Patents

Literature

55results about How to "Avoid serious deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

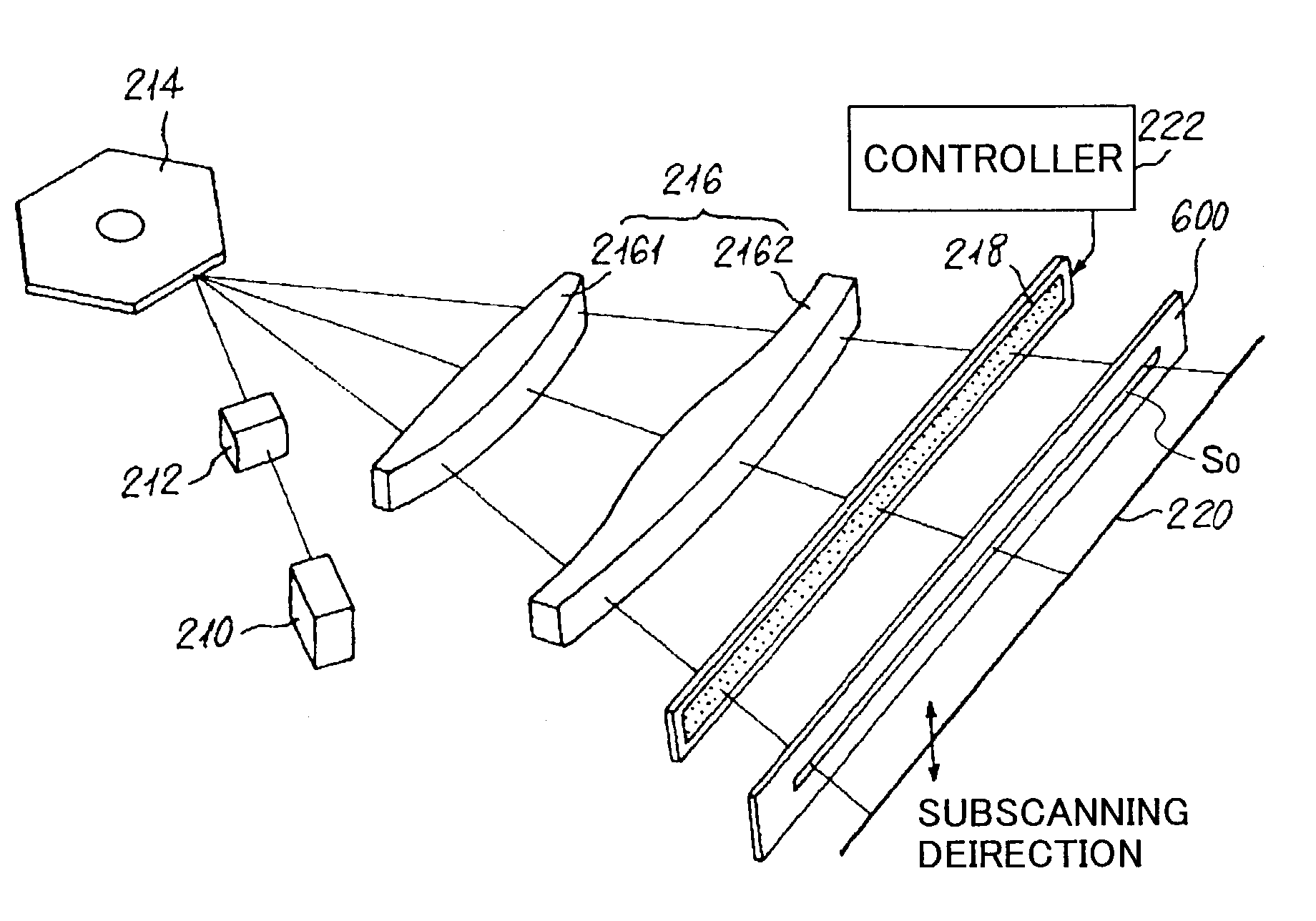

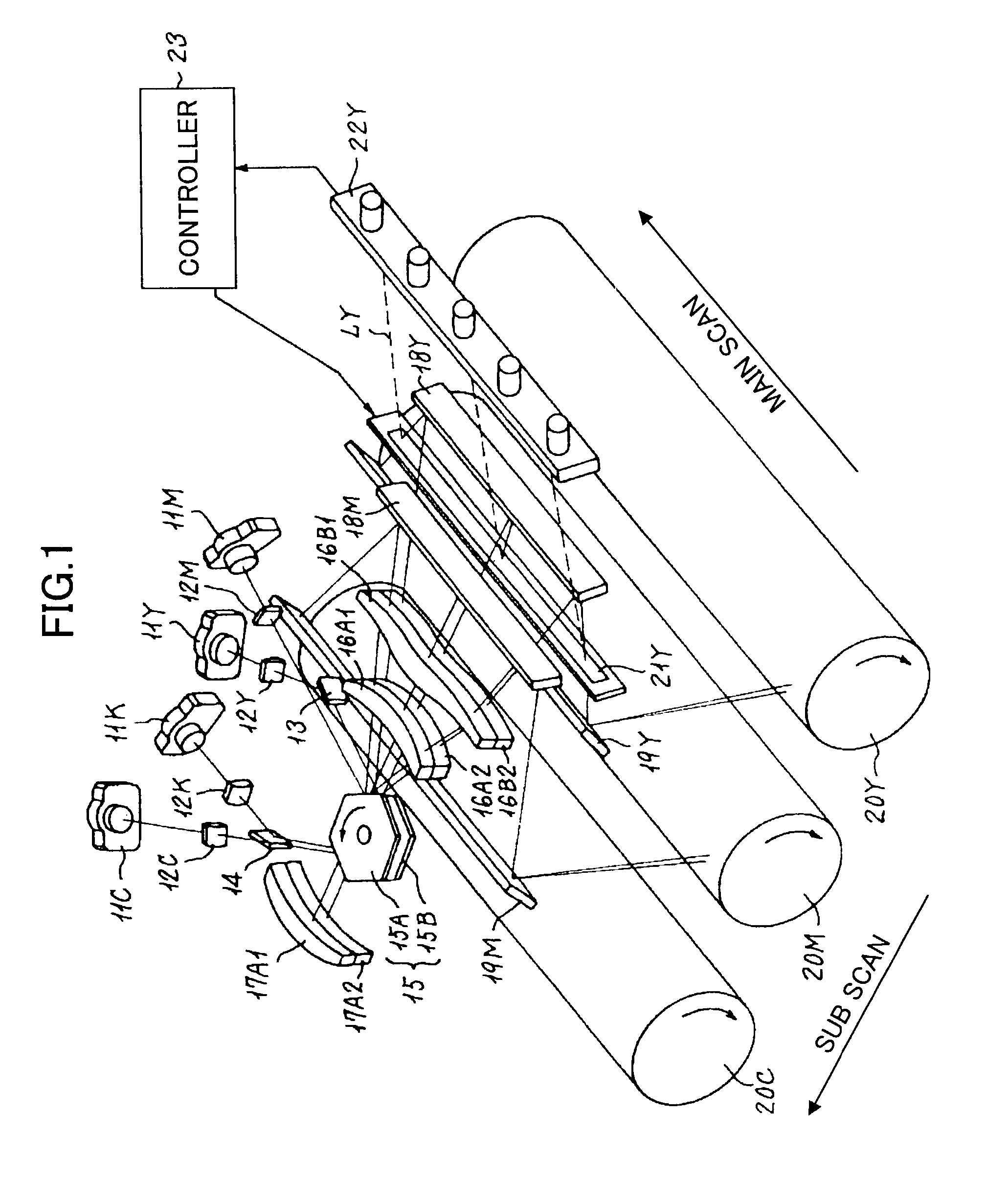

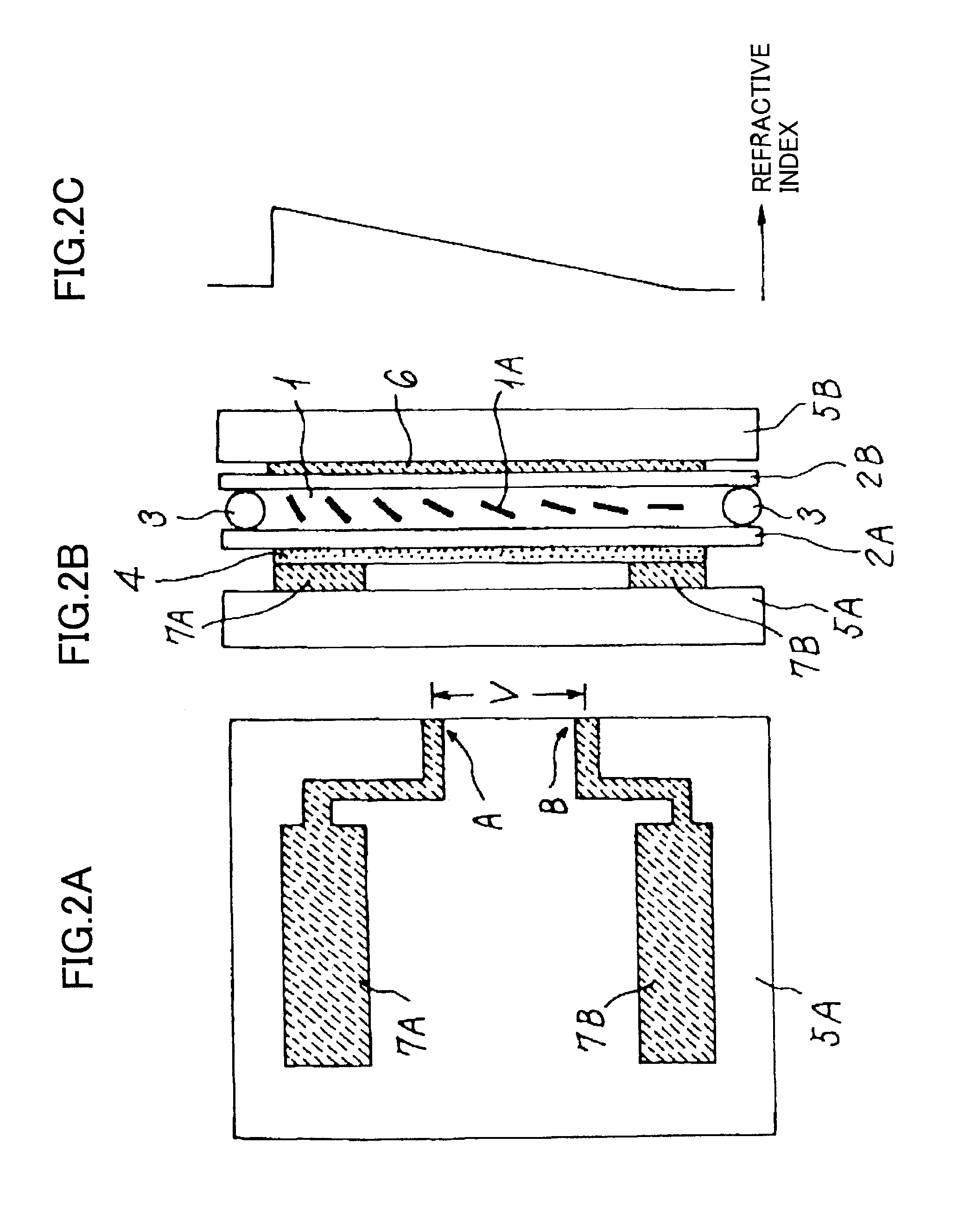

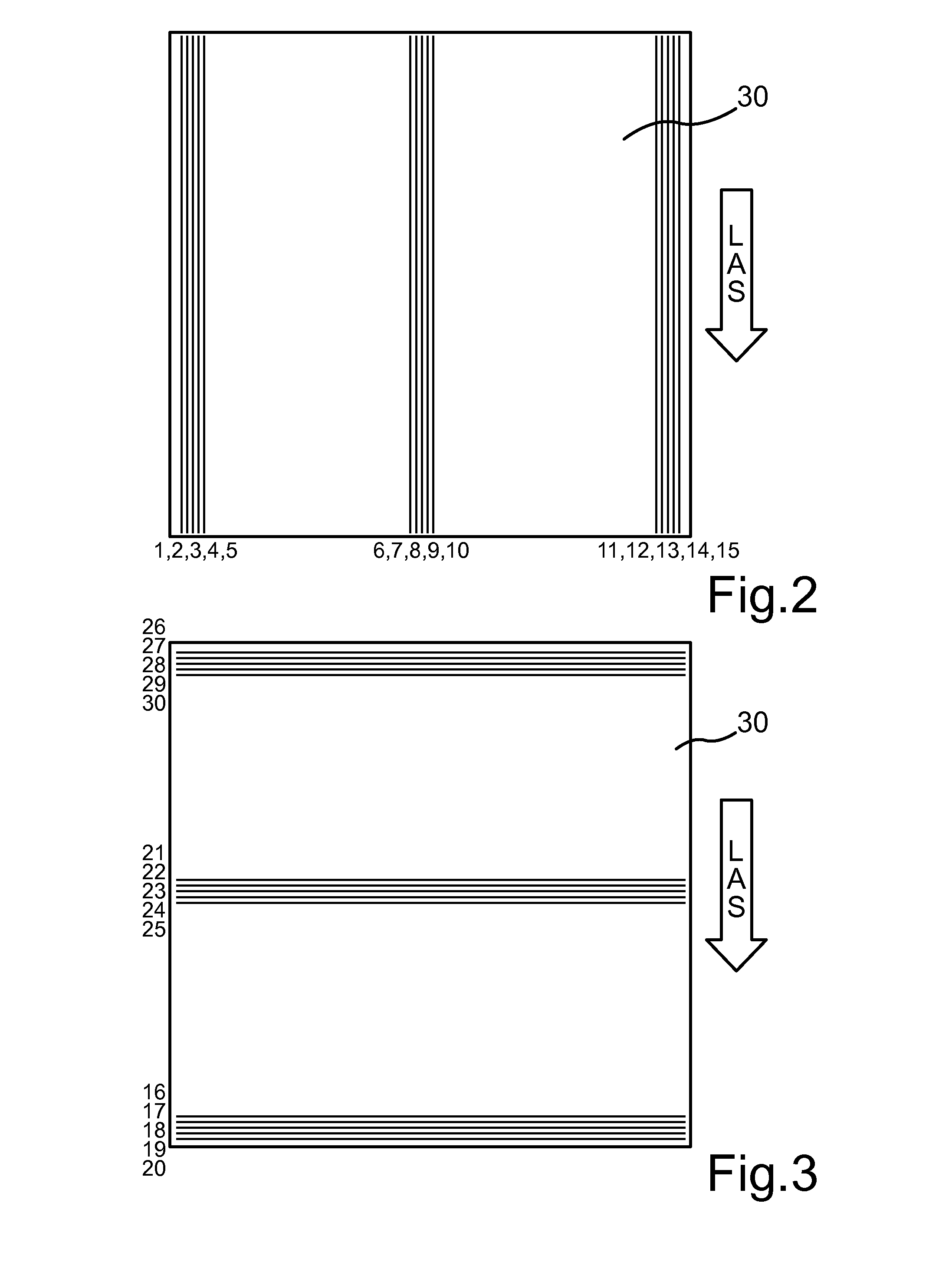

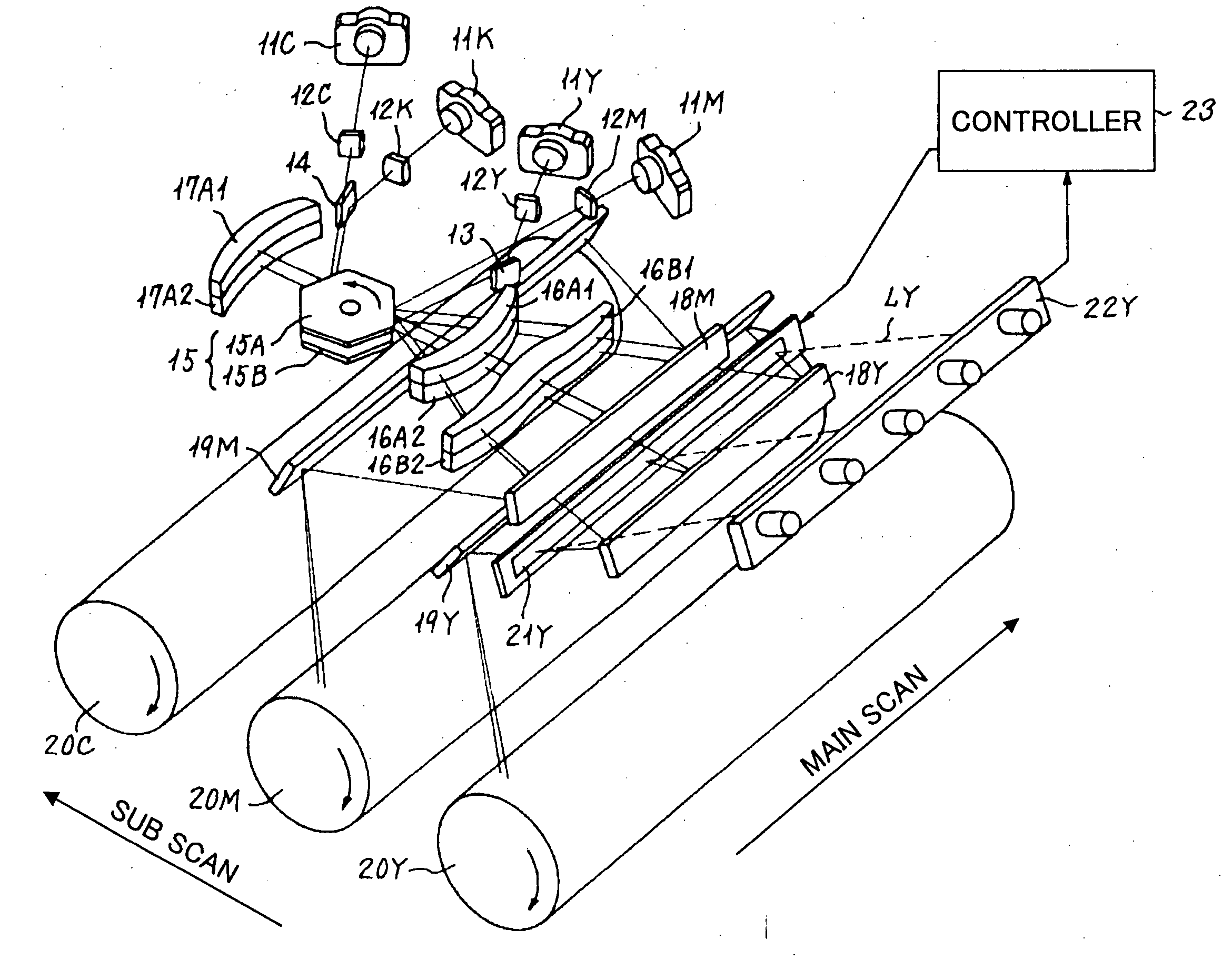

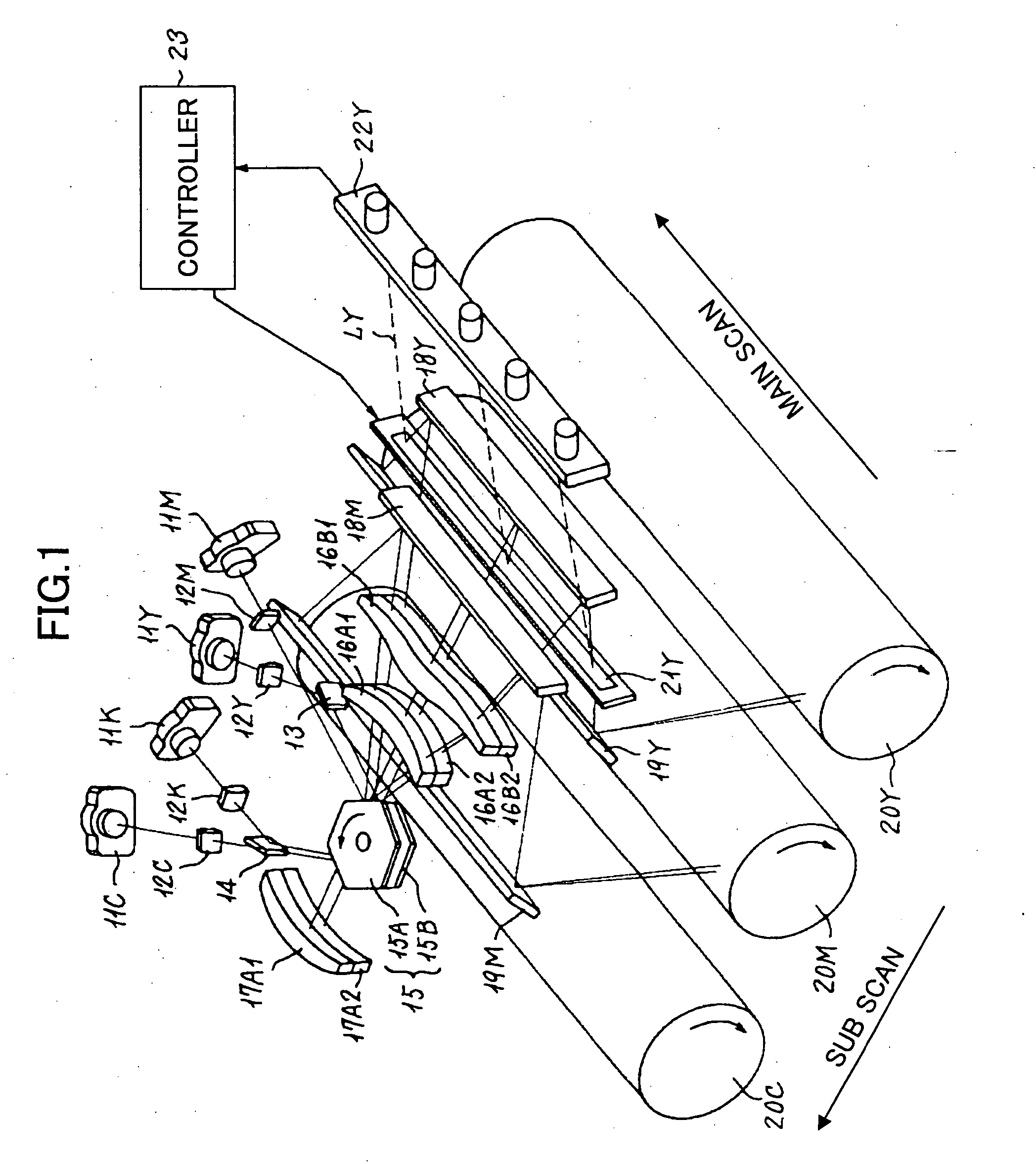

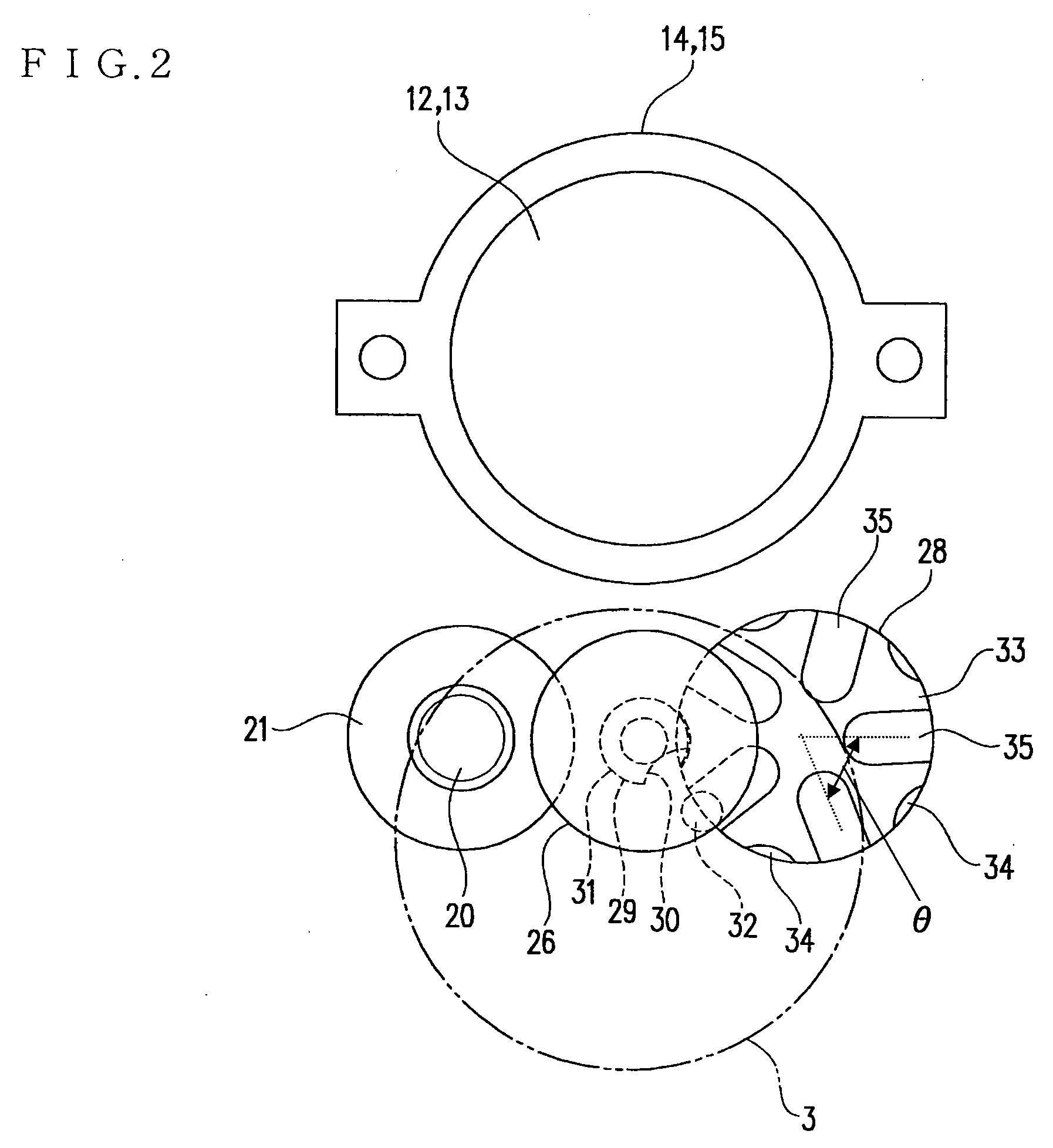

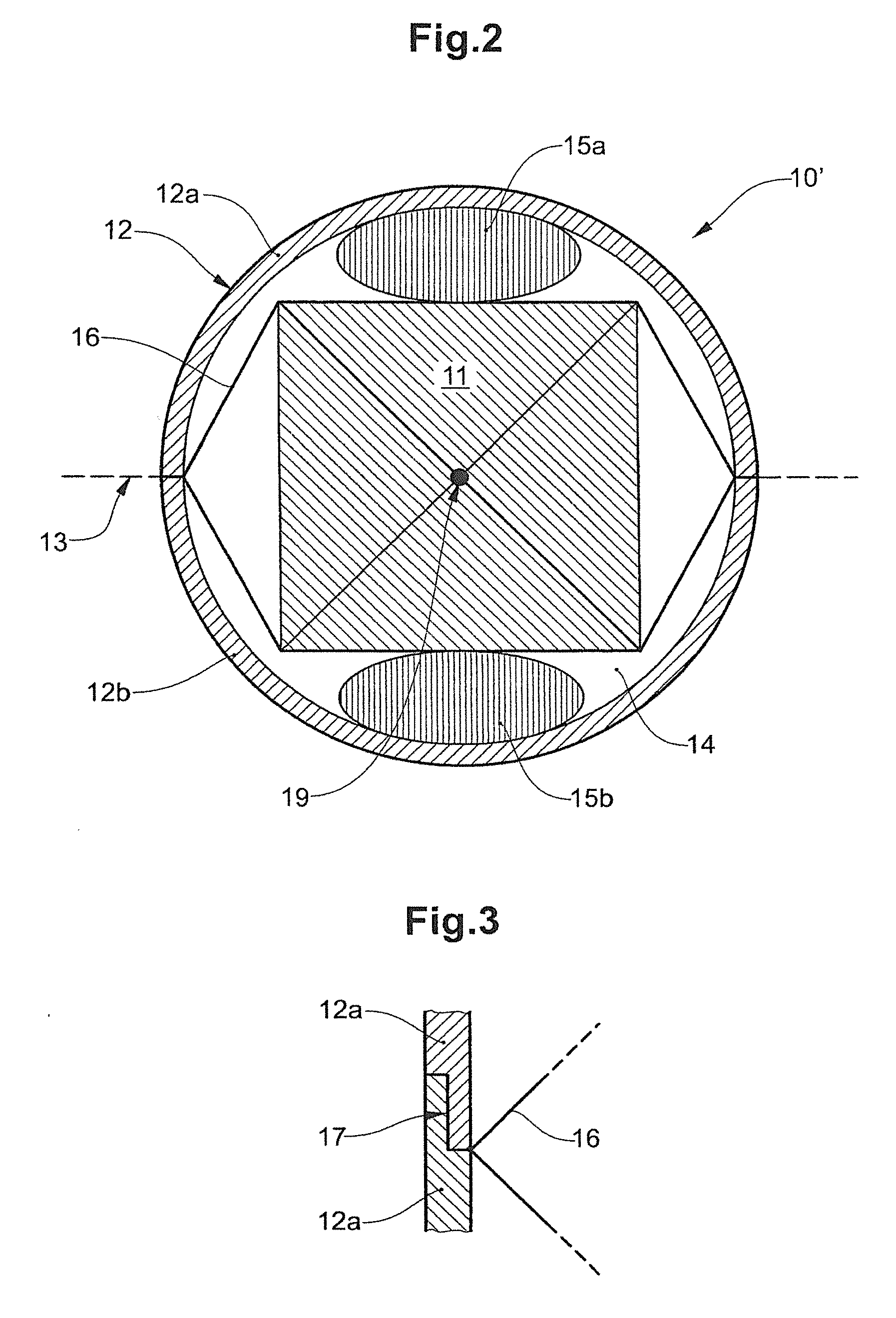

Image forming system employing effective optical scan-line control device

InactiveUS7050082B2High quality imagingAvoid serious deviationInking apparatusMountingsScan lineLight beam

An optical scanning characteristic control method is applied to an optical scanning system in which a beam is deflected, and the deflected beam is converged and directed toward a scanning surface, so that optical scanning of the scanning surface is performed by an optical spot formed thereon by the deflected beam. The method comprising the steps of a) disposing a beam deflection control device on the light path of the beam before it is incident on the scanning surface; and b) controlling a beam deflection amount of the beam deflecting device provide to an incident beam so as to control a scanning characteristic of the optical scanning.

Owner:RICOH KK

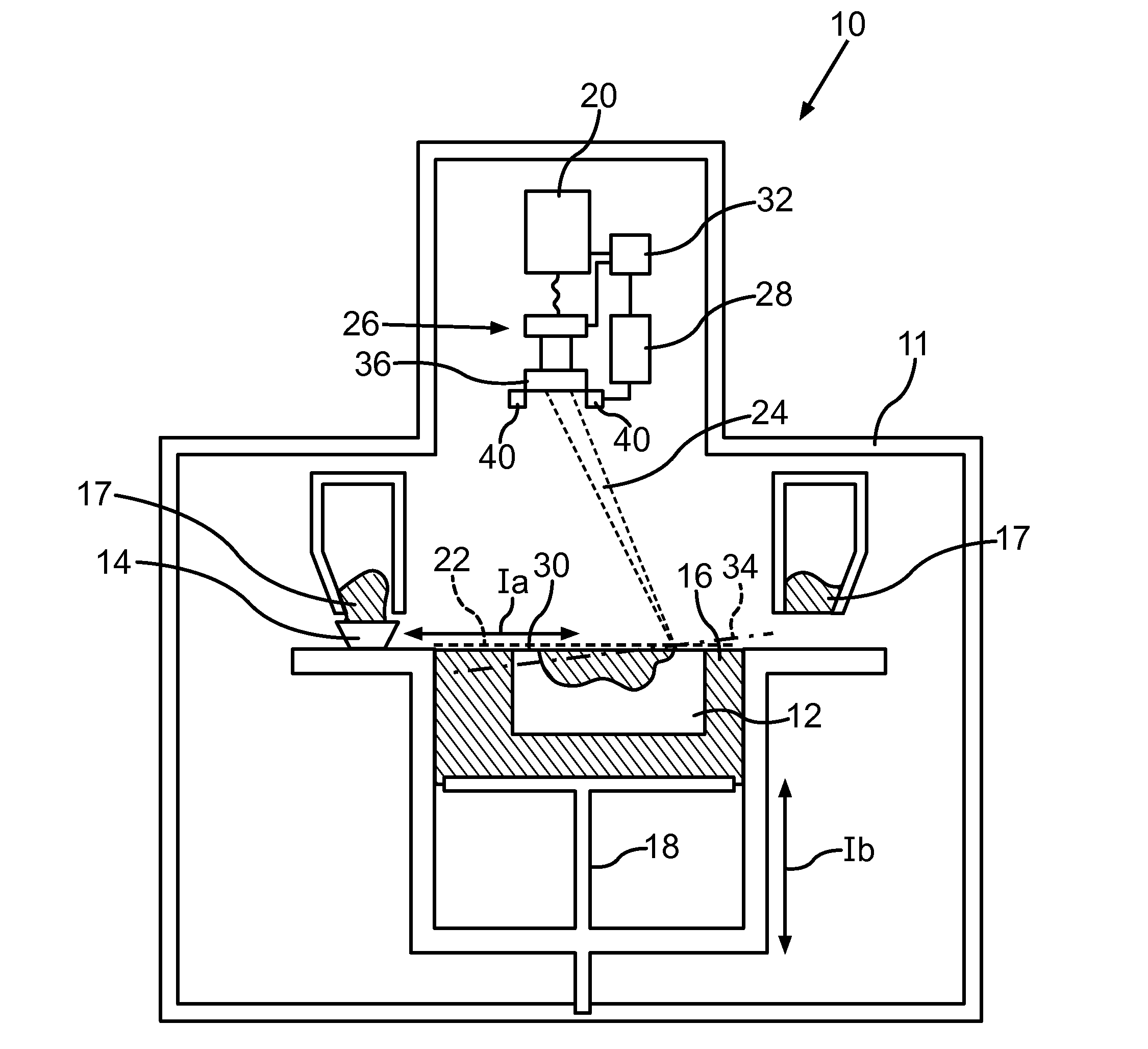

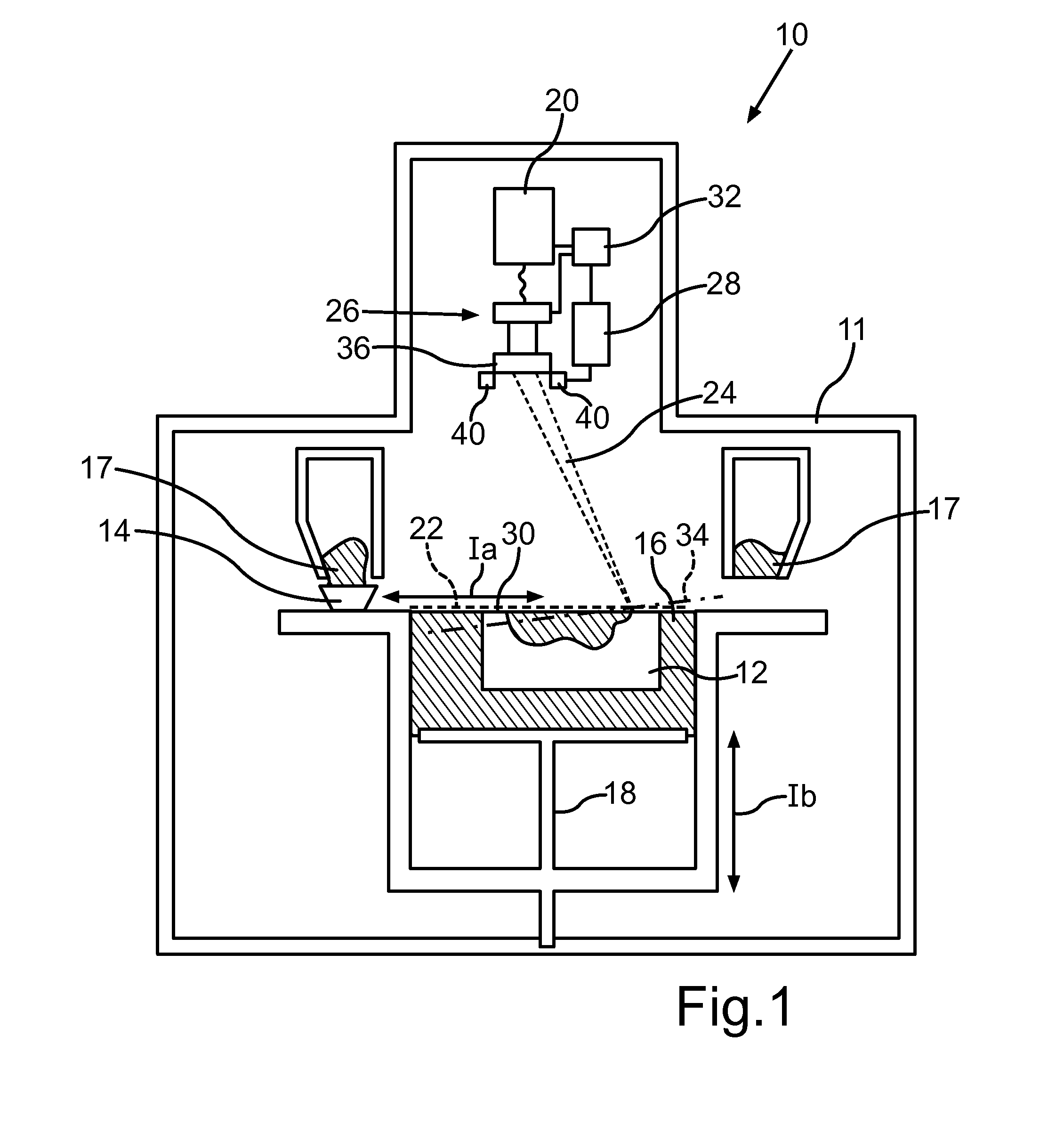

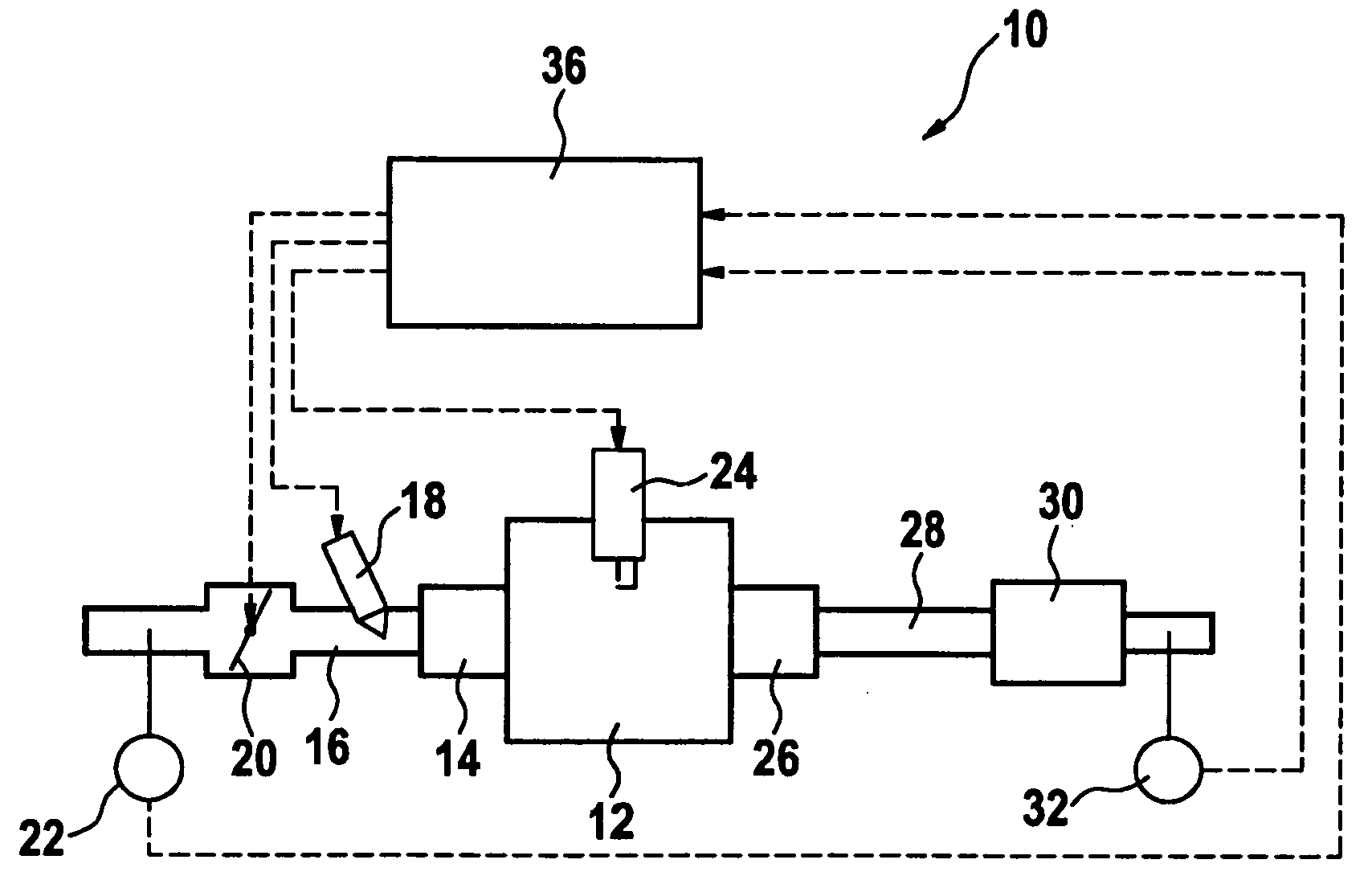

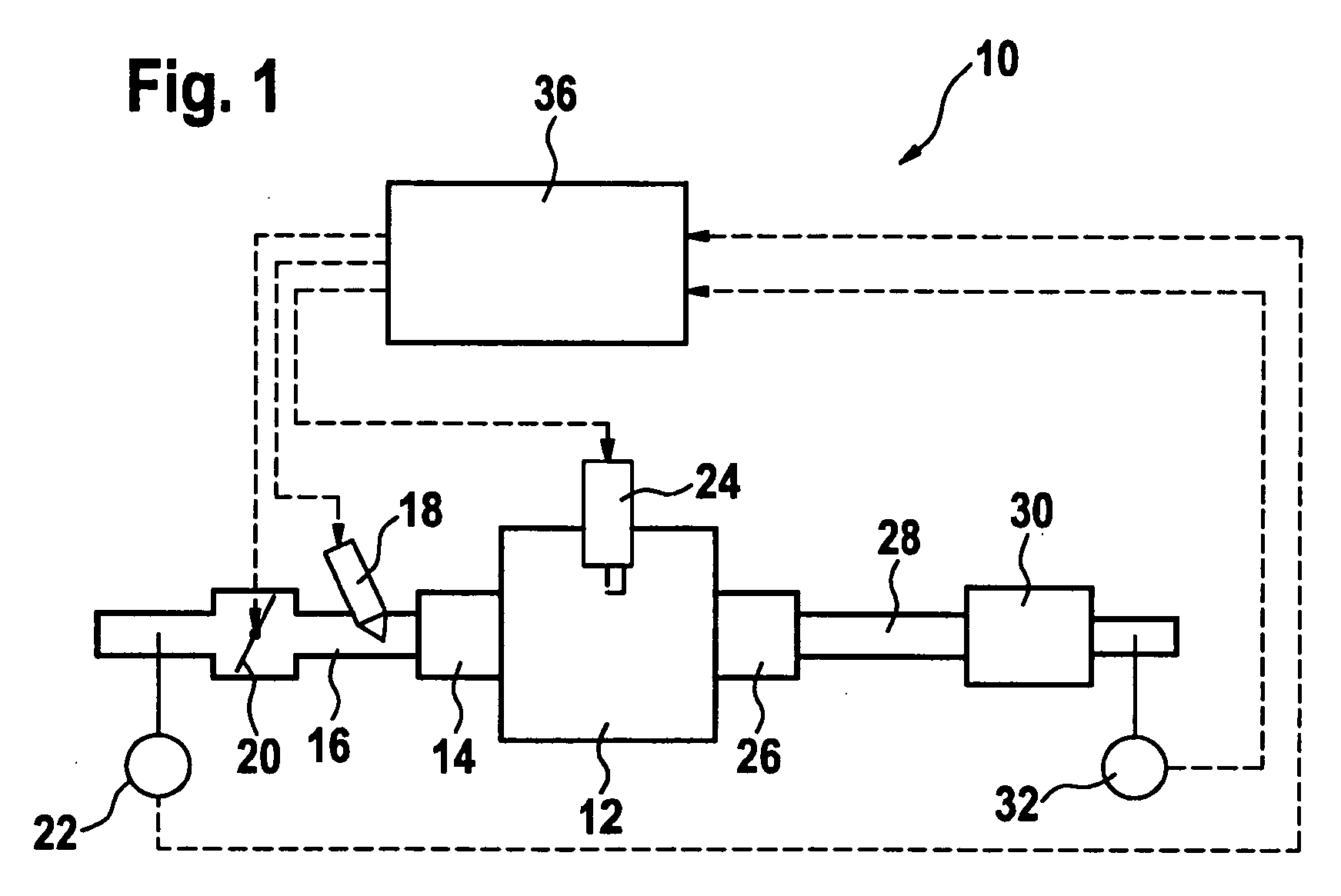

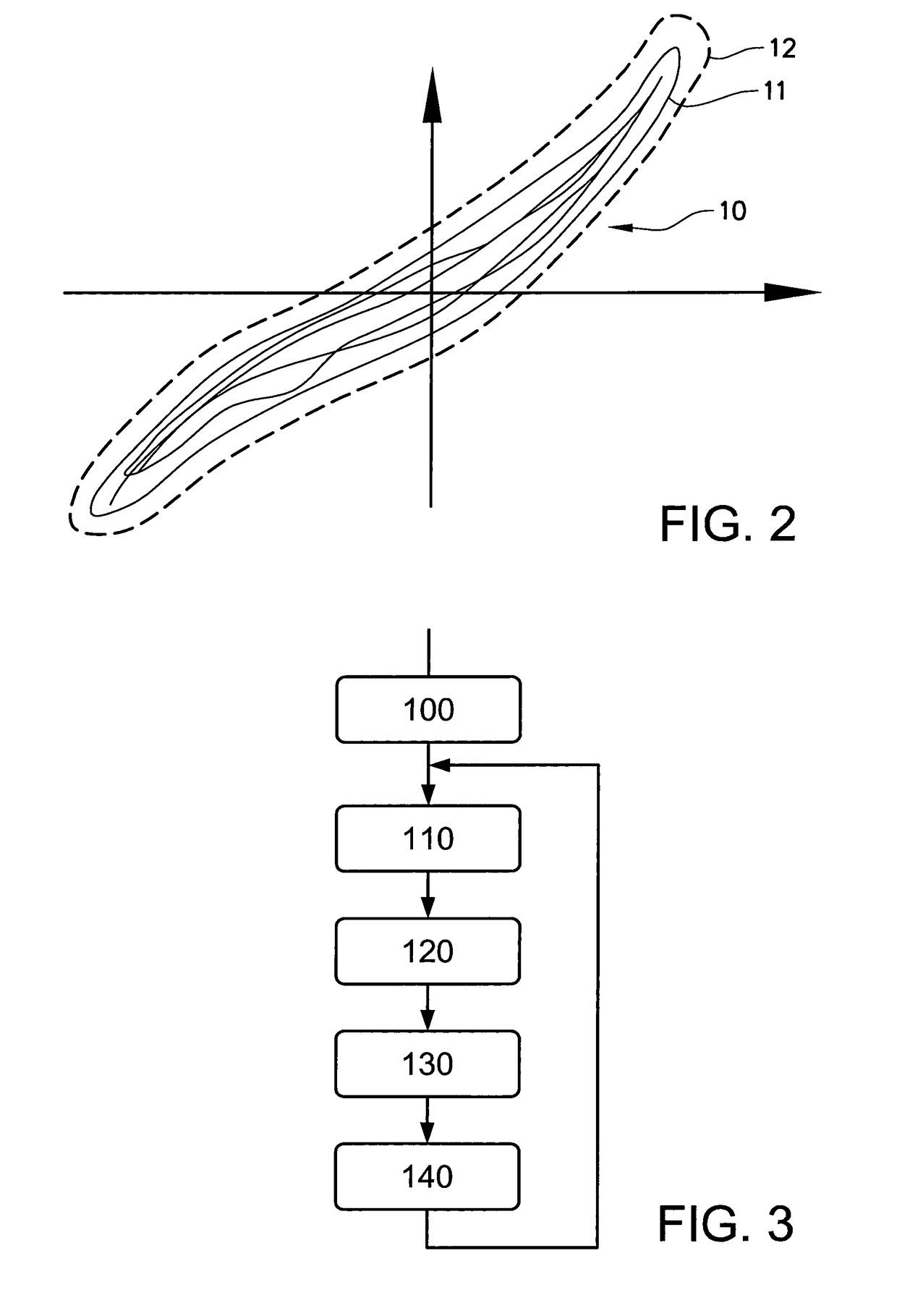

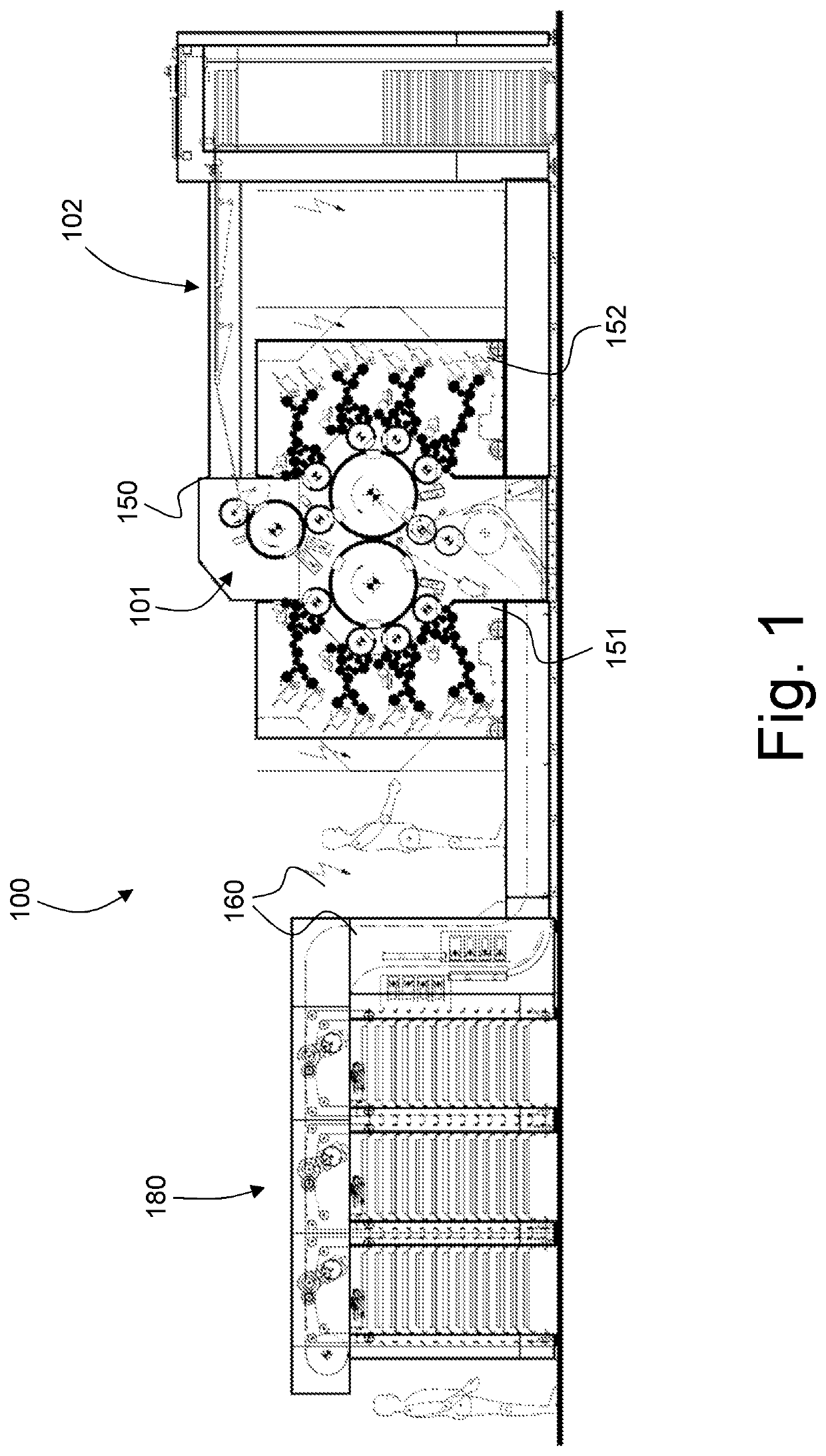

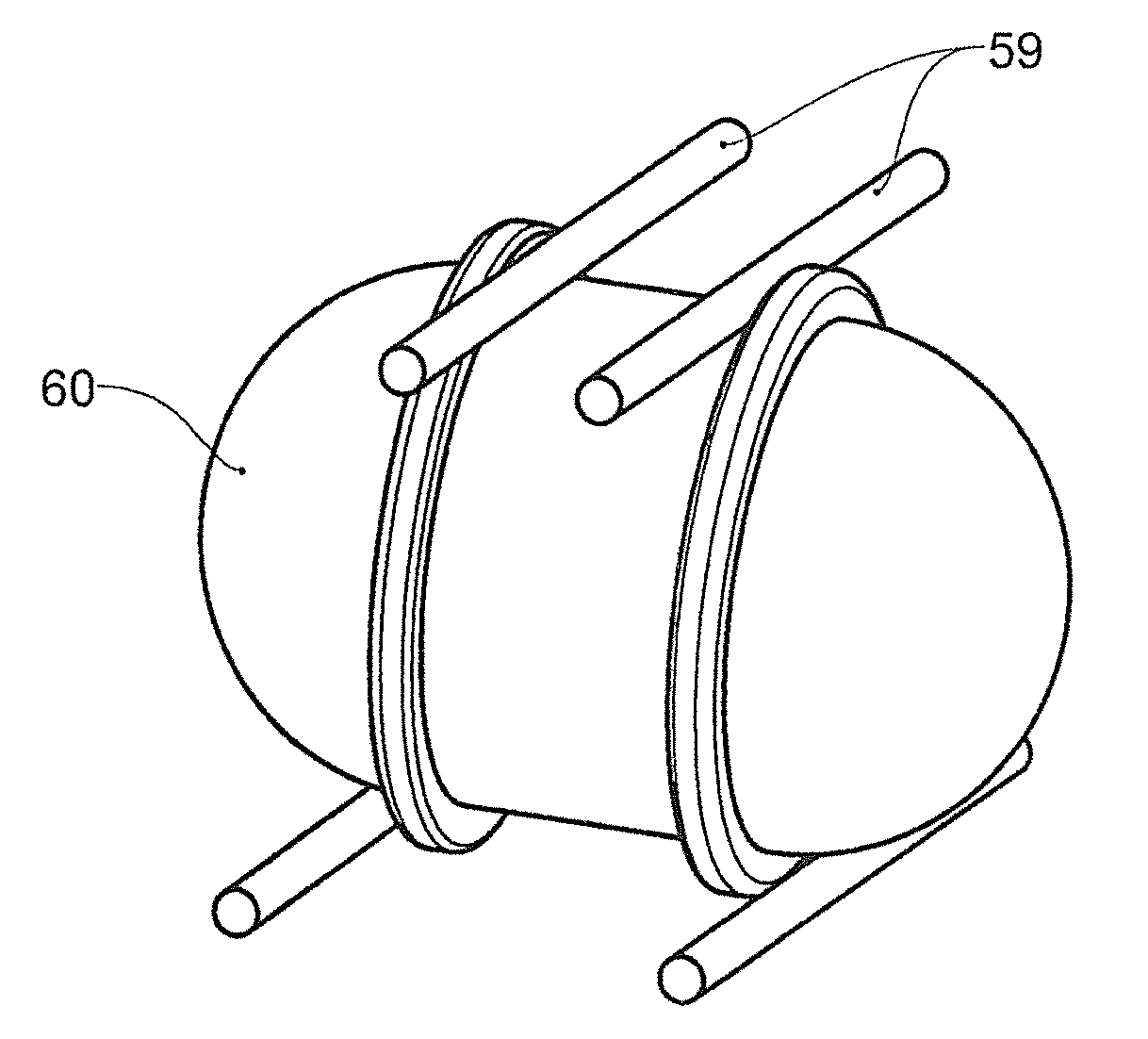

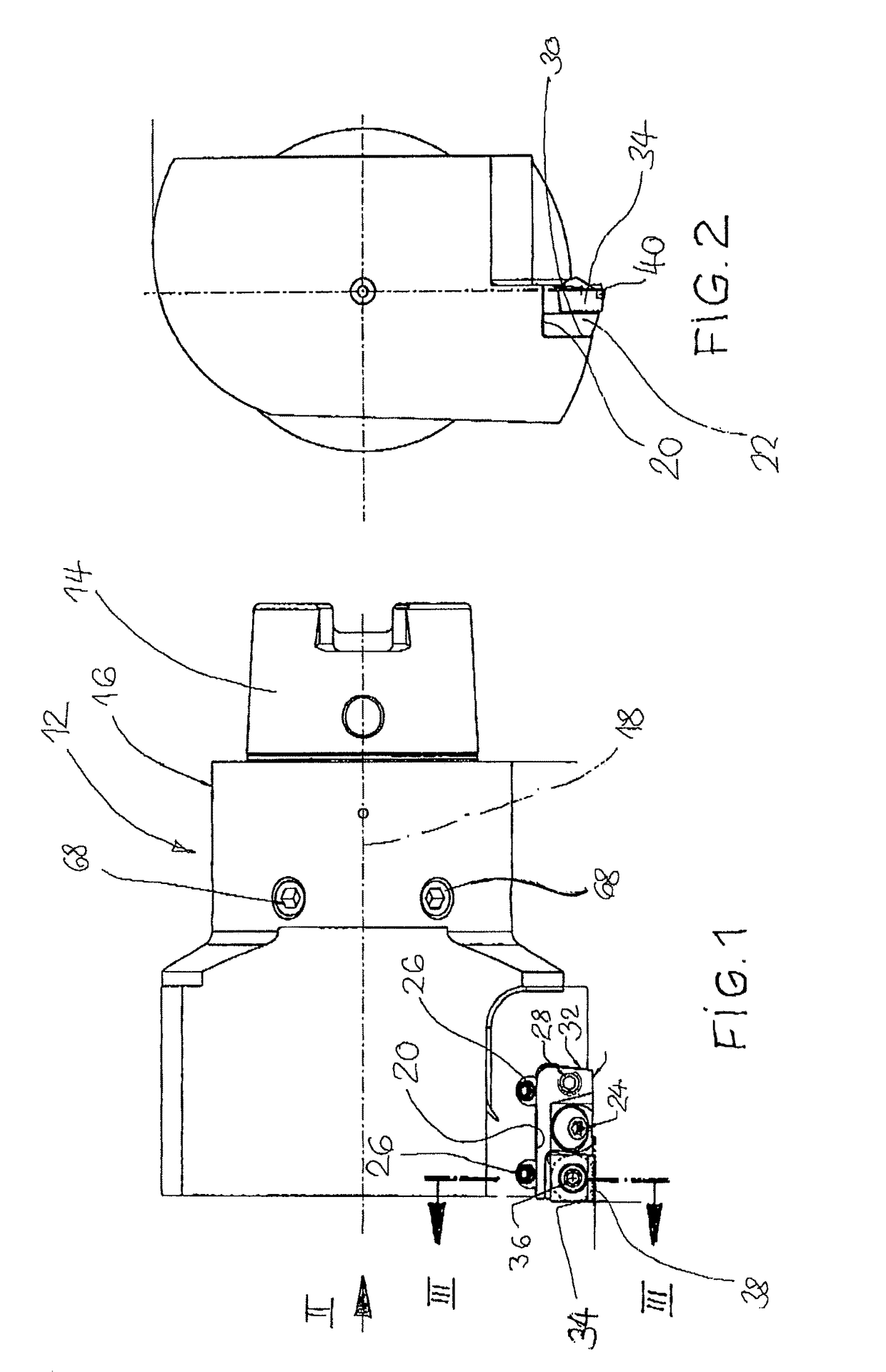

Device for the additive manufacture of a component

InactiveUS20160175935A1Free from damageRapid and simple for determiningAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyHigh energy beam

The invention relates to a device (10) for the additive manufacture of a component (12), comprising at least one coating device (14) for producing a powder layer (16) on a construction platform (18); at least one radiation source (20), in particular a laser, for producing a high-energy beam (24), by means of which the powder layer (16) in a construction surface area (22) can be melted and / or sintered locally to form a component layer (30); at least one deflection device (26), by means of which the high-energy beam (24) can be deflected onto different regions of the powder layer (16) and can be focused on the construction surface area (22); at least one measurement system (28), by means of which a cross-sectional geometry of the high-energy beam (24) on the powder layer (16) and / or the component layer (30) can be determined; and at least one equilibration device (32).

Owner:MTU AERO ENGINES GMBH

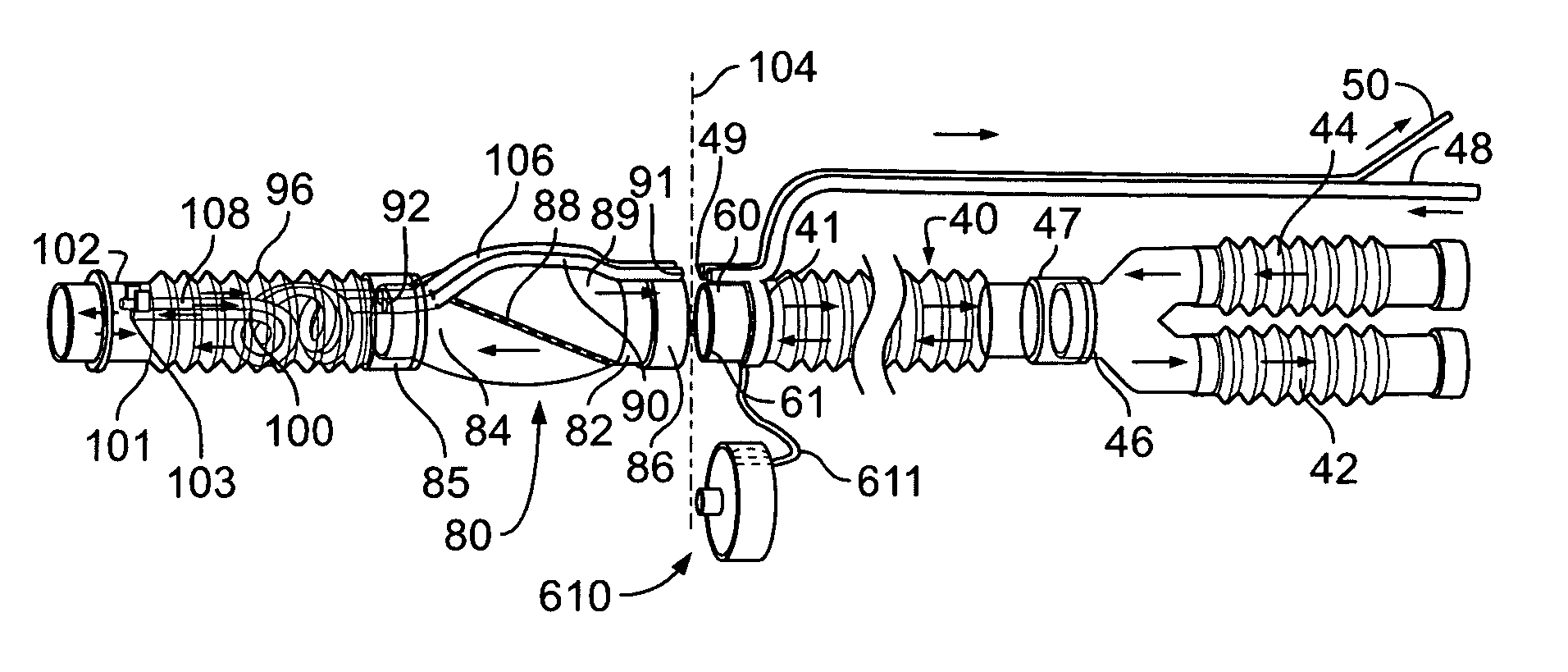

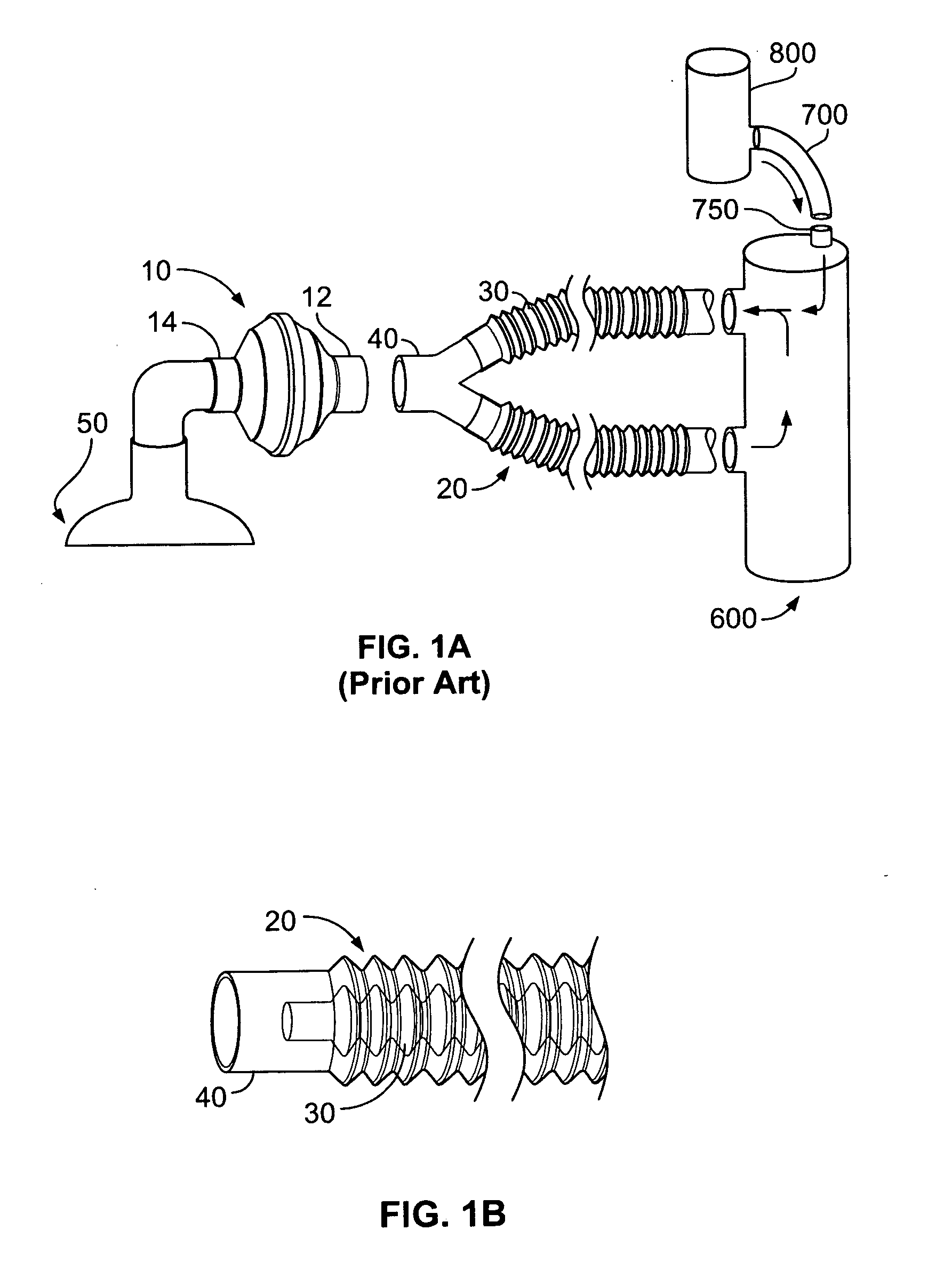

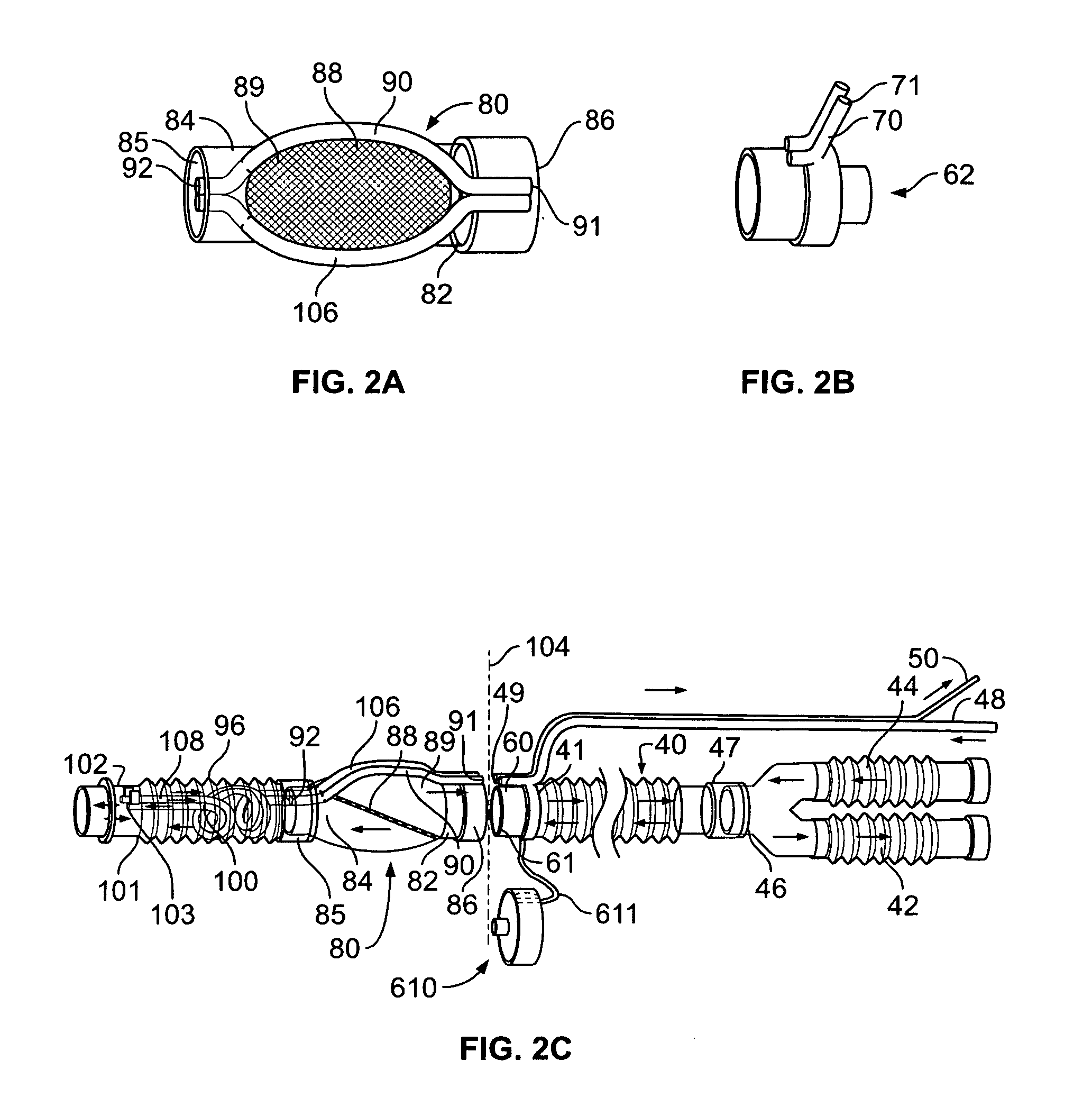

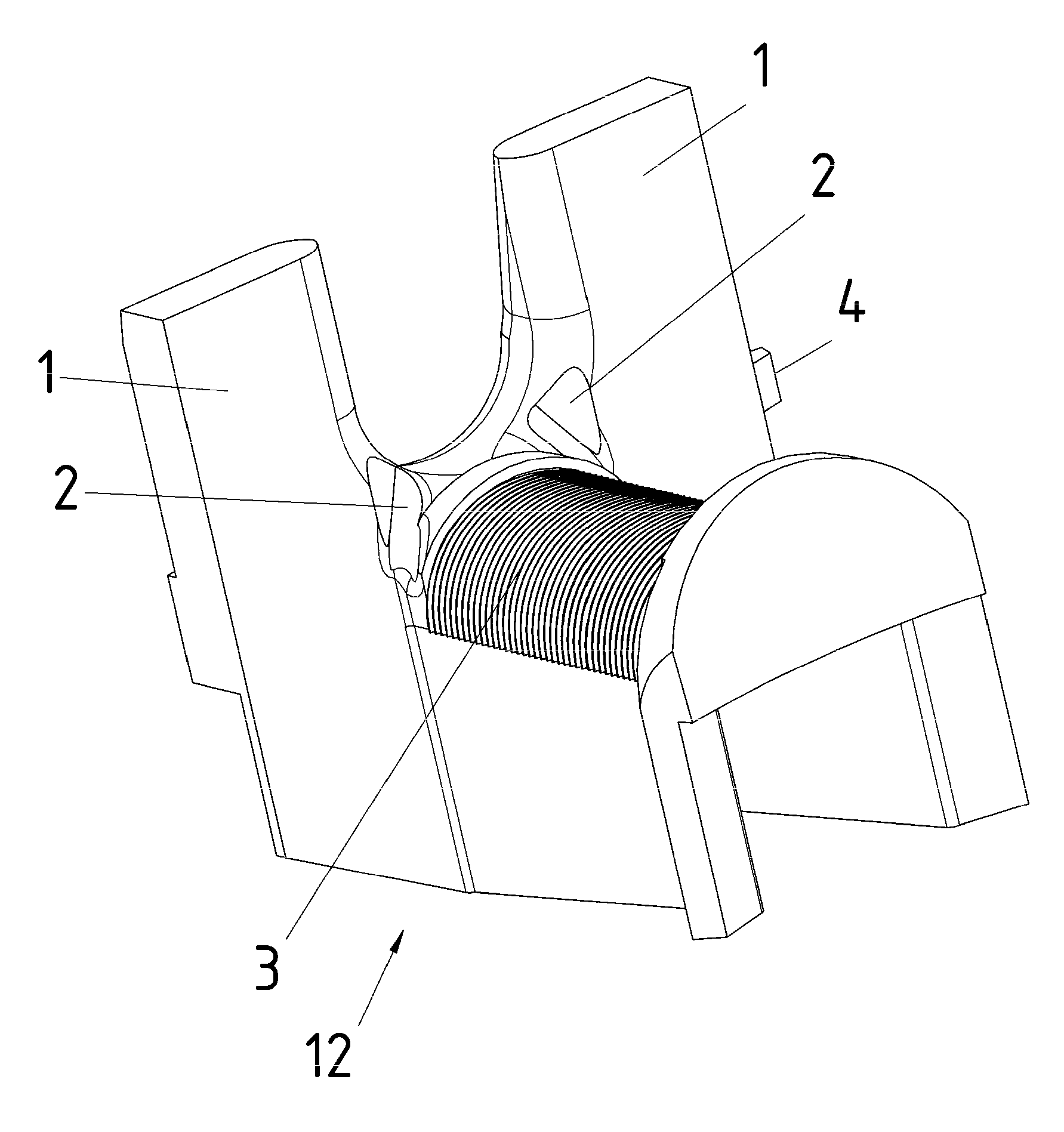

Multifunctional integrated filter and breathing conduit

InactiveUS20050188990A1Minimizing mixing spaceReduced dimensionRespiratorsBreathing filtersMedical wasteCatheter

A device for use in constructing a breathing circuit has at least a first tube and a filter; the filter has a proximal and a distal end; the first tube is attached to the filter distal end. A second tube can be attached to the filter proximal end, wherein the second tube can be detached from the filter for reuse in a breathing circuit formed with the foregoing components. The filter and the first tube may be disposed of after a single use. The first tube has a length sufficient to maintain the filter at a desired distance from a patient airway device when connected thereto. In a preferred embodiment, a fresh gas outlet is provided at the distal end of the first tube resulting in minimal or substantially no mixing space in the circuit, while the disposable first tube and filter create less medical waste than that created by prior art circuits. Mixing space refers to space distal of the fresh gas outlet into the circuit where the fresh gases can mix with recirculated or other gases. In embodiments, the mixing space is less than 15 cm3 or less than about 5 cm3, and the distal disposable filter and tube device is less than 50 cm in length.

Owner:FUKUNAGA ATSUO F +2

Image forming system employing effective optical scan-line control device

InactiveUS20060209166A1Avoid serious deviationRecording apparatusInking apparatusScan lineLight beam

An optical scanning characteristic control method is applied to an optical scanning system in which a beam is deflected, and the deflected beam is converged and directed toward a scanning surface, so that optical scanning of the scanning surface is performed by an optical spot formed thereon by the deflected beam. The method comprising the steps of a) disposing a beam deflection control device on the light path of the beam before it is incident on the scanning surface; and b) controlling a beam deflection amount of the beam deflecting device provide to an incident beam so as to control a scanning characteristic of the optical scanning.

Owner:RICOH KK

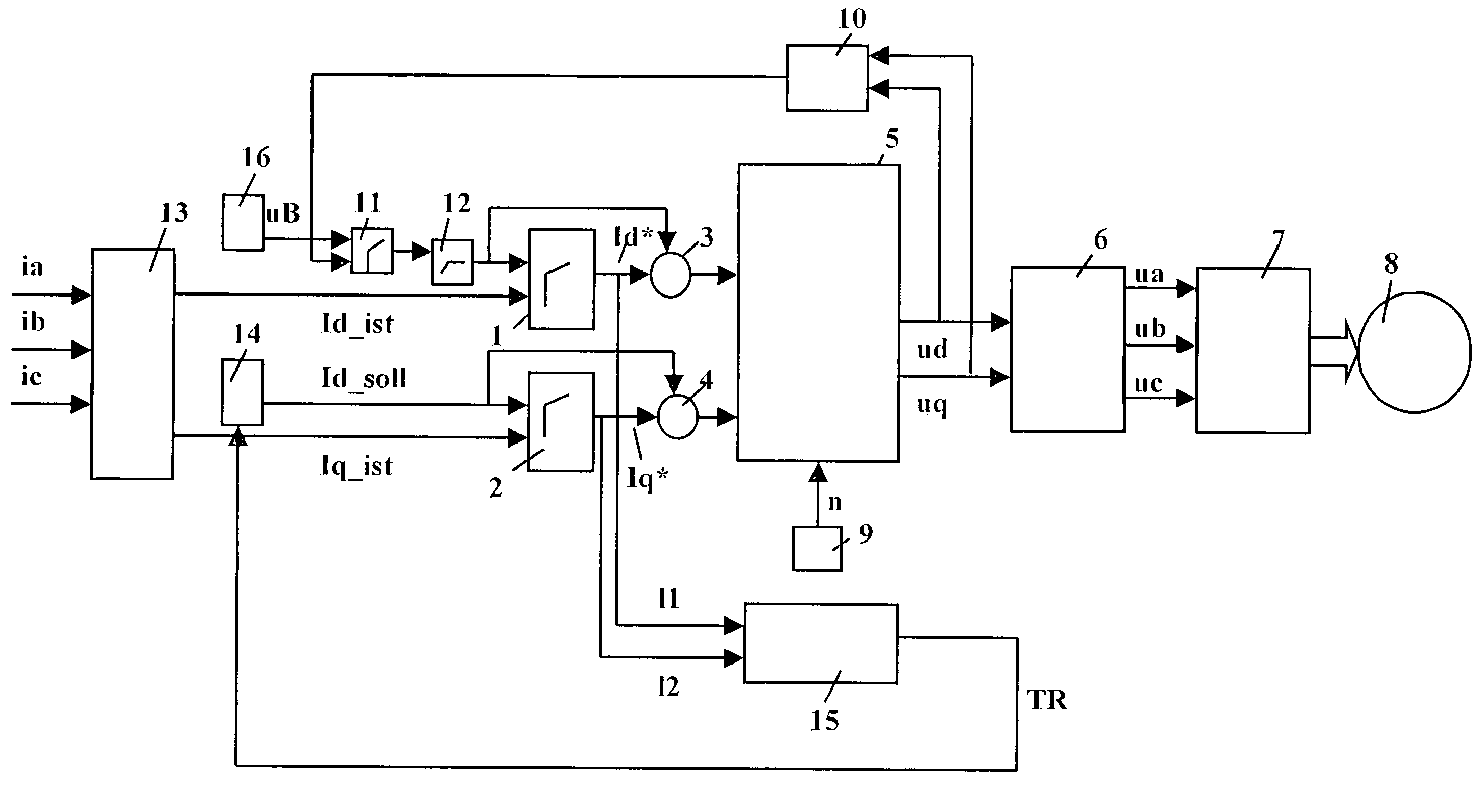

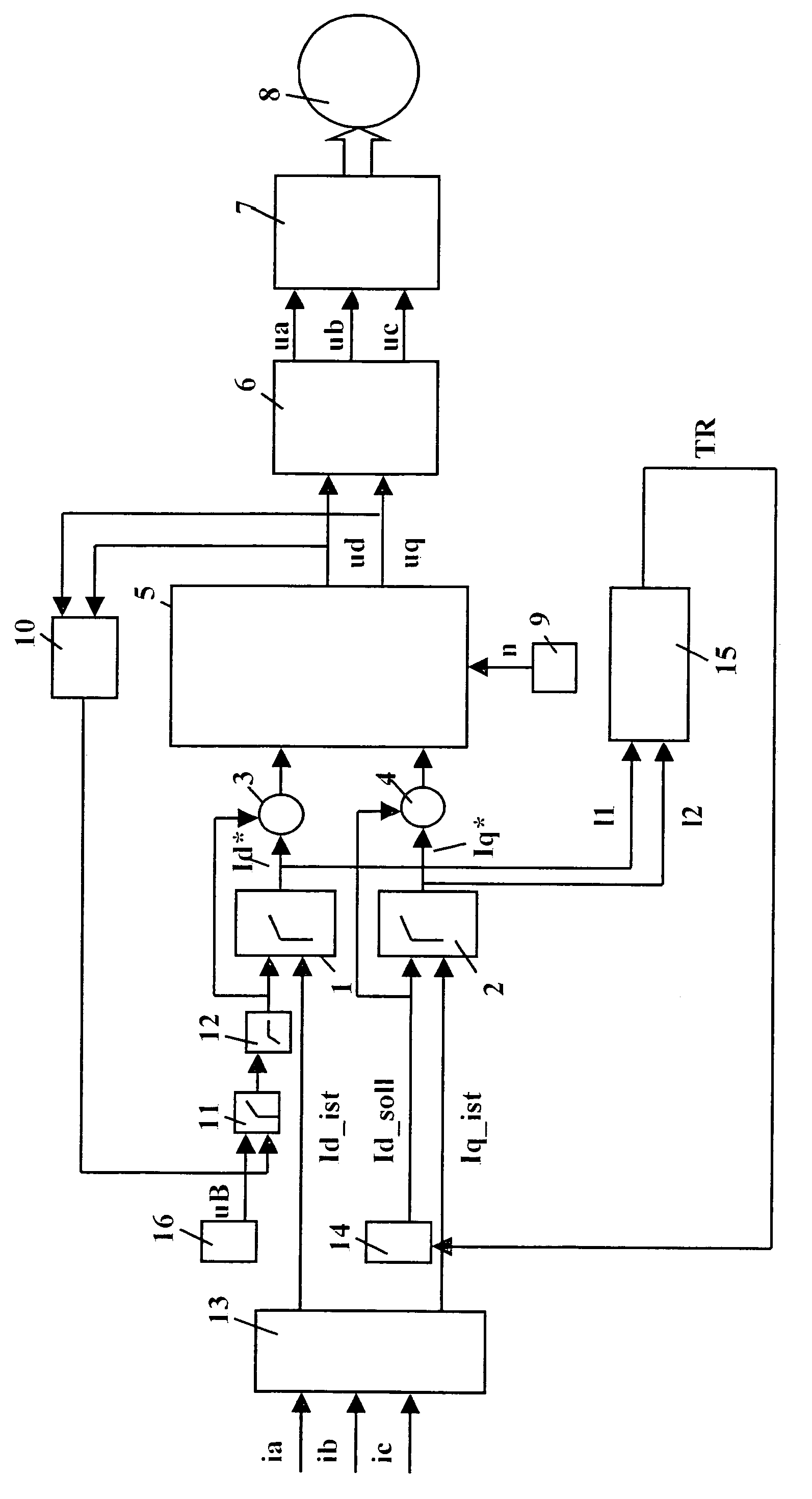

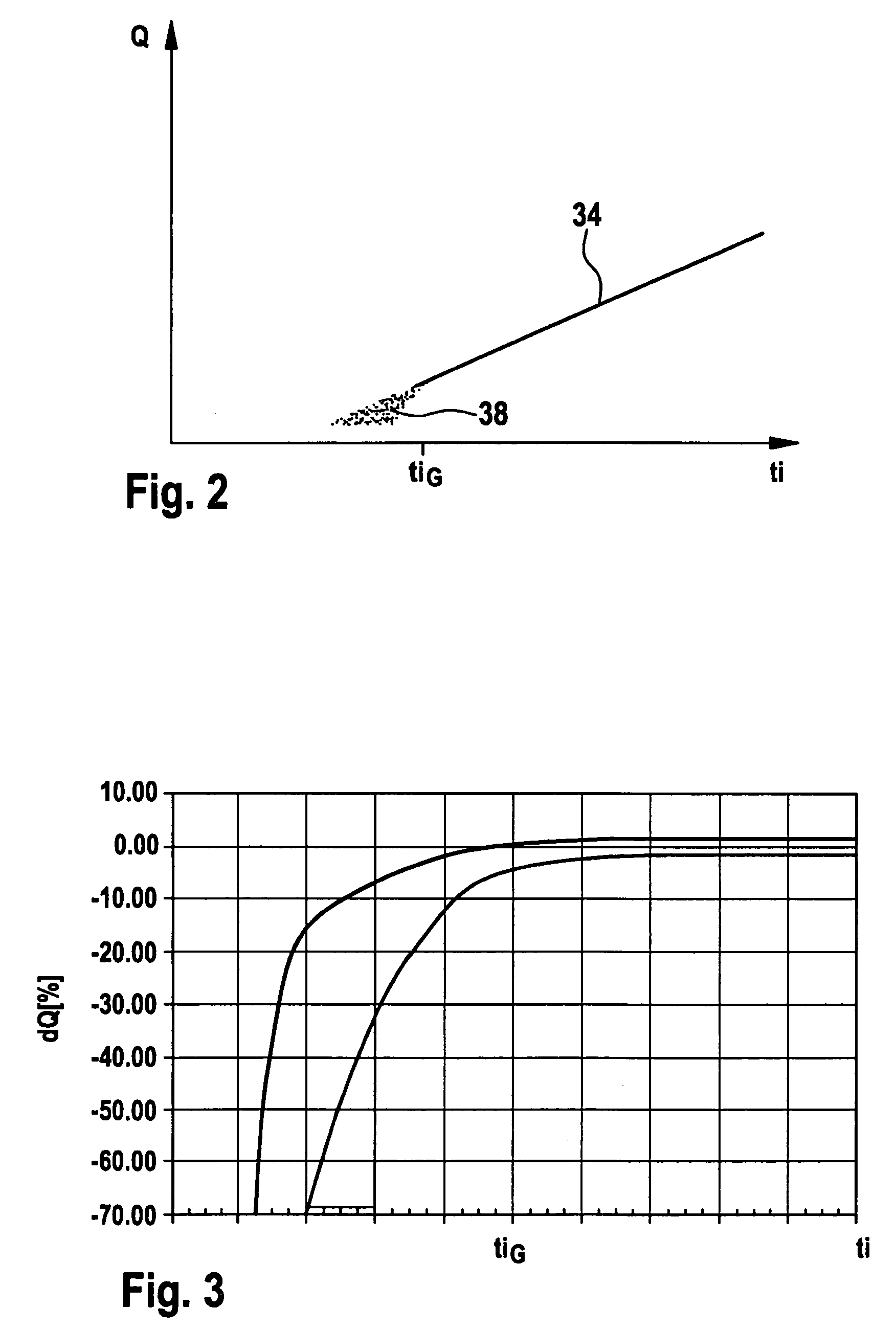

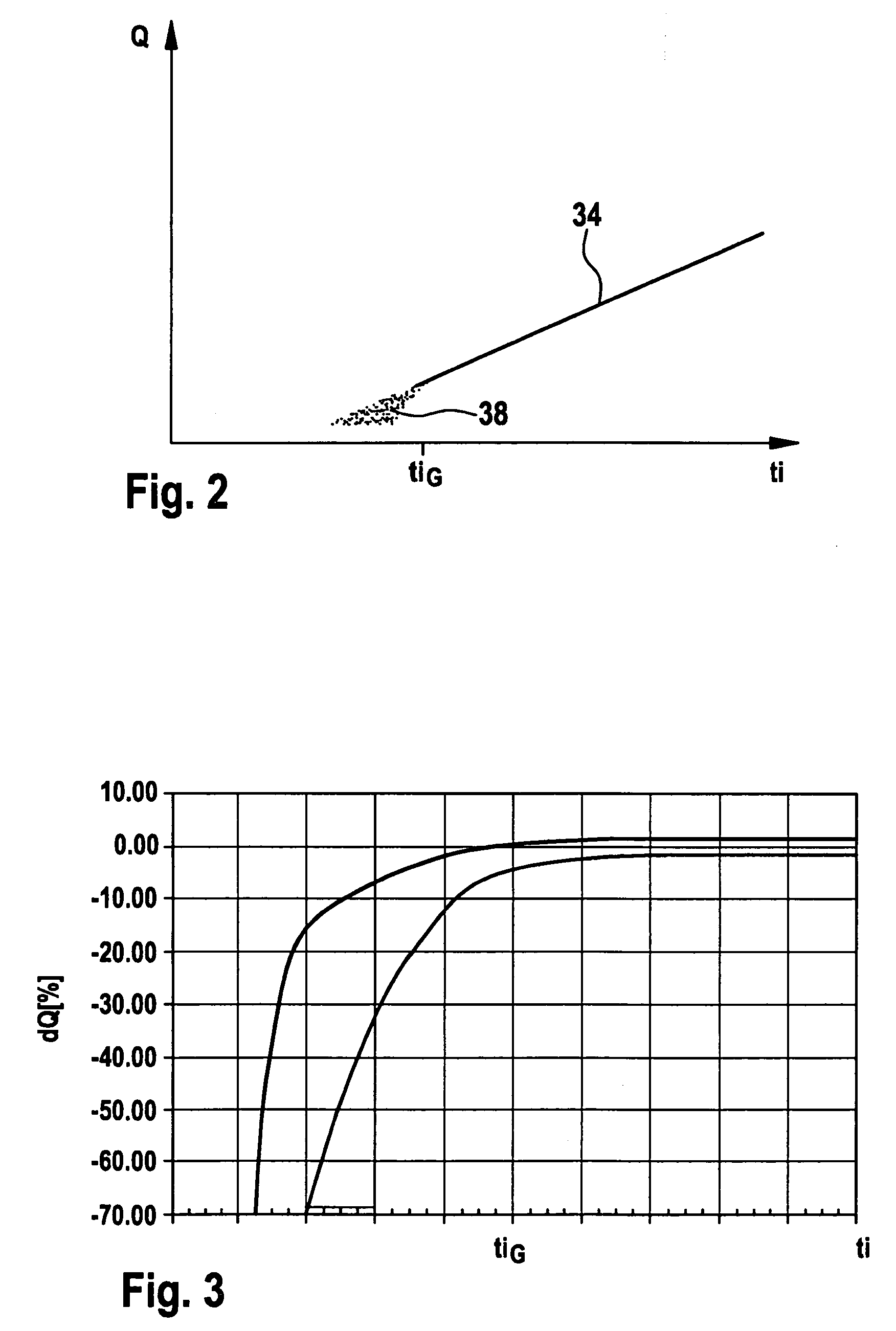

Method and device for determining the rotor temperature in a permanent magnet-excited synchronous machine

InactiveUS7099793B2Accurate informationAvoid serious deviationThermometer detailsCommutation monitoringEngineeringElectrical current

A method and a device for determining the rotor temperature in a permanent-magnet-excited synchronous machine are described, in which field-oriented regulation takes place. An estimator is provided which is supplied with the manipulated variables for the direct-axis current and the cross current made available by a direct-axis current controller and a cross current controller. The estimator determines an estimate for the rotor temperature using the manipulated variables mentioned and a temperature model of the synchronous machine.

Owner:ROBERT BOSCH GMBH

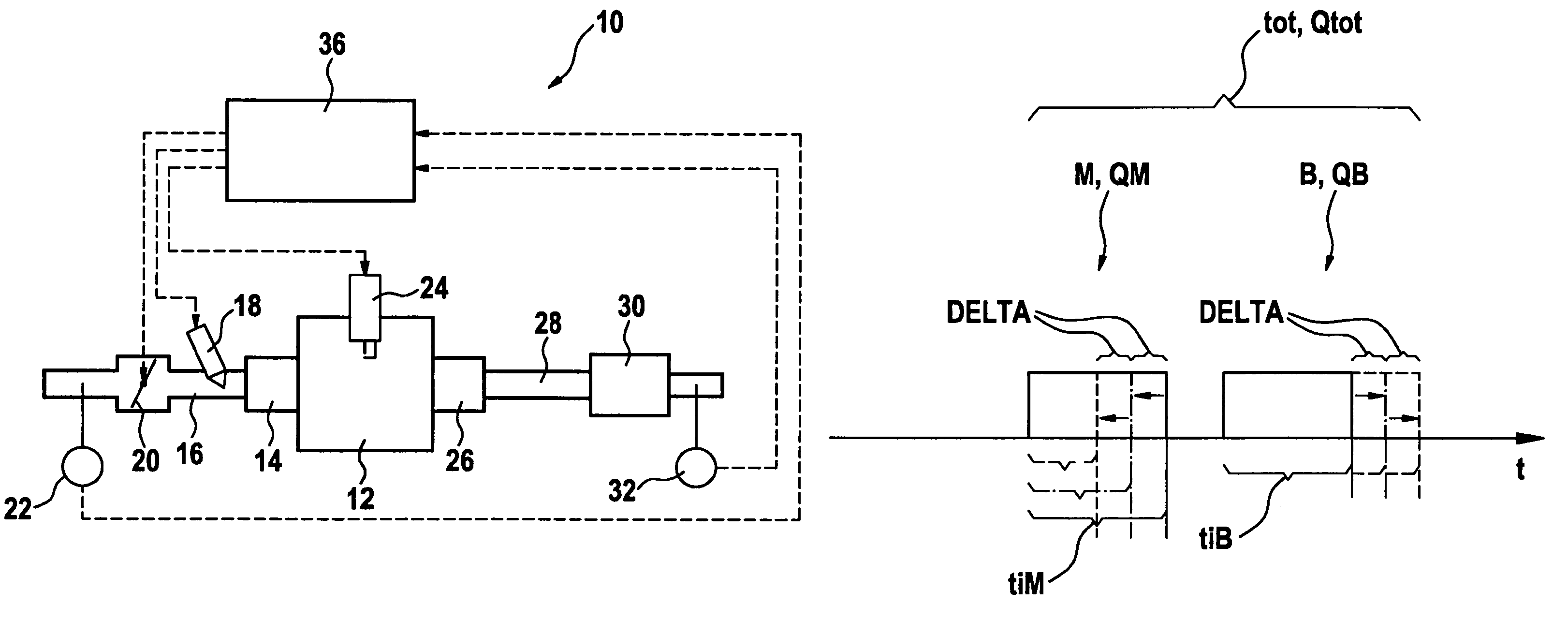

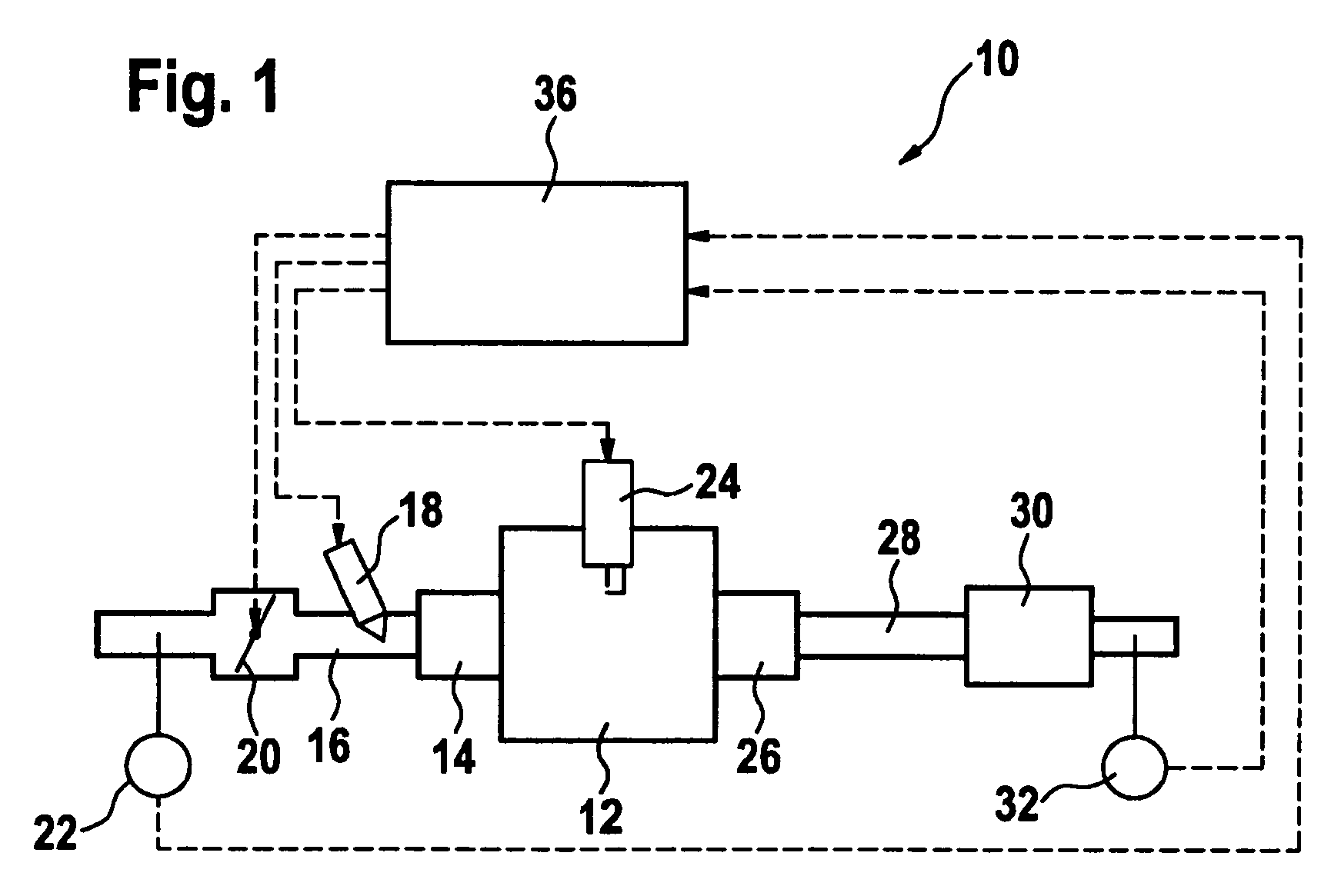

Method for operating an internal combustion engine

InactiveUS7881857B2Guaranteed uptimeTorque and running smoothnessElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

In a method for operating an internal combustion engine, the fuel is supplied to at least one combustion chamber via at least one injector, which method includes the following steps: a) a total injection is divided into a basic injection and at least one measured injection; b) the injection time of the measured injection is successively decreased and the injection time of the basic injection is successively increased so that a total injection quantity ascertained from a valve characteristic curve remains the same.

Owner:ROBERT BOSCH GMBH

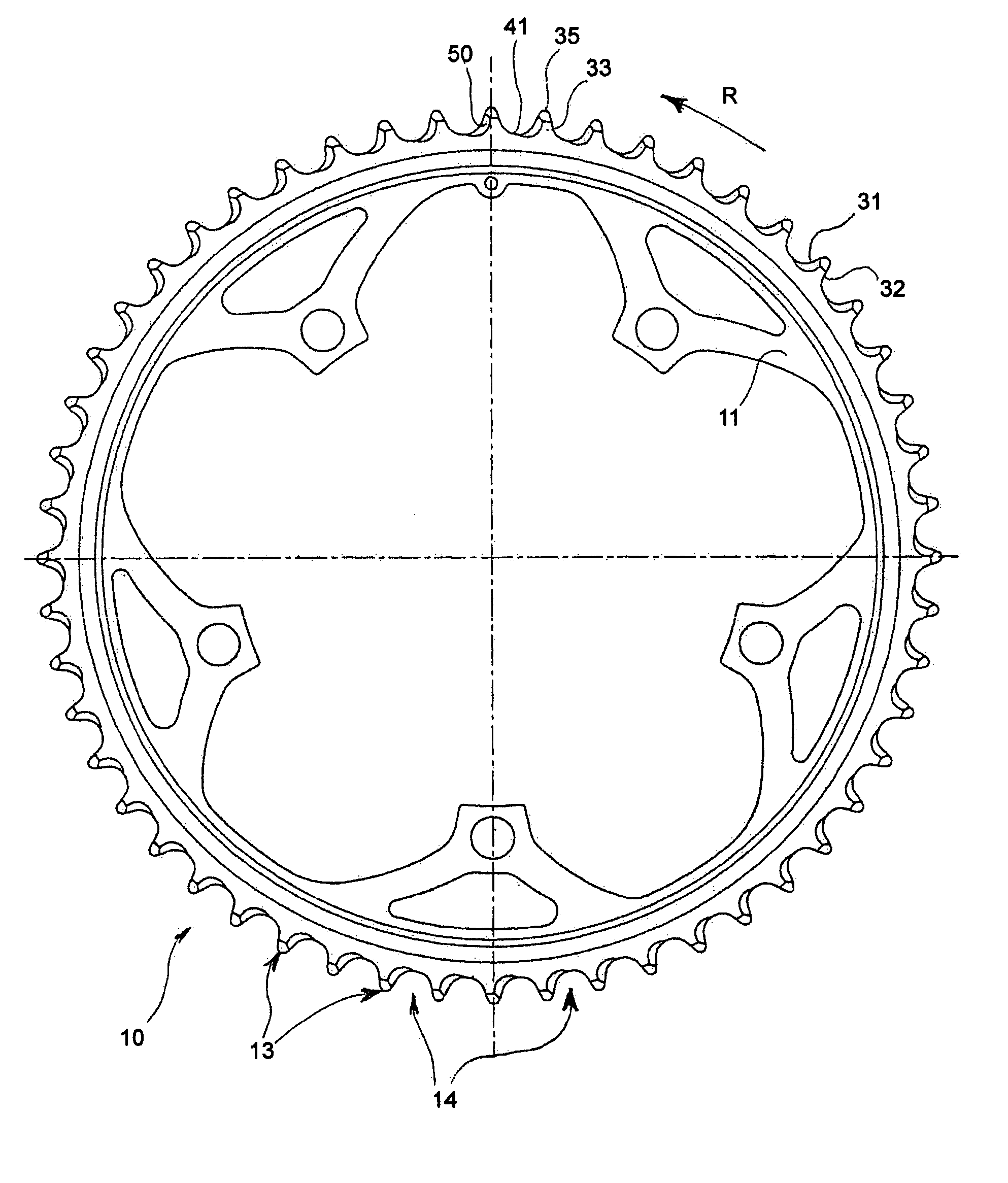

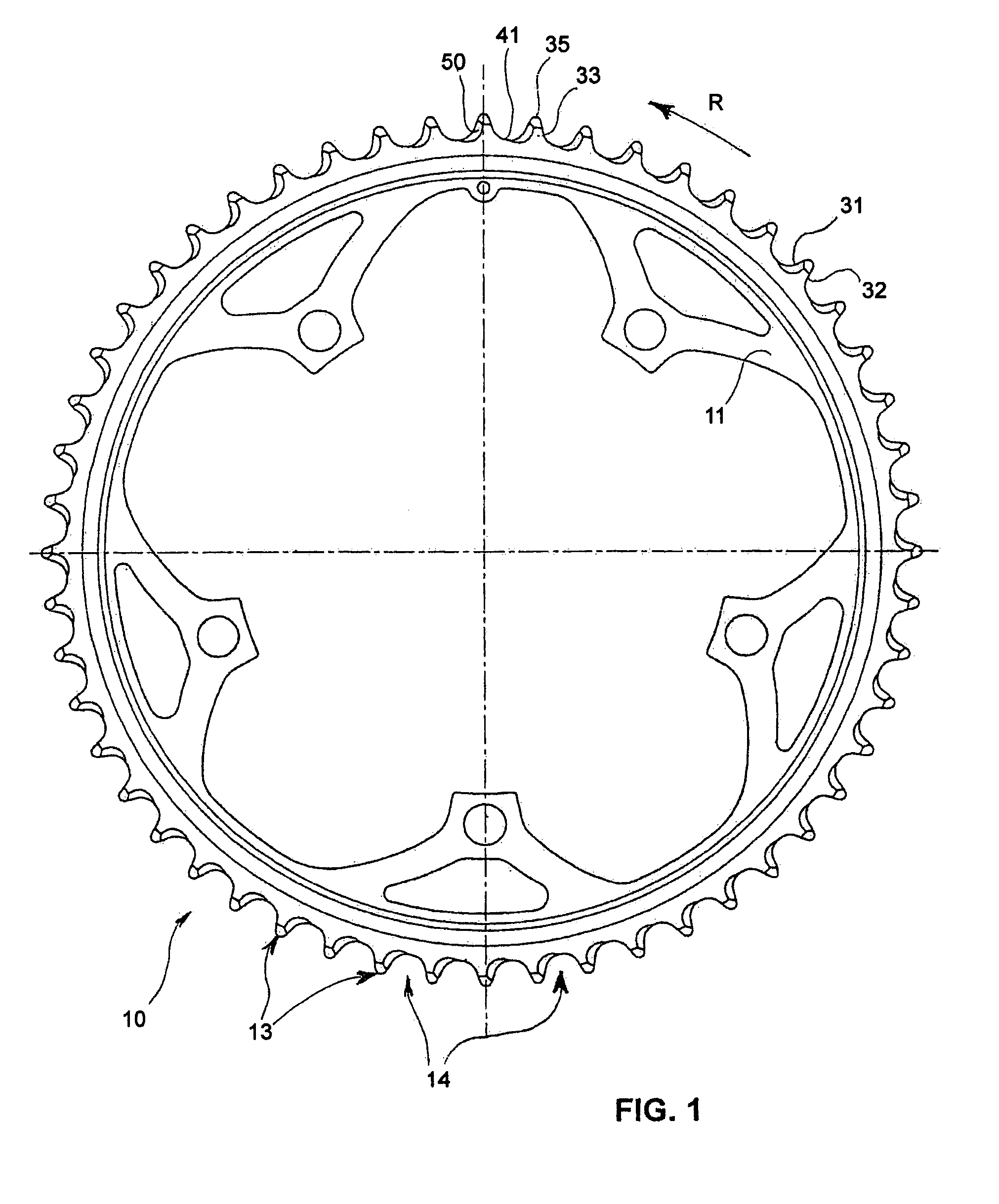

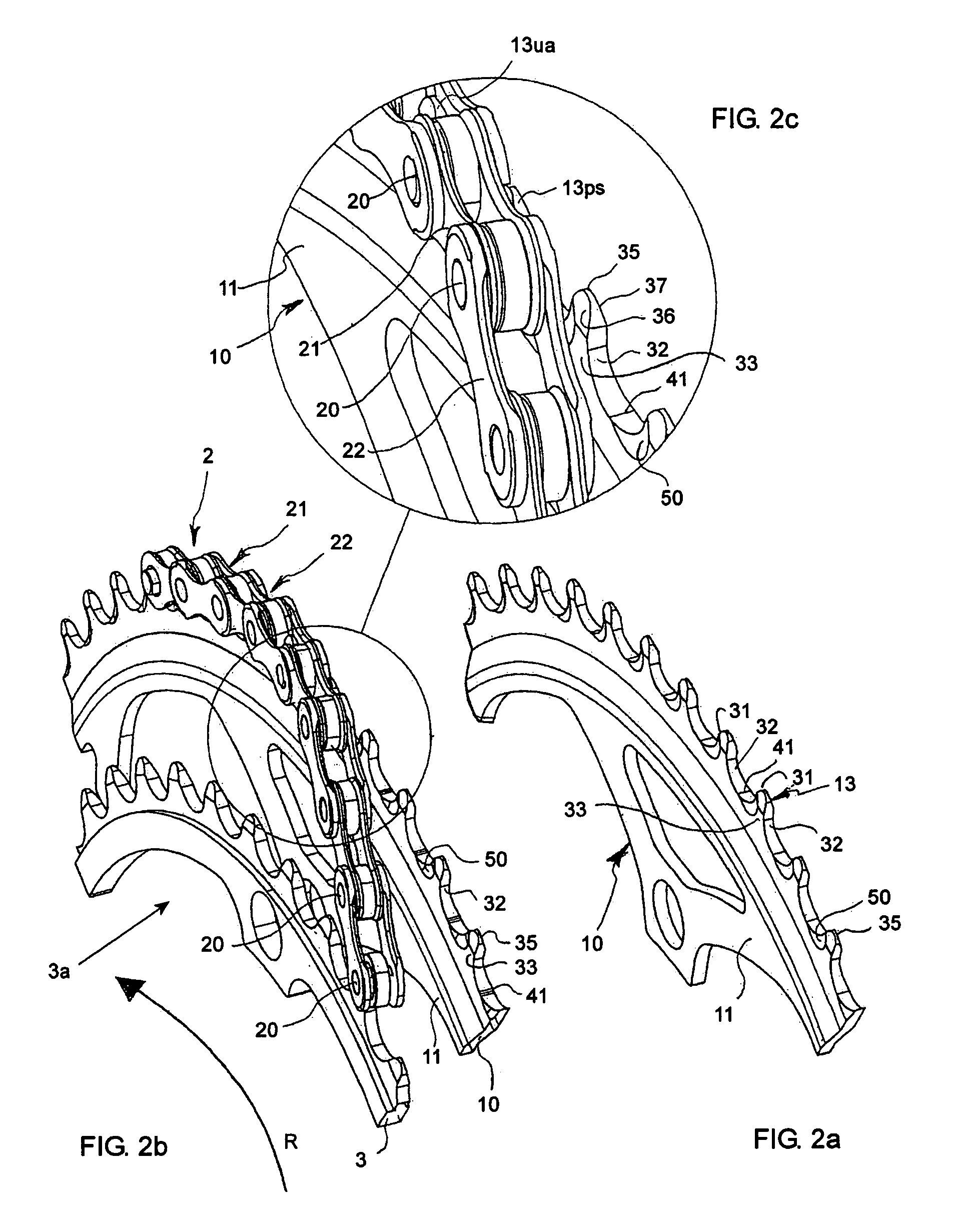

Sprocket of a chain transmission for a bicycle

InactiveUS7258638B2Easy to disengageReduce distractionsChain/belt transmissionPortable liftingSprocketEngineering

Owner:CAMPAGNOLO SRL

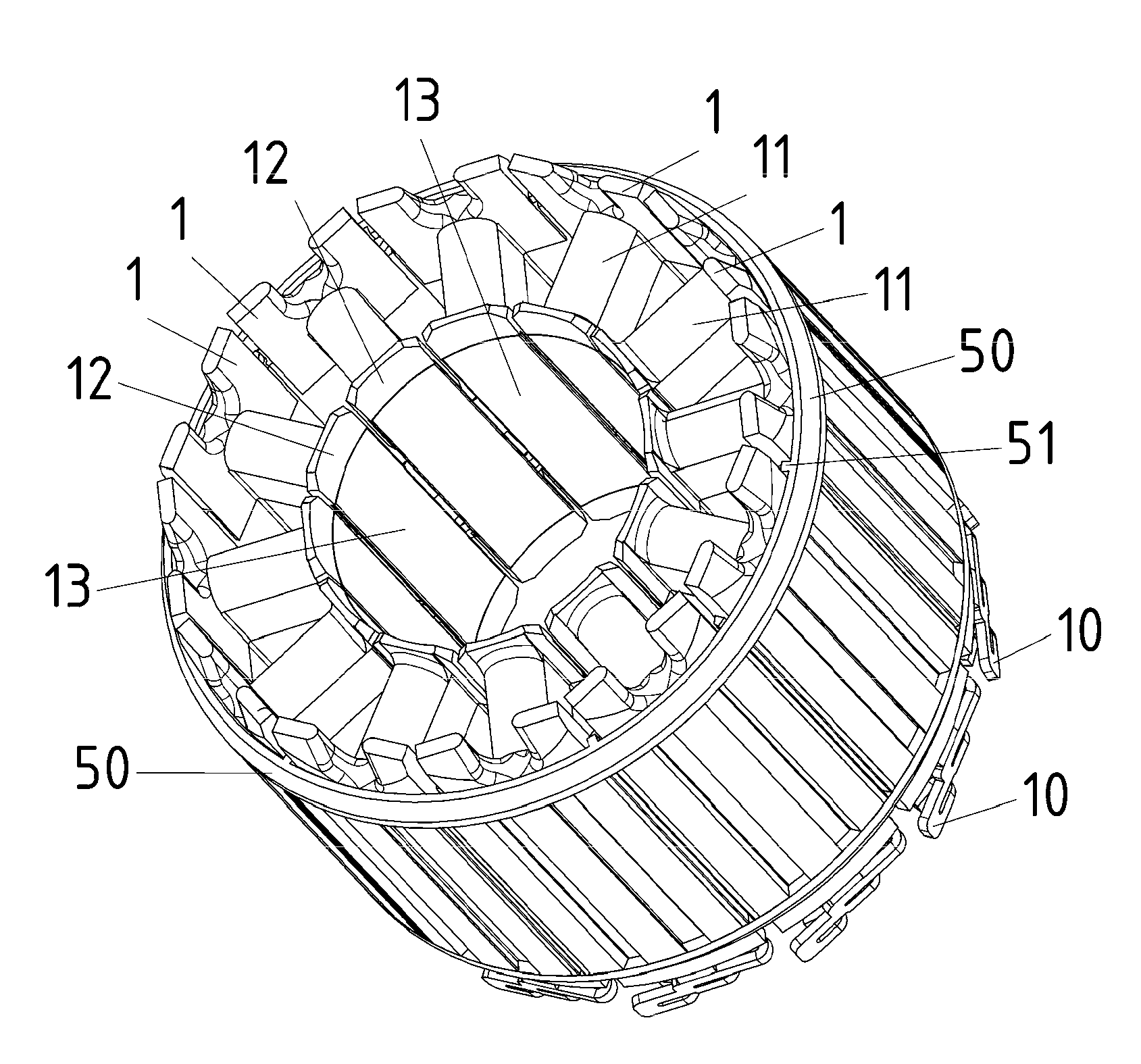

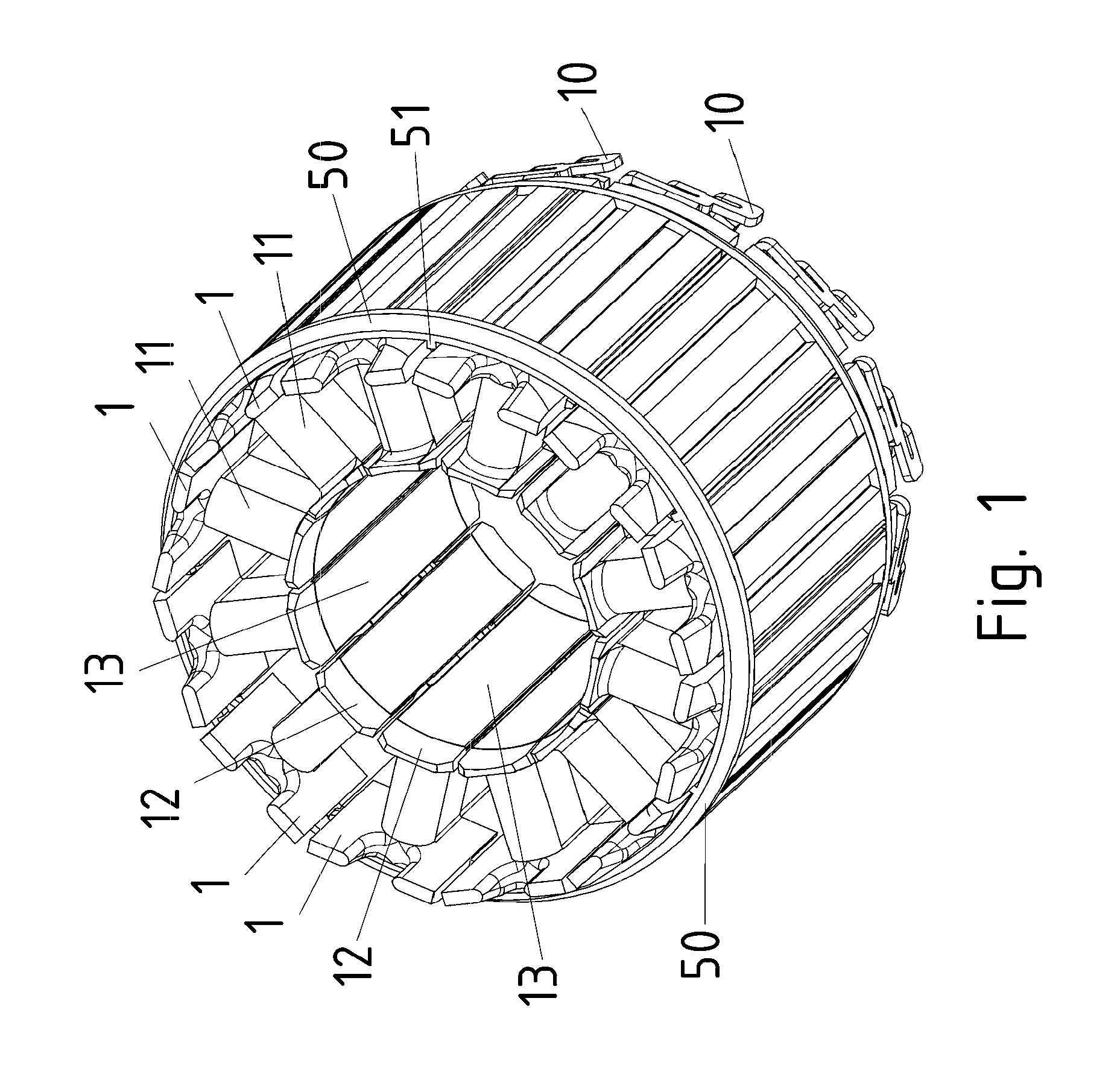

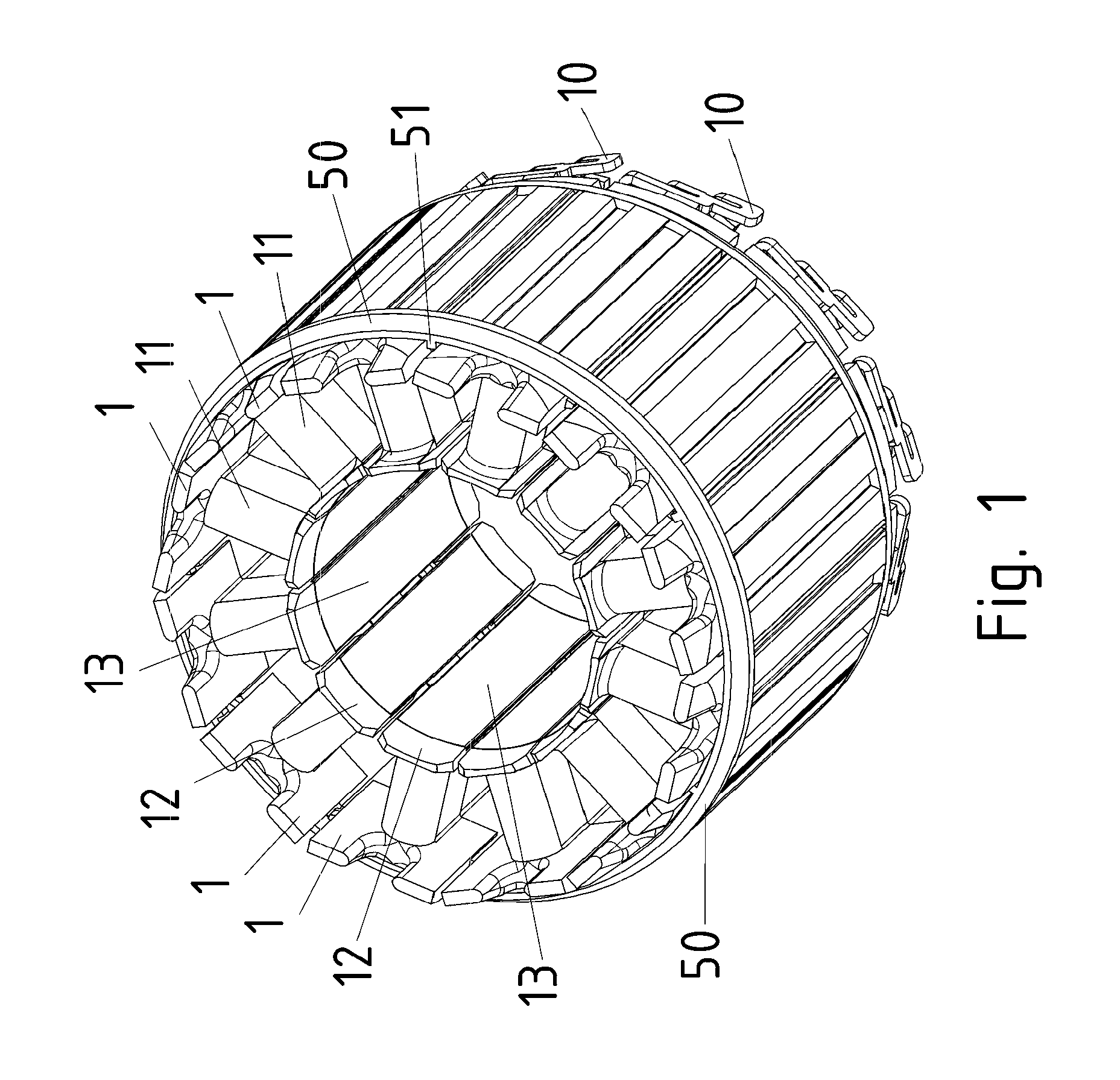

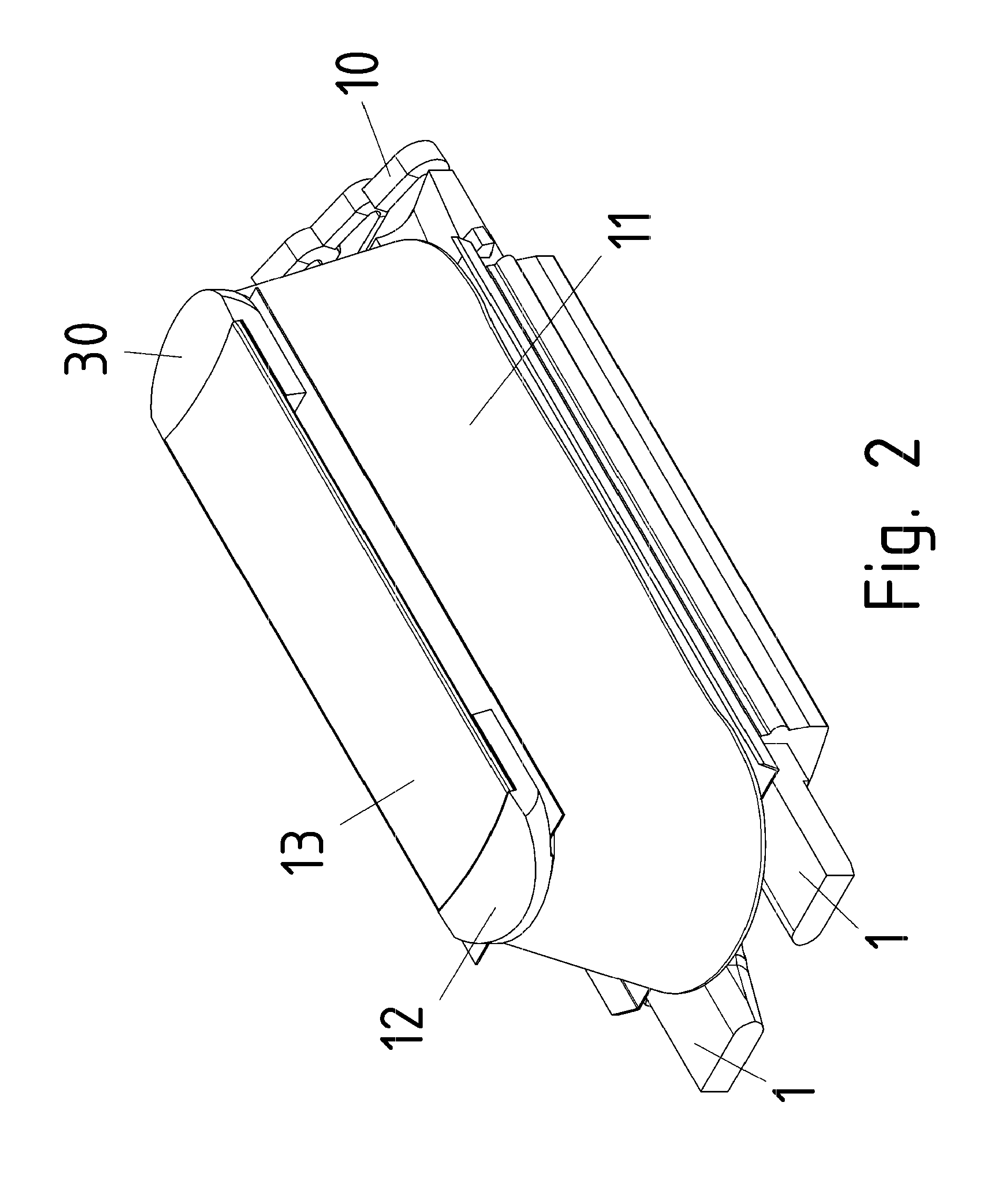

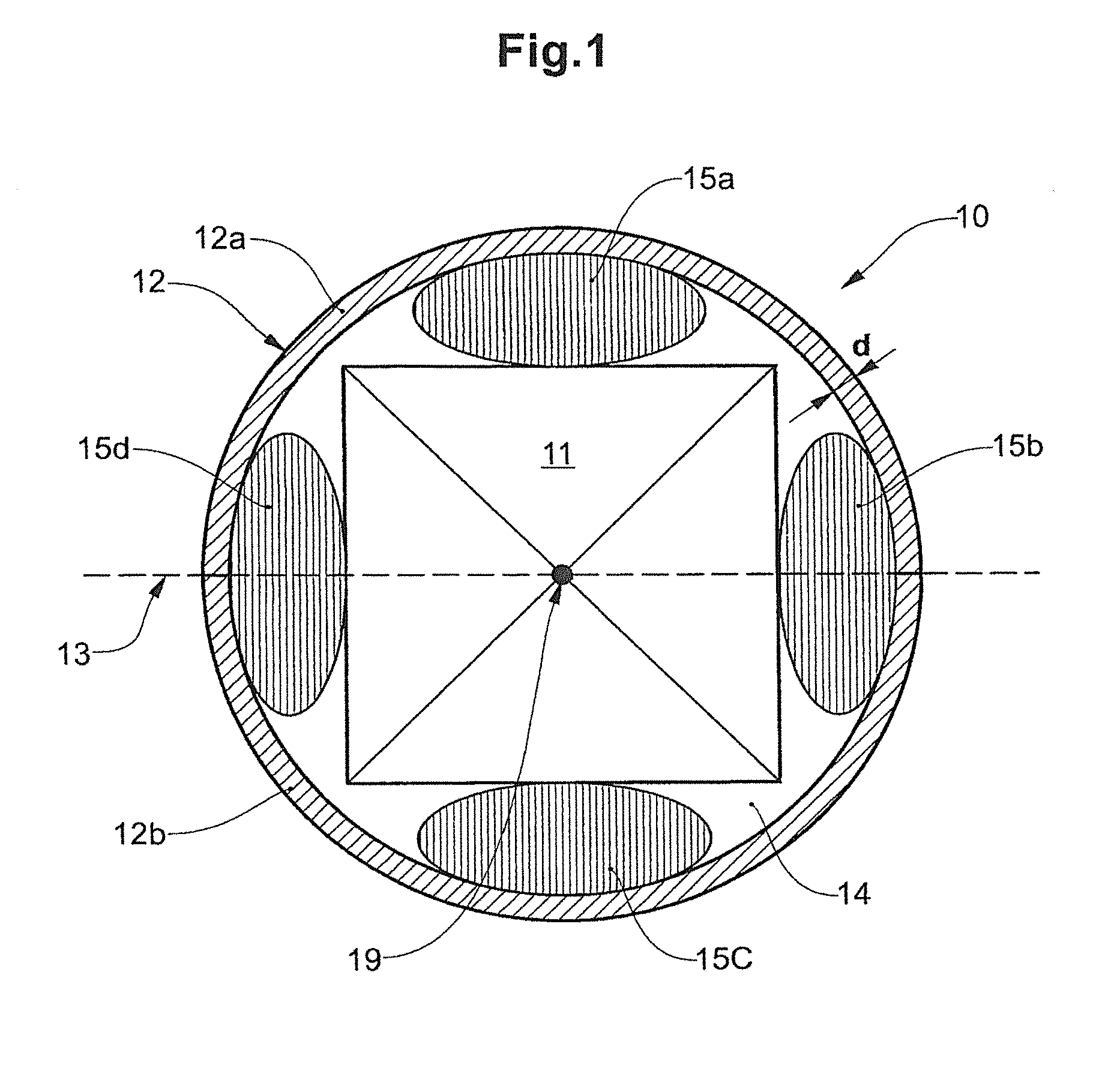

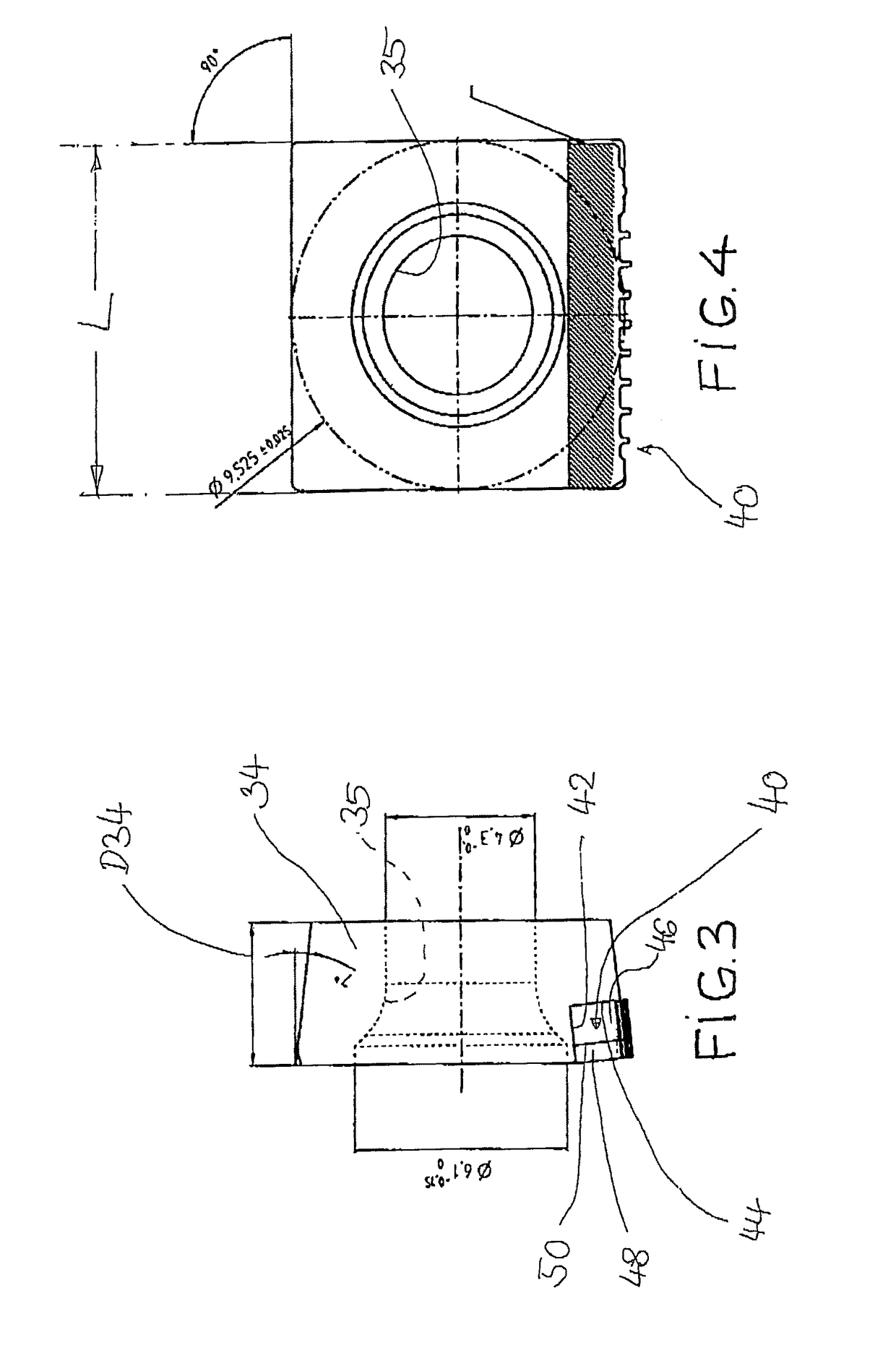

Electric Motor

ActiveUS20110115317A1Simplify production of electricImprove product qualityWindingsMagnetic circuitEngineeringConductor Coil

An electric motor includes a stator made up of individual segments disposed in the circumferential direction, each individual segment including a core stack around which a winding is provided and at whose axial terminal regions end caps are provided, the winding being produced by a winding wire, an end cap including at least one dome, in particular for delimiting the region of the winding, a wire inlet duct for rerouting the winding wire being provided in the base region of the dome, grooves being provided on the end cap, the distance of one groove with respect to the radially following groove and the diameter of the curvature of the respective groove being smaller than the diameter of the winding wire.

Owner:SEW-EURODRIVE GMBH & CO KG

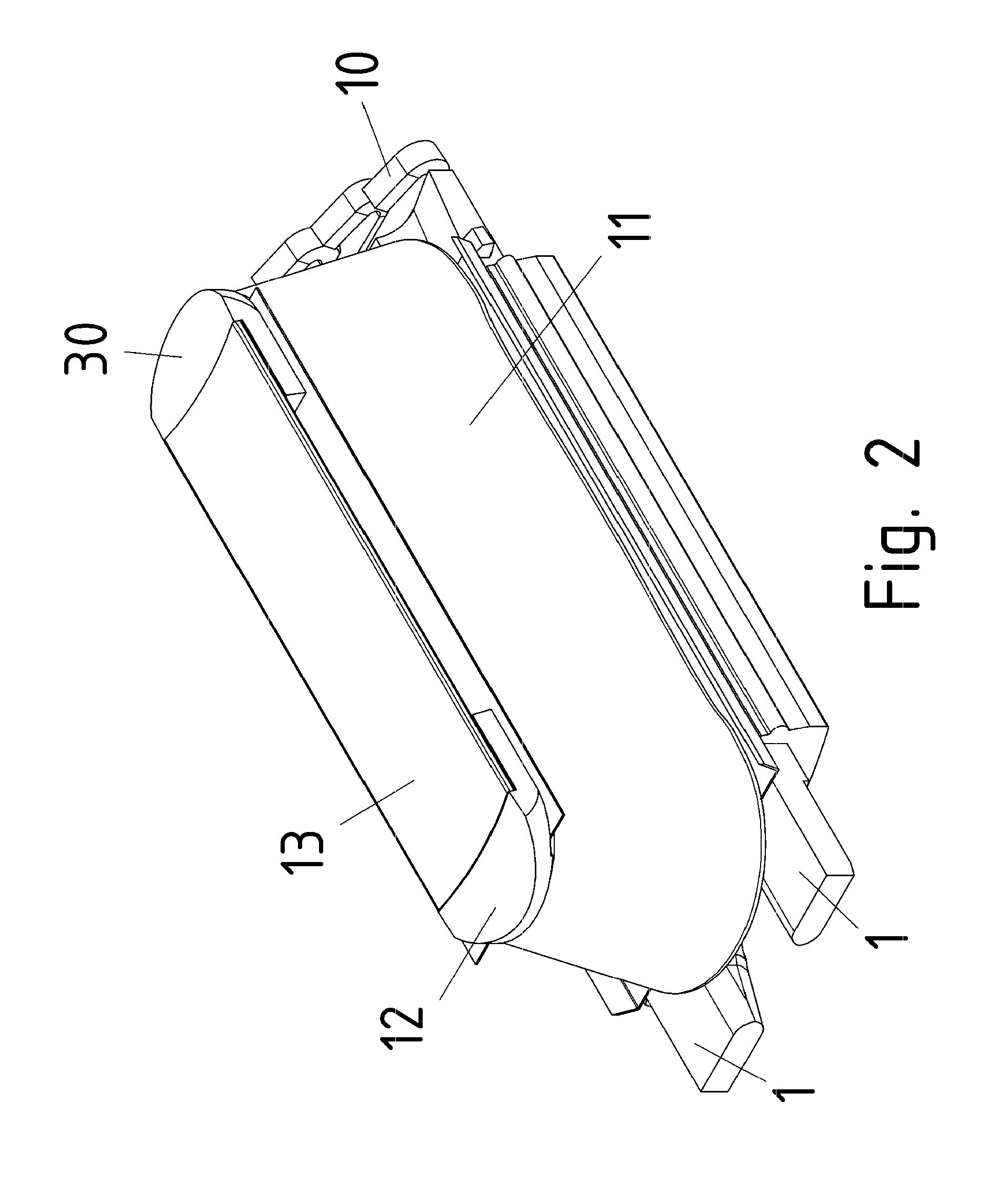

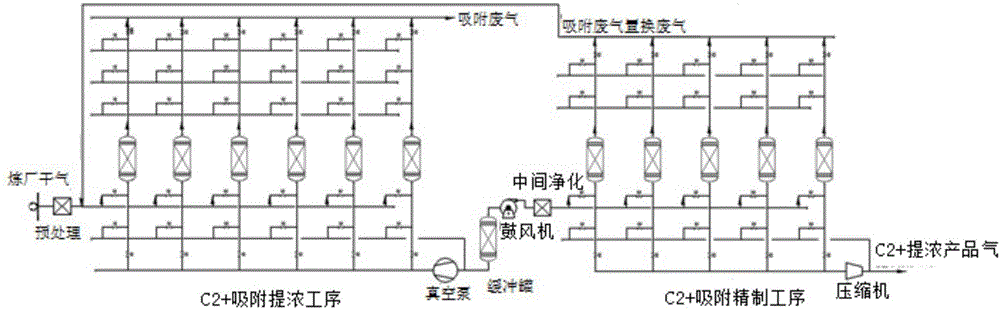

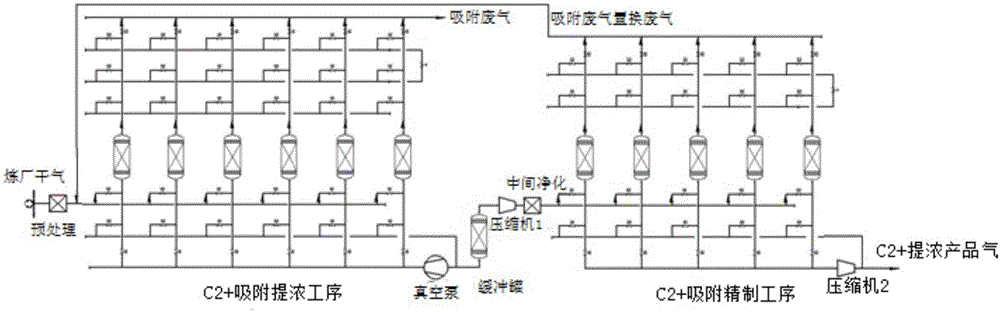

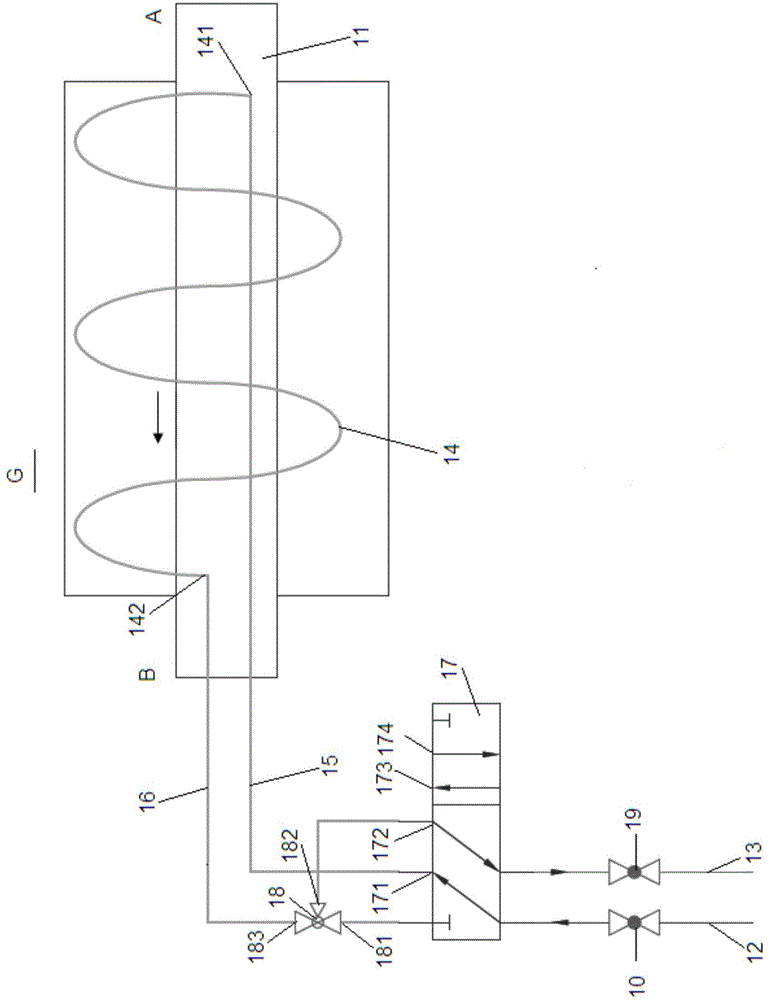

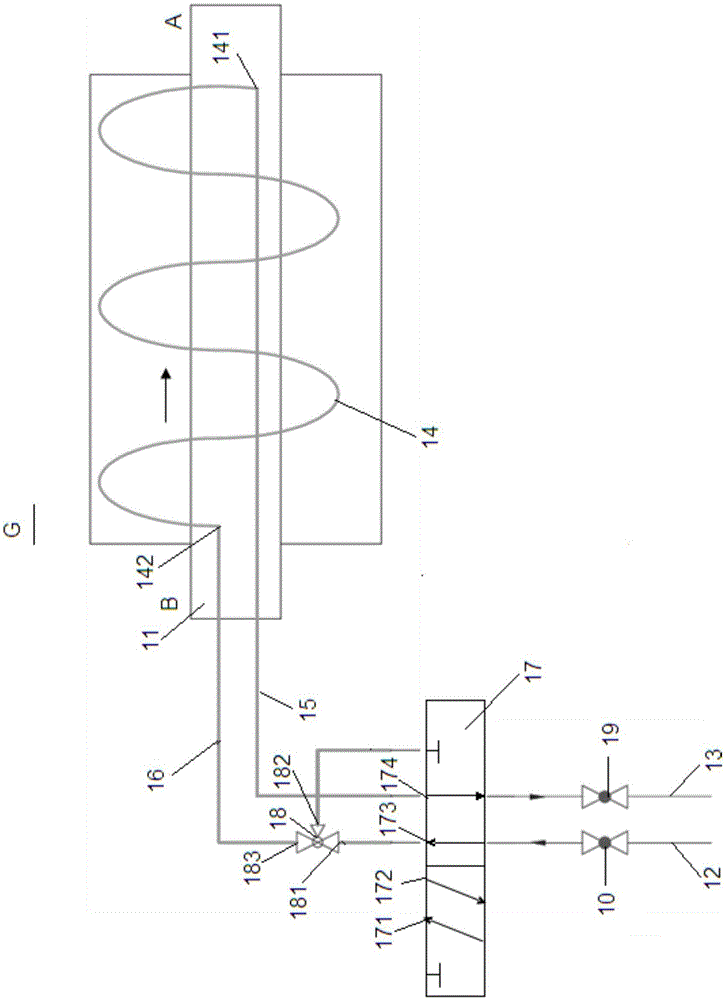

Two-stage PSA method for recovering C2+ from refinery dry gas according to concentration

ActiveCN107433107ABreak adsorption equilibriumReduce methane contentProductsGas treatmentHydrogenPetrochemical

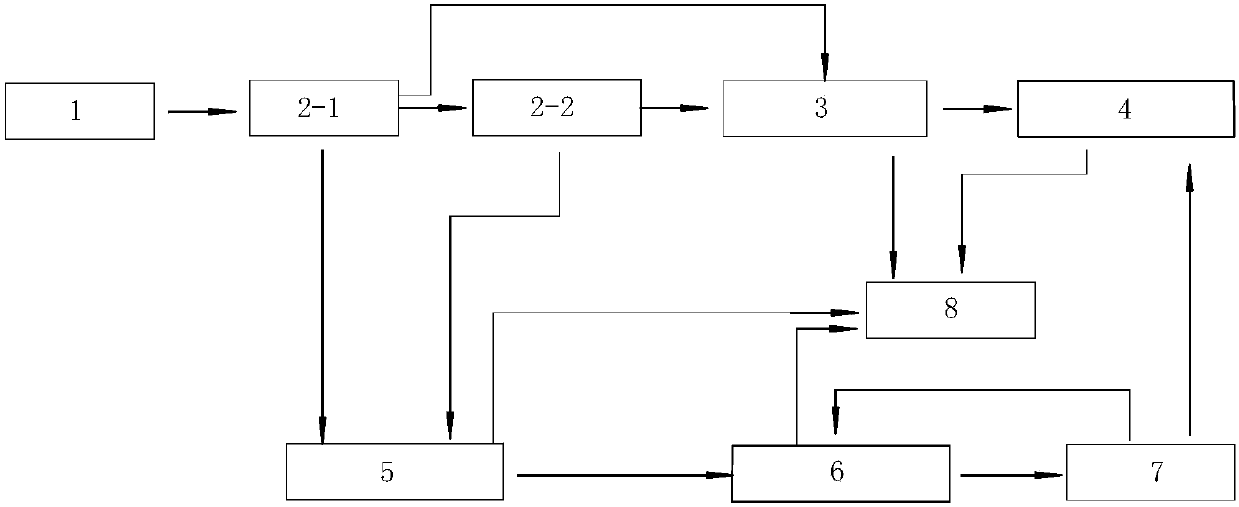

The invention discloses a two-stage PSA method for recovering C2+ from refinery dry gas according to concentration, which relates to the technical field of separating and recovery of in valuable substances in petrochemical tail gas. The method comprises a pretreatment process, a C2+ adsorption concentration process, an intermediate purifying process, and a C2+ adsorption refining process, wherein, the pre-treated refinery mixed dry gas is introduced into the CO2+ adsorption concentration process, then flowed non-adsorption phase gas is the adsorption exhaust gas, or directly taken as hydrogen (H2) product gas, or taken as fuel gas, or taken as raw material gas for extraction of hydrogen for output; the flowed adsorption phase gas forms the intermediate gas through the intermediate purifying process, and then is introduced into the C2+ adsorption refining process for refining, the flowed non-adsorption phase gas is taken as the raw material gas for mixing with the refinery mixed dry gas, a mixture is returned to the C2+ adsorption concentration process; the flowed adsorption phase gas has the C2+ concentration being more than 90-95% (a volume ratio), wherein the methane impurity concentration is less than 4%, the flowed adsorption phase gas is taken as the C2+ concentrate product gas for output, and the yield of C2+ is more than 90-95%.

Owner:SICHUAN TECHAIRS

Method for Operating an Internal Combustion Engine

InactiveUS20090299604A1Guaranteed uptimeTorque and running smoothnessElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

In a method for operating an internal combustion engine, the fuel is supplied to at least one combustion chamber via at least one injector, which method includes the following steps: a) a total injection is divided into a basic injection and at least one measured injection; b) the injection time of the measured injection is successively decreased and the injection time of the basic injection is successively increased so that a total injection quantity ascertained from a valve characteristic curve remains the same.

Owner:ROBERT BOSCH GMBH

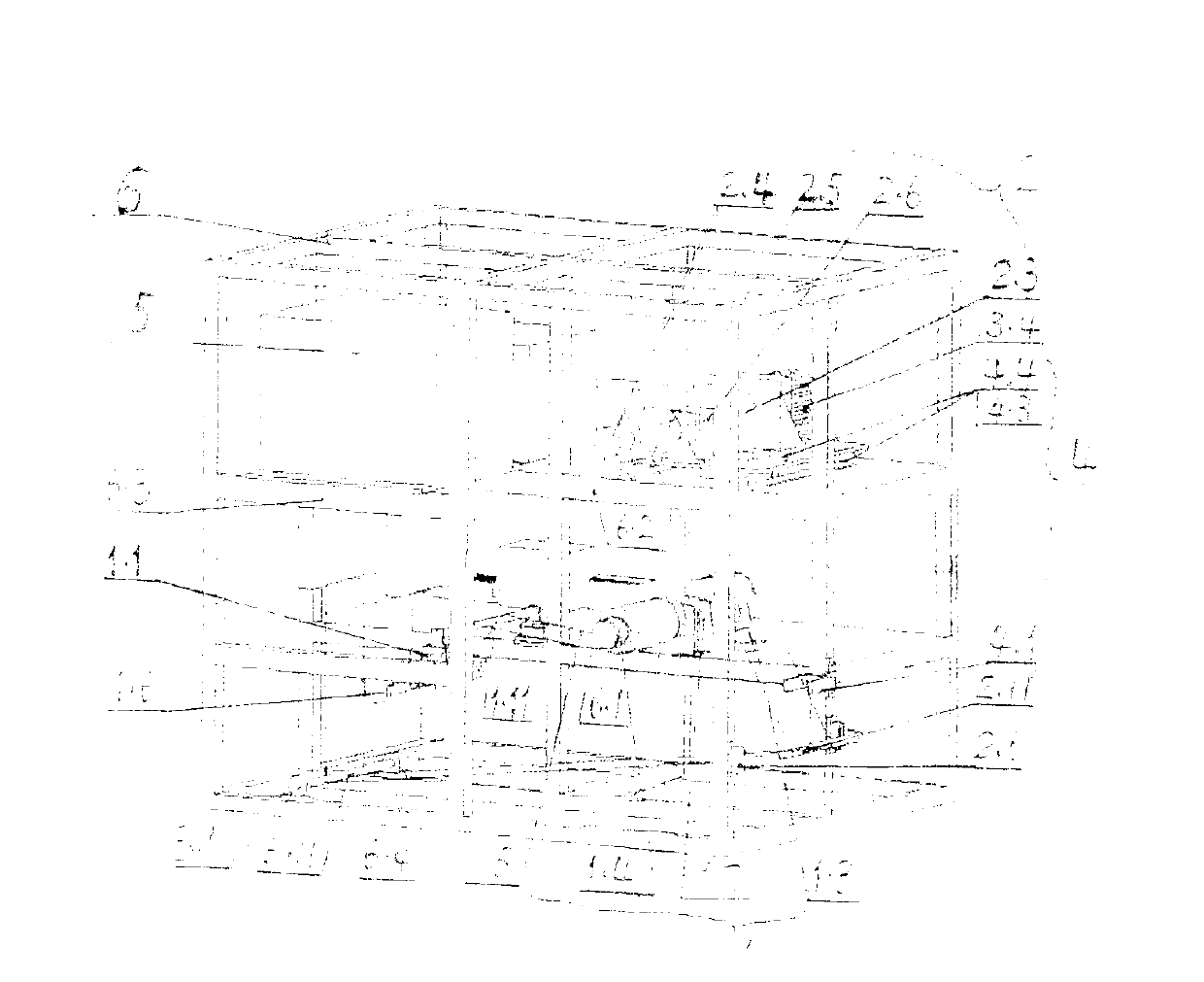

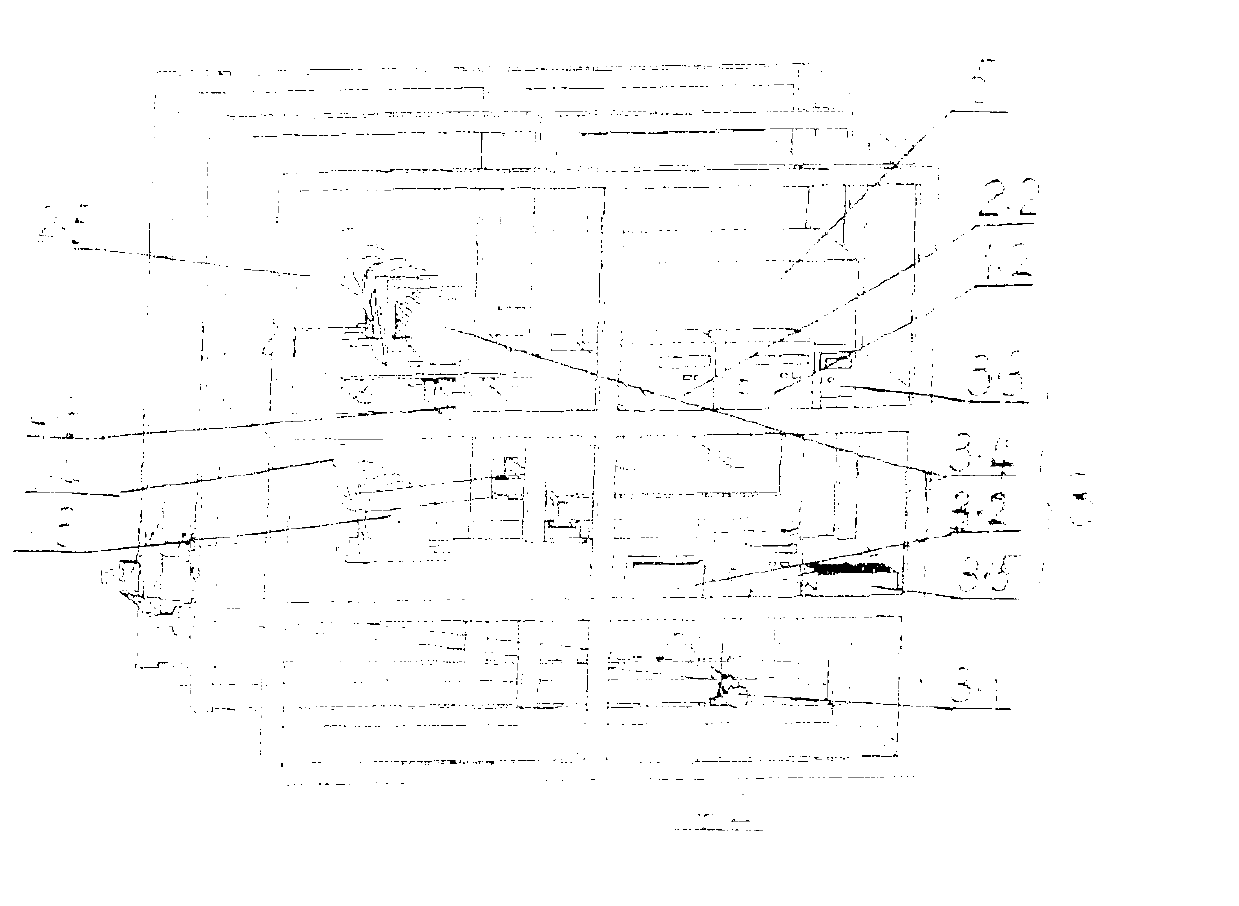

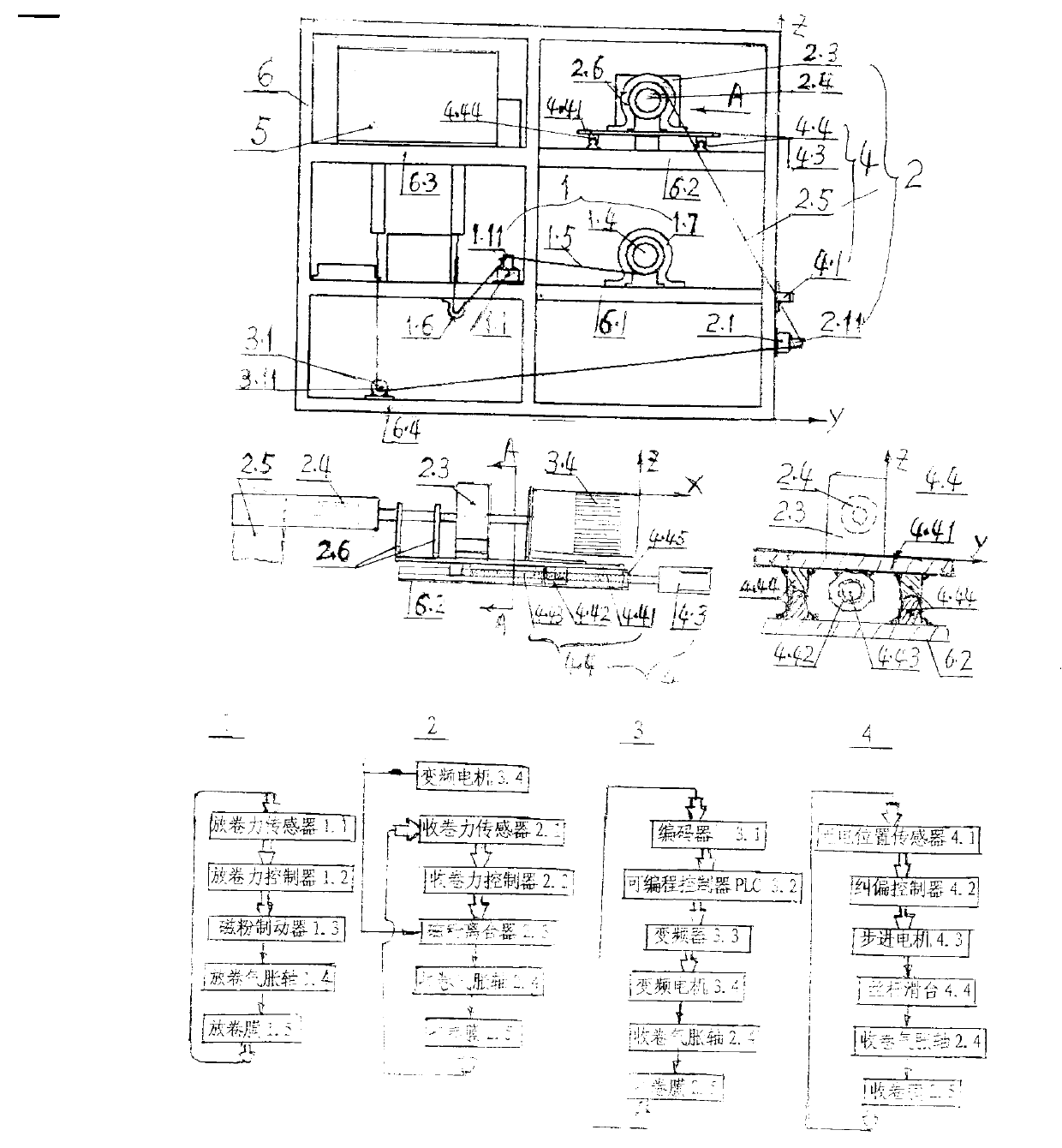

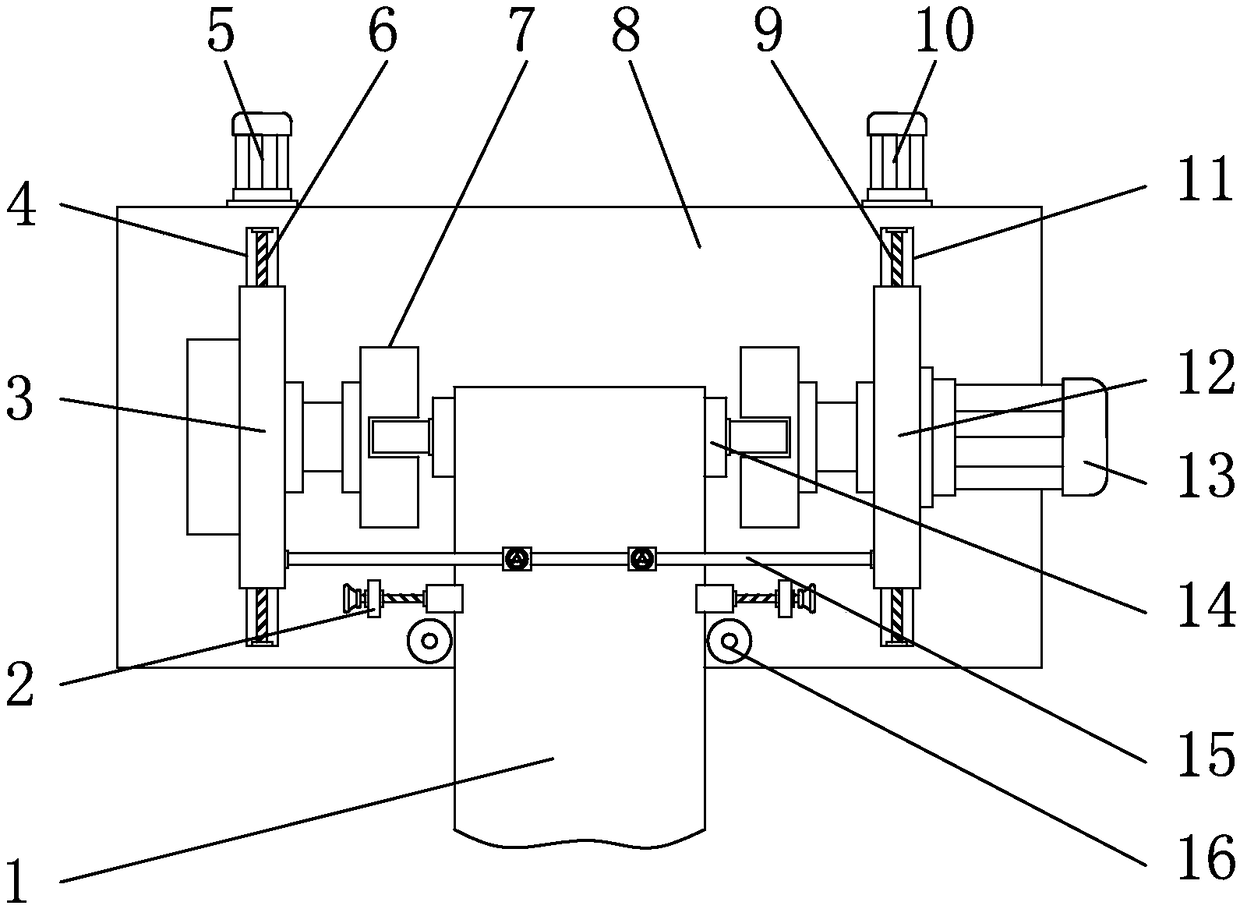

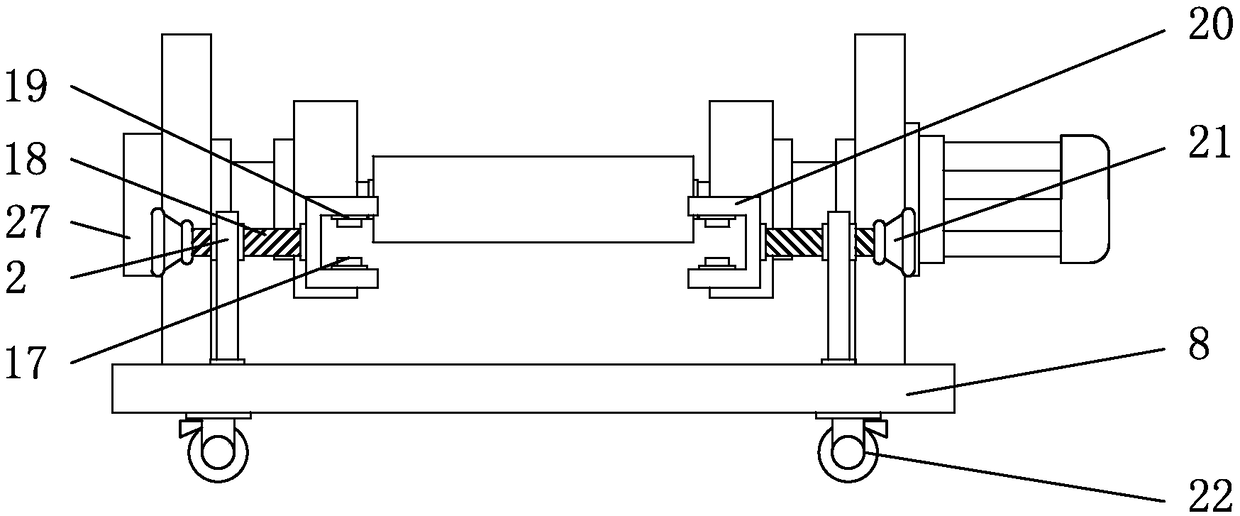

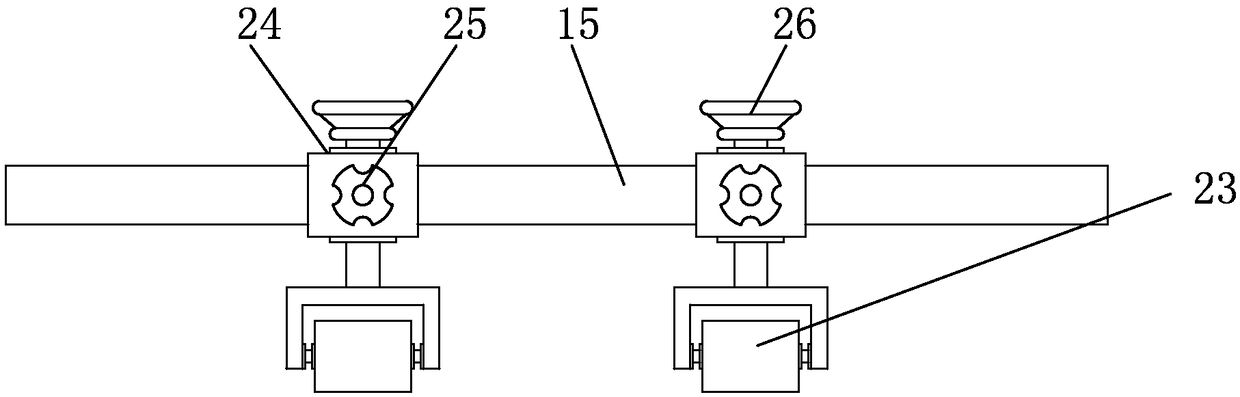

Automatic-deviation-rectification, constant-speed and constant-tension rewinding machine

The invention relates to an automatic-deviation-rectification, constant-speed and constant-tension rewinding machine. A magnetic powder brake and a cantilever unwinding inflation shaft are mounted on a rack; an unwinding membrane passes through an unwinding force sensor roll and an unwinding guide roll, and is delivered into a membrane processing device to form an unwinding tension control device; a screw rod sliding table and a stepping motor are fixed on the rack; a variable frequency motor, a magnetic powder clutch and a cantilever winding inflation shaft are fixed on the surface of the screw rod sliding table; a winding membrane sequentially passes through a photoelectric position sensor, a winding force sensor roll and an encoder roll, and finally passes into the membrane processing device to form a device for controlling winding tension, winding speed, deviation rectification and the like; and an unwinding force, winding force and deviation rectification controller with a program-controlled preset value is utilized to control constant tension of the membrane, and to rectify deviation automatically. The programmable logic controller (PLC), a frequency converter and the variable frequency motor are arranged to control the transmission of the membrane at the constant speed. The machine achieves multifunctional control, solves the problems of high stress deformation, non-uniform viscosity, the deviation and the like, is high in quality and efficiency, simple, reasonable in design, and convenient to operate and maintain, and is particularly applicable to rewinding of a polytetrafluoroethylene adhesive tape coil.

Owner:SICHUAN UNIV

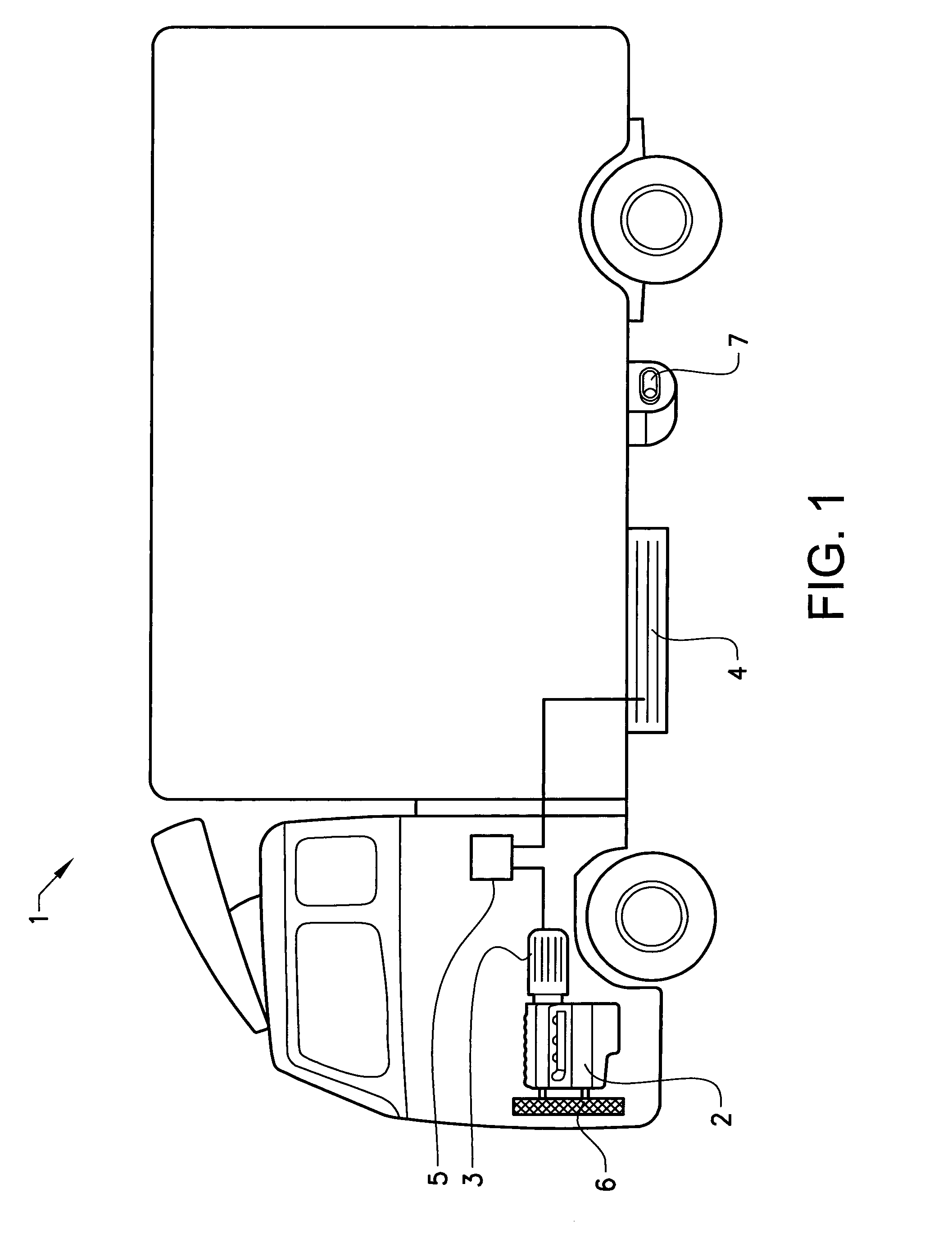

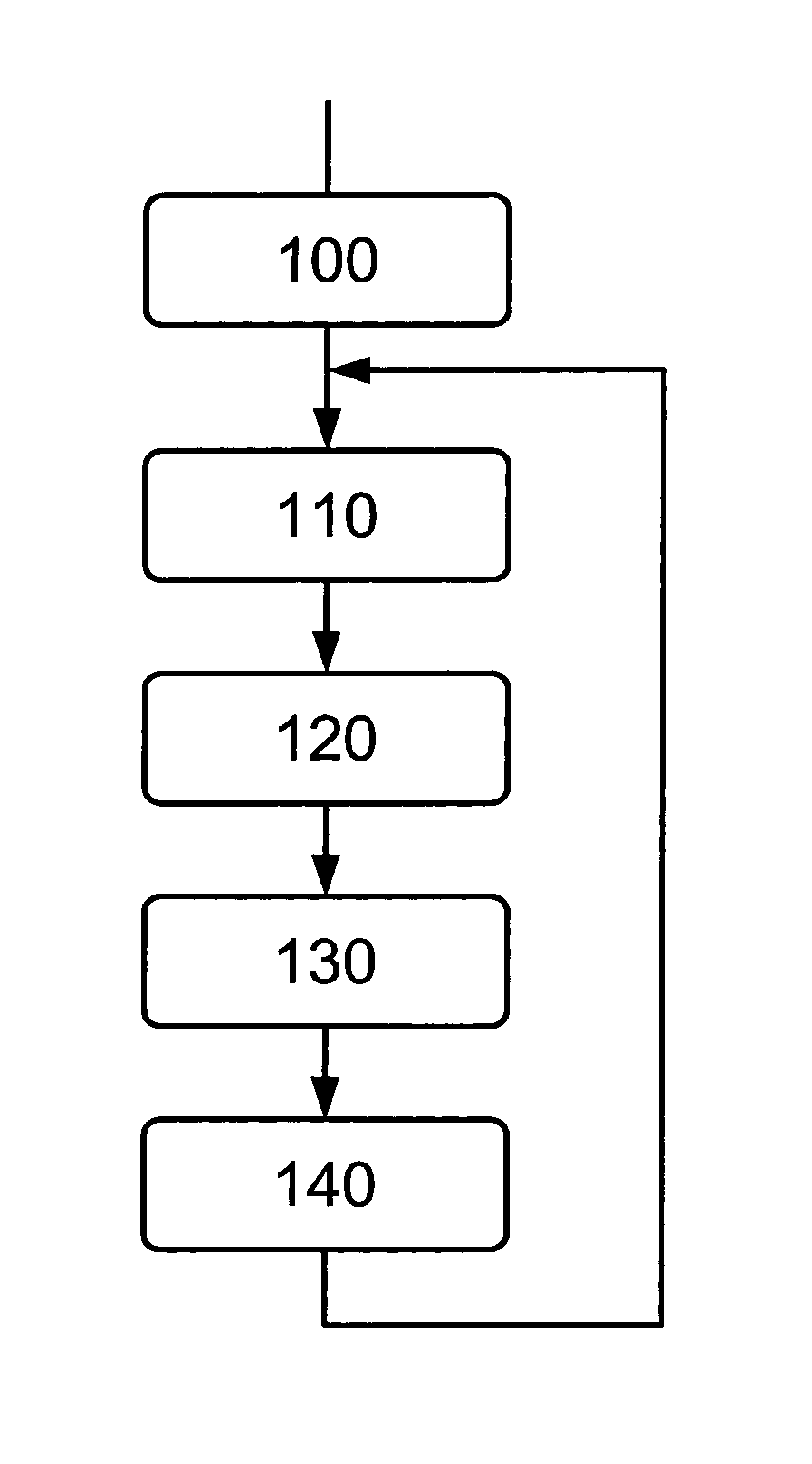

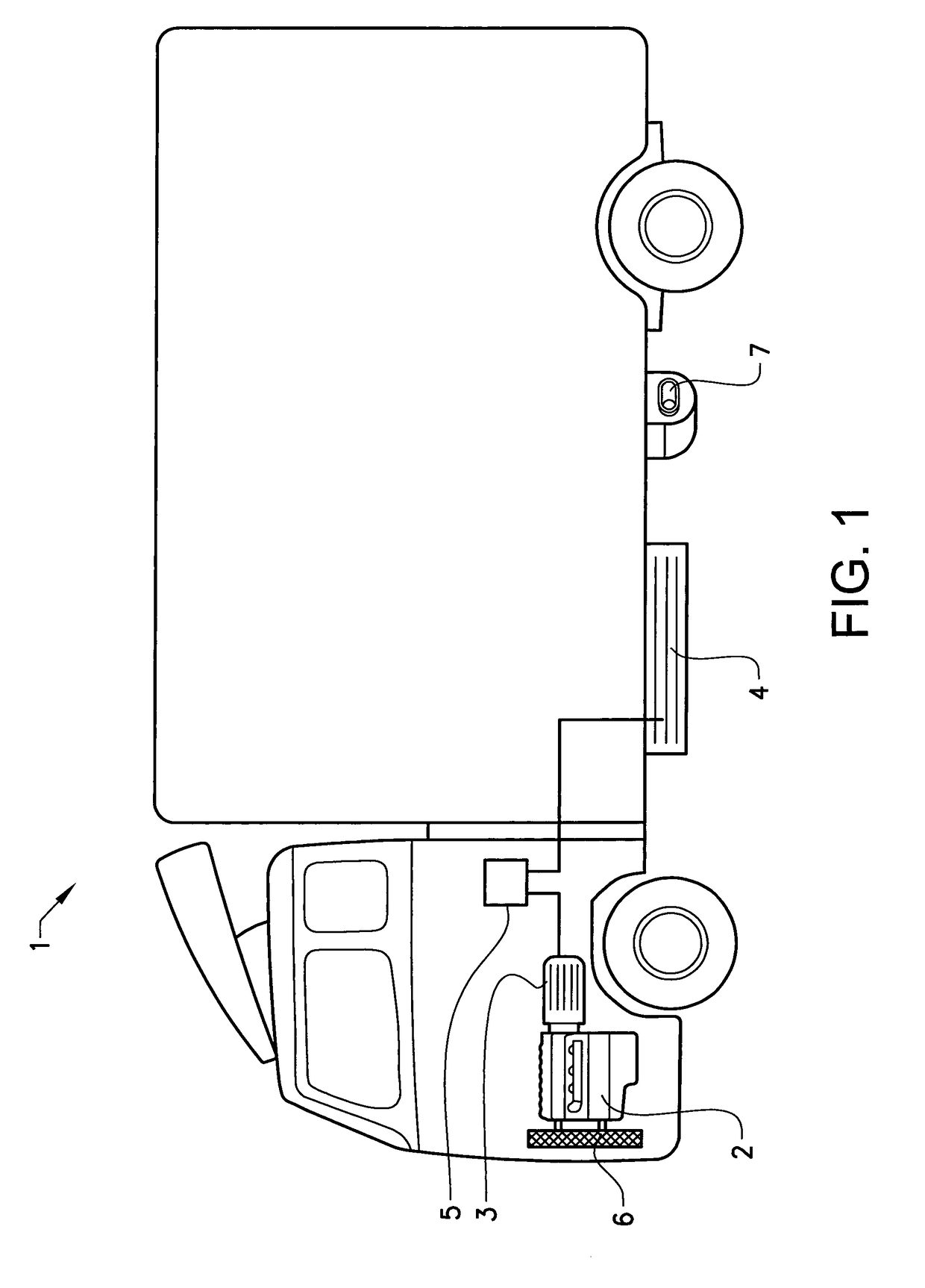

Method for monitoring state of health of a vehicle system

ActiveUS20160078690A1Avoid serious deviationEasy and cost-effectiveVehicle testingRegistering/indicating working of vehiclesState of healthEngineering

A method is provided for monitoring a state of health of a vehicle system and includes measuring a plurality of parameter values for the system at different running conditions as an end of line test, storing the parameter values in a fingerprint file, measuring the same plurality of parameter values that is comprised in the fingerprint file after a predefined time interval, adding a predefined, ageing offset to the fingerprint file, where the ageing offset corresponds to a predicted wear of the system during the predefined time interval, thereby obtaining a time modified fingerprint file for the system, comparing the measured values with the time modified fingerprint file, and issuing a message if the measured values deviates from the time modified fingerprint file. The state of health can be compared with initial measurements such that the state of health of a vehicle system or component can be monitored over a longer time period.

Owner:VOLVO LASTVAGNAR AB

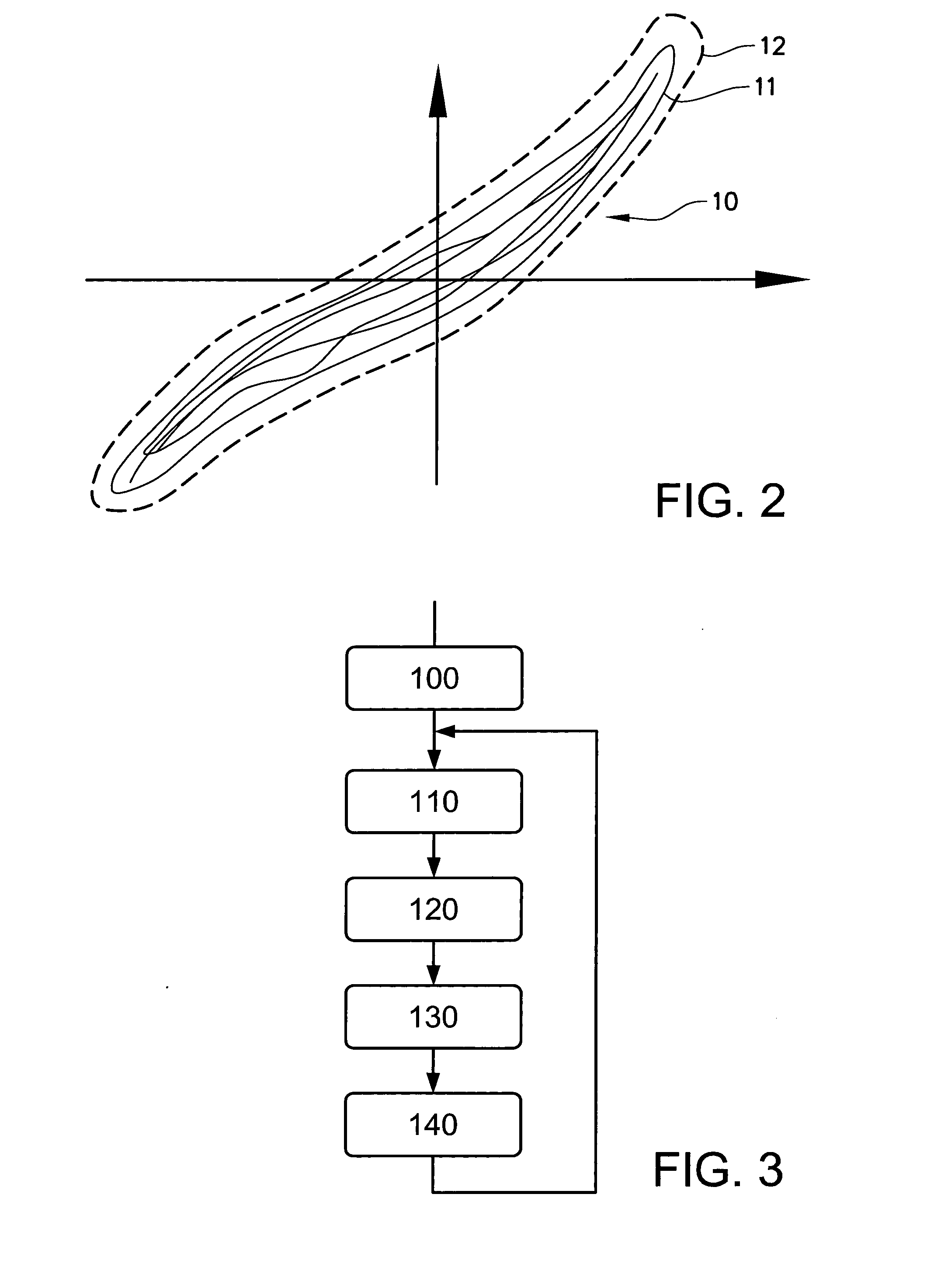

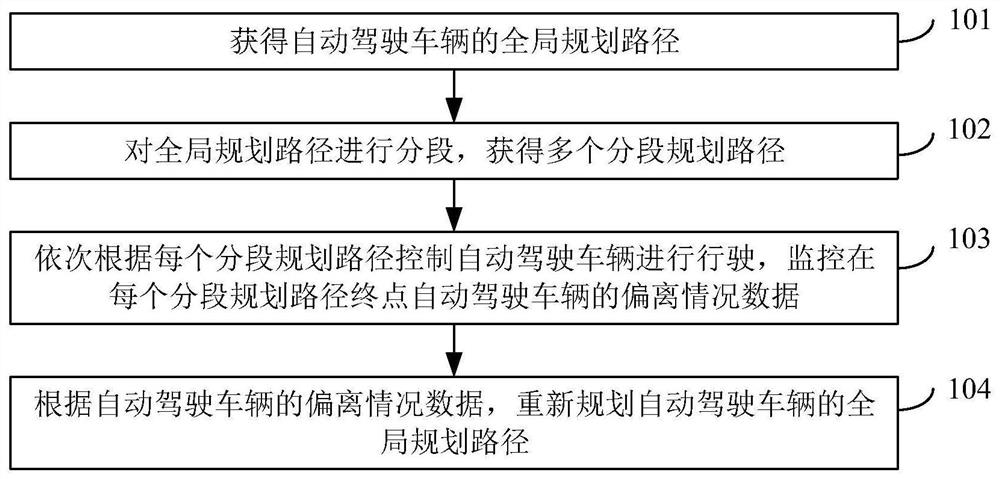

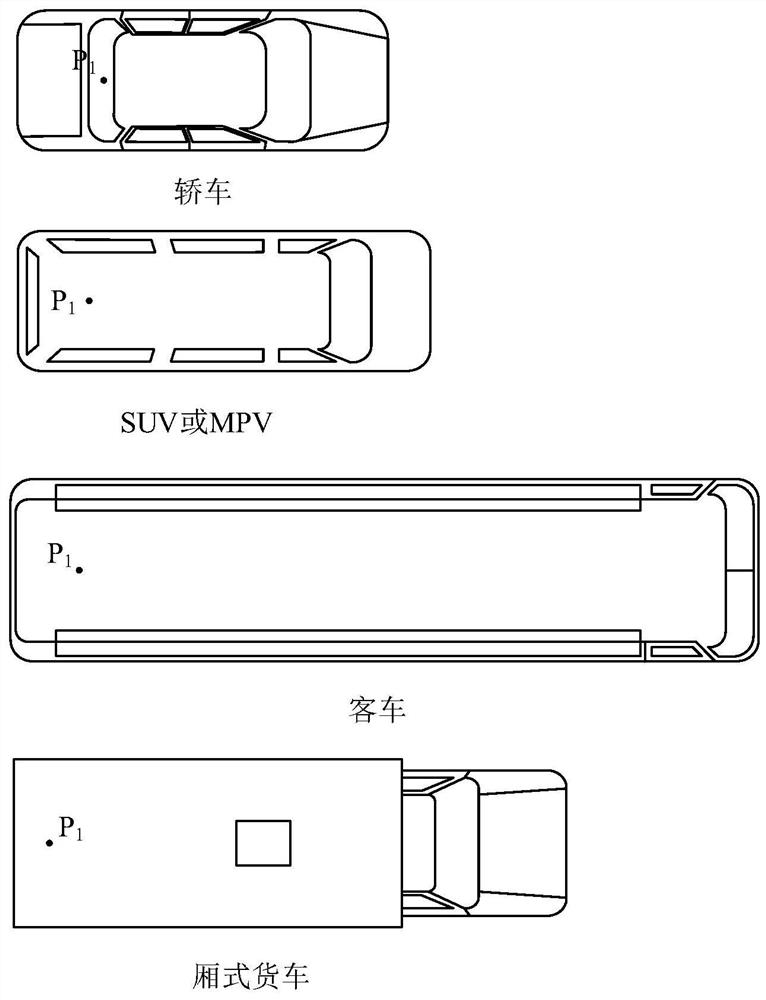

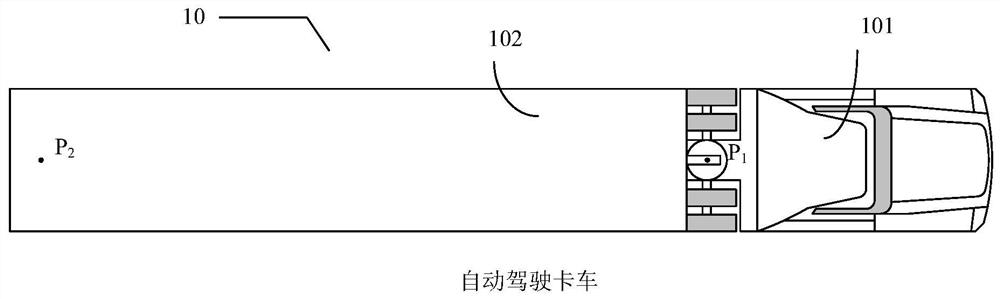

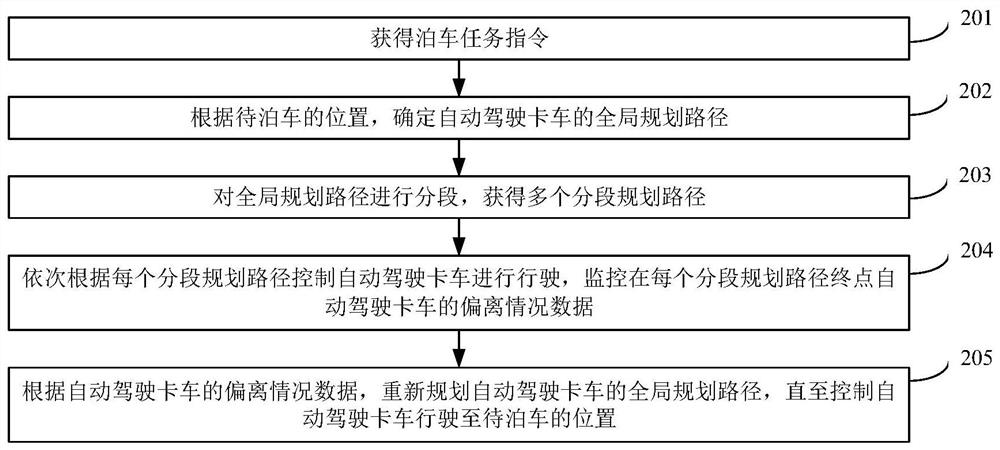

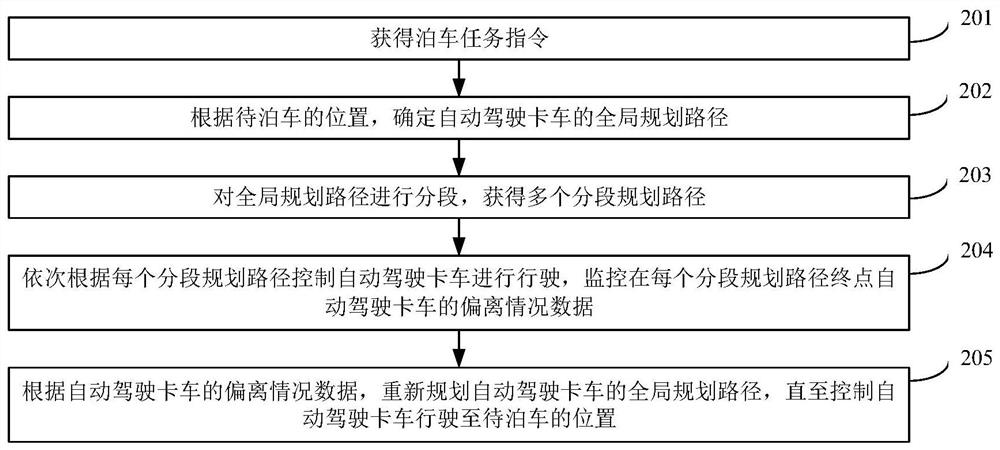

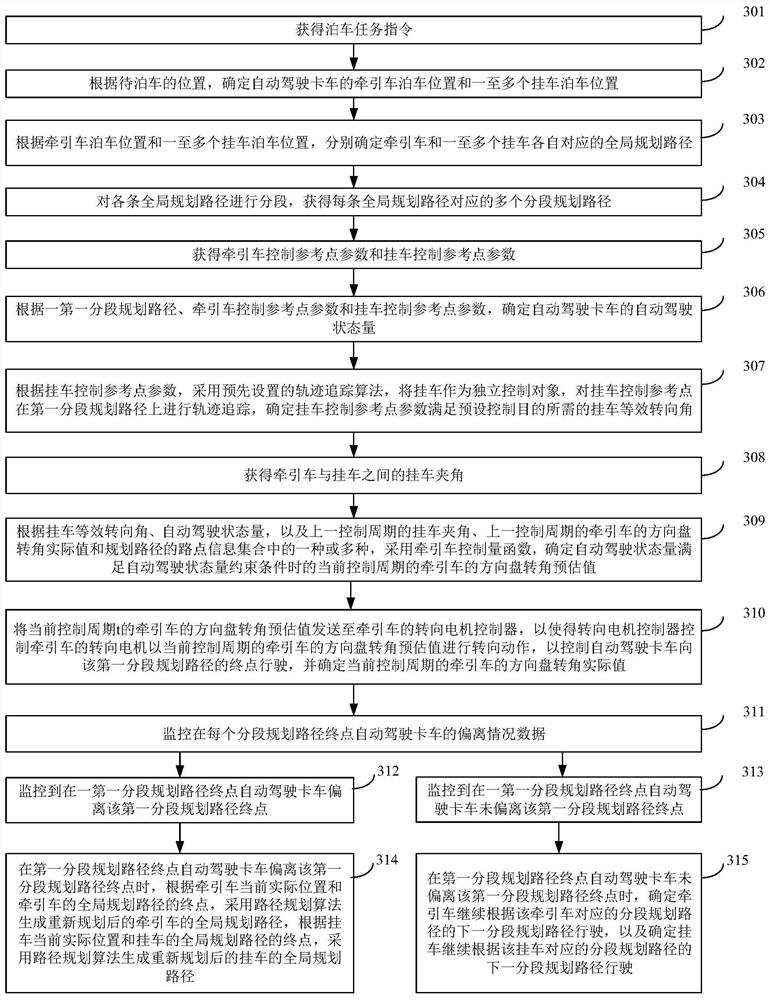

Driving planning method and device for automatic driving vehicle and automatic driving vehicle

ActiveCN112414418AAvoid serious deviationEnsure driving accuracyInstruments for road network navigationGlobal planningReal-time computing

The invention provides a driving planning method and device for an automatic driving vehicle and the automatic driving vehicle, and relates to the technical field of automatic driving. The driving planning method comprises the steps of obtaining a global planning path of the automatic driving vehicle; segmenting the global planning path to obtain a plurality of segmented planning paths; controlling the automatic driving vehicle to travel according to each segmented planning path in sequence, and monitoring deviation condition data of the automatic driving vehicle at the end point of each segmented planning path; and re-planning the global planning path of the automatic driving vehicle according to the deviation condition data of the automatic driving vehicle. Therefore, the driving condition of the automatic driving vehicle can be considered in real time, the automatic driving vehicle is prevented from seriously deviating from the originally planned path, and the driving accuracy of the automatic driving vehicle can be ensured.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

Method for determining energy efficiency of an energy system in a hybrid vehicle

InactiveUS20160039427A1Easy to useAvoid serious deviationHybrid vehiclesDigital data processing detailsElectricityHybrid vehicle

A method for determining the efficiency of an electric energy system of a hybrid vehicle includes determining a measure representative of a relation between the electrical, brake energy and the mechanical brake energy, by determining a requested brake energy for a first vehicle retardation, and by determining an actual electrical brake energy and the actual mechanical brake energy during the vehicle retardation, determining a new measure representative of a relation between the electrical brake energy and the mechanical brake energy at a subsequent second similar vehicle retardation, comparing the determined measures representative of a relation between the electrical brake energy and the mechanical brake energy of the first and second vehicle retardations, where the actual efficiency of the energy system is obtained from the change in the measure representative of a relation between the electrical brake energy and the mechanical brake energy of the first and second vehicle retardations.

Owner:VOLVO LASTVAGNAR AB

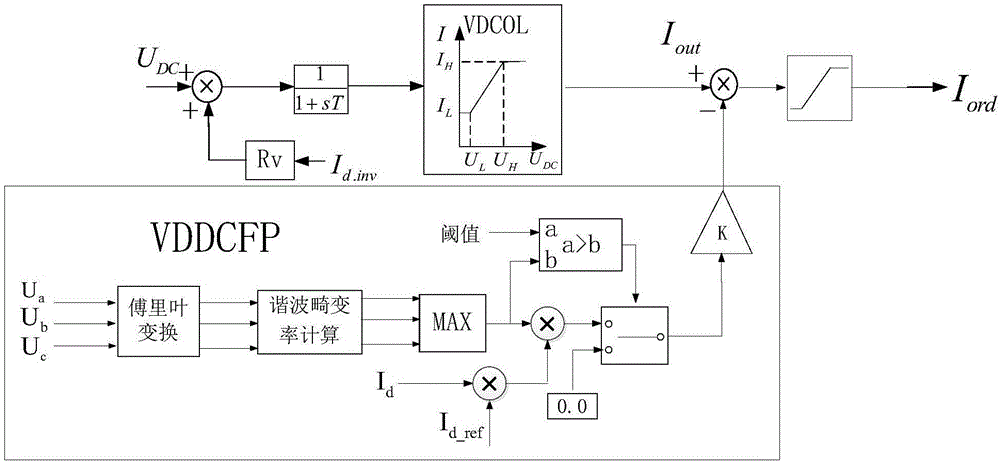

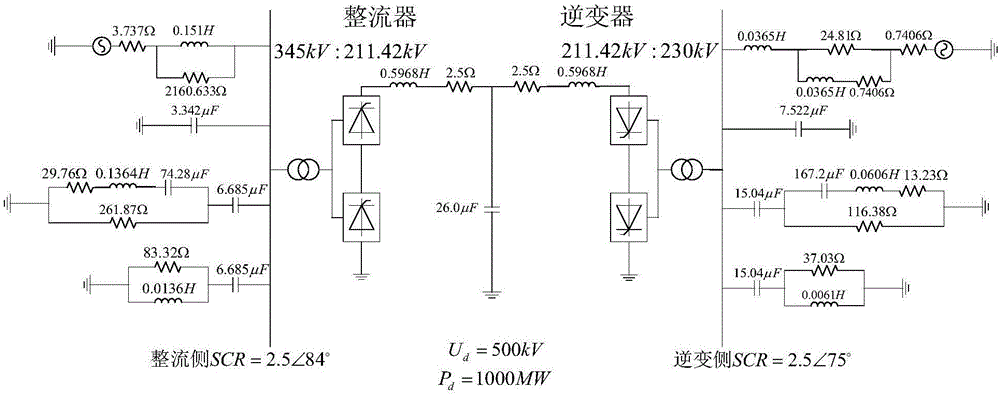

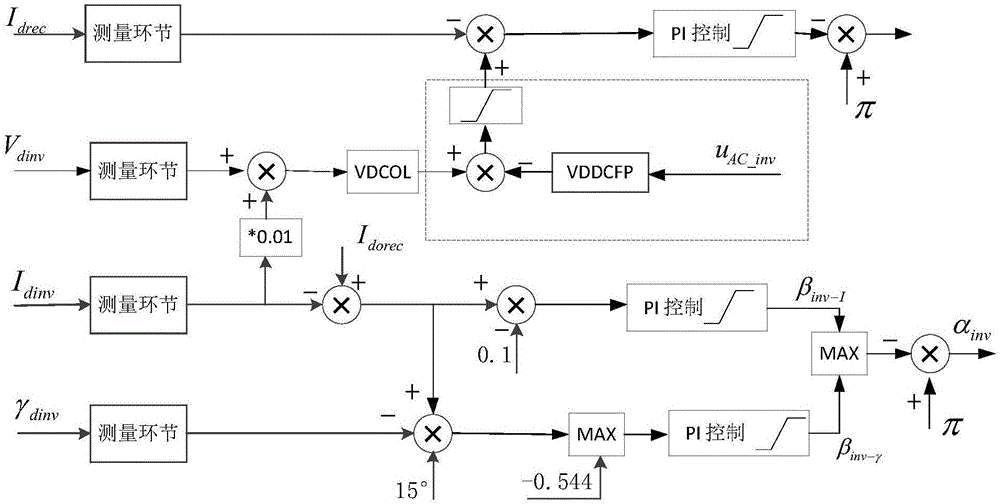

High voltage direct current system control method

InactiveCN105071424APrevent serious deviationDecrease the setting valueElectric power transfer ac networkDistortionVoltage amplitude

The invention discloses a high voltage direct current system control method. VDDCFP is arranged after a VDCOL controller. A VDDCFP control process comprises the steps that S1, three-phase voltage amplitude of an inverter side is monitored in real time, and the voltage value of each sub harmonic of a voltage instantaneous value through Fourier decomposition; S2, voltage distortion current limiting is carried out, namely the harmonic distortion rate is calculated through the voltage amplitude of each sub harmonic after Fourier decomposition, and the maximum harmonic distortion rate in three-phase voltage is taken as a feedback signal; S3, direct current deviation current limiting is carried out, namely the difference between a direct current instantaneous value Id and a rated value Id_ref is calculated in a direct current setting value, and the difference is used as an input signal with the feedback signal in step S2 in a gain process; and S4, an optimizing algorithm is used to select the appropriate gain size. According to the invention, when the harmonic distortion rate of commutation bus voltage is high, direct current is reduced; and commutation is failed due to insufficient influence of harmonics on commutation voltage time area.

Owner:SICHUAN UNIV +4

Multi-stage multi-section nanofiltration salt separation treatment system and process

ActiveCN109824187AImprove interception effectAchieve a high degree of separationMultistage water/sewage treatmentAlkali metal chloridesSolubilityEvaporation

The invention discloses a multi-stage multi-section nanofiltration salt separation treatment system. The multi-stage multi-section nanofiltration salt separation treatment system comprises a pretreatment unit, a nanofiltration unit A, a nanofiltration unit B, a NaCl evaporation crystallization unit and a Na2SO4 evaporation crystallization unit. The invention also discloses a multi-stage multi-section nanofiltration salt separation treatment method. The multi-stage multi-section nanofiltration salt separation treatment method comprises the following steps: (1) nanofiltration process, (2) NaCl concentration crystallization process, and (3) Na2SO4 concentration crystallization process. According to the method, different stages and different sections of nanofiltration treatment are adopted, sothat Cl- and SO42- are highly separated; after separation is carried out, a nanofiltration water-producing side basically only contains NaCl, the concentration of NaCl accounts for 99% of soluble solids in the nanofiltration water-producing side, and the nanofiltration water-producing side only needs ordinary evaporation crystallization to produce high-quality NaCl crystalline salt; and the nanofiltration concentrated water is subjected to salt separation by a thermal-cold method combining evaporation crystallization to freezing crystallization so as to obtain high-purity Na2SO4 crystallizedsalt.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Method for monitoring state of health of a vehicle system

ActiveUS9697652B2Avoid serious deviationEasy and cost-effectiveRegistering/indicating working of vehiclesElectric/hybrid propulsionTime segmentState of health

A method is provided for monitoring a state of health of a vehicle system and includes measuring a plurality of parameter values for the system at different running conditions as an end of line test, storing the parameter values in a fingerprint file, measuring the same plurality of parameter values that is comprised in the fingerprint file after a predefined time interval, adding a predefined ageing offset to the fingerprint file, where the ageing offset corresponds to a predicted wear of the system during the predefined time interval, thereby obtaining a time modified fingerprint file for the system, comparing the measured values with the time modified fingerprint file, and issuing a message if the measured values deviates from the time modified fingerprint file. The state of health can be compared with initial measurements such that the state of health of a vehicle system or component can be monitored over a longer time period.

Owner:VOLVO LASTVAGNAR AB

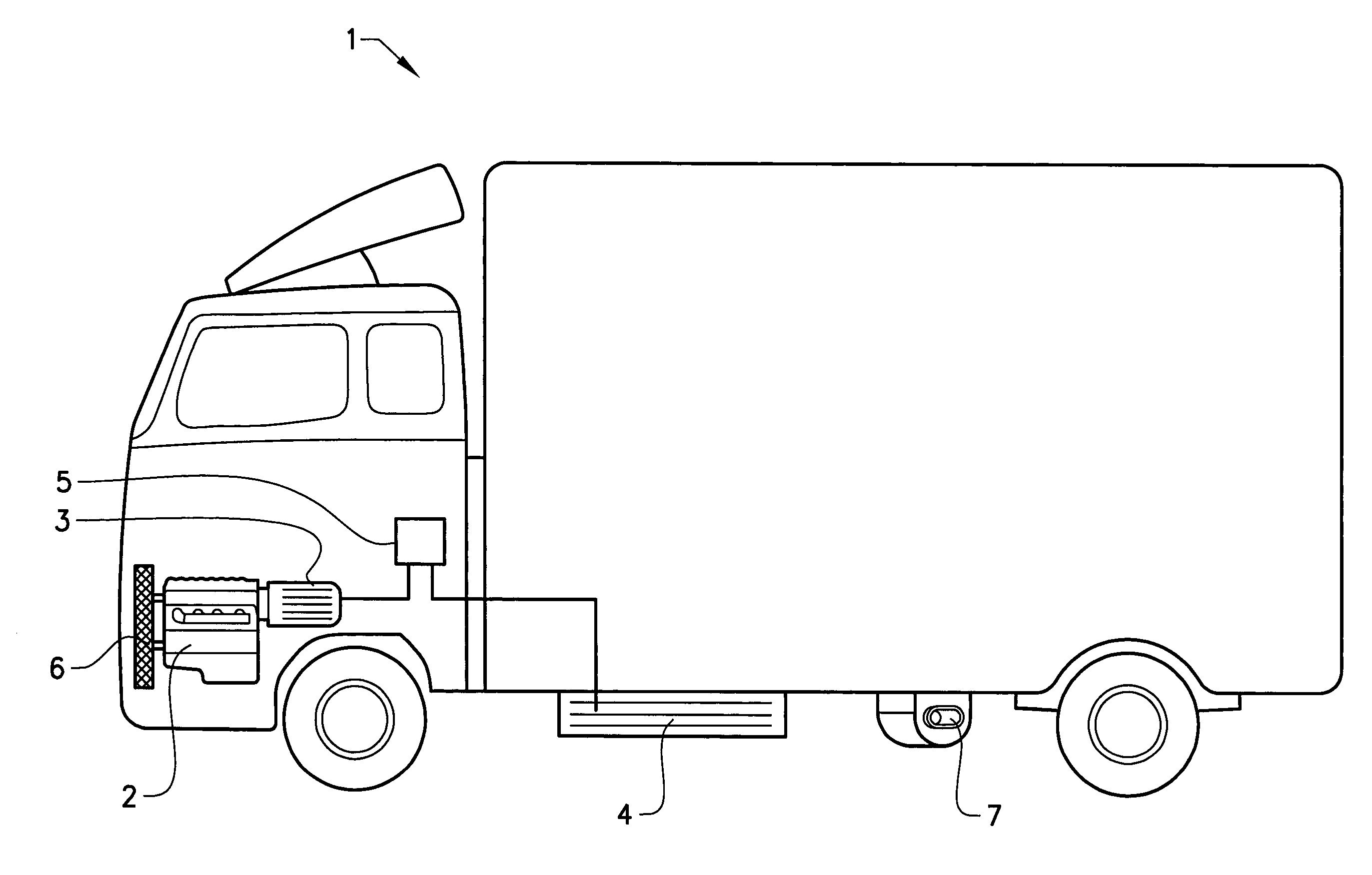

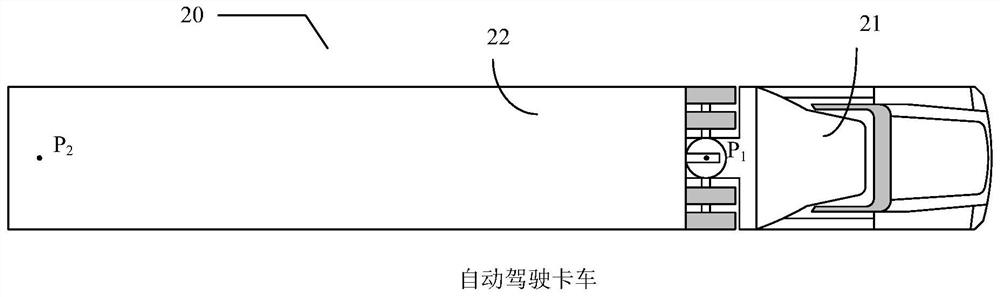

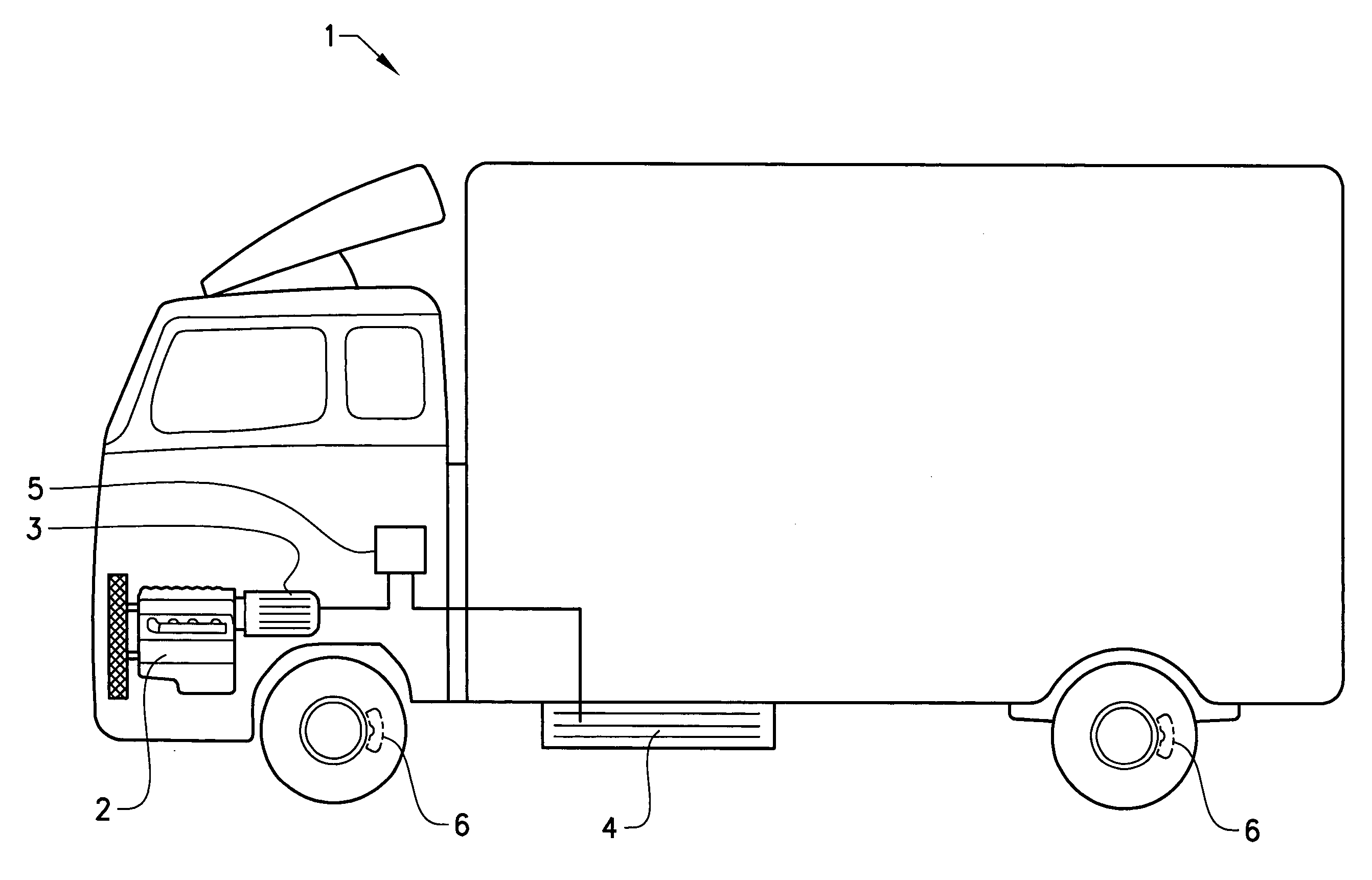

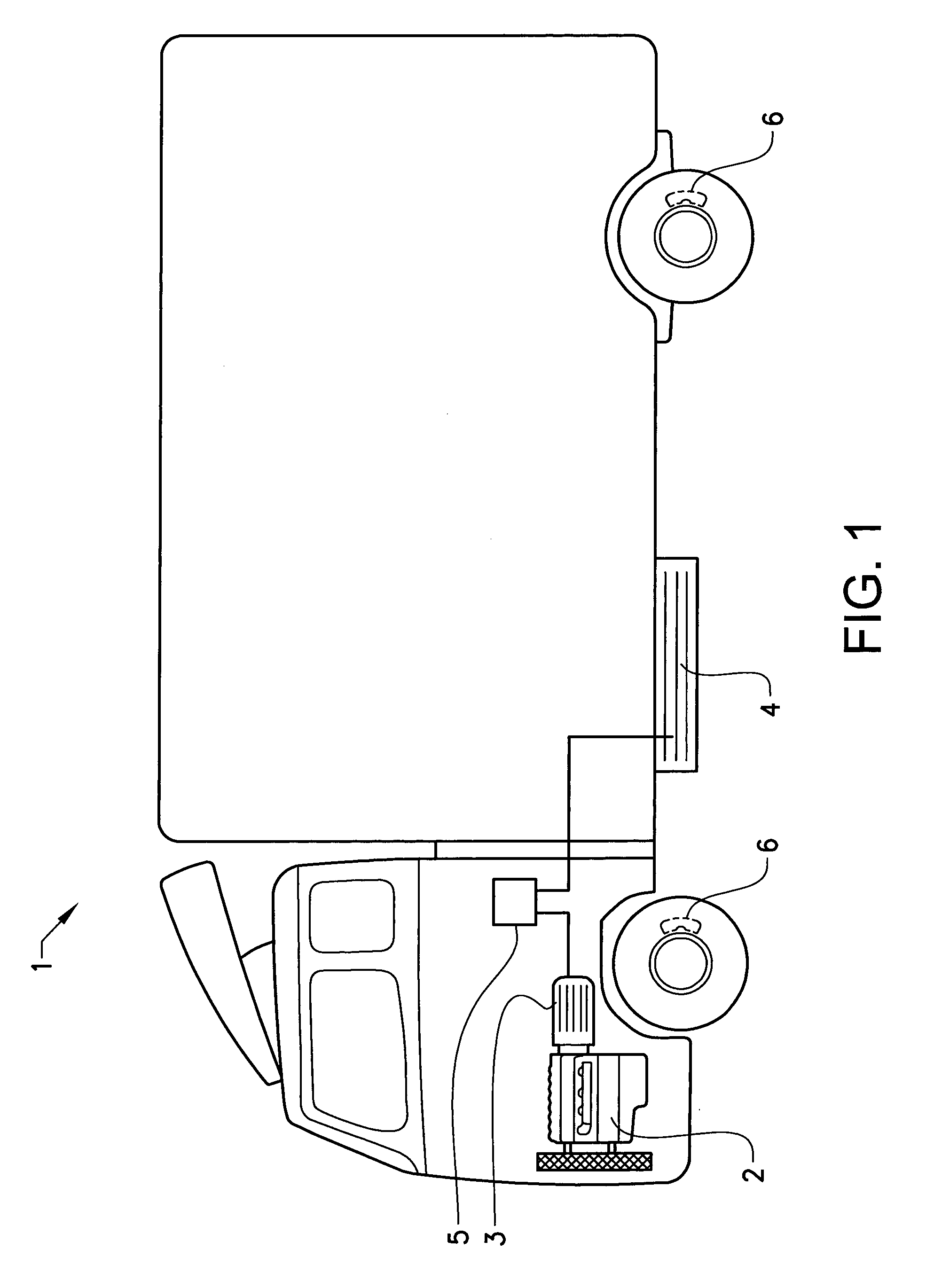

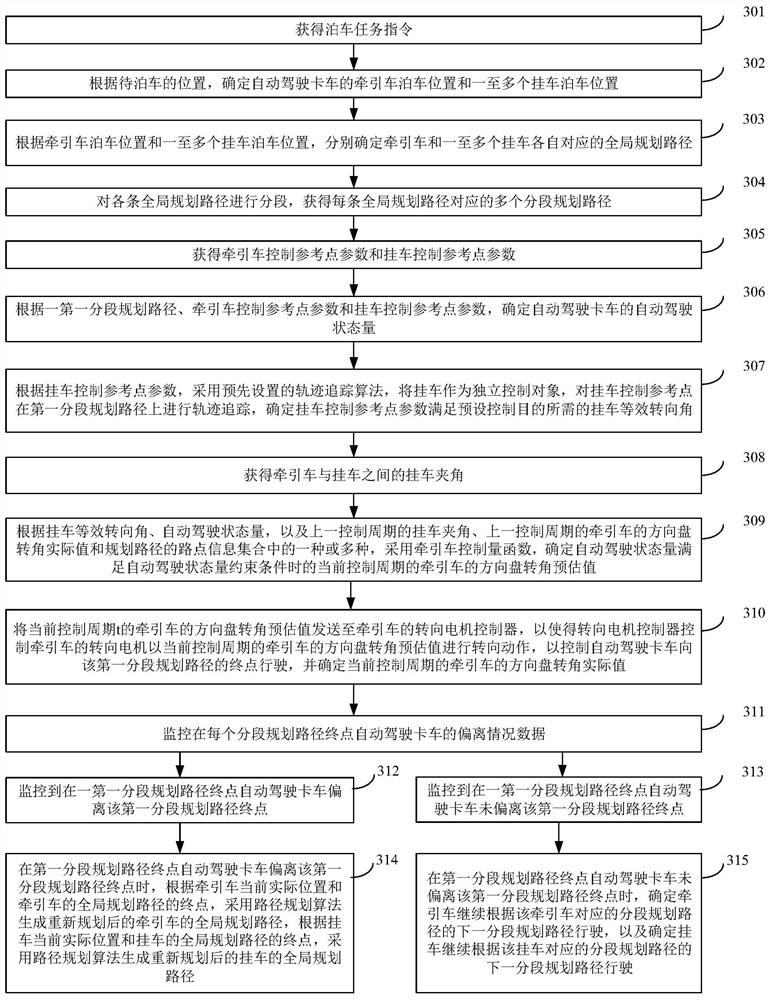

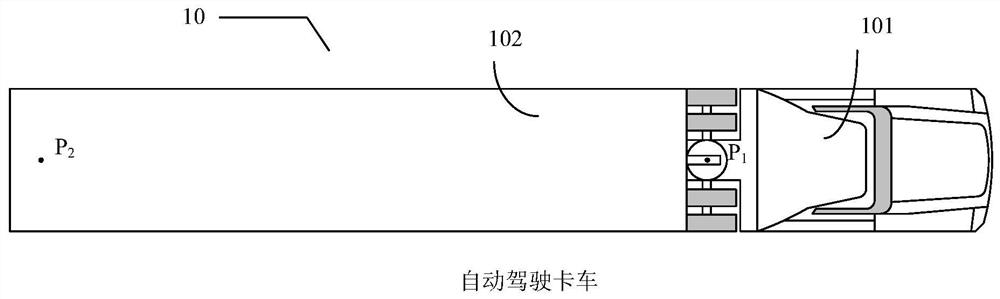

Parking control method and device of automatic driving truck and automatic driving truck

The invention provides a parking control method and device of an automatic driving truck and the automatic driving truck, and relates to the technical field of automatic driving. The method comprisesthe steps of obtaining a parking task instruction, wherein the parking task instruction includes a to-be-parked position; determining a global planning path of the automatic driving truck according tothe to-be-parked position; segmenting the global planning path to obtain a plurality of segmented planning paths; enabling the automatic driving truck to run according to each segmented planning pathin sequence, and monitoring deviation condition data of the automatic driving truck at the end point of each segmented planning path; and according to the deviation condition data of the automatic driving truck, re-planning a global planning path of the automatic driving truck till that the automatic driving truck is controlled to run to the to-be-parked position. According to the embodiment of the invention, the driving condition of the automatic driving truck can be considered in real time, the automatic driving truck is prevented from seriously deviating from the originally planned path, and the parking driving accuracy of the automatic driving truck can be ensured.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

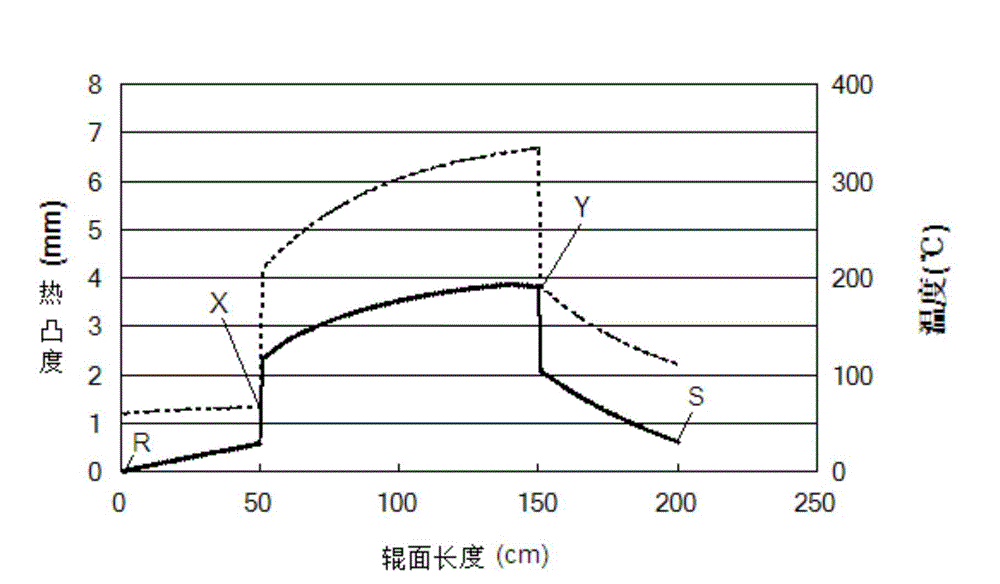

Method and system for improving roller surface temperature uniformity

ActiveCN105441848AUniform temperatureAvoid serious deviationHot-dipping/immersion processesEngineeringCooling medium

The invention discloses a method for improving roller surface temperature uniformity. The method includes controlling a cooling medium to enter a cooling path in a roller from one of two ends at the axial direction of the roller in an alternative inverting manner, and to be discharged from the other end. A system for improving roller surface temperature uniformity comprises the roller, a gas feeding pipe and a gas discharging pipe, wherein the cooling medium path extending at the axial direction of the roller is disposed in the roller, two ends of the cooling medium path are provided with a cooling medium inlet and a cooling medium outlet, the gas feeding pipe is alternatively connected to the cooling medium inlet at one of the two ends of the cooling medium path, and when the gas feeding pipe is alternatively connected to the cooling medium inlet at one of the two ends of the cooling medium path, the gas discharging pipe is communicated with the cooling medium outlet at the other end of the cooling medium path. The system and the method can improve roller surface temperature uniformity and improve roller surface temperature symmetry.

Owner:宝钢日铁汽车板有限公司

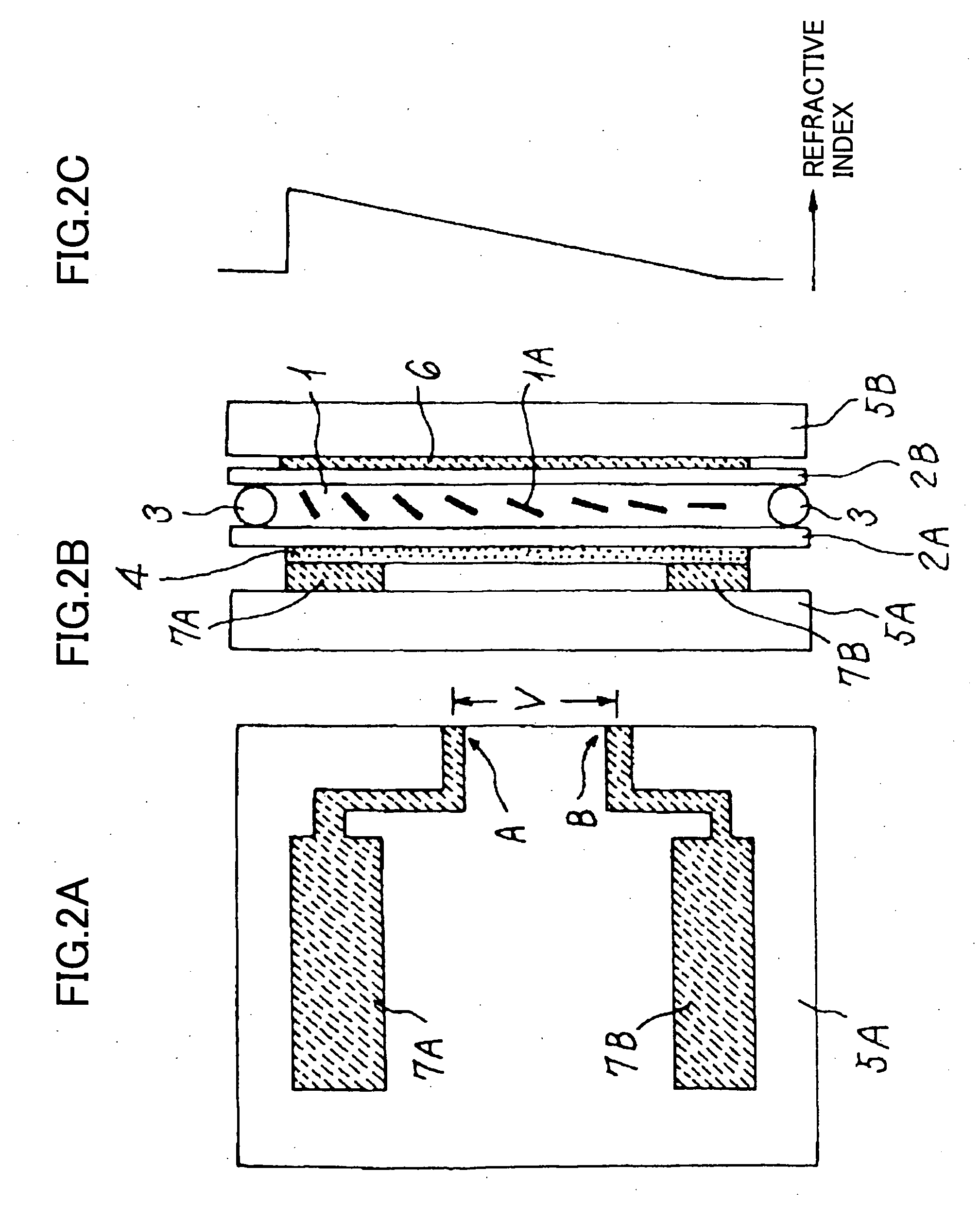

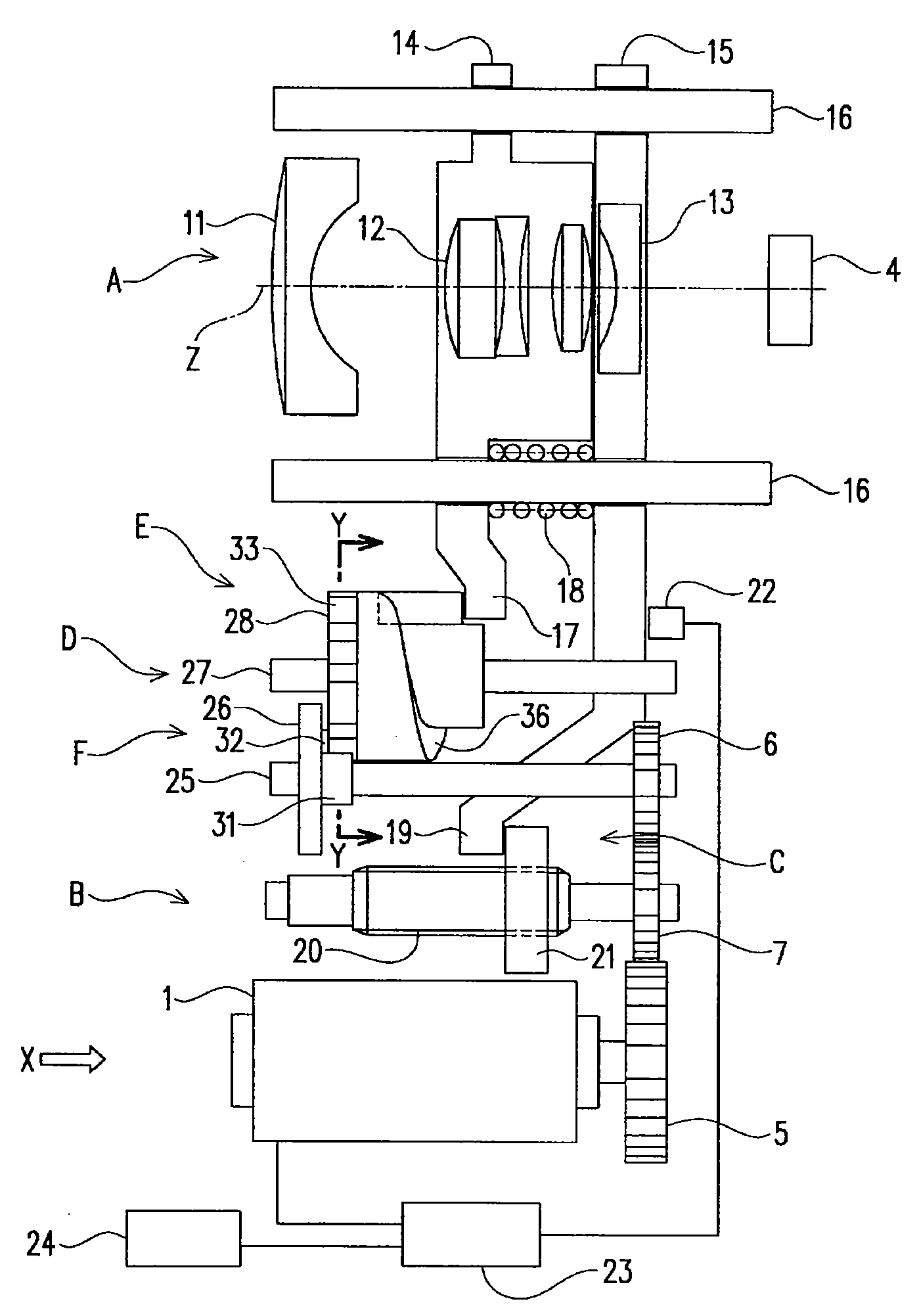

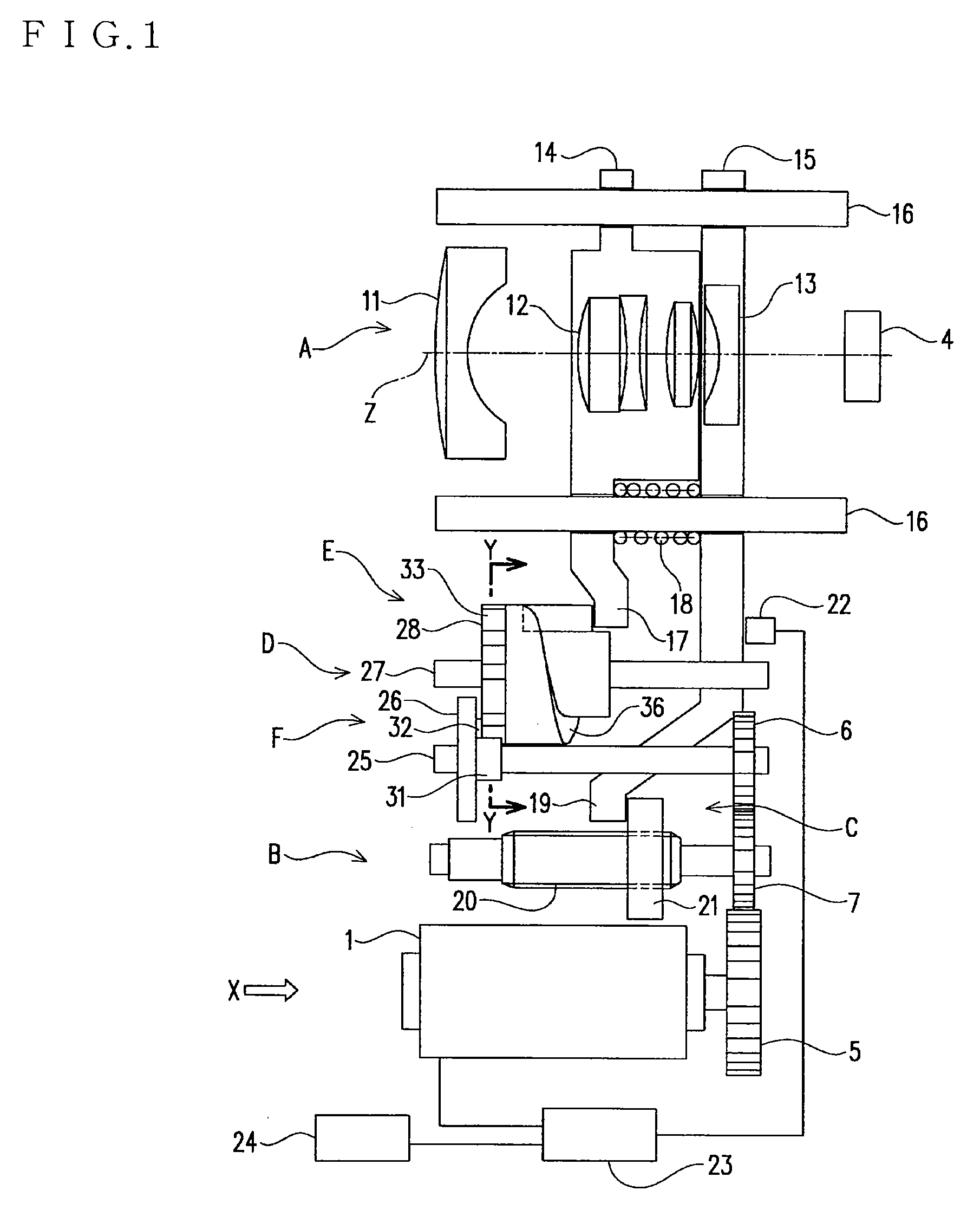

Zoom lens device

A zoom lens device is reduced in size and capable of zoom operation with the number of steps large enough to display the value as a zoom lens. The zoom lens device comprises lens system (A) with a first lens group, a second lens group, and a third lens group arranged on optical axis (Z). It comprises zoom mechanism (E) for changing the focal distance of lens system (A) by changing the second lens group in the direction of optical axis (Z). It comprises focus mechanism (C) for adjusting the image forming position of lens system (A) by moving the third lens group13 in the same direction as optical axis (Z). It also comprises driving force transmitting section (B) for transmitting the driving force from the motor to zoom mechanism (E) and focus mechanism (C). Driving force transmitting section (B) includes stopwork (D) like Geneva drive (F) for intermittently transfer the driving force from the driving source to zoom mechanism (E).

Owner:PANASONIC CORP

Infrared ray deviation preventing and correcting device used for processing box body plate of television transmitter

ActiveCN108746247AGuarantee the quality of windingImprove compactnessMetal working apparatusInfraredDrive motor

The invention discloses an infrared ray deviation preventing and correcting device used for processing a box body plate of a television transmitter. The infrared ray deviation preventing and correcting device comprises a base, a rolling roller shaft and a sliding rod. A first groove and a second groove are formed in the positions, close to the two ends, of the top of the base correspondingly. A first correcting screw rod and a second correcting screw rod are installed in the first groove and the second groove correspondingly. A first drive motor and a second drive motor are installed at the positions, corresponding to the first groove and the second groove, of one side of the base through bolts correspondingly. An output shaft of the first drive motor and an output shaft of the second drive motor are fixedly connected with the first correcting screw rod and the second correcting screw rod correspondingly. A first supporting plate and a second supporting plate are installed on the portions, above the base, of the first correcting screw rod and the second correcting screw rod correspondingly. Installing bases are installed on the inner side of the first supporting plate and the innerside of the second supporting plate correspondingly. According to the infrared ray deviation preventing and correcting device, a guide roller is installed on the base, a certain effect of guiding thebox body plate in the conveying process is achieved, and the situation of severe deviation is avoided.

Owner:浙江联品电子科技有限公司

Electric motor

ActiveUS8638019B2Solve the complicated productionImprove product qualitySynchronous generatorsWindingsStructural engineeringElectric motor

An electric motor includes a stator made up of individual segments disposed in the circumferential direction, each individual segment including a core stack around which a winding is provided and at whose axial terminal regions end caps are provided, the winding being produced by a winding wire, an end cap including at least one dome, in particular for delimiting the region of the winding, a wire inlet duct for rerouting the winding wire being provided in the base region of the dome, grooves being provided on the end cap, the distance of one groove with respect to the radially following groove and the diameter of the curvature of the respective groove being smaller than the diameter of the winding wire.

Owner:SEW-EURODRIVE GMBH & CO KG

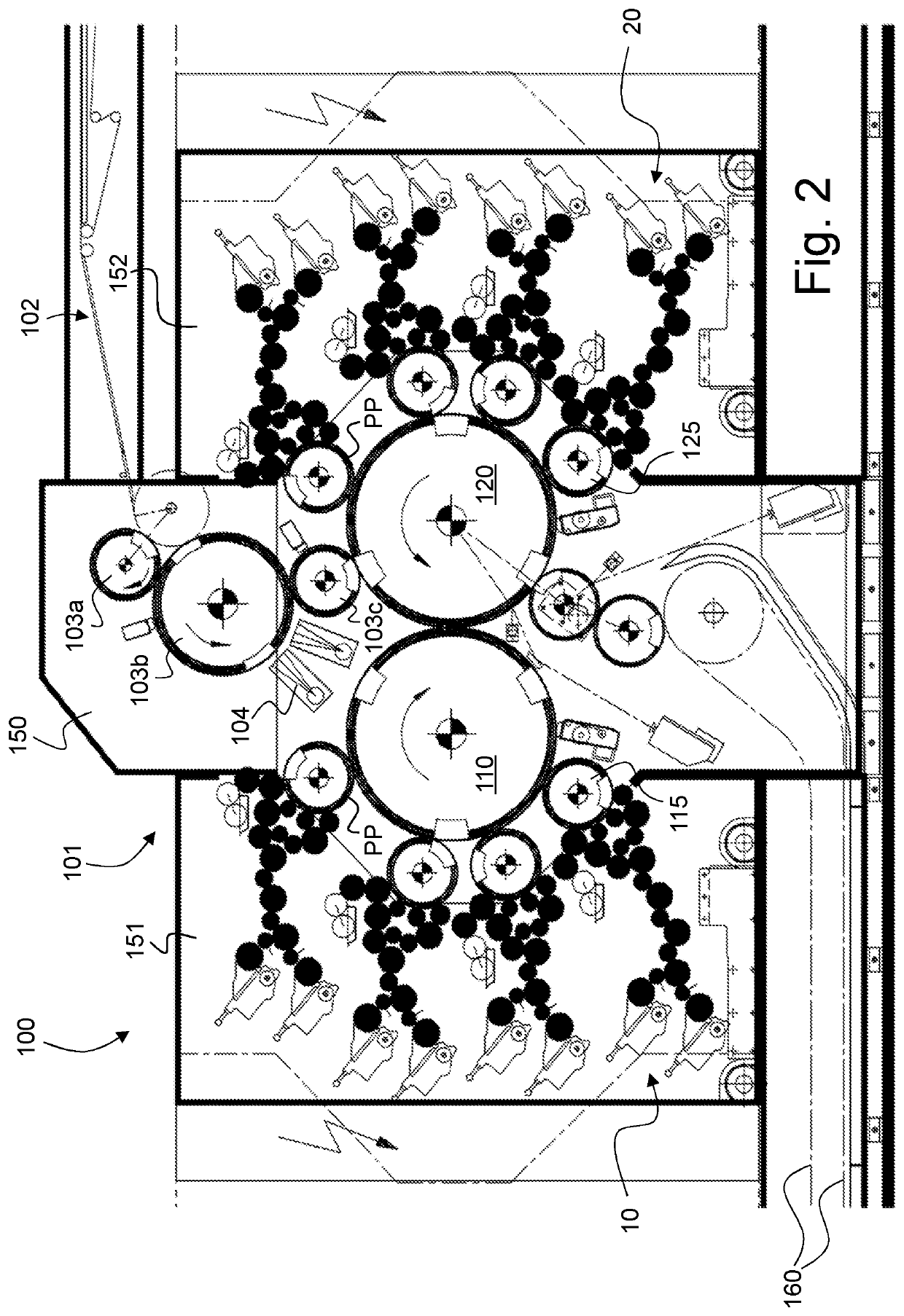

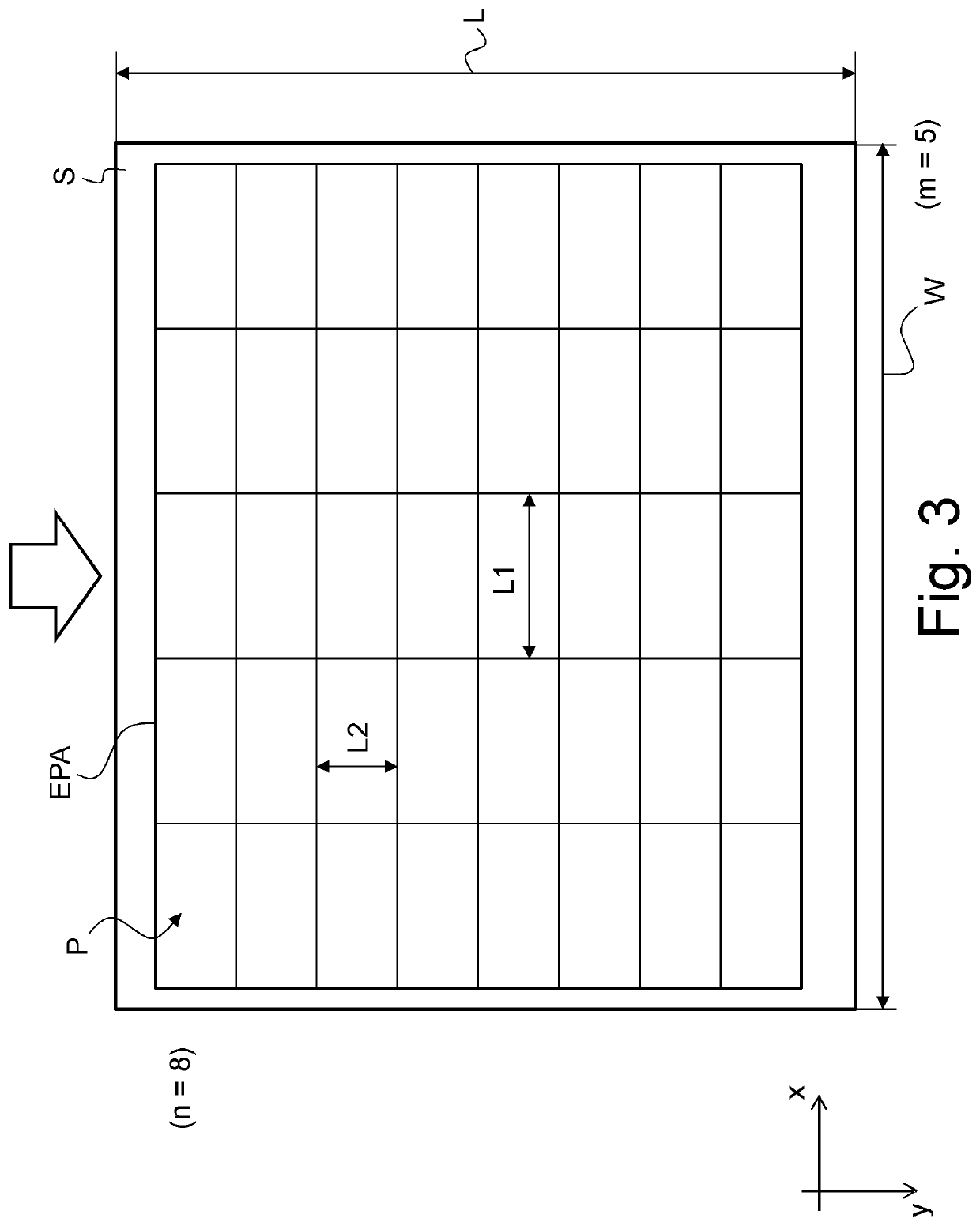

Measuring and correcting print-to-print register of a multicolour print formed on printed material

ActiveUS10556420B2Easy to solveEffective correctionRotary pressesPrinting press partsReference imageStructural engineering

There is described a process of measuring print-to-print register of a multicolour print (A-D) provided in an effective printed area (EPA) of the surface of printed material, which multicolour print (A-D) is formed on the printed material by means of one or more printing presses and includes at least a first pattern (A) and a second pattern (B) distinguishable from the first pattern (A), the effective printed area (EPA) being provided with a matrix arrangement of individual imprints (P) which are each provided with the multicolour print (A-D) and are repeated over the surface of the effective printed area (EPA) along a pattern of rows and columns. Measurement of an actual print-to-print register between the first and second patterns (A, B), as reflected on the printed material, is derived from processing and finding a correspondence between (i) at least one sample image (SIA, SIB) of the printed material covering at least a portion of the first and second patterns (A, B), and (ii) at least one corresponding reference image (RIA, RIB) generated using prepress design data of the first and second patterns (A, B). Furthermore, the process is repeated for multiple ones of the individual imprints (P) so as to derive a set of multiple measurements of the actual print-to-print register between the first and second patterns (A, B) at various imprint locations over the effective printed area (EPA), which set of multiple measurements is mapped into a corresponding print-to-print register map (MB-A, MC-A, MD-A, . . . ) that is representative of print-to-print register deviations at the various imprint locations. Also described is a measuring device for carrying out this process and a process of measuring and correcting print-to-print register of a multicolour print.

Owner:KBA NOTASYS SA

Transportable packaging unit and method for producing said type of packaging unit

InactiveUS20160090226A1Avoid serious deviationGood for scrollingPower operated devicesSolid materialBiomedical engineering

Owner:WRH WALTER REIST HLDG

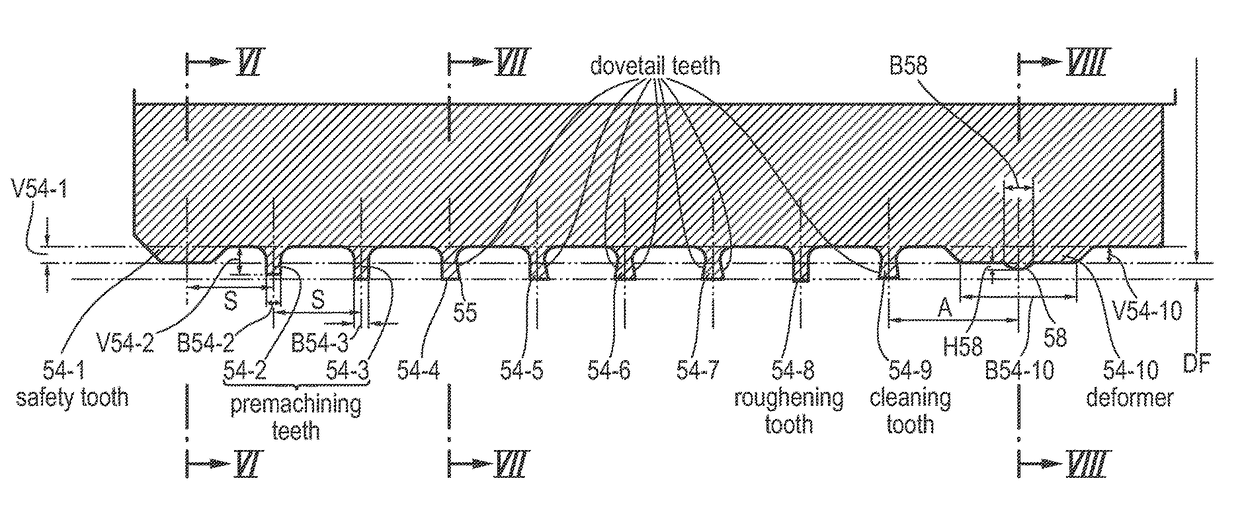

Method and tool for producing a surface of predetermined roughness

ActiveUS9643265B2Excellent and permanent adhesion of layerLong tool life travelMolten spray coatingInternal combustion piston enginesEngineeringMechanical engineering

For producing a cylindrical surface that has a surface structure of predetermined geometry suitable for application of material by thermal spraying, a geometrically predetermined groove structure of minimal depth and width is introduced into the surface by a tool embodied as a follow-on tool in that a groove cross-section is processed successively to a final size. In order for the surface to be producible in mass production with constant quality, the groove structure is worked in such that first a base groove is introduced with a groove bottom width that is smaller than the groove bottom width of the finished groove. Subsequently, at least one flank of the base groove is processed for producing an undercut groove profile by a non-cutting action or cutting action wherein the introduced groove structure is deformed in such a way that the groove openings are constricted by upsetting deformations of material.

Owner:MARTINREA HONSEL GERMANY +1

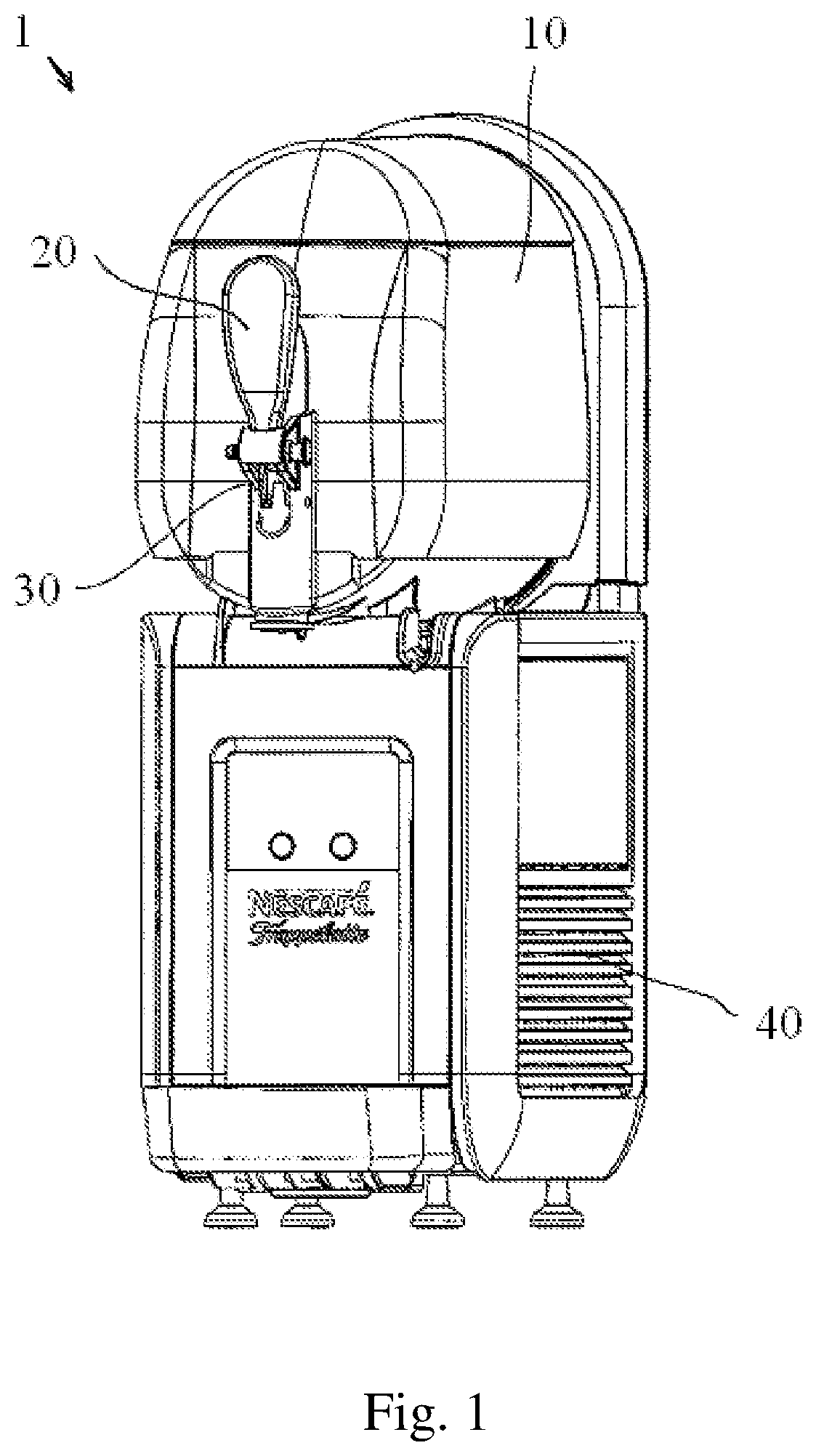

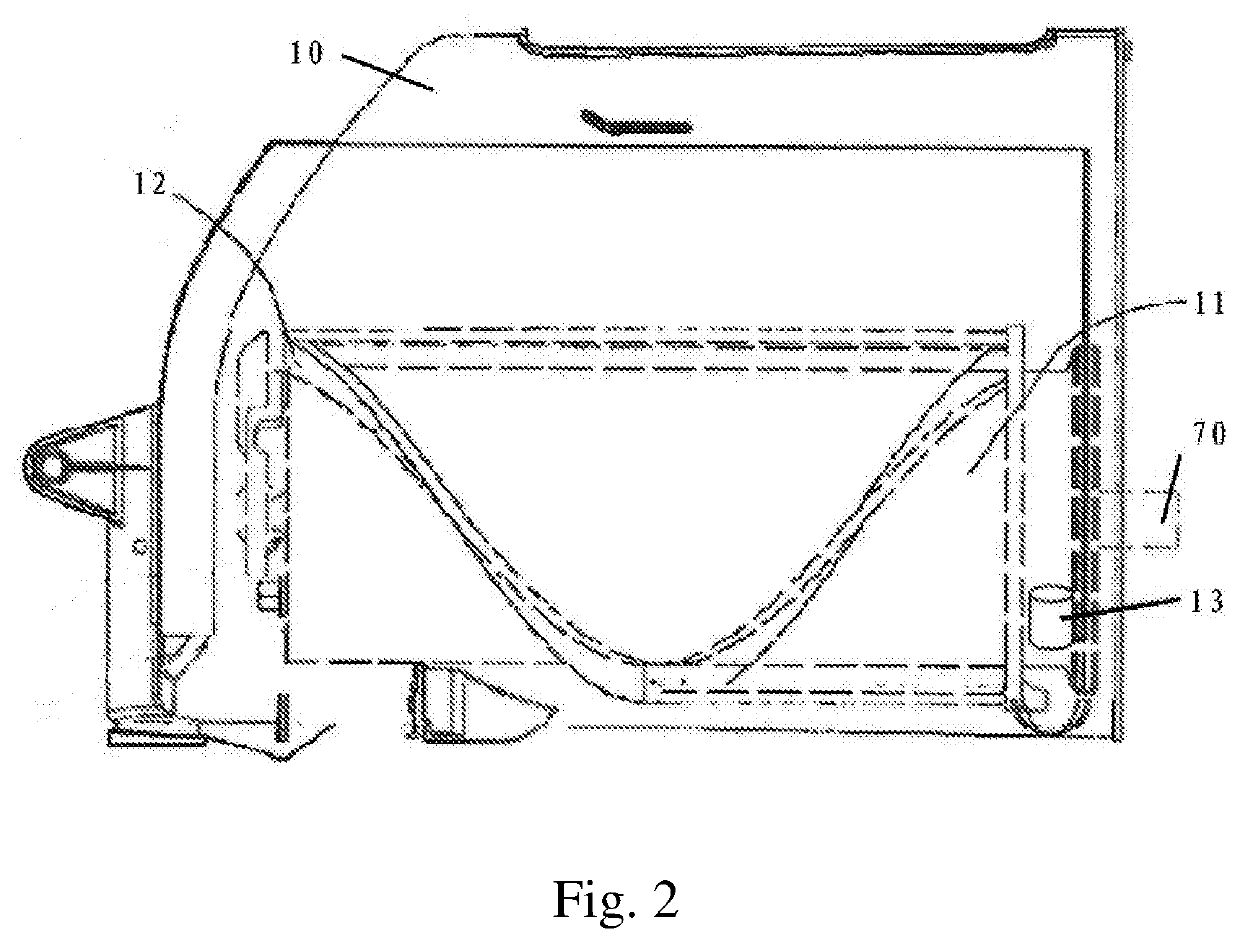

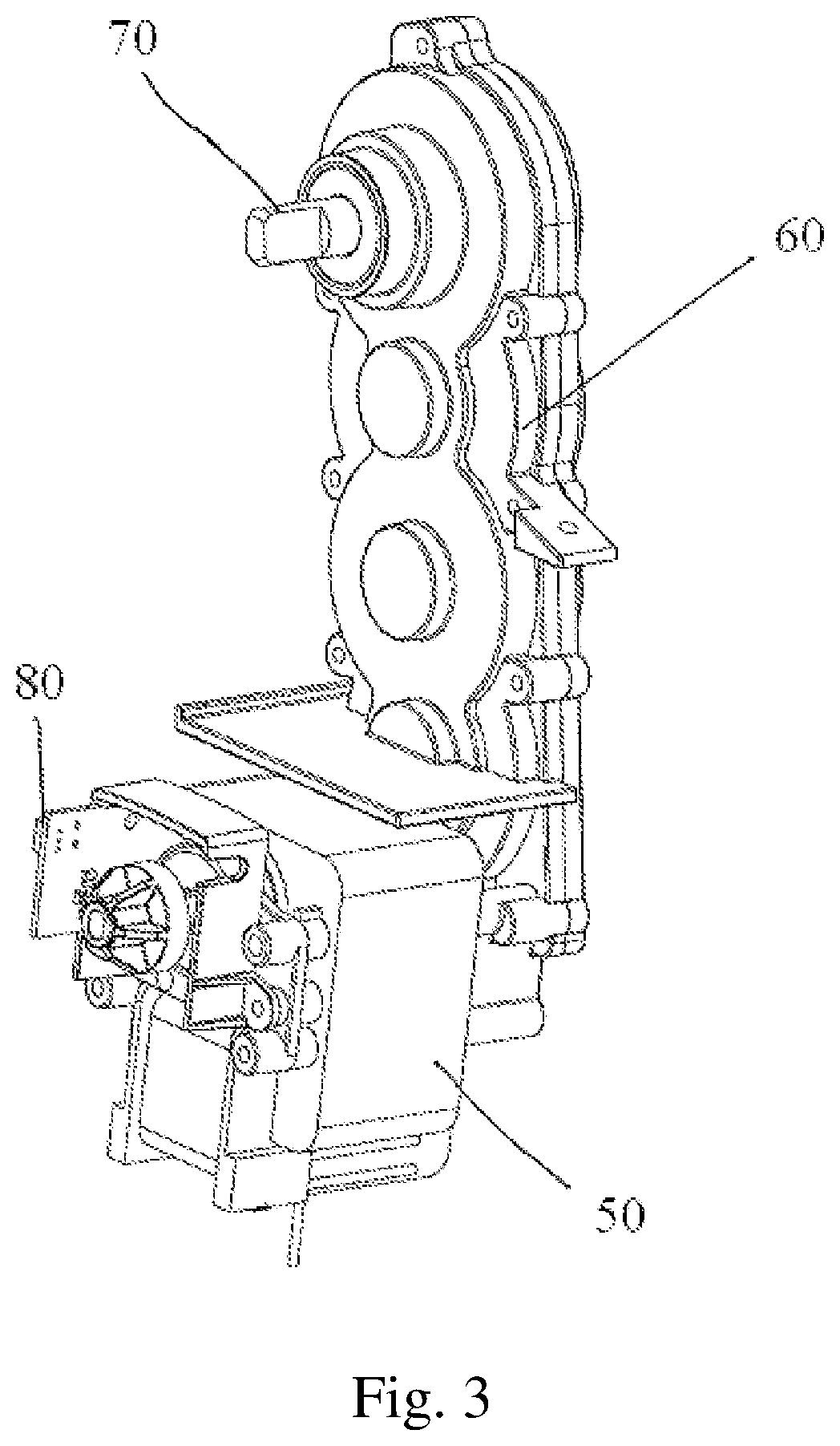

Viscous semi-liquid food dispenser and method and system for controlling food characteristics

ActiveUS20210204563A1Improve adaptabilityAvoid influenceProgramme controlComputer controlTemperature controlProcess engineering

A control method for a viscous semi-liquid frozen or hot food dispenser comprising a stirring means configured to stir the food, a motor (50) configured to drive the stirring means to rotate, a refrigerating means or heating means configured to input cold energy or heat energy into the food, a rotation speed sensor (80) configured to detect a stirring speed, and a temperature sensor (13) configured to detect the food temperature, the control method comprising the steps of: a) refrigerating or heating the food by the refrigerating means or heating means; b) comparing the food temperature detected by the temperature sensor (13) with a target preset value of the food temperature, and determining to continue the refrigeration or heating, or to stop the refrigeration or heating and to keep stopping for a preset time; c) intervening by corresponding adjustment of the target preset value when a data set collected from the rotation speed sensor (80) shows that change trend of the rotation speed meets predefined intervention conditions; and d) returning to step a) for the next cycle. The control method for a viscous semi-liquid food dispenser is capable of controlling viscosity of food accurately and reliably to maintain consistence of the characteristics of the dispensed product and minimize the influence from the environment as much as possible.

Owner:SOC DES PROD NESTLE SA

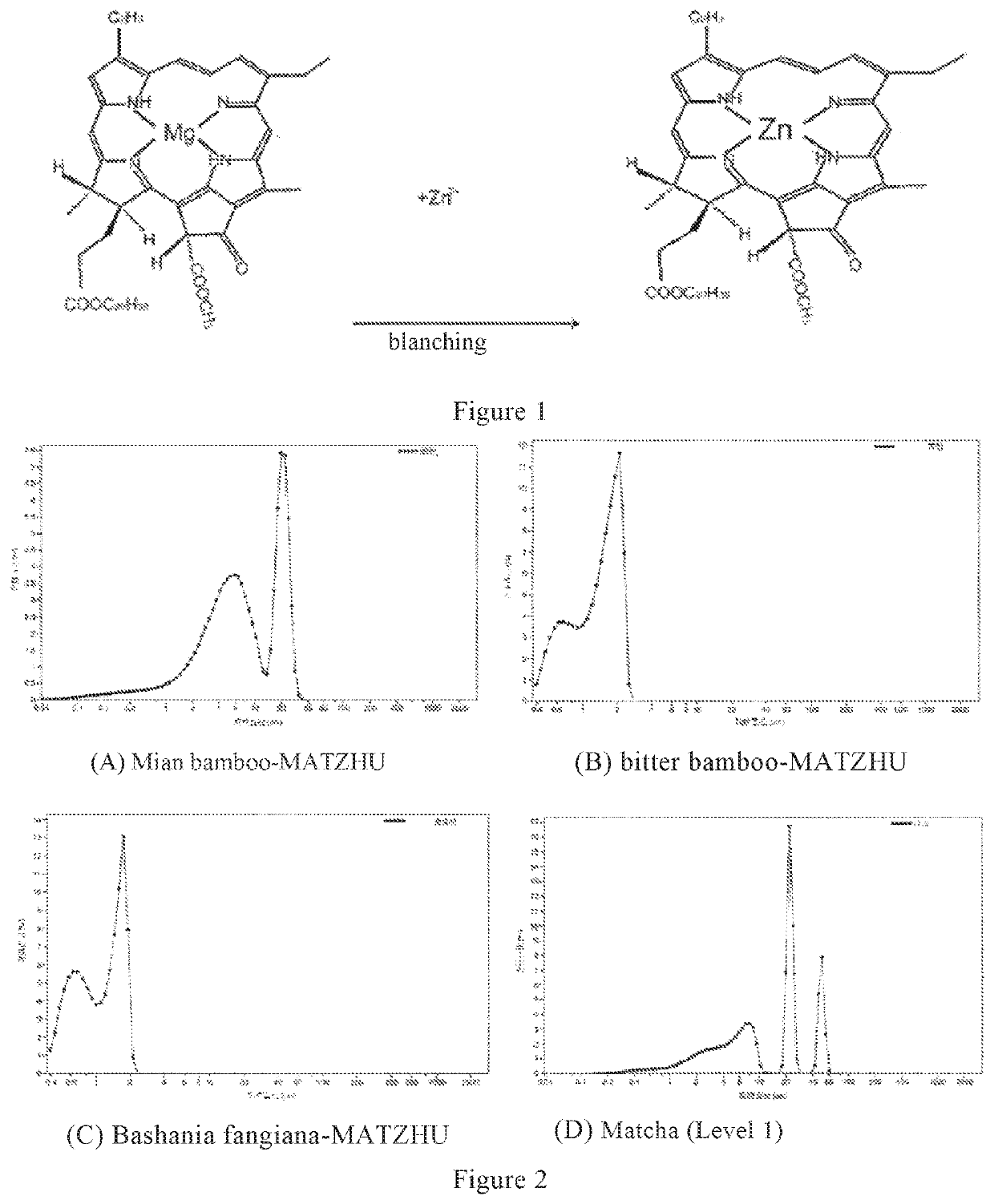

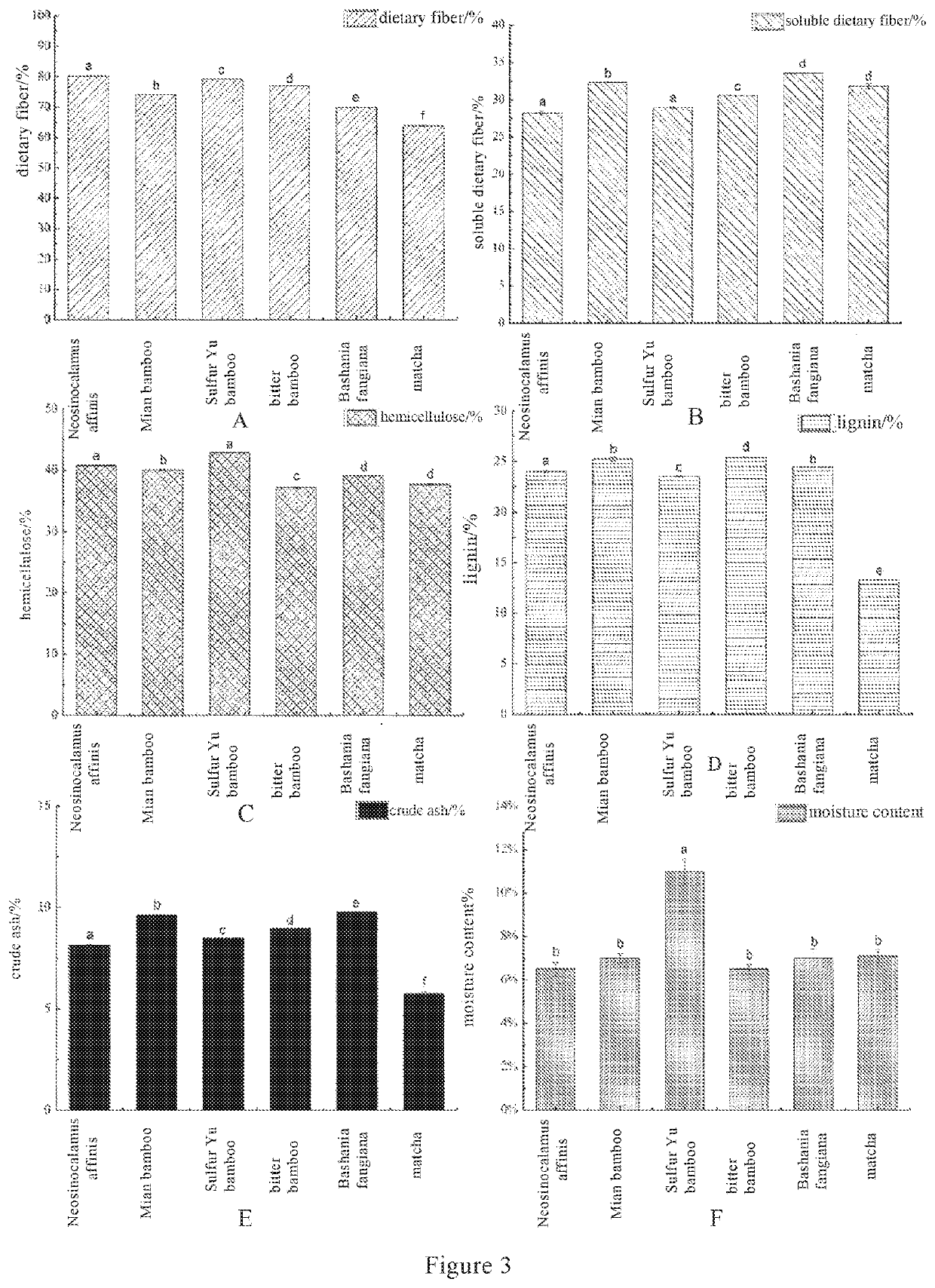

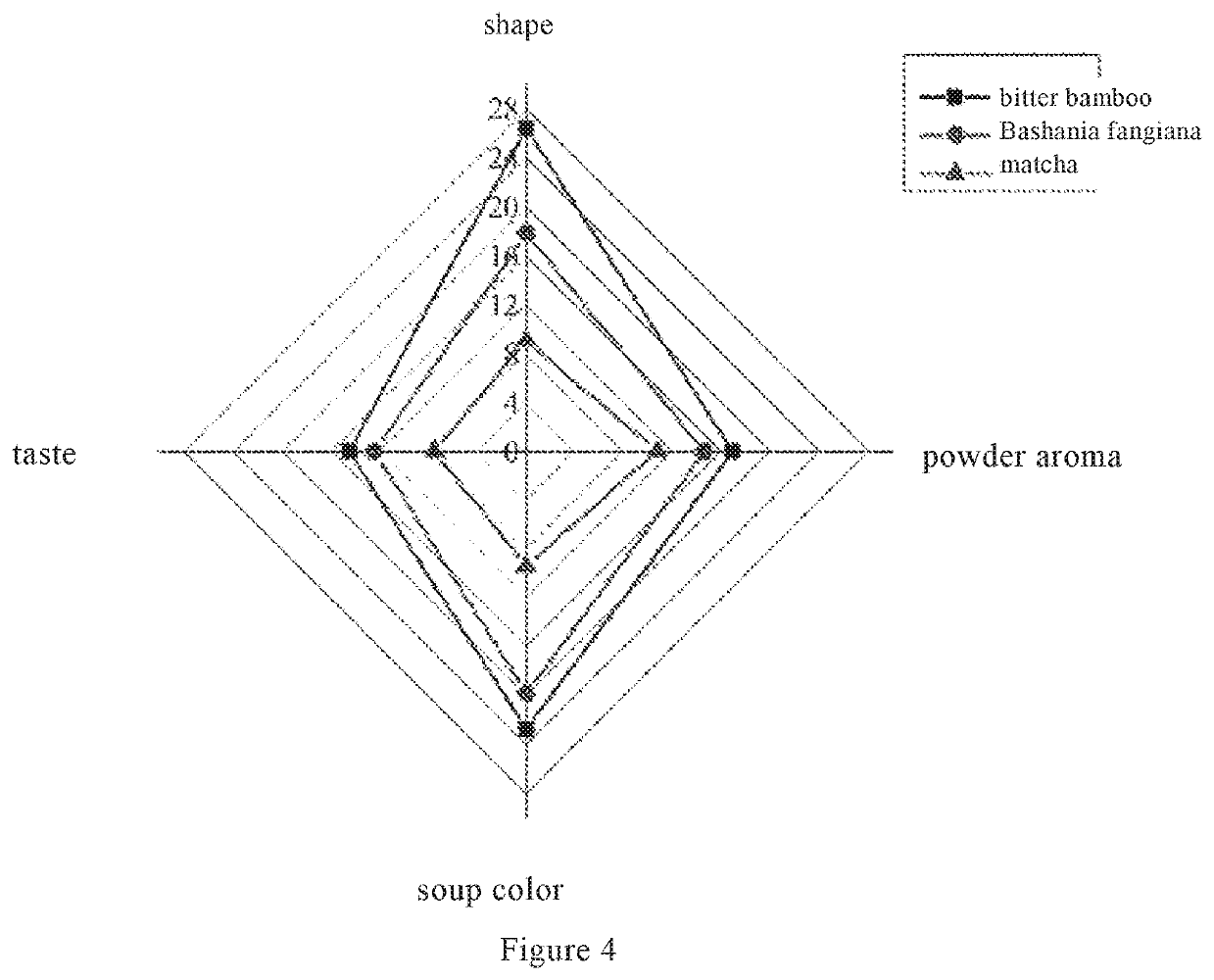

Fine bamboo powder and preparation method therefor and use thereof

ActiveUS20210177927A1High thermal stabilityLight stabilityOrganic active ingredientsSkeletal disorderCoumaric acidDietary supplement

A MATZHU is prepared by using leaves of Gramineae (Graminae) and Bambusoideae plant as raw materials. The MATZHU has a stable emerald color and an average powder particle size of 800 to 10,000 meshes. The MATZHU also has a total amount of dietary fiber of ≥60%, a content of lignin of ≥20% and a content of minerals of ≥7%. The MATZHU includes at least three or more bamboo leaf characteristic components, such as orientin, isoorientin, vitexin, isovitexin, adenosine, δ-hydroxylysine and p-coumaric acid. The method for the MATZHU preparation includes, in turn, performing blanching and color protection, drying and superfine grinding the raw materials. By utilizing the thermal stability and the light stability of the MATZHU, the MATZHU may be used as a raw food material, a functional ingredient, or a dietary supplement.

Owner:SENLONG BIO TECH CO LTD

Parking control method and device for self-driving truck, and self-driving truck

The present application provides a parking control method and device for an automatic driving truck, and the automatic driving truck, which relate to the technical field of automatic driving. The method includes: obtaining a parking task instruction; the parking task instruction includes a location to be parked; determining the global planning path of the self-driving truck according to the location to be parked; segmenting the global planning path to obtain multiple segments Plan the path; control the self-driving truck to drive according to each segment planning path in turn, and monitor the deviation data of the self-driving truck at the end of each segment planning path; re-plan the self-driving truck’s route according to the deviation data of the self-driving truck Globally plan the path until the self-driving truck is controlled to the location to be parked. The embodiment of the present application can consider the driving situation of the self-driving truck in real time, avoid the self-driving truck from seriously deviating from the originally planned route, and ensure the parking accuracy of the self-driving truck.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

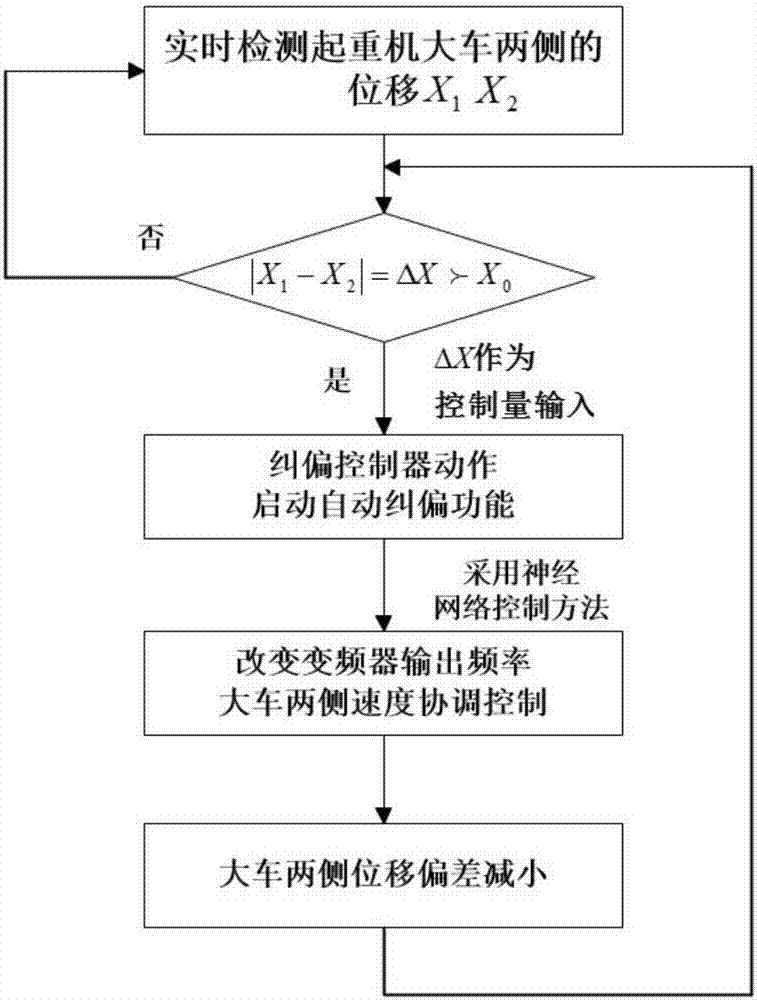

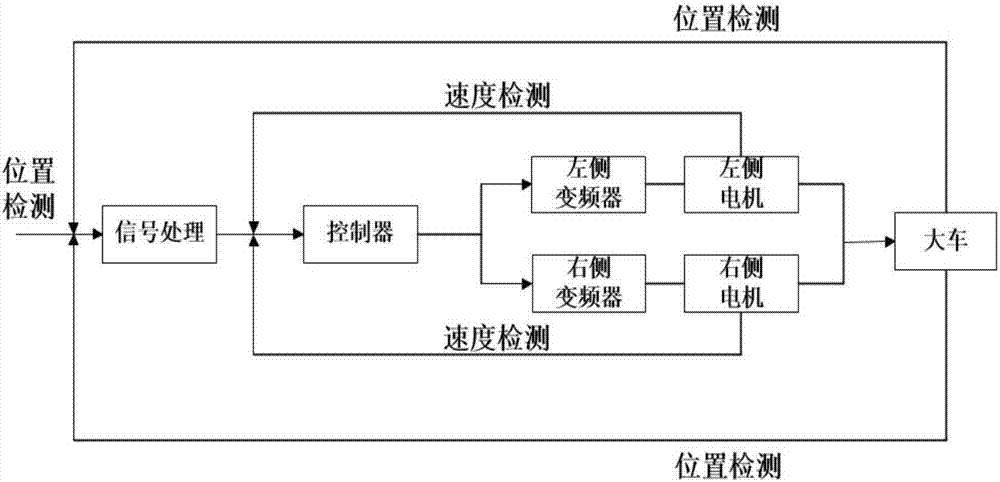

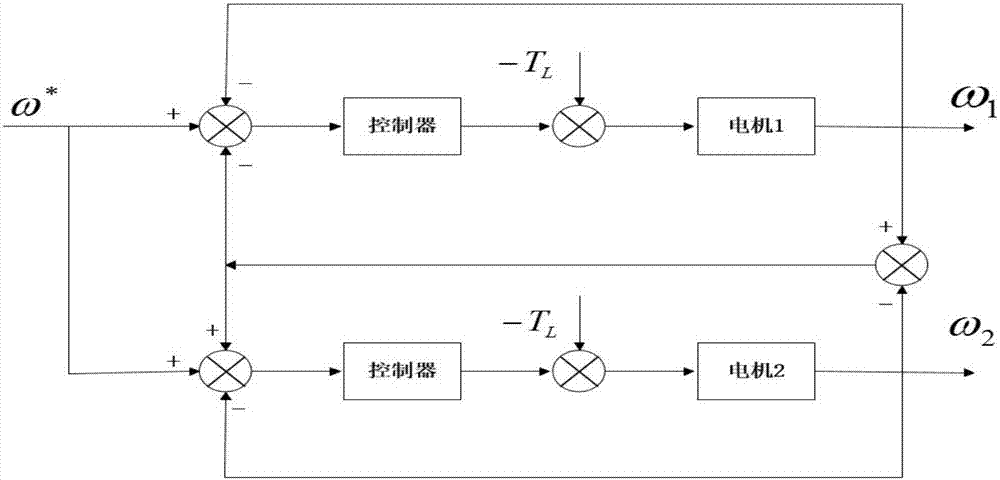

Deviation correction control method and system during traveling of bridge crane cart

The invention discloses a deviation rectification control method and system for a car of a bridge crane in the walking process. The method comprises the steps of detecting real-time displacement signals on the two sides of the car in real time in the walking process of the car; comparing the real-time displacement signals on the two sides of the car for obtaining a displacement difference value; adopting the displacement difference value as a control signal and controlling the walking speed and the displacement of the two sides of the car for adjusting the deviation of the two sides. The system comprises a detection module used for detecting the real-time displacement signals on the two sides of the car in real time in the walking process of the car, a comparison module used for comparing the real-time displacement signals on the two sides of the car for obtaining the displacement difference value, and a deviation rectification controller used for adopting the displacement difference value as the control signal and controlling the walking speed and the displacement of the two sides of the car for adjusting the deviation of the two sides. According to the deviation rectification control method and system, the deviation problem in the walking process of the car of the bridge crane can be effectively solved, the stability in the operation process of the bridge crane can be improved, the maintenance cost can be lowered, and the production efficiency can be improved.

Owner:CENT SOUTH UNIV

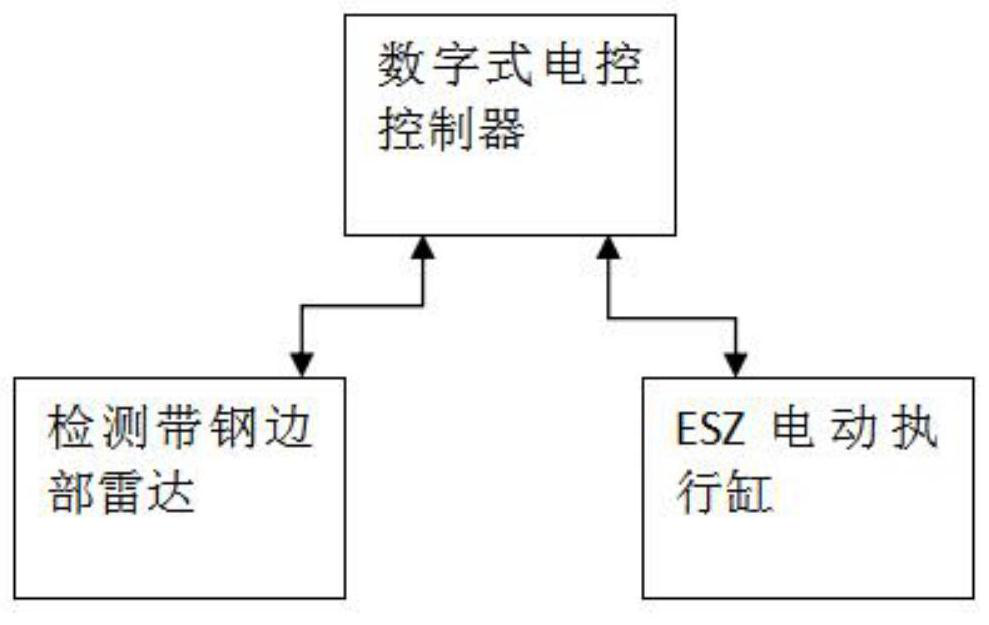

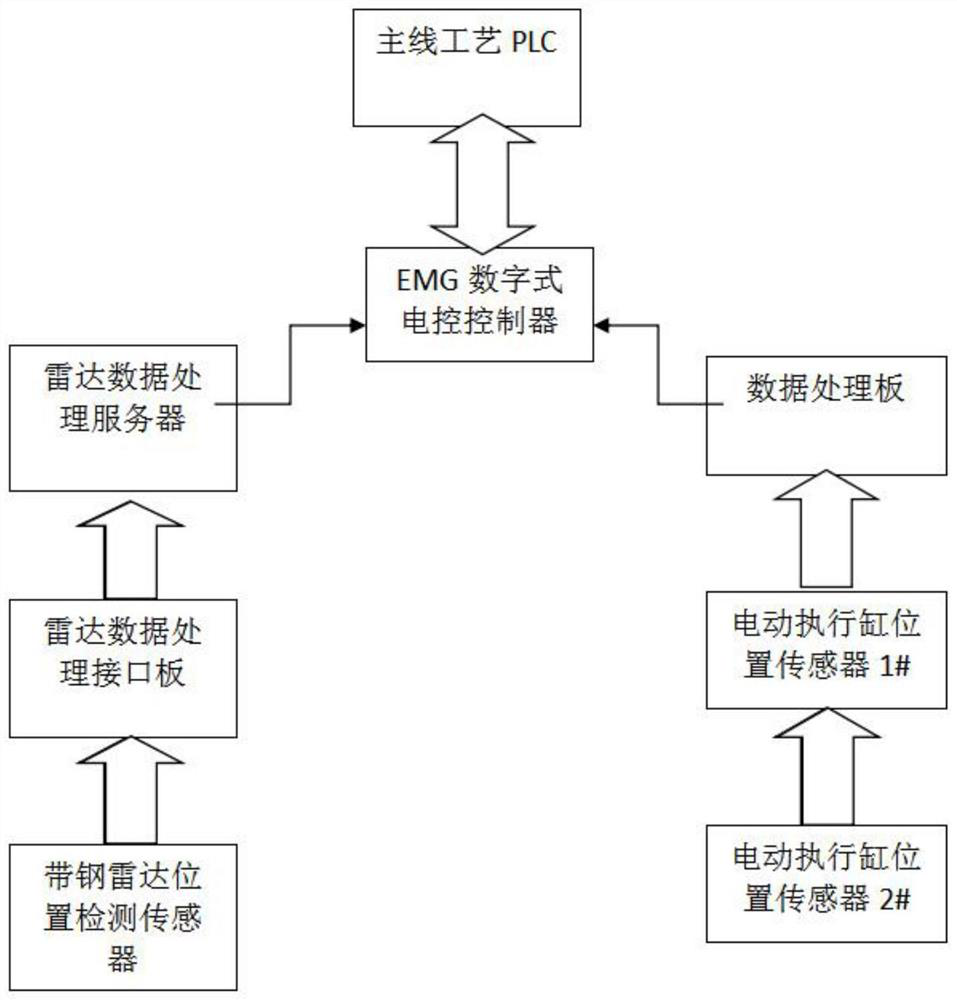

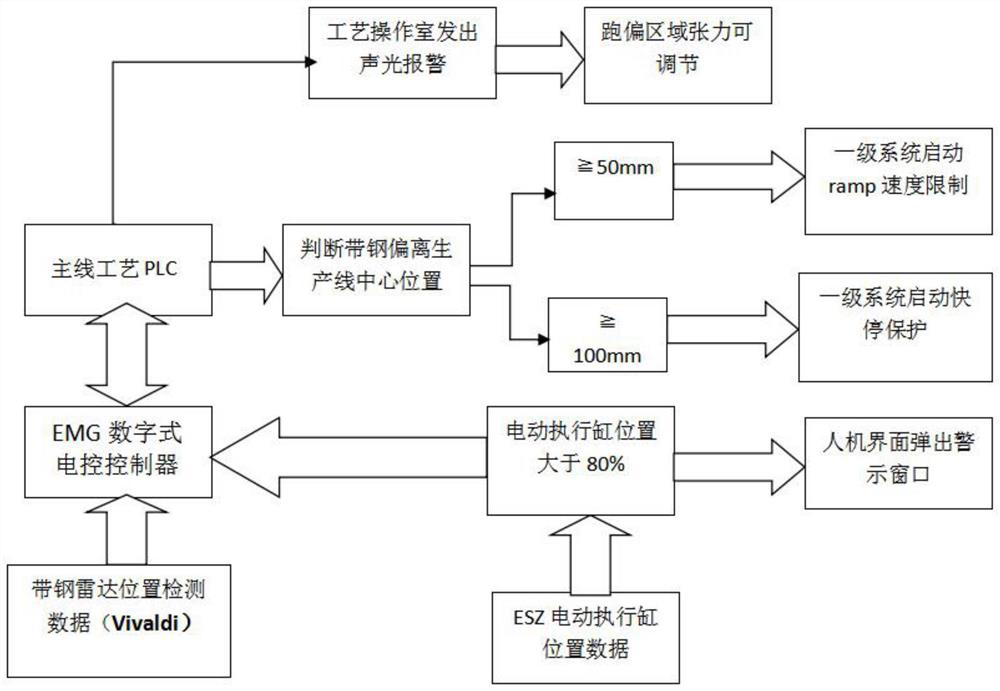

A control method for preventing strip breakage in annealing furnace of cold rolling processing line

ActiveCN111440942BReduce the degree of deviationAvoid serious deviationFurnace typesHeat treatment process controlEarly warning systemControl system

The invention discloses a control method for preventing strip breakage in the annealing furnace of a cold rolling processing line. A backup protection function is added to the original correction system. Ramp speed limit, early warning prompt system, tension compensation system control, when the strip steel deviates from the production center line by 50mm, the starting ramp speed limit is 60m / min, even if the shape of the incoming material is poor, the degree of deviation of the strip steel can be significantly reduced. It effectively avoids the serious deviation of the strip in the furnace, and at the same time greatly reduces the accident of strip breakage in the annealing furnace, so that the continuous and reliable operation of the cold rolling processing line is guaranteed.

Owner:SD STEEL RIZHAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com