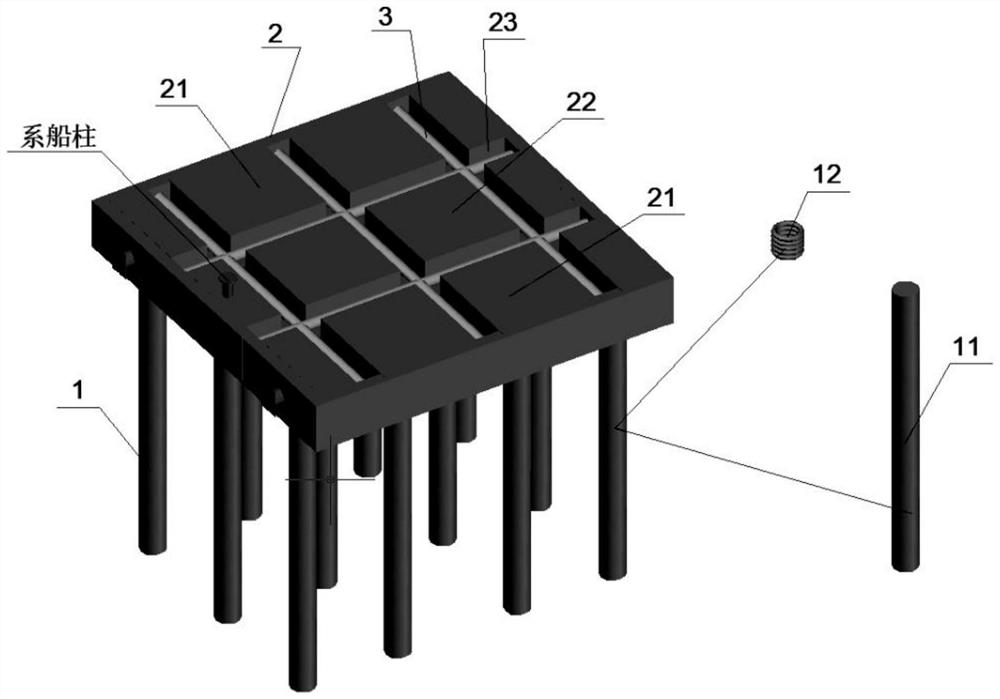

[0059] This embodiment mainly introduces the design of a prefabricated pier structure for wharf engineering; please refer to the specific structure figure 1 , figure 1 The overall installation diagram of the prefabricated abutment provided by the present invention.

[0060] A prefabricated pier structure for wharf engineering, comprising a pile foundation 1, a slotted modular pier 2, a connecting steel frame 3, and ancillary facilities;

[0061] The pile foundation 1 is connected with the lower end of the slotted modular abutment 2;

[0062] The connecting steel frame 3 is located in the slot 23 at the upper end of the slotted modular abutment 2;

[0063] The auxiliary facilities are prefabricated on the slotted modular abutment 2 .

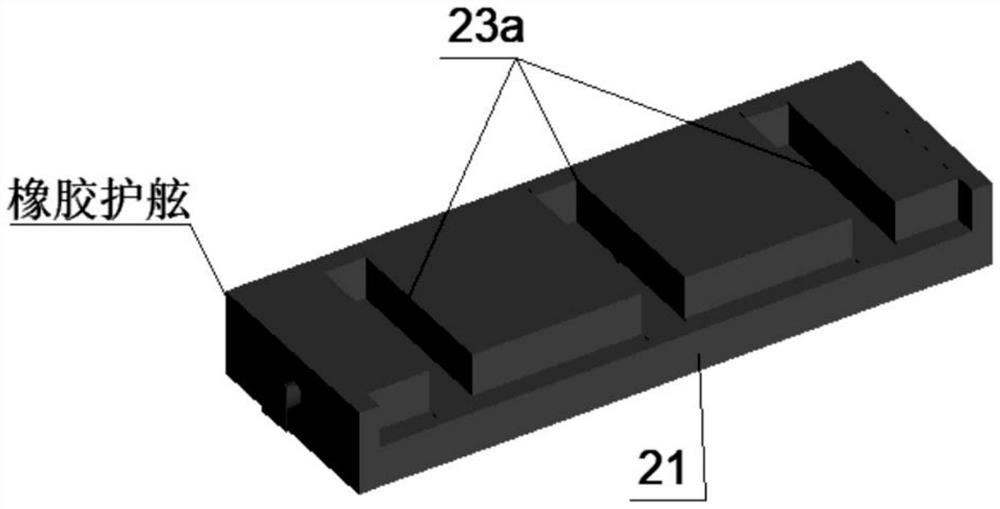

[0064] Further, the slotted modular abutment 2 includes a ship docking module 21 and a mooring module 22; please refer to the specific structures of the ship docking module 21 and the mooring module 22 image 3 and Figure 4 ; image 3 The ...

Embodiment 2

[0082] Based on the above Embodiment 1, this embodiment mainly introduces an optimal design of a prefabricated pier structure for wharf engineering.

[0083] A prefabricated pier structure for wharf engineering includes: pile foundation 1, slotted modular pier 2, connecting steel frame 3, and auxiliary facilities.

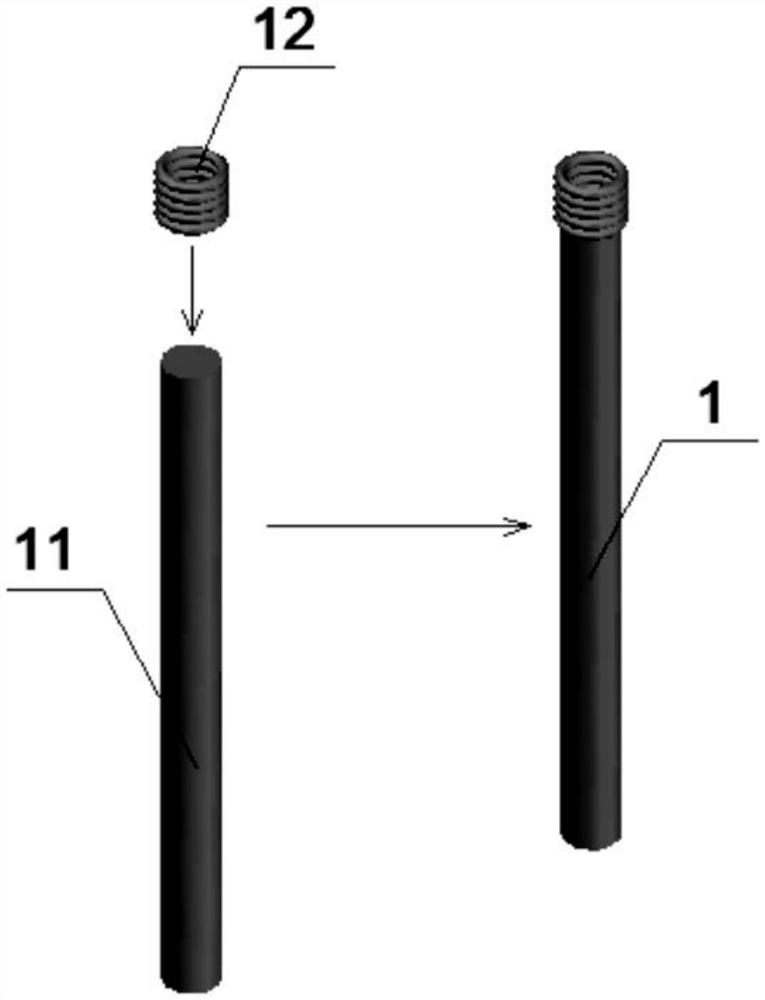

[0084] As a preferred technical solution of the present invention, the pile foundation 1 is composed of a steel pipe pile 11 and a corrugated steel pipe 12 . The slotted modular pier 2 can be divided into a ship-berthing module 21 and a mooring module 22 according to actual needs and construction lifting capacity. The slotted modular abutment 2 is internally provided with a slot 23 and a reserved pile hole 24 .

[0085] As a preferred technical solution of the present invention: after the pile driving is completed, the ship-receiving module 21 and the mooring module 22 are respectively hoisted on the upper part of the pile foundation 1, and the corrugated steel pi...

Embodiment 3

[0099] Based on the above-mentioned embodiments 1-2, this embodiment mainly introduces a method for using a prefabricated pier structure for wharf engineering, which includes the following steps:

[0100] S1, prepare the pile foundation 1, and connect the steel pipe pile 11 and the corrugated steel pipe 12 into one body;

[0101] S2. Use piling ship to sink piles;

[0102] S3. Prefabricate the ship docking module 21 and the mooring module 22, and simultaneously install the auxiliary facilities in place at one time;

[0103] S4, hoist the ship-berthing module 21 and the mooring module 22 on the upper part of the pile foundation 1, and the reserved pile holes 24 are directly supported on the top surface of the pile foundation 1;

[0104] S5. Connect the pile foundation 1 with the ship-berthing module 21 and the mooring module 22 to form a whole by grouting, and the bottom formwork can adopt a simple hanging formwork process;

[0105] S6, hoist the connecting steel frame 3 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com