Multi-stage multi-section nanofiltration salt separation treatment system and process

A treatment system and nanofiltration technology, applied in the field of water treatment, can solve the problems of miscellaneous salt hazardous waste, secondary pollution, non-reuse of miscellaneous salts, etc., to reduce the amount of salt water, ensure stable operation, and improve resistance to water quality fluctuations. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

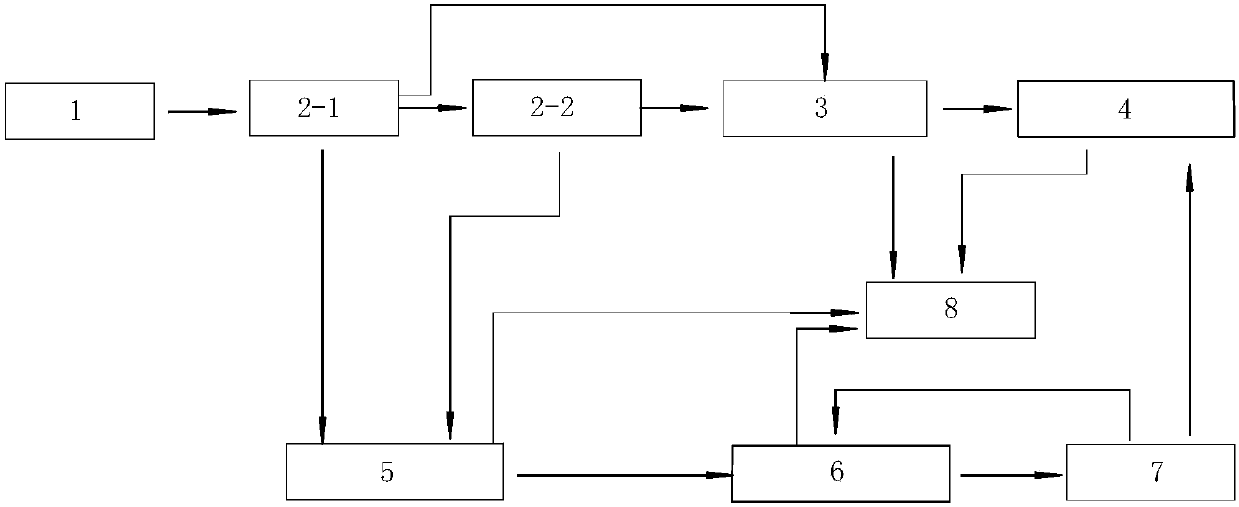

[0031] A multi-stage and multi-stage nanofiltration salt separation treatment system, which includes a pretreatment unit 1, a nanofiltration A unit 2-1, a nanofiltration B unit 2-2, a NaCl deep concentration unit 3, a NaCl evaporation crystallization unit 4, and a NaCl evaporation crystallization unit 4. 2 SO 4 Deep concentration unit 5, Na 2 SO 4 Evaporation and crystallization unit 6, freezing crystallization unit 7 and reuse water unit 8, pretreatment unit 1 is connected with the water inlet side of nanofiltration A unit 2-1, the output of nanofiltration A unit 2-1 and nanofiltration B unit 2-2 The water side is connected to the water inlet side of the NaCl deep concentration unit 3, and the concentrated water side of the nanofiltration A unit 2-1 and the nanofiltration B unit 2-2 is connected to the NaCl deep concentration unit 3. 2 SO 4 The water inlet side of the deep concentration unit 5 is connected, and the product water side and concentrated water side of the nano...

Embodiment 2

[0035] Utilize the system described in embodiment 1 to carry out the method for multistage and multistage nanofiltration salt separation, take the wastewater discharged from a certain chemical industry park as an example, the wastewater volume Q: 100m 3 / h, TDS: 12268mg / L, Cl - : 5924mg / L, SO 4 2- : 996mg / L.

[0036] The wastewater is firstly treated by a pretreatment process to remove suspended solids, colloids, turbidity and hardness in the wastewater, and obtain Q: 25m 3 / h, TDS: 49073mg / L, Cl - : 25884mg / L, SO 4 2- : 3982mg / L high-salt industrial wastewater;

[0037] (1) Nanofiltration process, high-salt industrial wastewater is firstly treated by nanofiltration of nanofiltration unit A, and the concentrated water is then treated by nanofiltration of nanofiltration unit B, and the produced water of nanofiltration unit A and nanofiltration unit B is mixed Get Q: 17.5m 3 / h, TDS is 37001mg / L, Cl - : 26509mg / L, SO 4 2- : 65mg / L nanofiltration product water, get con...

Embodiment 3

[0045] Utilize the system described in embodiment 1 to carry out the method for multistage multistage nanofiltration salt separation, take the wastewater discharged from a certain chemical industry park as an example, the wastewater volume Q: 150m 3 / h, TDS: 9450mg / L, Cl - : 4000mg / L, SO 4 2- : 1100mg / L.

[0046] The wastewater is firstly treated by a pretreatment process to remove suspended solids, colloids, turbidity and hardness in the wastewater, and obtain Q: 34m 3 / h, TDS: 48127mg / L, Cl - : 24750mg / L, SO 4 2- : 4920mg / L high-salt industrial wastewater;

[0047] (1) Nanofiltration process, the concentrated brine is treated by nanofiltration of Nanofiltration A unit 2-1 to obtain Q: 23.8m 3 / h, TDS is 42433mg / L, Cl - : 25000mg / L, SO 4 2- : 340mg / L of nanofiltration product water and Q: 10.2m 3 / h, TDS is 65209mg / L, Cl - : 20653mg / L, SO 4 2- : 20022mg / L nanofiltration concentrated water;

[0048] (2) NaCl concentration and crystallization process, the nanofil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com