Preparation method of food-grade microcrystalline wax

A microcrystalline wax, food-grade technology, applied in the field of petroleum microcrystalline wax preparation, can solve the problems of narrow selection range of raw material wax, large material loss, high quality requirements, etc., to reduce production links and environmental pollution, improve selectivity, The effect of increasing severity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

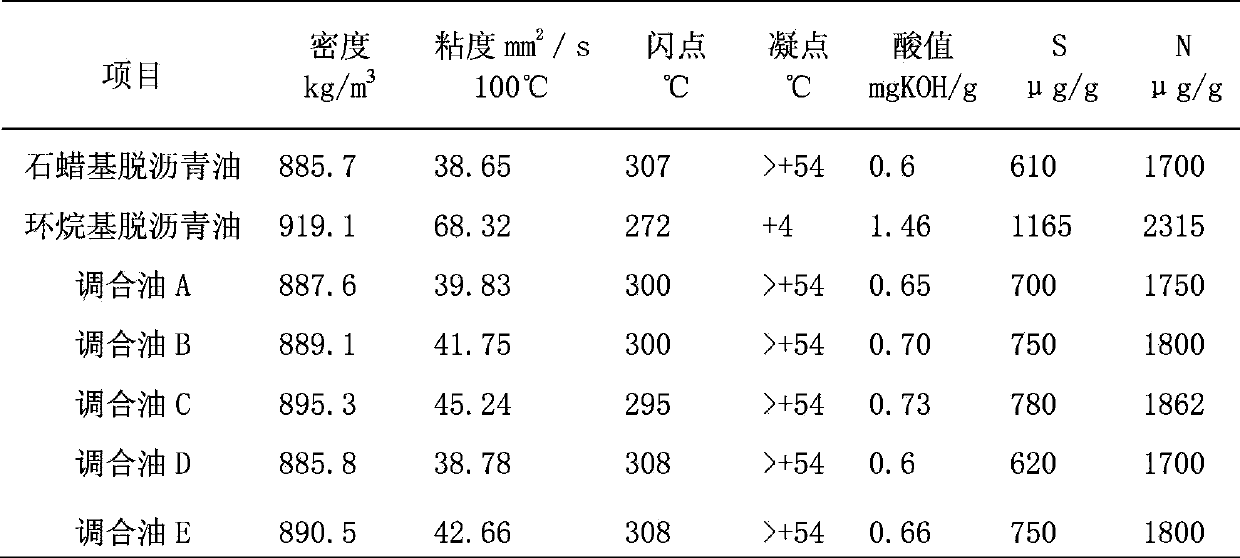

[0021] Paraffin-based deasphalted oil and naphthenic deasphalted oil were fully mixed at a weight percentage of 96:4. The properties of paraffin-based deasphalted oil, naphthenic deasphalted oil, and blended oil A after mixing are shown in Table 1.

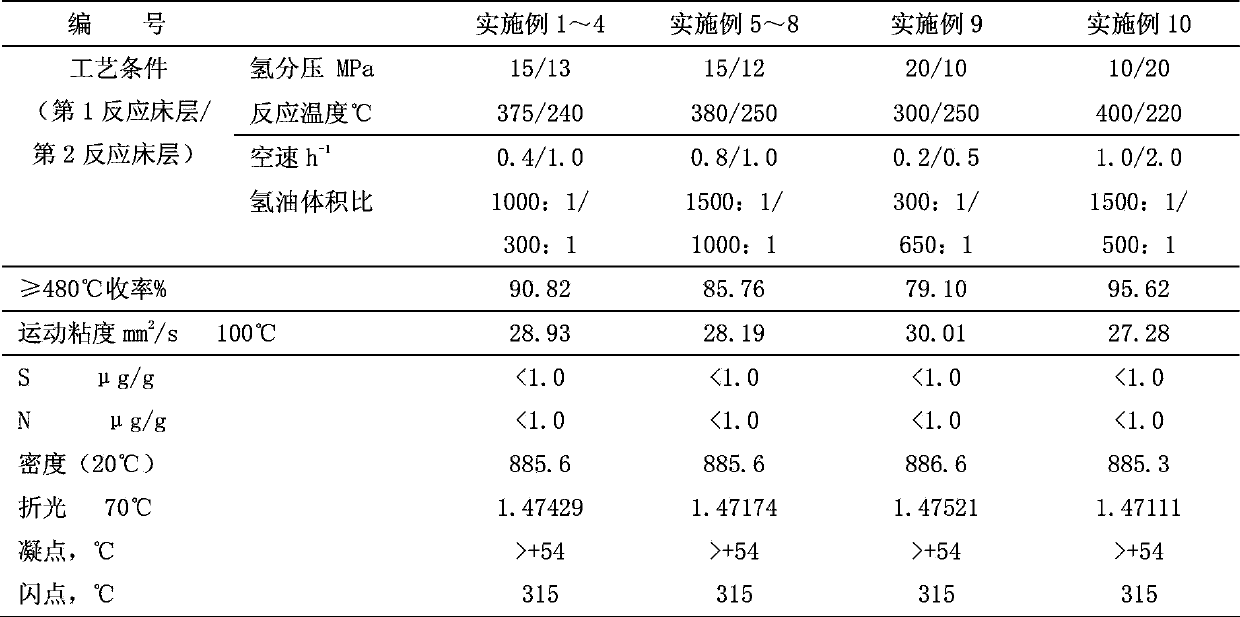

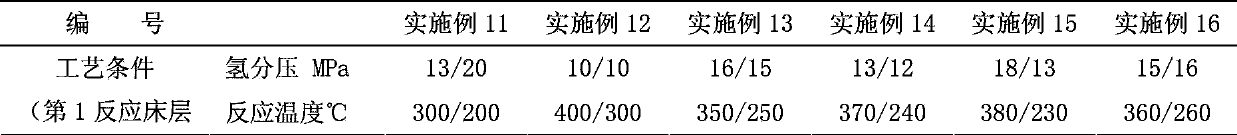

[0022] The mixed oil enters the two-stage hydrogenation reactor for hydrogenation reaction, and the hydrogenated oil obtained is fractionated and cut to obtain a heavy fraction at 480°C to 750°C. The operating parameters of the reaction conditions and the property analysis of the heavy fraction are shown in Table 2. Catalyst property analysis See the first set of catalyst systems in Table 4.

[0023] 480℃~750℃ heavy distillate, mixed with dewaxing solvent at a ratio of 1:4, the dewaxing solvent is a mixture of butanone and toluene, in which the weight of butanone accounts for 50% of the mixture, and toluene accounts for 50%, gradually cool down to lower the temperature To -20°C, after filtration, wax filtrate and oily wax paste ar...

Embodiment 2

[0025] Using the blended oil A raw material and hydrogenation process conditions in implementation 1, the hydrogenation catalyst is selected as the second group of catalysts in Table 4, and the heavy fraction at 480°C to 750°C is mixed with the dewaxing solvent, and the dewaxing solvent is acetone and benzene The mixture, wherein the weight of acetone accounts for 70% of the mixture, benzene accounts for 30%, gradually cooled down to -15 ° C, filtered to obtain wax filtrate and oil-containing wax paste, after recovery of oil-containing wax paste, deoiled wax is obtained, and the obtained de-oiled wax is obtained. Oily wax is mixed with 5% (mass fraction) clay, and described clay is commercially available clay, stirred at 130 DEG C for 10 minutes, filtered to obtain food-grade microcrystalline wax product after removing clay, and the yield of food-grade microcrystalline wax product and The property analysis is shown in Table 5.

Embodiment 3

[0027] Using the blended oil A raw material and hydrogenation process conditions in implementation 1, the hydrogenation catalyst is selected as the third group of catalysts in Table 4, and the heavy fraction at 480°C to 750°C is mixed with the dewaxing solvent, and the dewaxing solvent is methyl ethyl ketone and A mixture of benzene, wherein the weight of butanone accounts for 70% of the mixture, and benzene accounts for 30%. Gradually cool down and lower the temperature to -15°C. After filtration, wax filtrate and oily wax paste are obtained. After the oily wax paste is recovered, deoiled wax is obtained. The deoiled wax is mixed with 10% (mass fraction) of white clay, the white clay is commercially available white clay, stirred at 110°C for 20 minutes, and the food-grade microcrystalline wax product is obtained after filtering and removing the white clay, and the food-grade microcrystalline wax product is collected See Table 5 for rate and property analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com