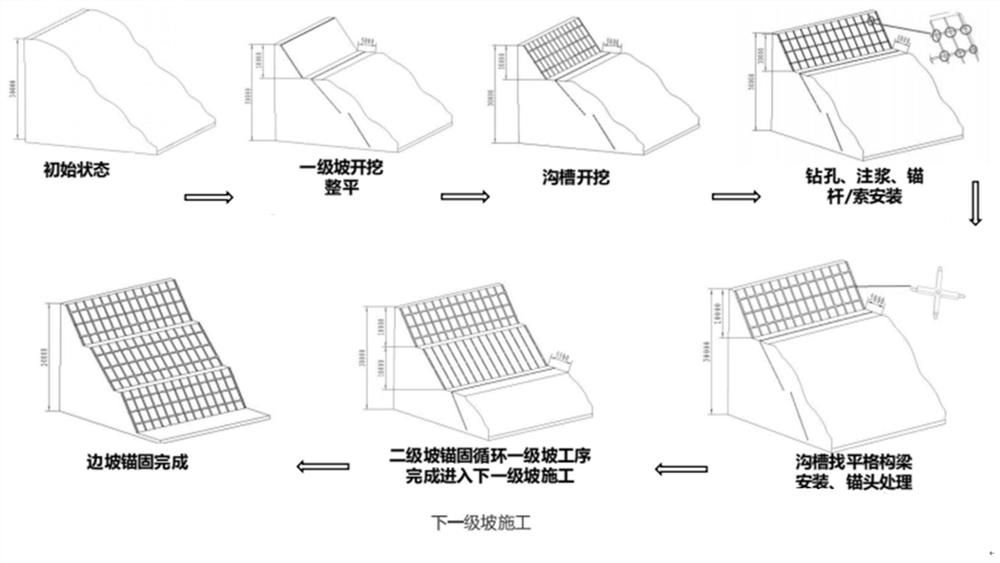

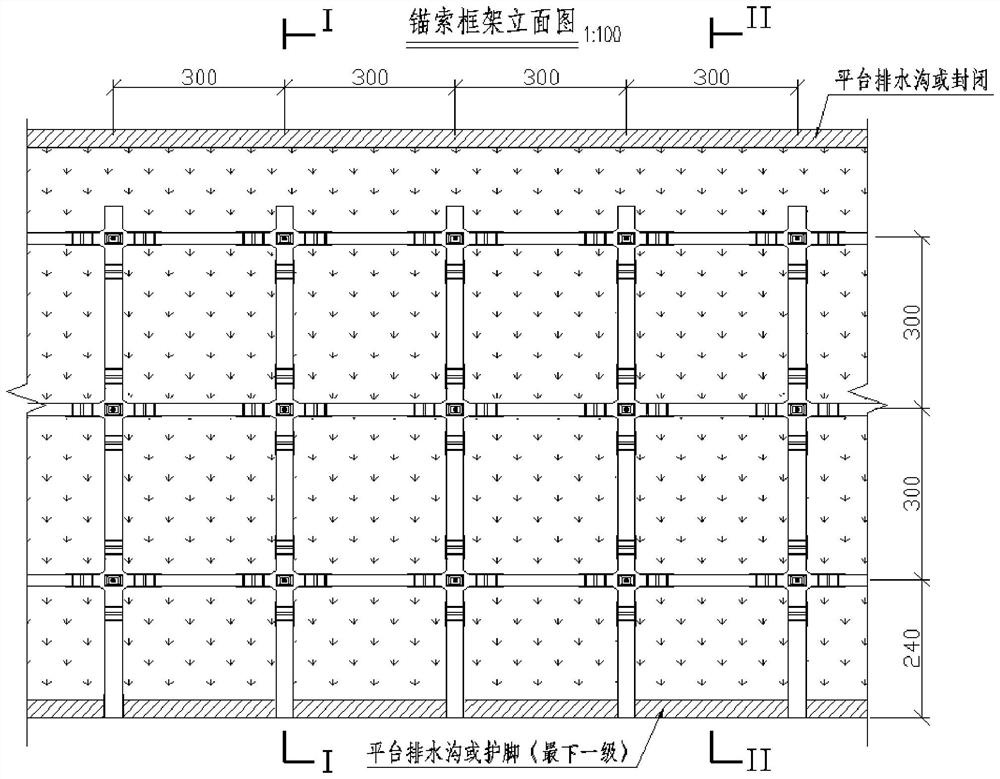

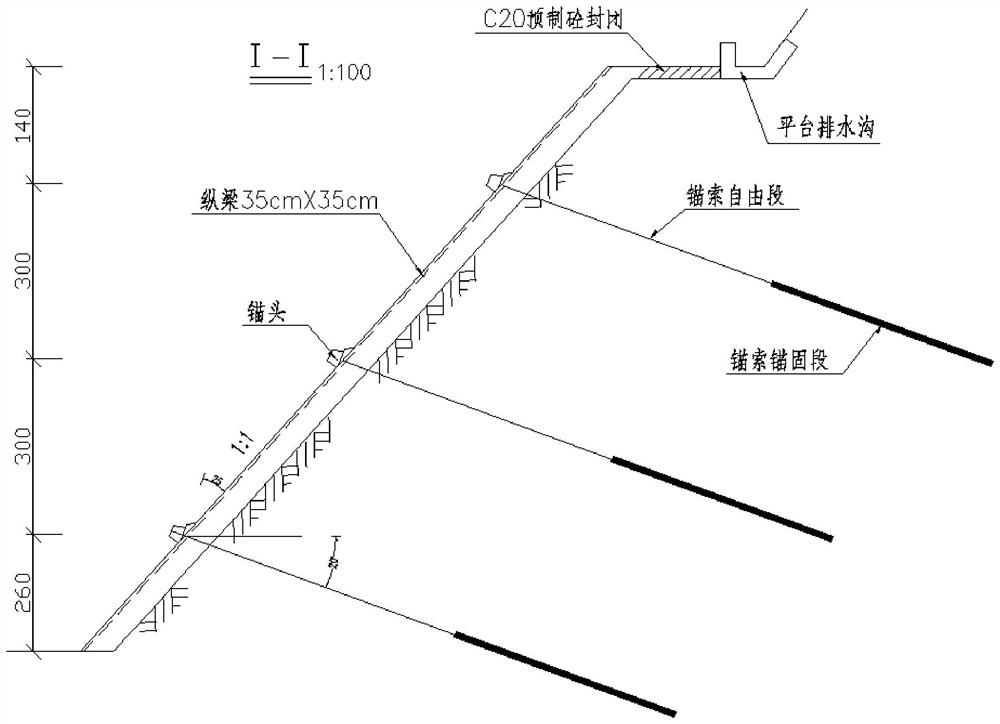

Mechanical construction method for side slope anchoring

An anchoring and slope technology, applied in the direction of basic structure engineering, construction, excavation, etc., can solve the problems of large manpower and material resources, poor overall linearity, discontinuous construction, etc., and achieve concrete saving, high construction quality, and high drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Orientation terms such as up, down, left, right, front, back, front, back, top, and bottom that are mentioned or may be mentioned in this specification are defined relative to their structures, and they are relative concepts. Therefore, it is possible to make corresponding changes according to its different positions and different usage states. Accordingly, these or other directional terms should not be construed as limiting terms.

[0032] The implementations described in the following exemplary examples do not represent all implementations consistent with the present disclosure. Rather, they are merely examples of implementations consistent with aspects of the disclosure.

[0033] The terminology used in the present disclosure is for the purpose of describing particular embodiments only, and is not intended to limit the present disclosure. As used in this disclosure, the singular forms "a", "the", and "the" are intended to include the plural forms as well, unless th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com