Patents

Literature

39results about How to "Reduce the degree of deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

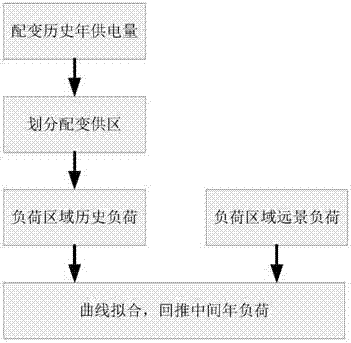

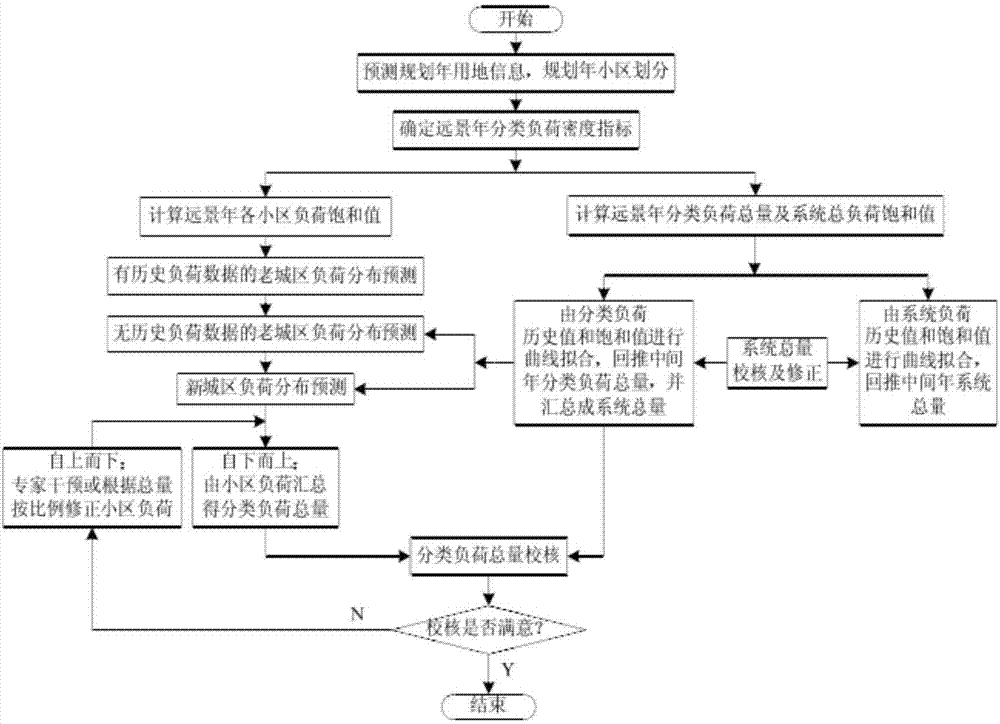

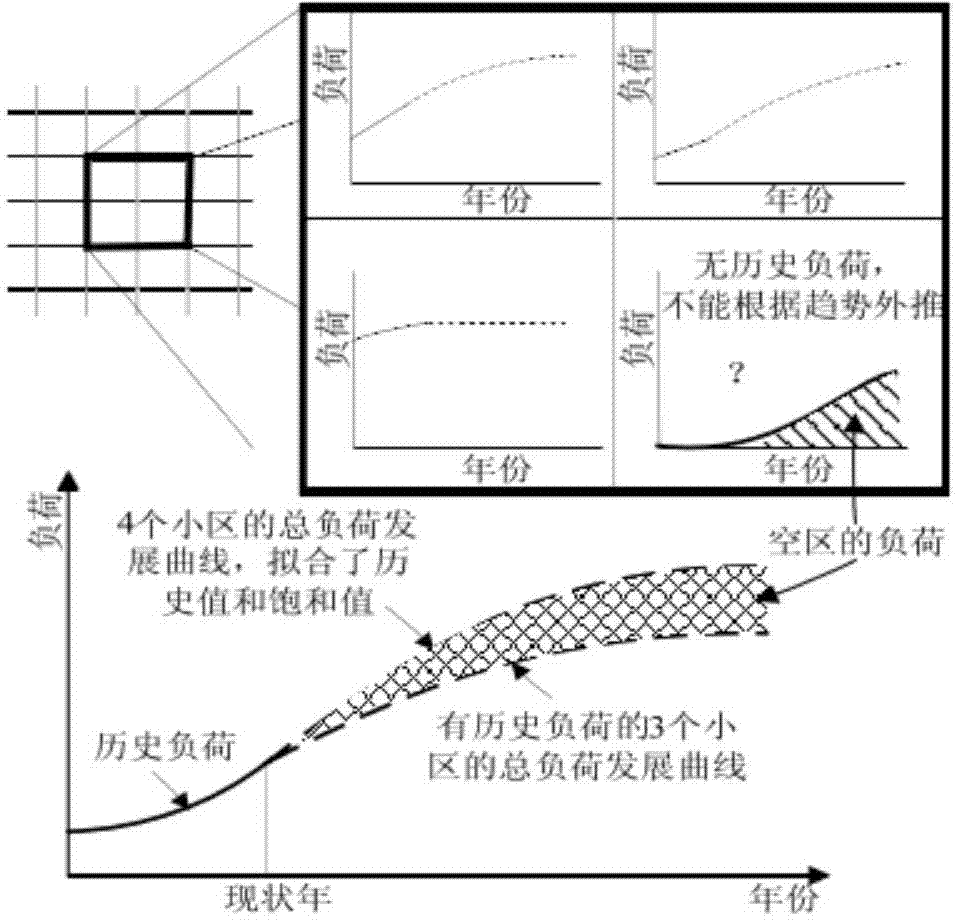

Space load prediction method

The invention relates to a space load prediction method and belongs to the field of power systems. The method includes the steps of firstly, predicting the land using information of a planning year, and dividing lands of the planning year according to communities to determine the classification load density index of a future year; secondly, calculating the load saturation value of each community in the future year, and calculating the total classification load amount and total load saturation value of the future year at the same time; thirdly, using the data of the second step to predict the load distribution of an old city area; fourthly, using the data of the second step to predict the load distribution of a new city area through space deduction; fifthly, checking the load prediction result of the planning year; sixth, continuing checking if the checking result is unsatisfactory until the checking result is satisfactory. By the method, the problem that the prediction load of all same-classification old city areas is obtained according to unified classification load average density is solved, prediction precision is improved effectively, and additional data can be obtained easily.

Owner:STATE GRID CORP OF CHINA +1

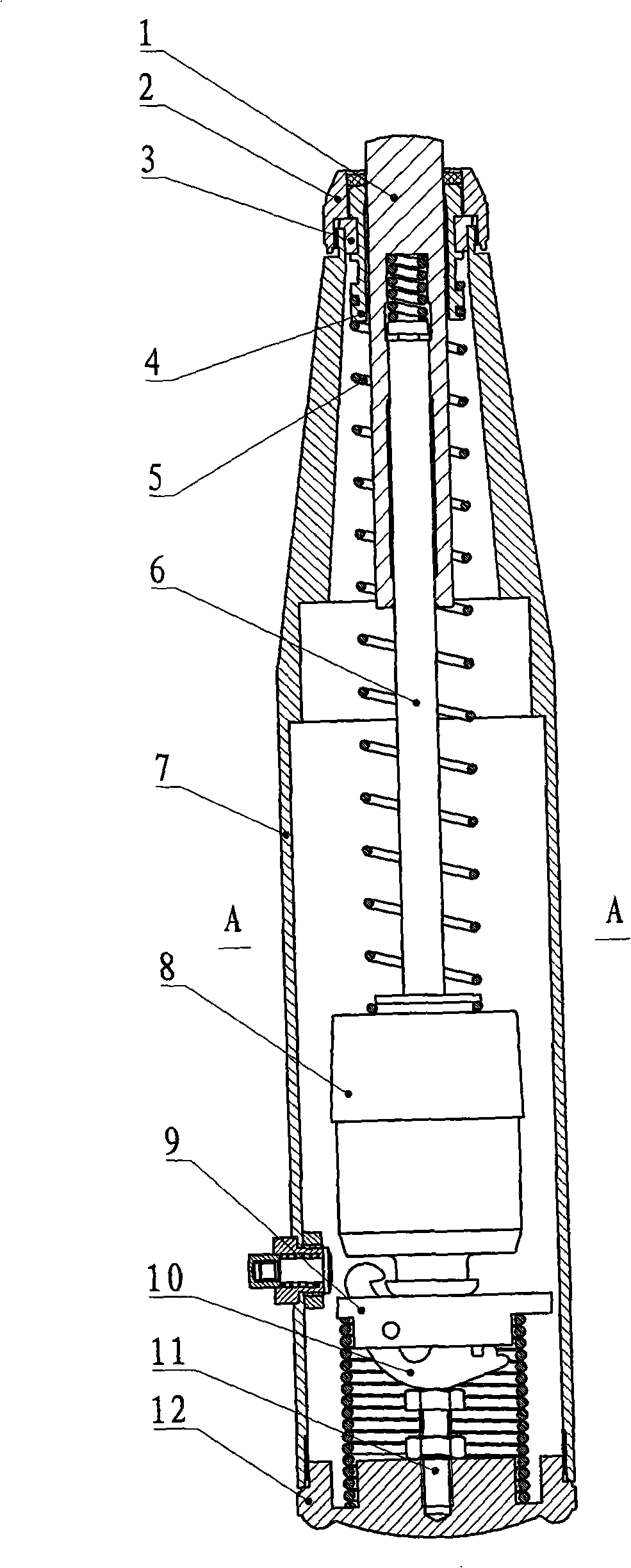

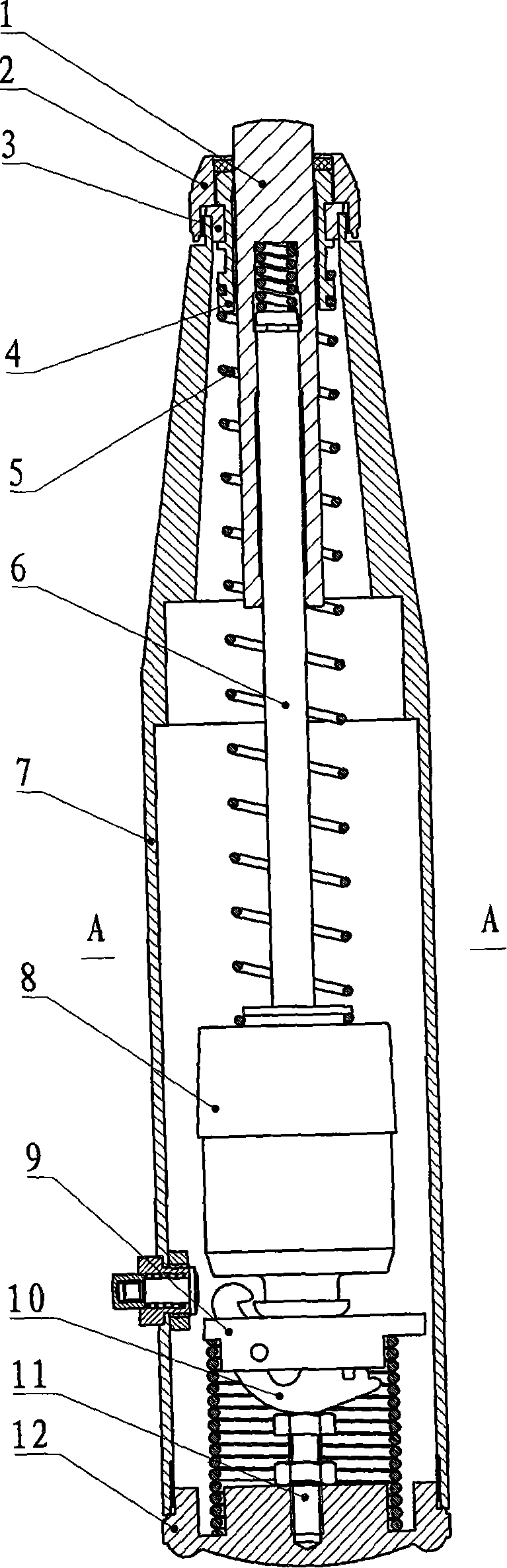

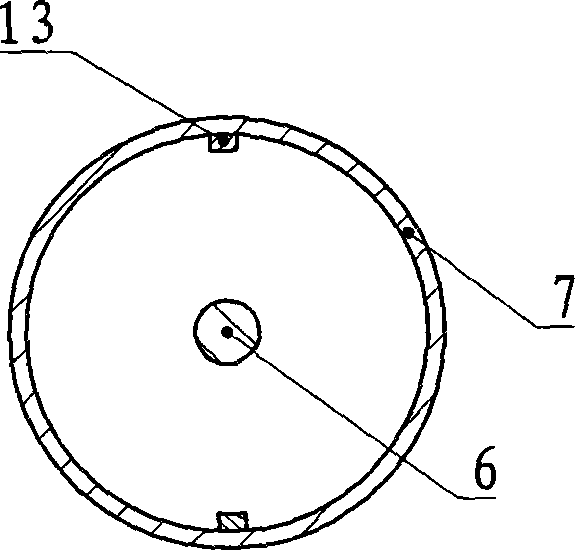

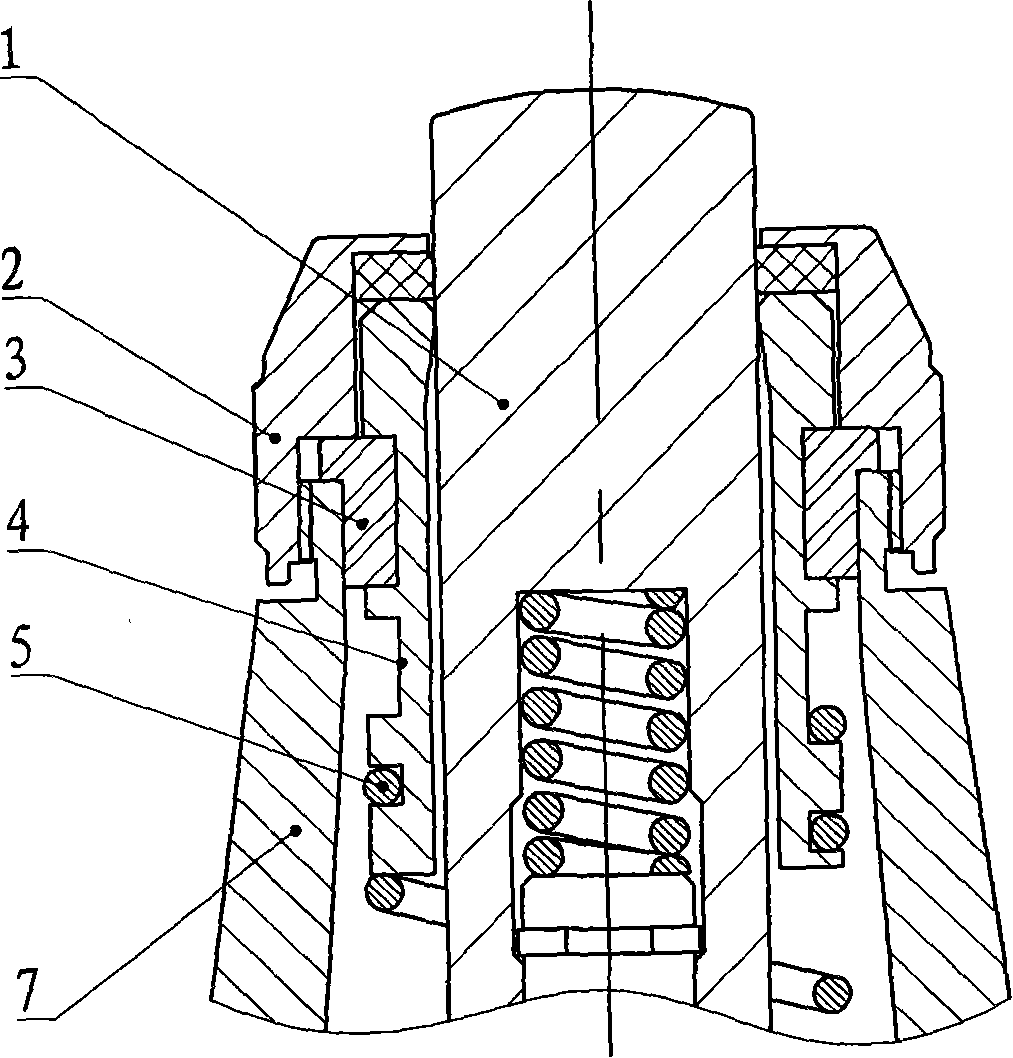

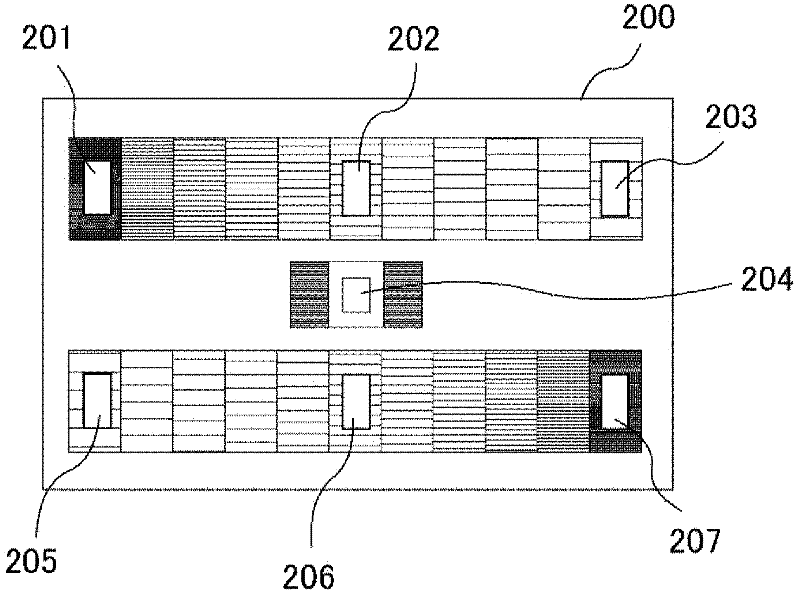

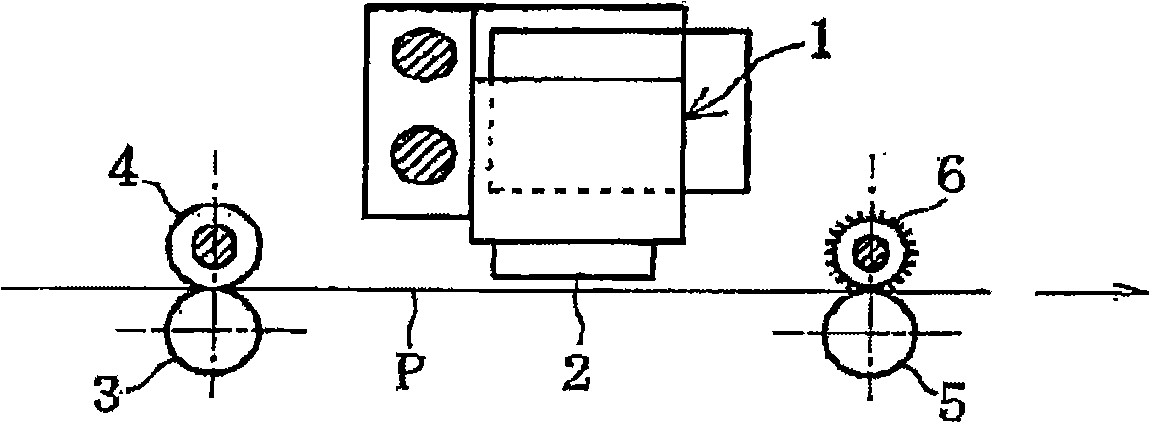

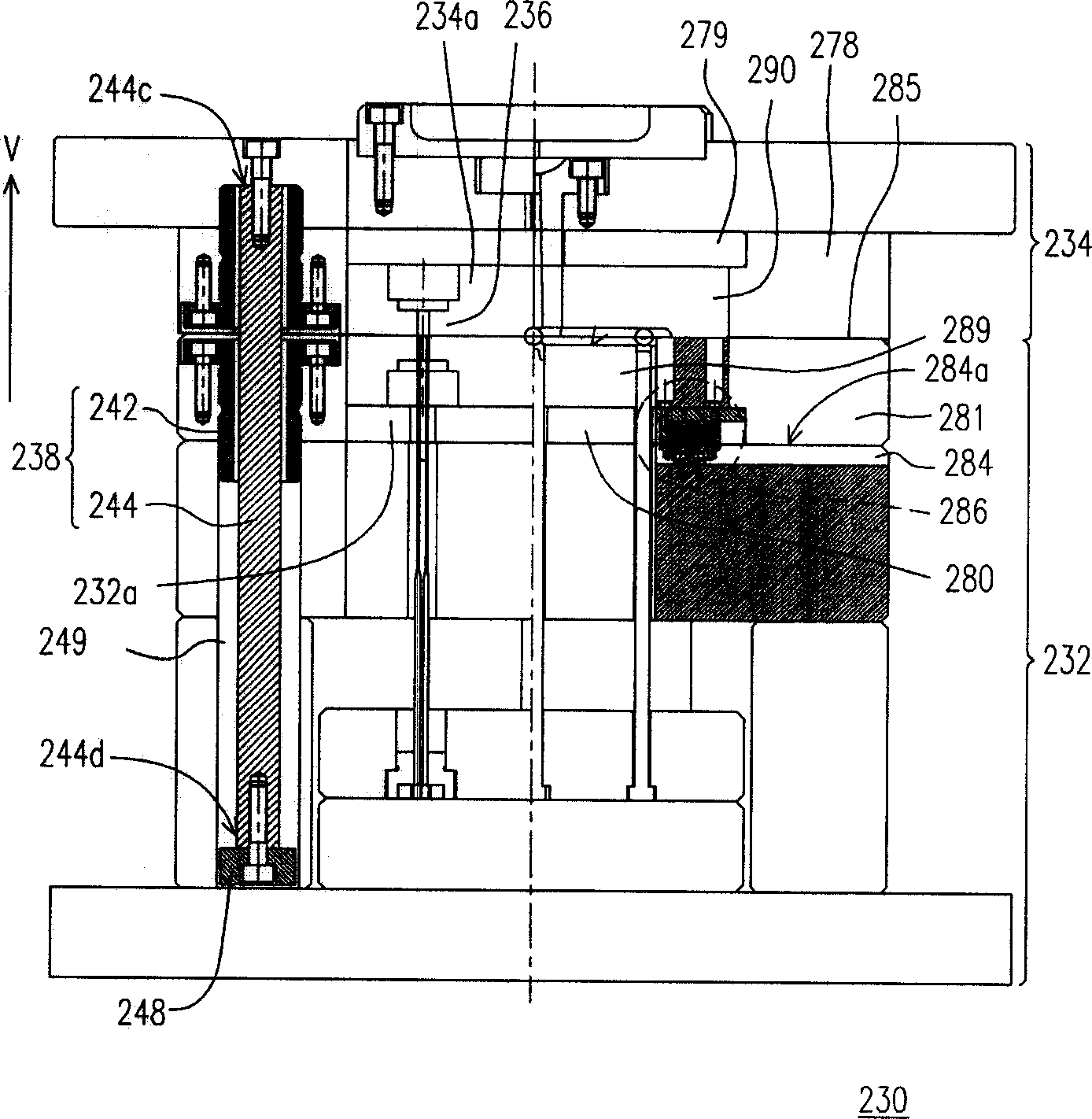

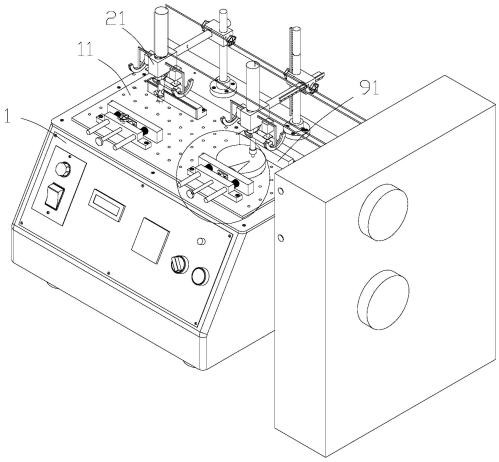

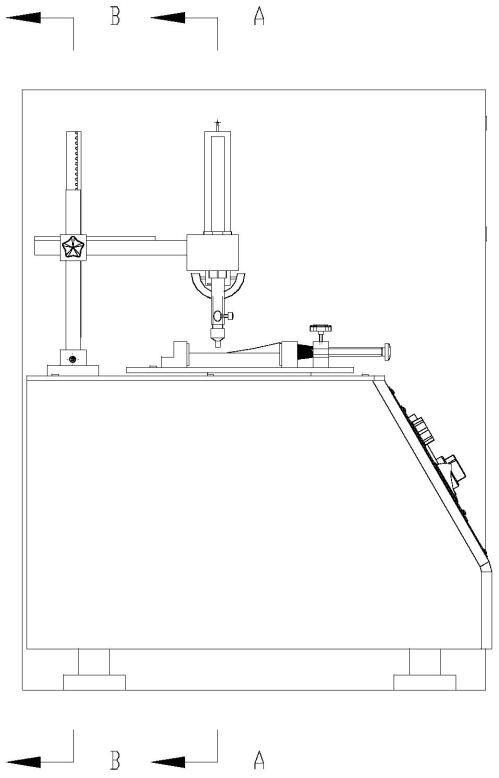

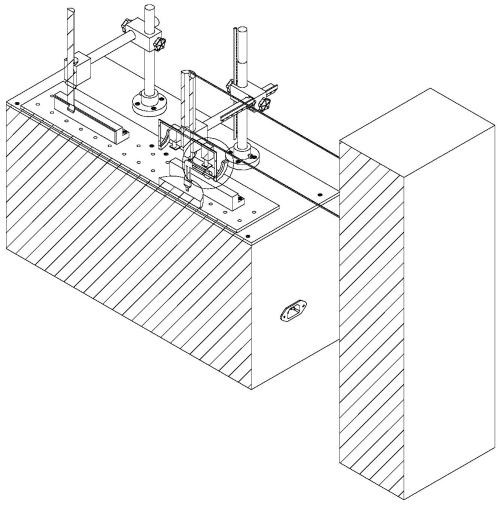

Digital rebound tester

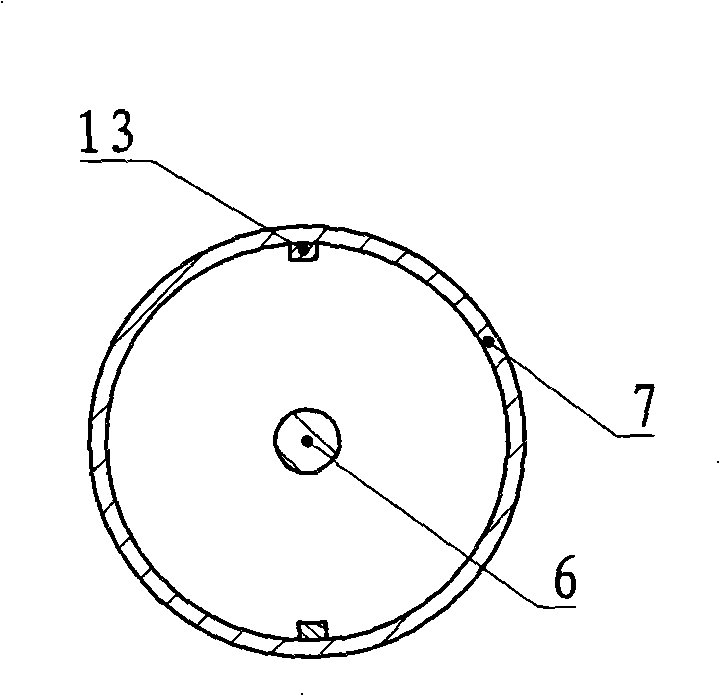

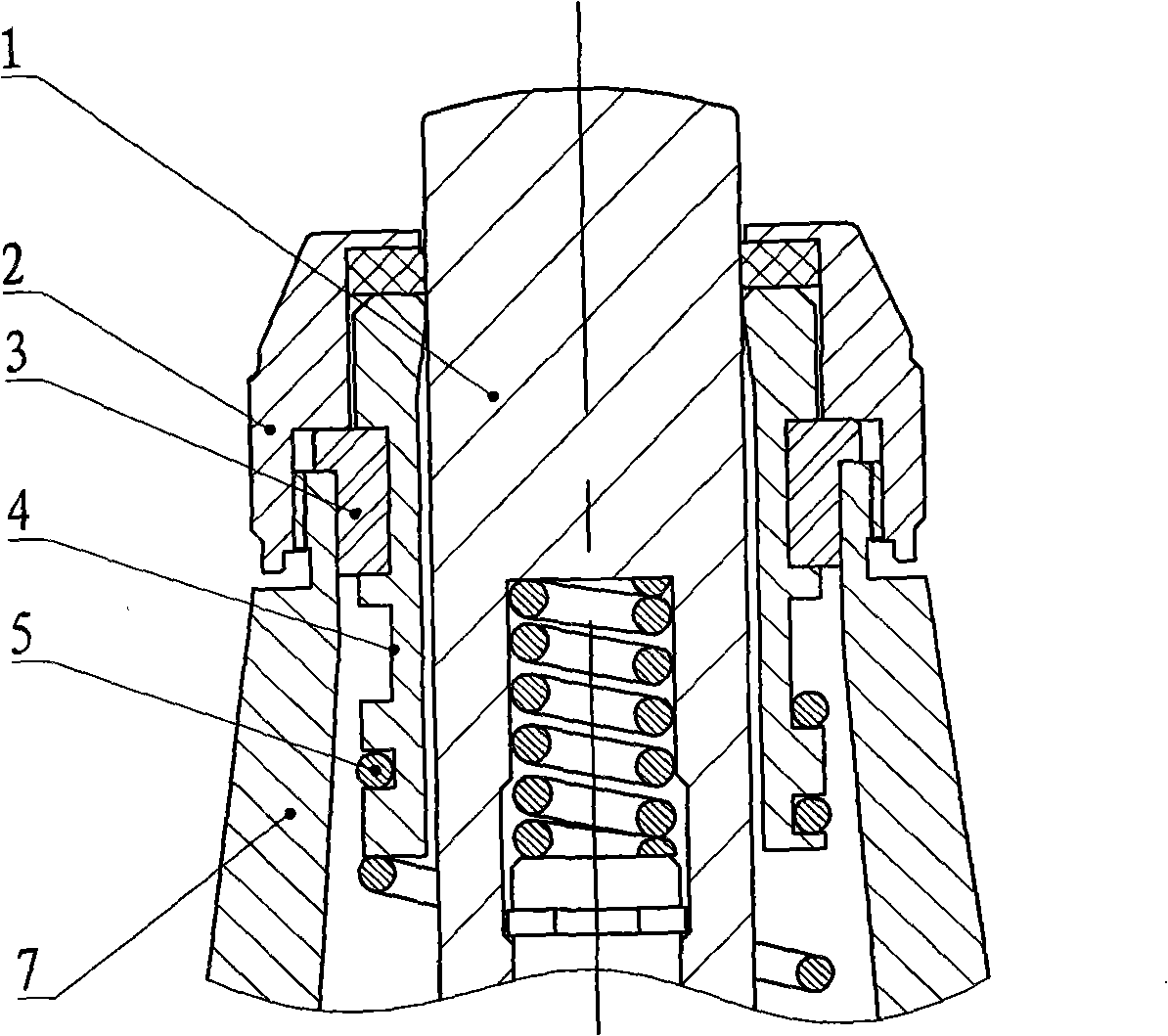

ActiveCN101329240AHigh measurement accuracyAvoid influenceInvestigating material hardnessEngineeringForce sensor

The invention provides a digital resiliometer which is provided with a resiliometer shell [2, 7] which is internally provided with a spring component which is provided with a pullback spring [5]; the front end of the pullback spring is arranged on a spring base [4] and the rear end thereof is connected with a spring hammer; the pullback spring is arranged at the front end of the resilliometer shell through the pullback spring; the pullback spring base and the resiliometer shell are connected with each other by a force sensor [3]. The digital resiliometer fully abandons a pointer system which is necessary for traditional resiliometer; compared with the prior art, the digital resiliometer simplifies the mechanical structure of the resiliometer, omits the point system which has most complicated mechanical structure in the resiliometer, completely eliminates the problems such as measurement precision, stability, and durability, etc. due to the pointer system, radiacally improves the measurement precision, stability, durability and service life of the digital resiliometer, effectively simplifies the production process and flows of the mechanical parts of the digital resiliometer, thus reducing the comprehensive production cost of the mechanical part of the digital resiliometer.

Owner:舟山市博远科技开发有限公司

Transformer substation infrared image segmentation method based on improved two-dimensional Otsu algorithm

ActiveCN105205829AReduce the degree of deviationReduce mistakesImage enhancementImage analysisFeature extractionImage segmentation

The invention discloses a transformer substation infrared image segmentation method based on an improved two-dimensional Otsu algorithm, solves the problem that the conventional two-dimensional Otsu algorithm has error segmentation and incomplete target segmentation; the method lies in that the weight adaptive algorithm of the morphology is adopted for performing denoising on an input image, and the improved two-dimensional Otsu algorithm is finally adopted for performing image segmentation. According to the transformer substation infrared image segmentation method provided by the invention, target regions can be divided completely and effectively, and a good foundation is laid for characteristic extraction of subsequent target regions.

Owner:DATONG POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +2

Digital rebound tester

ActiveCN101329240BHigh measurement accuracySimple mechanical structureInvestigating material hardnessEngineeringForce sensor

The invention provides a digital resiliometer which is provided with a resiliometer shell [2, 7] which is internally provided with a spring component which is provided with a pullback spring [5]; the front end of the pullback spring is arranged on a spring base [4] and the rear end thereof is connected with a spring hammer; the pullback spring is arranged at the front end of the resilliometer shell through the pullback spring; the pullback spring base and the resiliometer shell are connected with each other by a force sensor [3]. The digital resiliometer fully abandons a pointer system which is necessary for traditional resiliometer; compared with the prior art, the digital resiliometer simplifies the mechanical structure of the resiliometer, omits the point system which has most complicated mechanical structure in the resiliometer, completely eliminates the problems such as measurement precision, stability, and durability, etc. due to the pointer system, radiacally improves the measurement precision, stability, durability and service life of the digital resiliometer, effectively simplifies the production process and flows of the mechanical parts of the digital resiliometer, thus reducing the comprehensive production cost of the mechanical part of the digital resiliometer.

Owner:舟山市博远科技开发有限公司

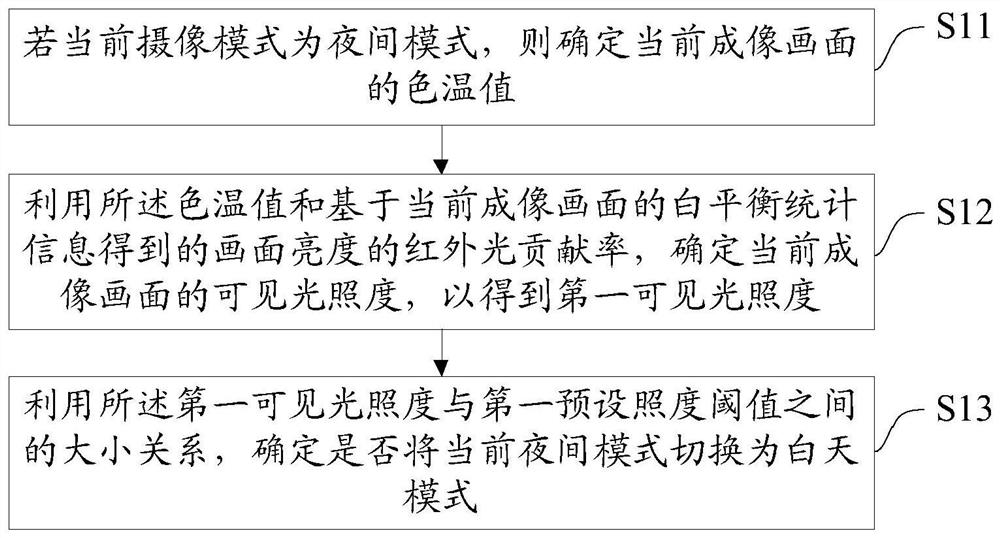

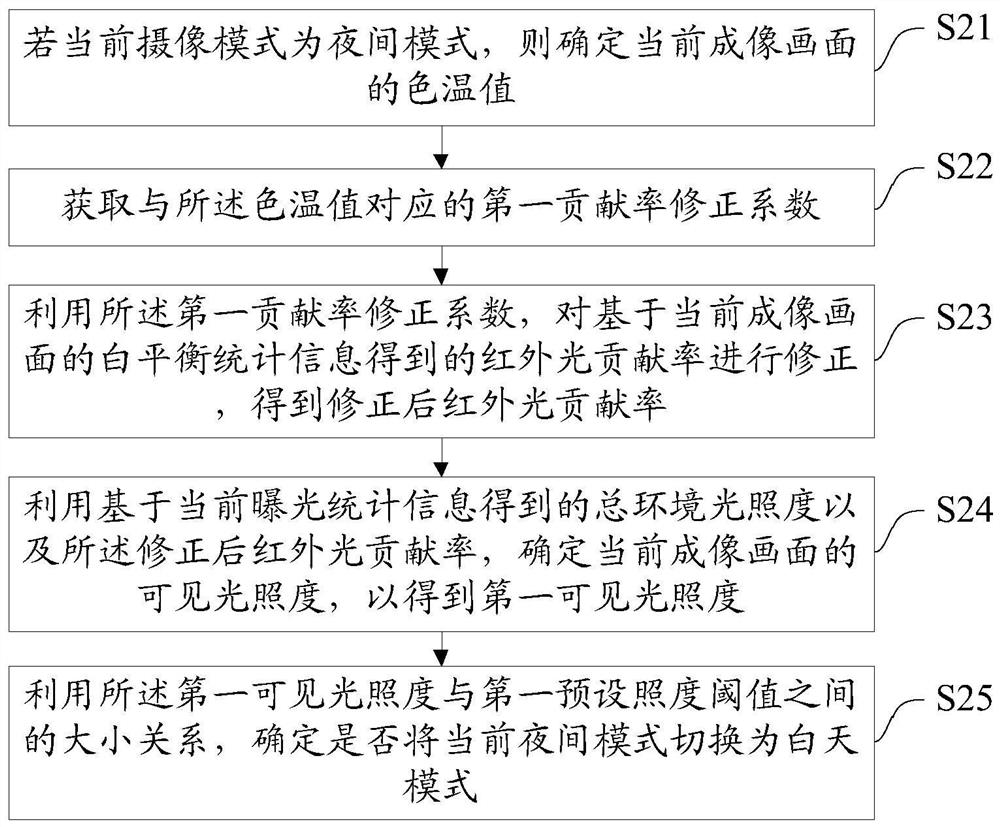

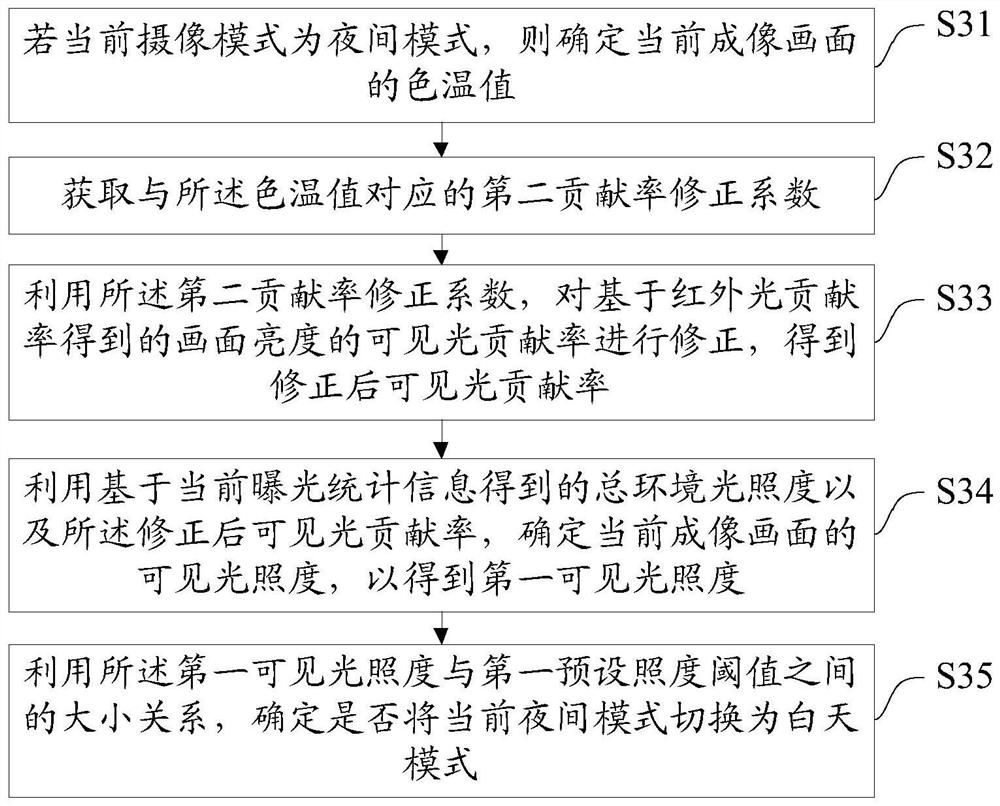

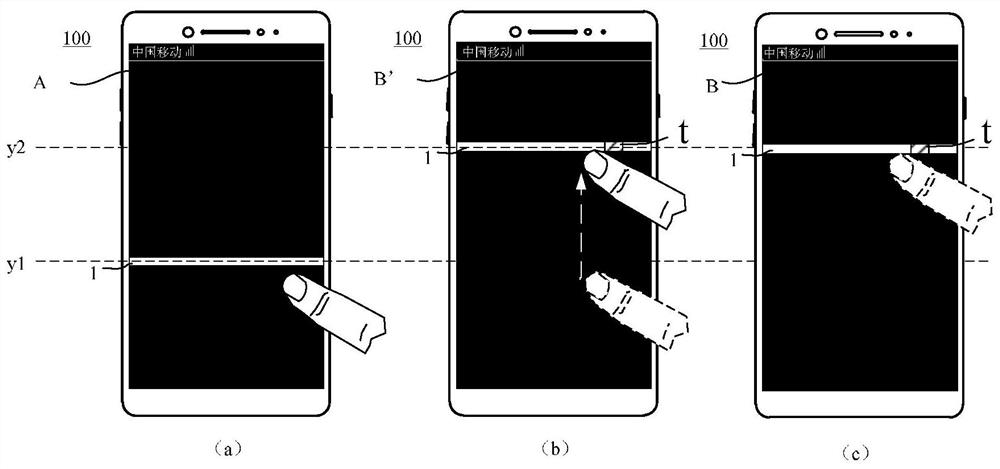

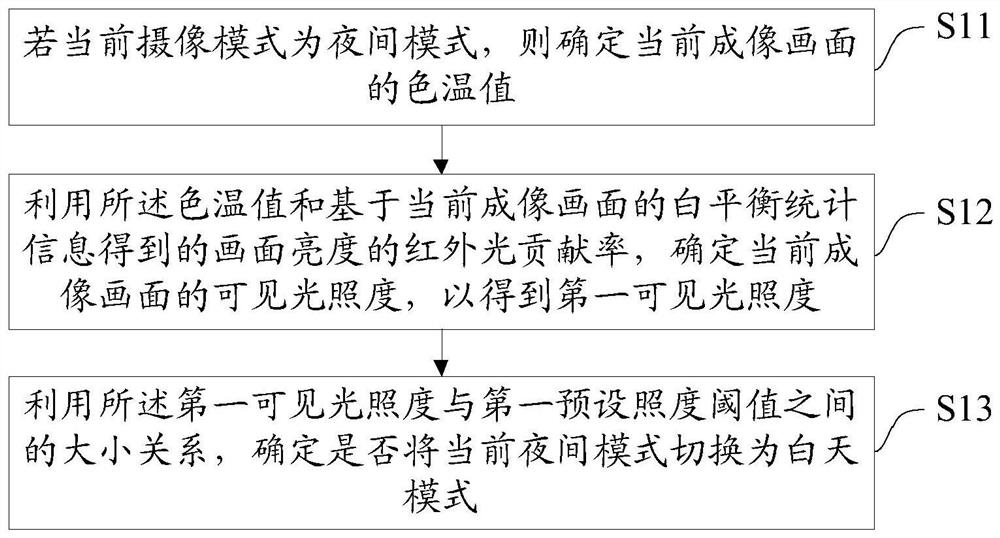

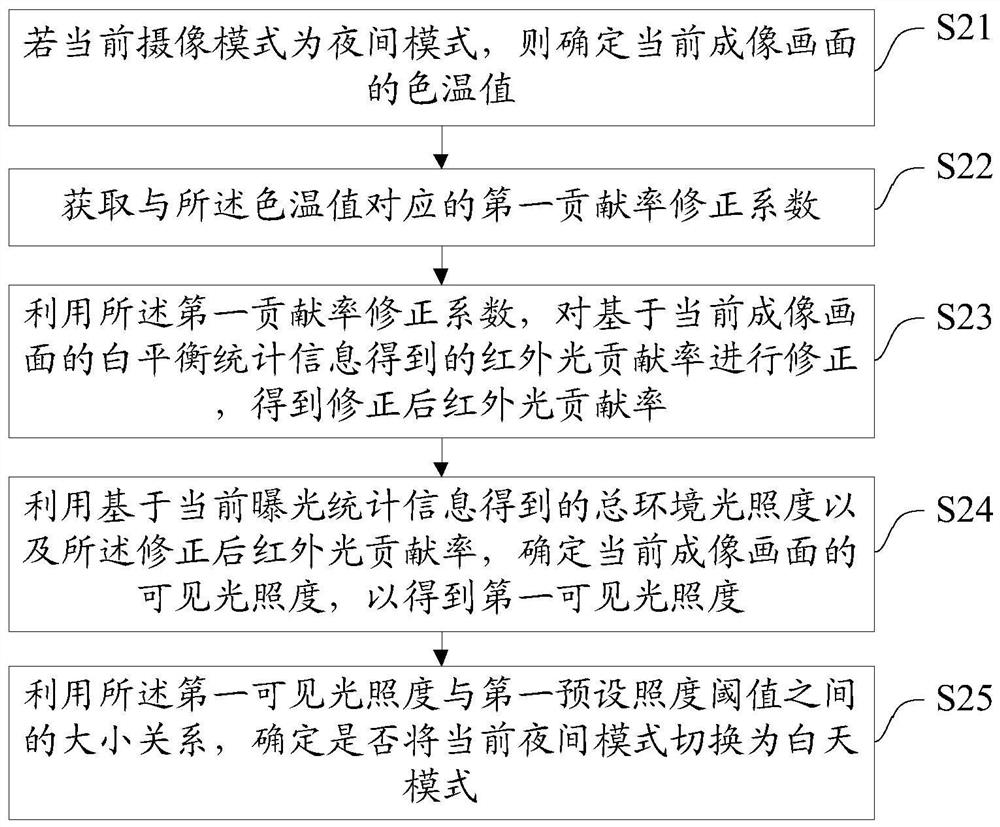

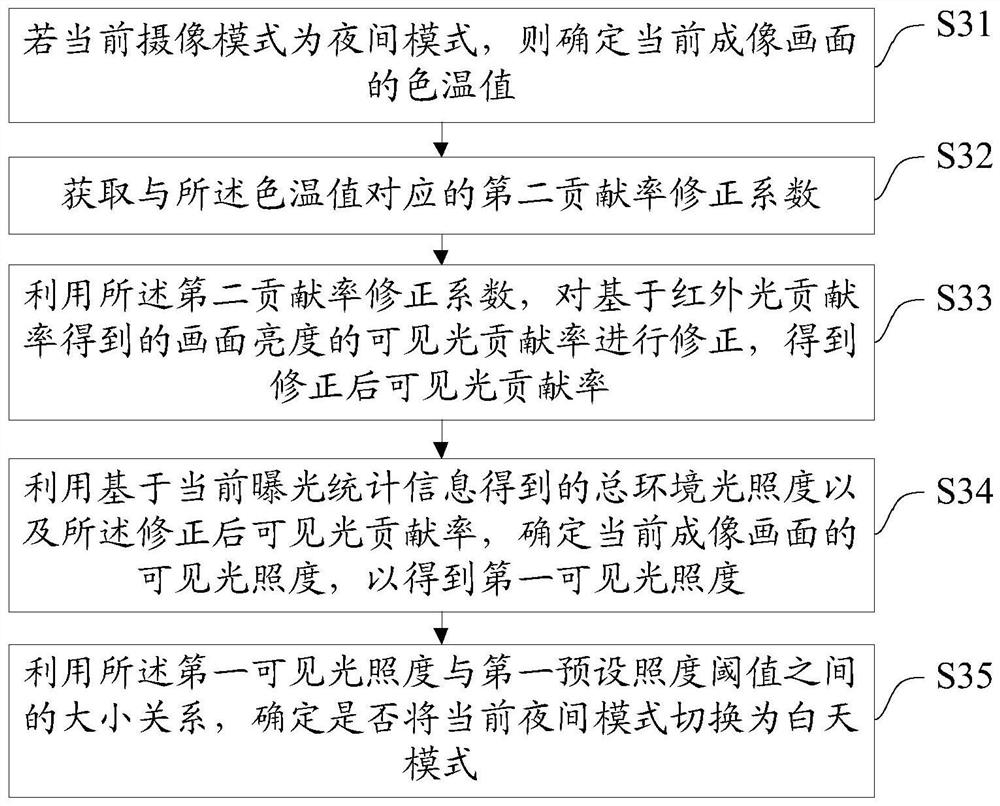

Camera, day and night mode switching method and device thereof, equipment and medium

ActiveCN111726514AImprove accuracyReduce the degree of deviationImage enhancementTelevision system detailsPhysicsColor temperature

The invention discloses a camera, a day and night mode switching method and device thereof, equipment and a medium. The method comprises the steps: determining a color temperature value of a current imaging image if a current photographing mode is a night mode; determining the visible illuminance of the current imaging picture by using the color temperature value and the infrared light contribution rate of the picture brightness obtained based on the white balance statistical information of the current imaging picture, and determining whether to switch the current night mode to the daytime mode by using the size relationship between the visible illuminance and a first preset illuminance threshold. According to the method disclosed in the invention, in the process of determining the visiblelight illuminance in the night mode, the influence of the infrared light contribution rate obtained based on the white balance statistical information on the visible light illuminance is considered;the influence of the color temperature value of the imaging picture in the current night mode on the visible light illuminance is further considered, so that the deviation degree between the imaging picture and the actual visible light illuminance is reduced, and the problem of repeated switching of day and night modes is effectively solved.

Owner:ZHEJIANG UNIVIEW TECH

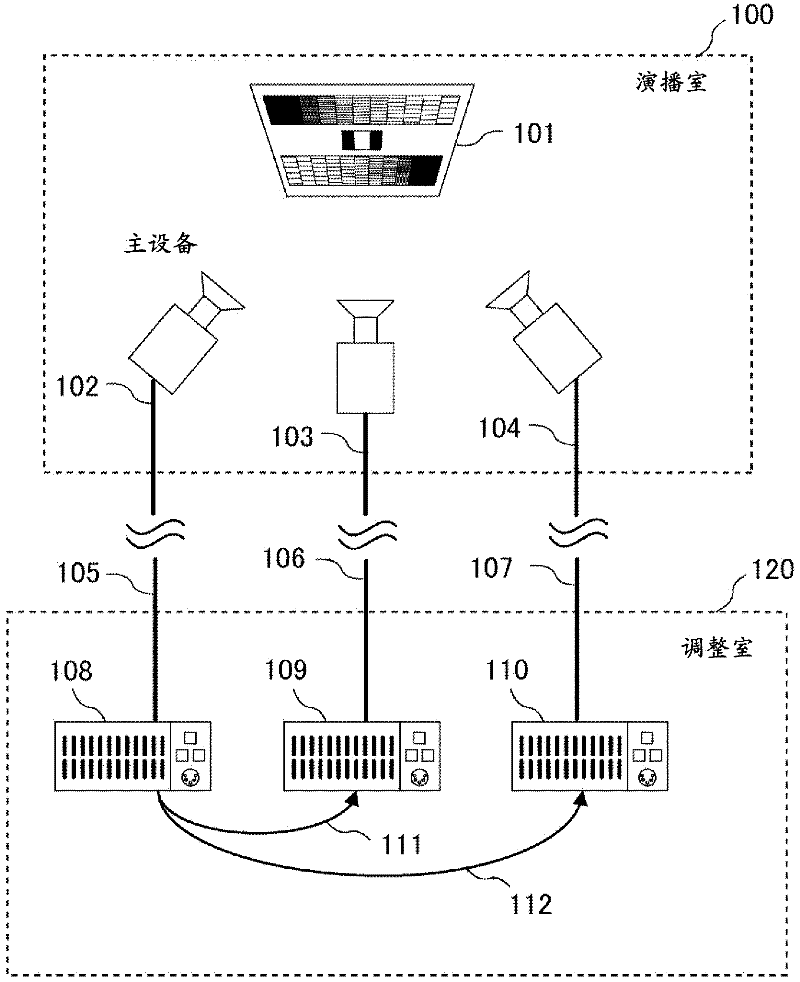

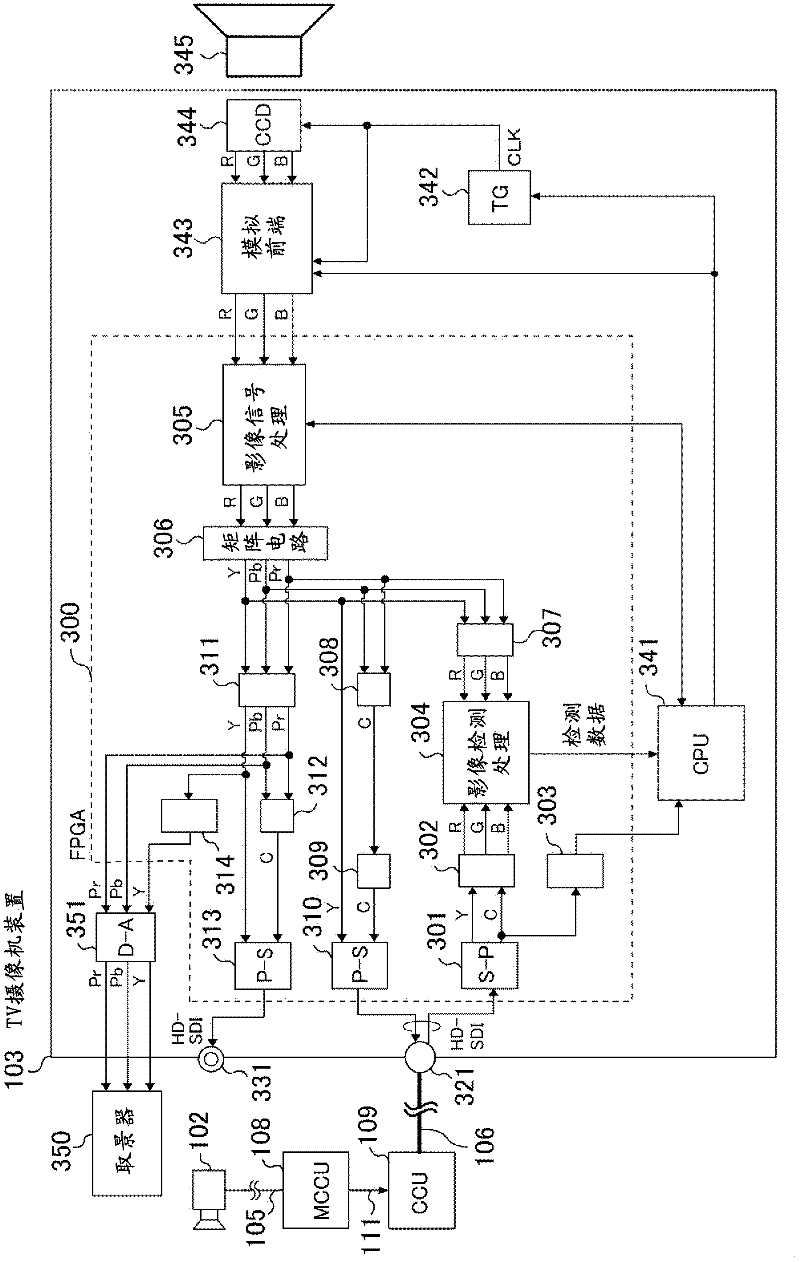

Television camera and television camera control system

ActiveCN102461176AReduce color adjustment timeAchieve regulationTelevision system detailsPicture signal generatorsCamera controlControl system

Provided is a television camera using a solid-state imaging device, wherein color signal adjustment between TV cameras can be performed easily and quickly without relying on the level of skill of an operator. The serial digital signal of a TV camera (a master) acting as the standard for color signal adjustment is directly input into another TV camera (a slave) that adjusts the color signal, and the image level of each channel of the slave is automatically adjusted in a manner such that the image level of each channel of the master corresponds with that of the slave.

Owner:ITACHI KOKUSAI ELECTRIC INC

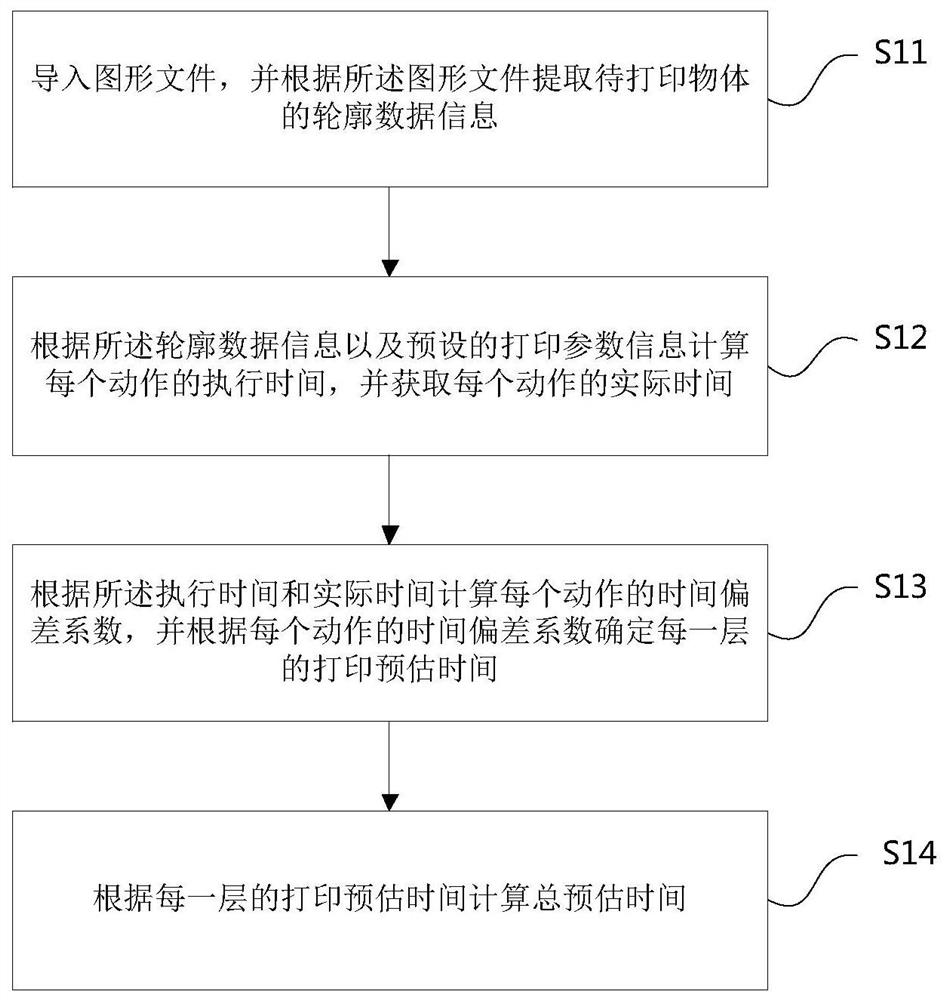

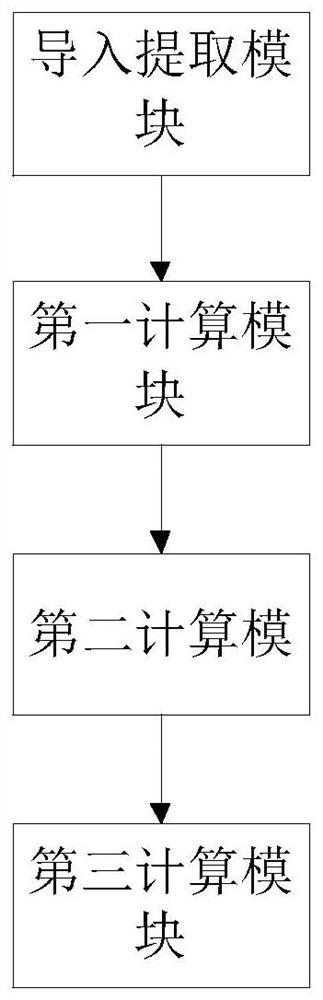

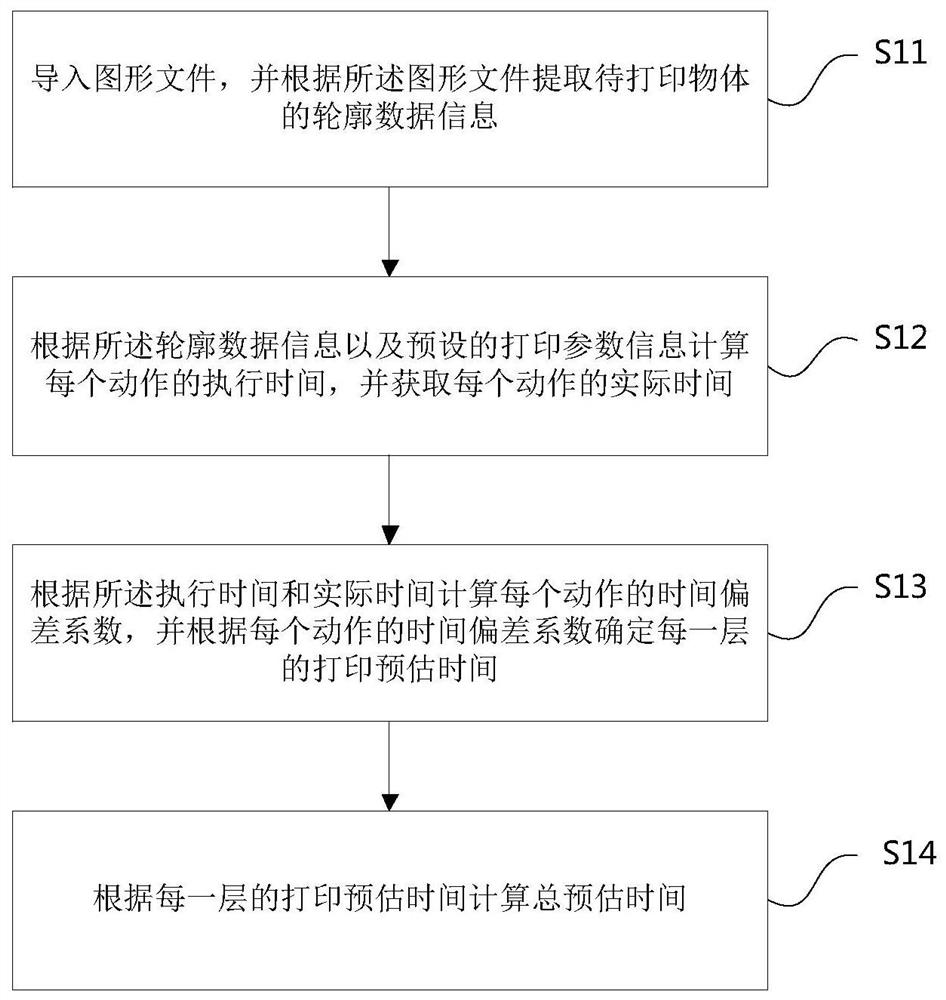

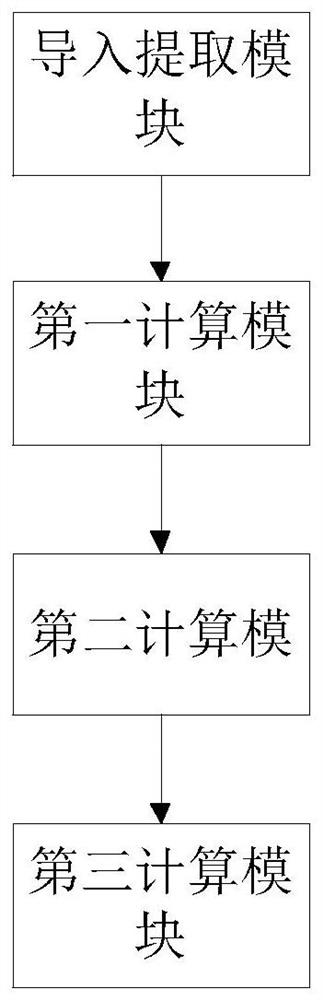

SAL 3D printing time estimation method and system based on learning algorithm

ActiveCN112380716AImprove estimation accuracyAccurate Total Estimated TimeDesign optimisation/simulationComplex mathematical operationsAlgorithmData information

The invention relates to an SAL 3D printing time estimation method and system based on a learning algorithm. The method comprises the steps that a graphic file is imported, and contour data information of a to-be-printed object is extracted; the execution time of each action is calculated according to the contour data information and preset printing parameter information, and the actual time of each action is acquired; the time deviation coefficient of each action is calculated according to the execution time and the actual time, and the estimated printing time of each layer is estimated according to the time deviation coefficient of each action; and a total estimated time is calculated. The time deviation coefficient conforming to the machine characteristics and the working environment isdetermined in a learning mode, and the execution time of each action is corrected, so that the printing estimation time of each layer is obtained, finally, the accurate total estimation time is obtained, learning iteration is continuously performed along with use of the machine, the accurate estimation effect is achieved. Estimation precision of the printing time is greatly improved.

Owner:武汉奇造科技有限公司

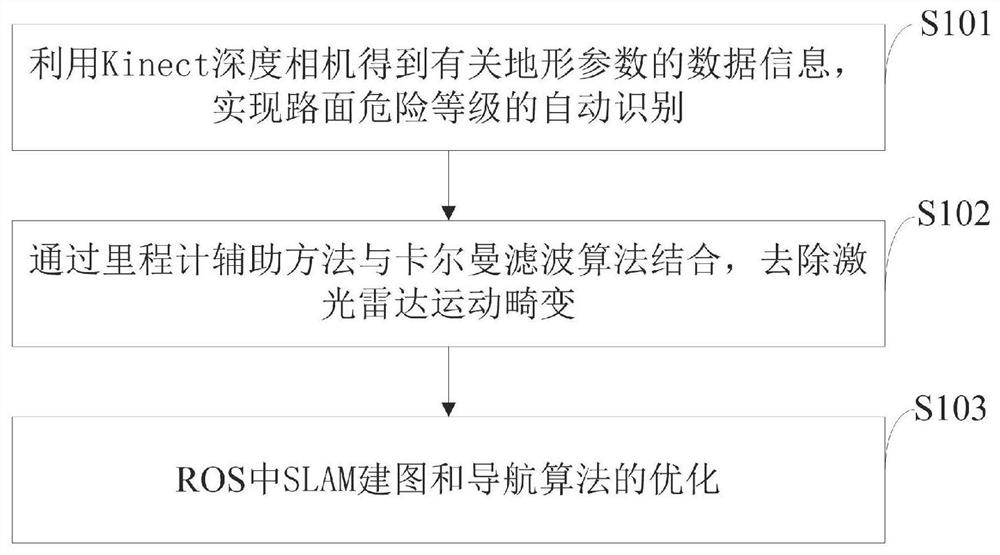

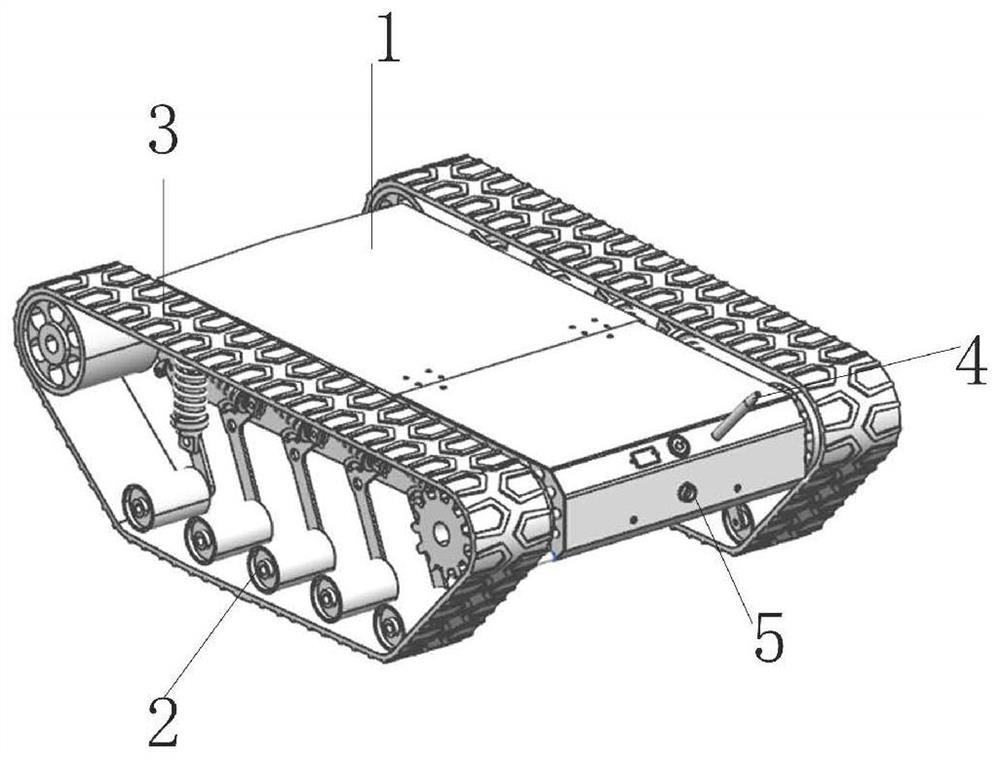

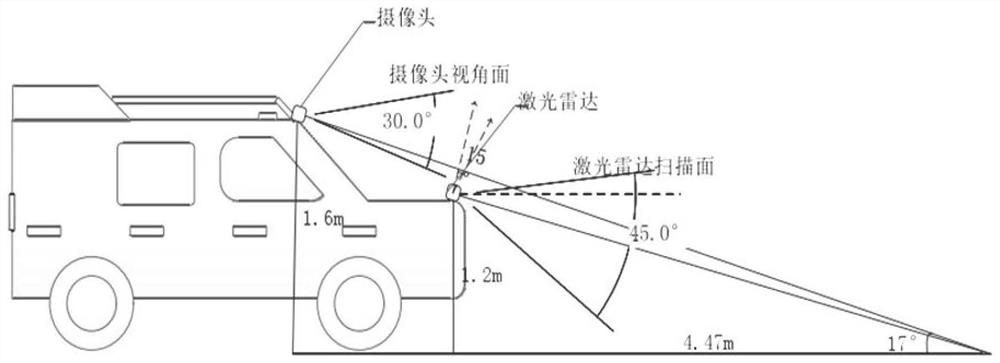

Terrain sensing method and system thereof, storage medium and computer equipment

ActiveCN113465728AReduce the degree of deviationReduce distance errorSubsonic/sonic/ultrasonic wave measurementInternal combustion piston enginesEngineeringRoad surface

The invention belongs to the technical field of terrain perception, and discloses a terrain perception method and a system thereof, a storage medium and computer equipment, a Kinect depth camera is utilized to obtain data information related to terrain parameters, and automatic identification of a road surface danger level is realized; a speedometer auxiliary method is combined with a Kalman filtering algorithm to remove laser radar motion distortion; and SLAM mapping and navigation algorithm optimization in ROS is realized. According to the method, the robot is globally positioned on the X axis and the Y axis, the distance error is smaller than 10 cm, and the angle error is smaller than 0.2 rad; the size error between the grid map and the real environment is less than 1cm; the deviation degree between the real navigation path of the robot and the algorithm estimation path is less than 10cm; the mobile robot can carry out loopback when mapping is carried out in an environment with a similar structure; and the variance of the preprocessed point cloud data collected by the laser radar is less than 0.1.

Owner:CHONGQING VOCATIONAL INST OF ENG

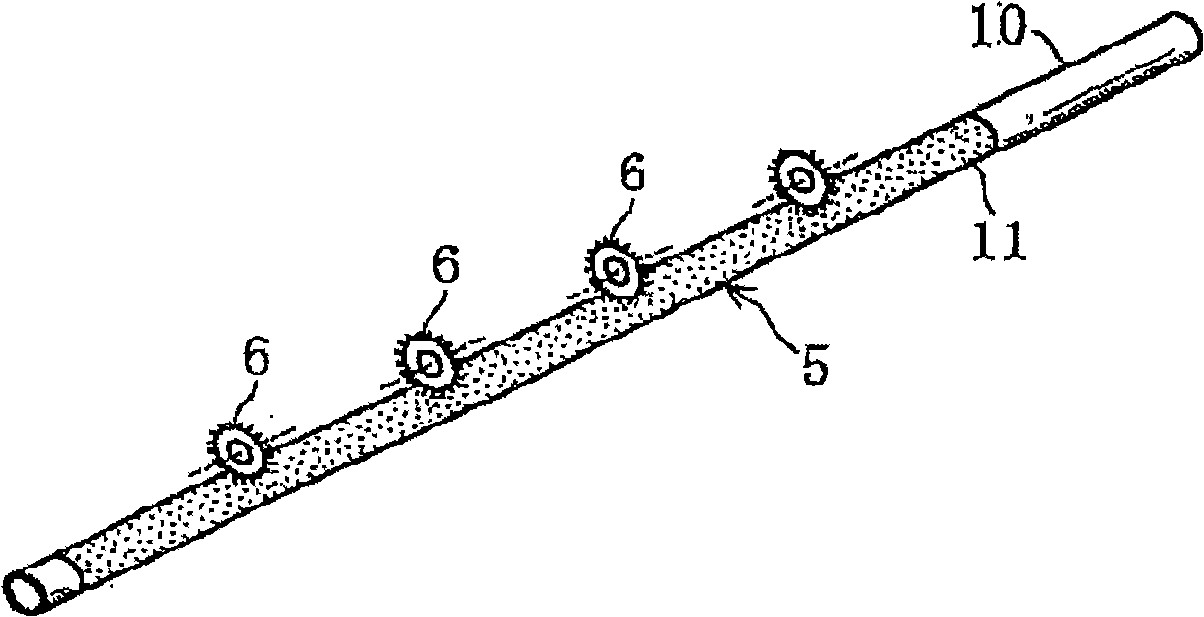

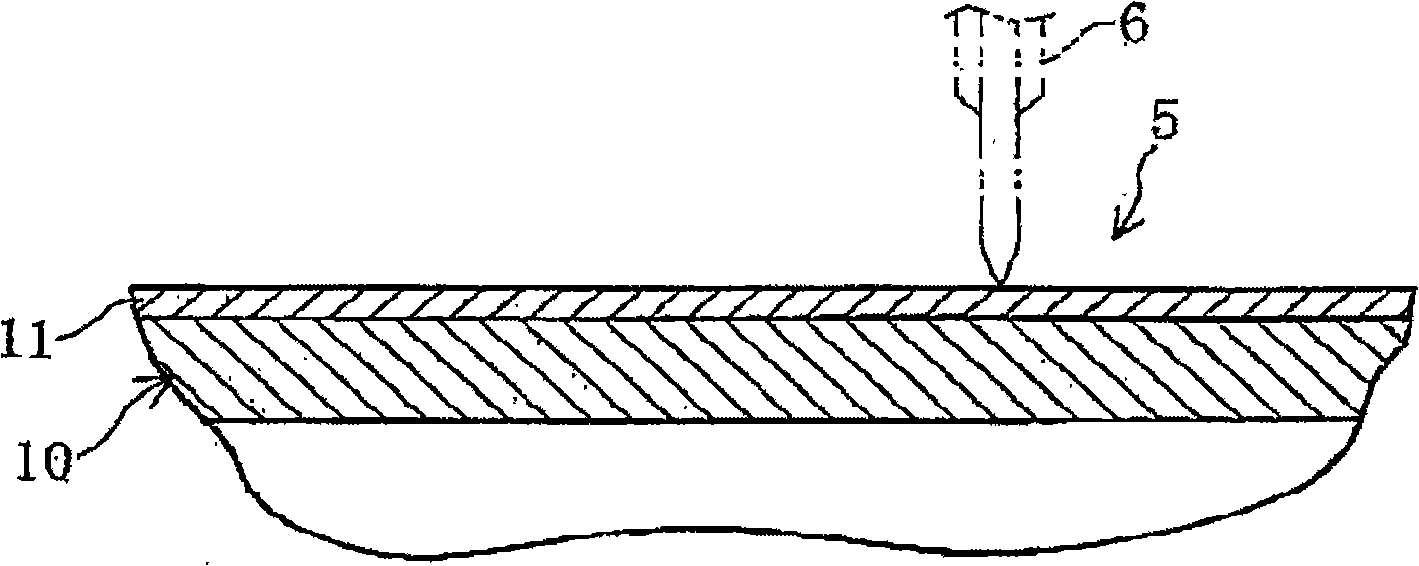

Line paper rolling wheel of printer

InactiveCN101293435AAvoid wear and tearGuaranteed persistenceOther printing apparatusArticle feedersImaging qualityImage recording

The invention discloses a marking roller of a printer that confirms feed accuracy of convey so as to further improve a recorded image quality in high picture image recording cases and reduce making fee. The marking roller of the printer provided by the invention is located in a rear end more closer to a recording paper convey direction compared with the recording print head of the printer for driving a plurality of gear-like rollers to convey the recording paper, including: a roller body formed by cylinder materials made of steel; a metal heat deposited layer formed on a surface of the roller body made of metal materials with 30 to 75 HRB hardness. The thickness of the metal heat deposited layer is 30 to 100 microns.

Owner:SANCALL

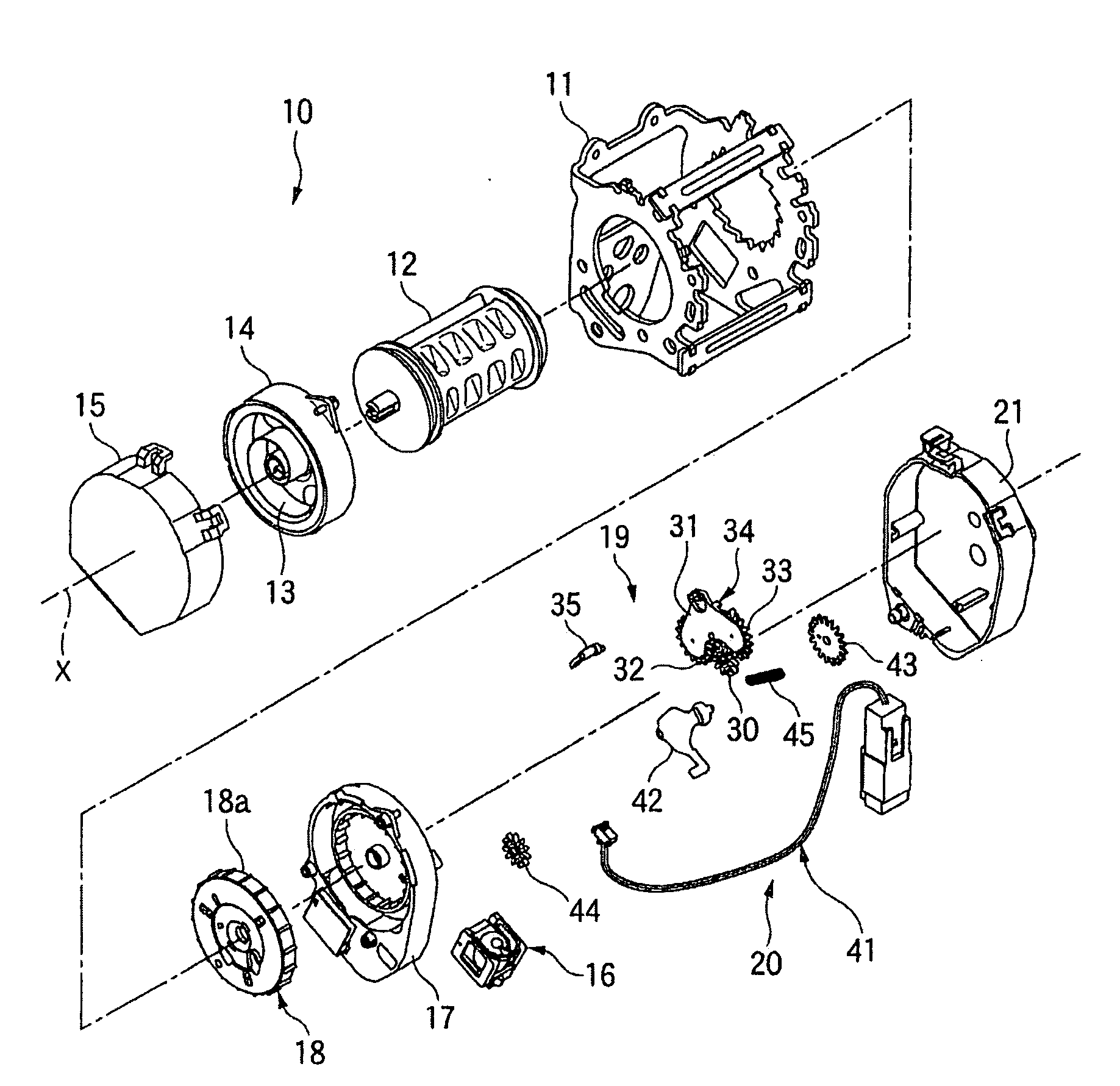

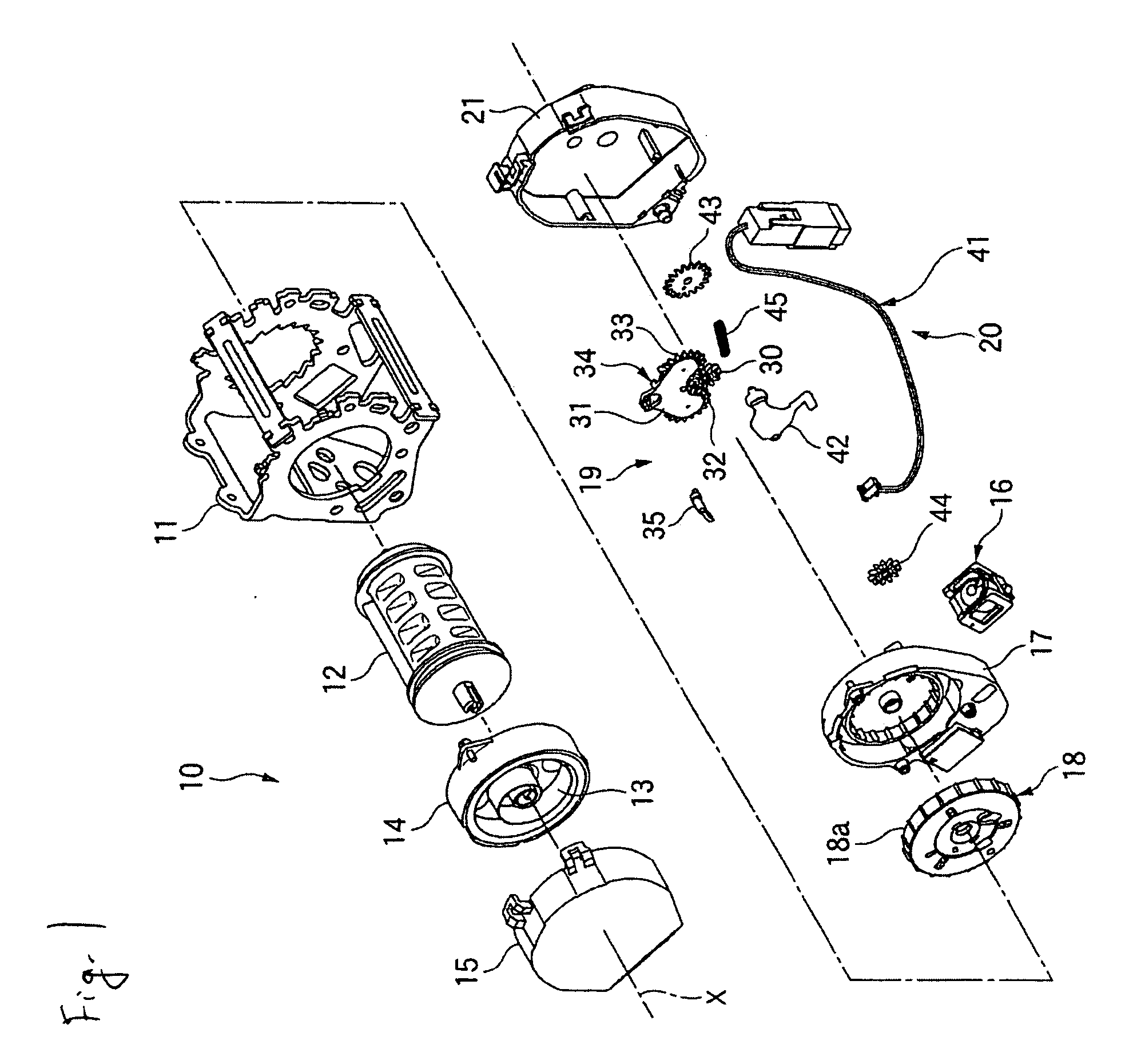

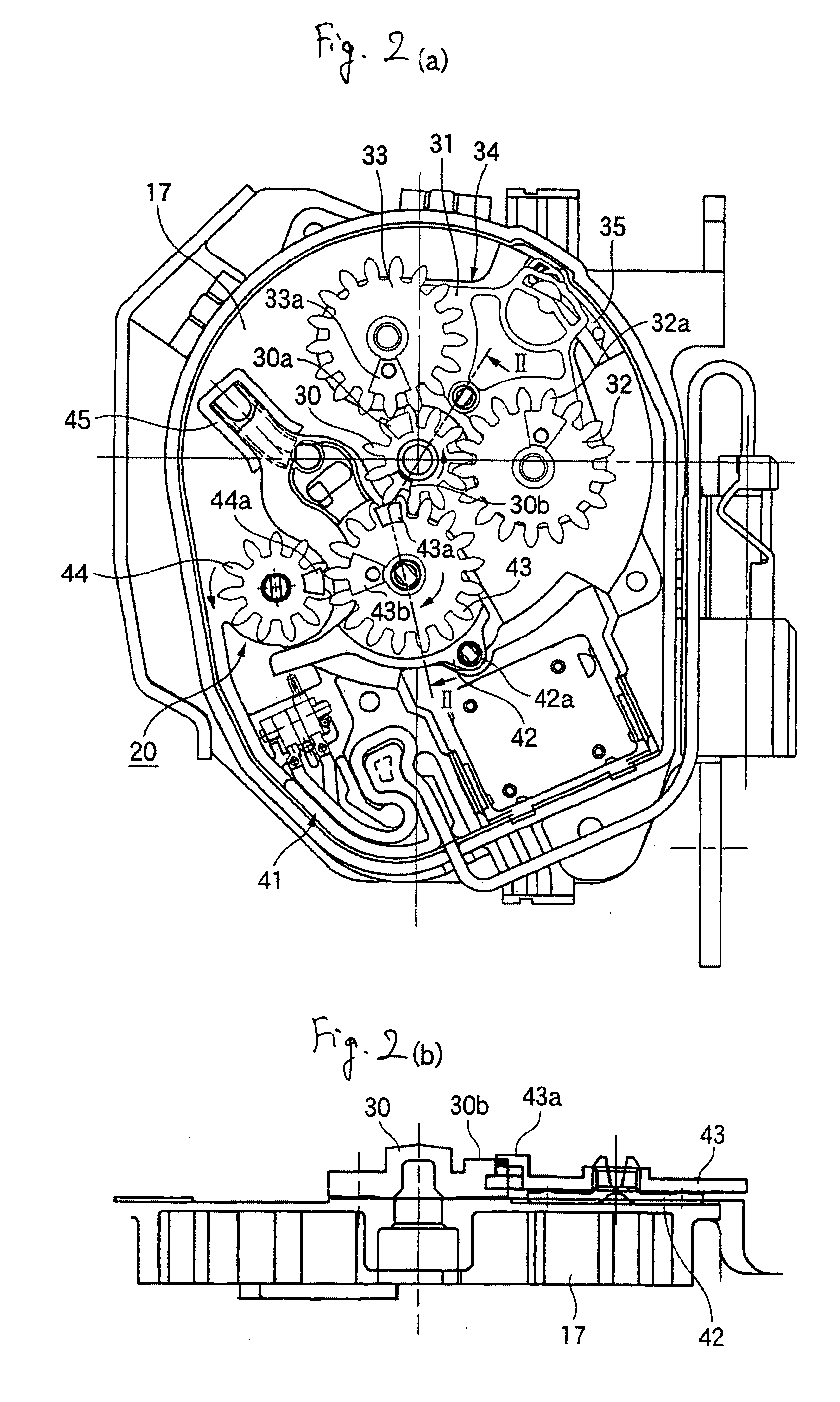

Seat belt apparatus

ActiveUS20080116044A1High reliabilityReduce deviationBelt retractorsBelt control systemsSeat beltBelt safety

In a seat belt apparatus, a first projecting portion and a second projecting portion which are capable of being brought into abutment with each other so that a switch lever is shifted from a switch OFF position to a switch ON position are provided on a side of a drive gear and a side of a first gear, respectively. A third projecting portion and a fourth projecting portion, which are capable of being brought into abutment with each other so that the switch lever is shifted from the switch ON position to the switch OFF position, are provided on the side of the first gear and a side of a second gear. An abutment position between the first and second projecting portions and an abutment position between the third and fourth projecting portions differ from each other in an axial direction of a spindle.

Owner:AUTOLIV DEV AB

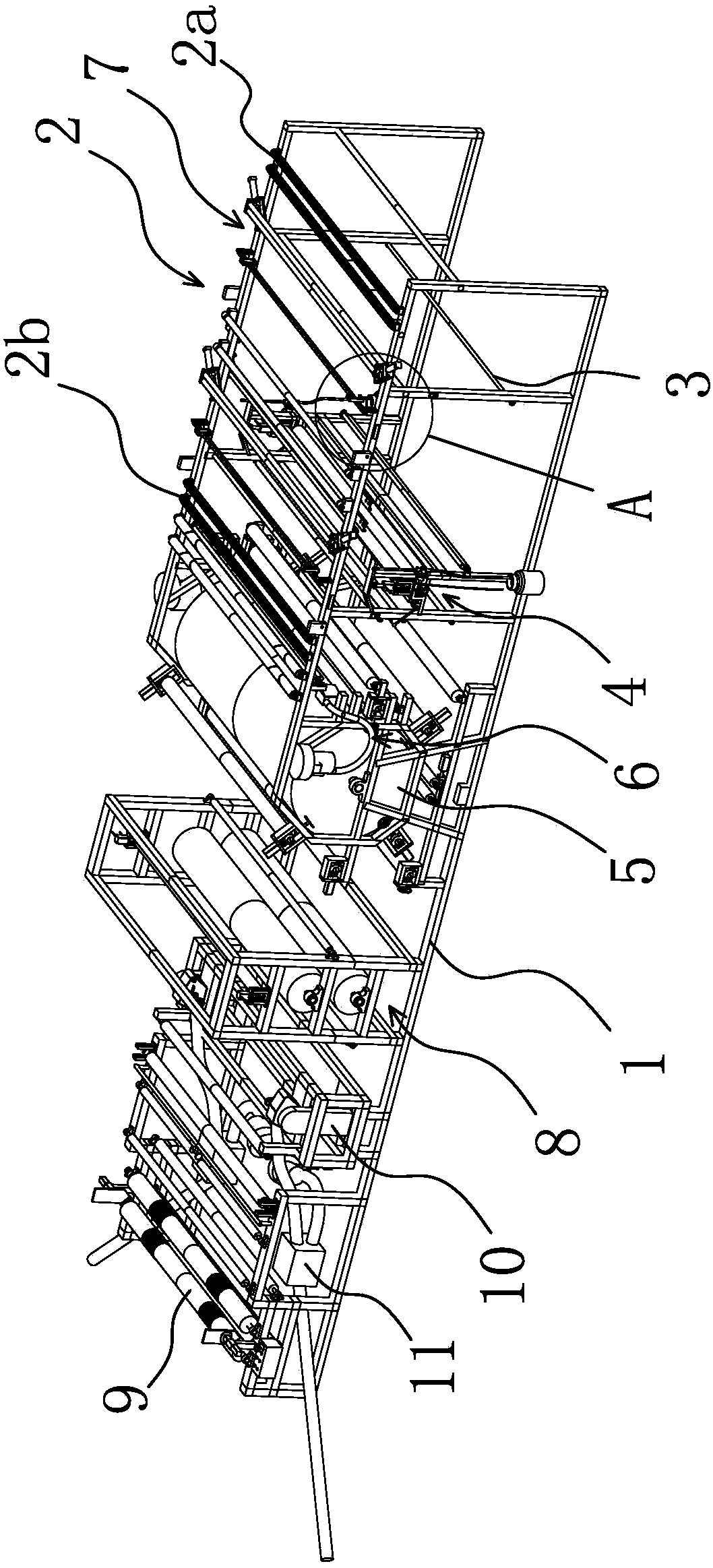

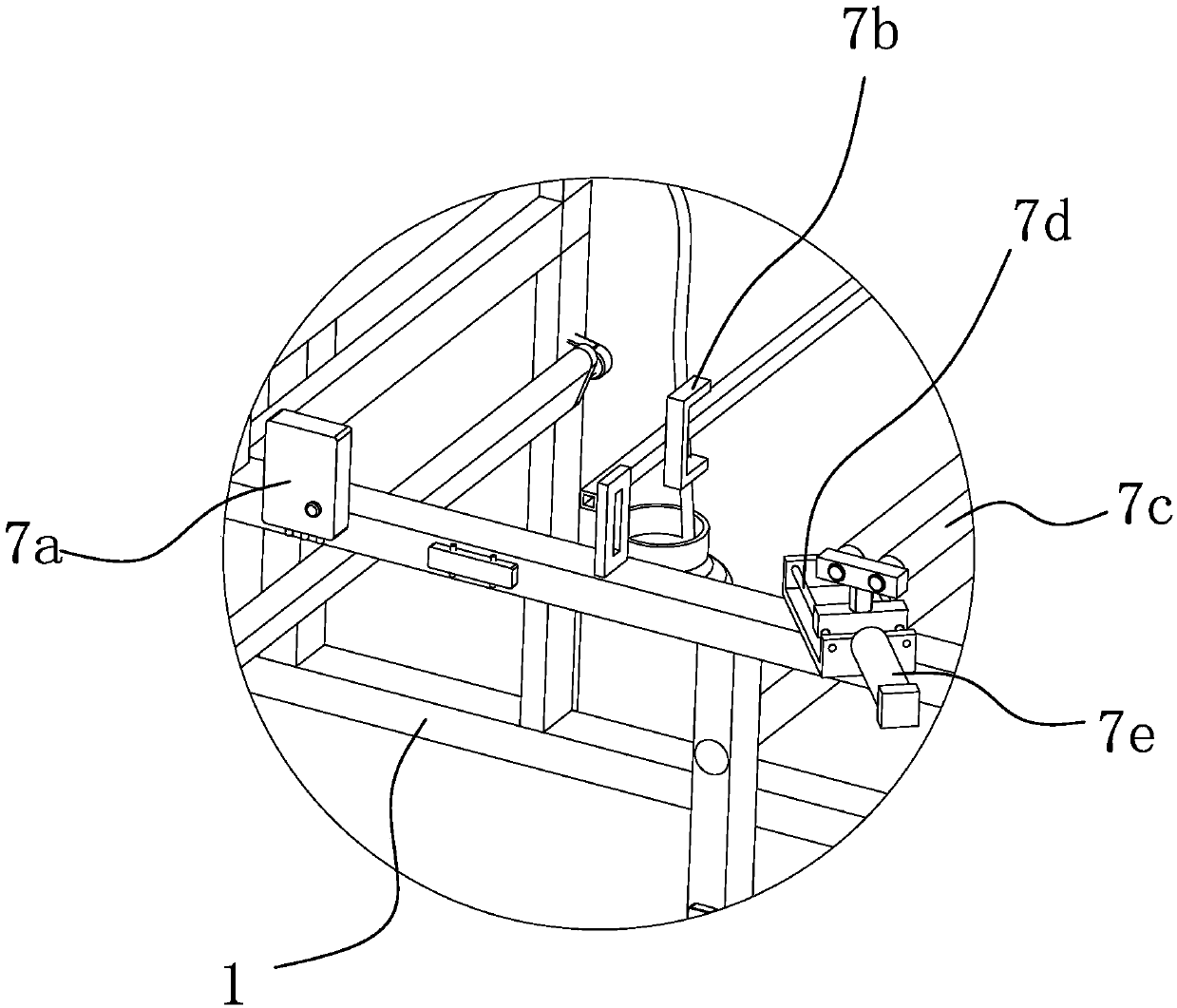

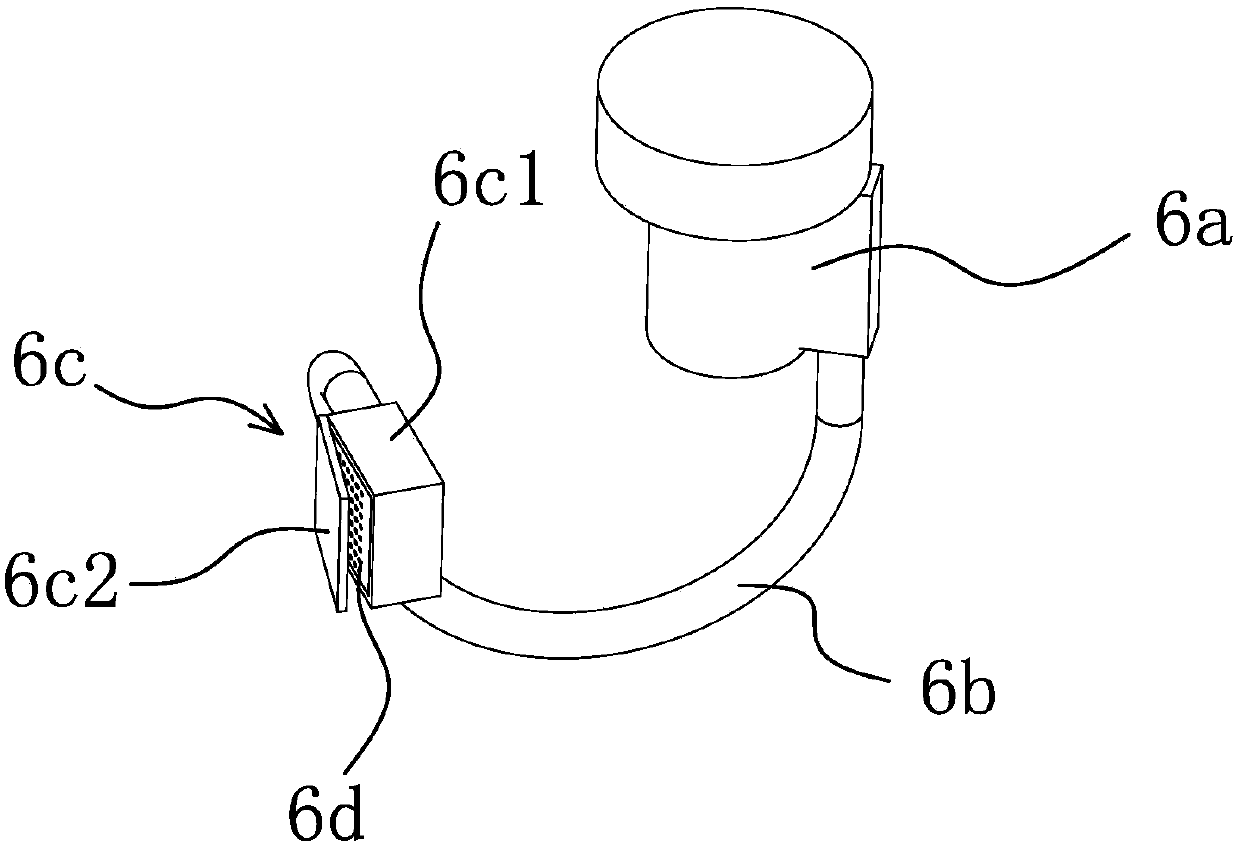

Cloth sponge compounding machine

ActiveCN107672276AAvoid crimping againImprove flatnessLamination ancillary operationsLaminationEngineeringMechanical engineering

The present invention provides a cloth sponge compounding machine, belongs to the technical field of machinery, and solves the problems that folds and turned edges are easy to produce when cloth and sponge are compounded in the prior art. The cloth sponge compounding machine comprises a frame, a cloth feeding device is arranged above the front end of the frame, a thermal compounding device is arranged at the back of the cloth feeding device, each of the two sides of the frame is provided with an anti-curling device, each anti-curling device is located between the cloth feeding device and the thermal compounding device, each anti-curling device comprises a fan I, a venting tube and an air-out component, the air-out component is in communication with the fan I through the venting tube, the air-out component is arranged at a position near the edge of a cloth feeding path on the frame, and the air-out component is provided with an air outlet facing the edge of the cloth feeding path. By use of the cloth sponge compounding machine, the edge of a compounded cloth finished product is neat and regular, and processing efficiency is high.

Owner:HIGHER TECH CO LTD

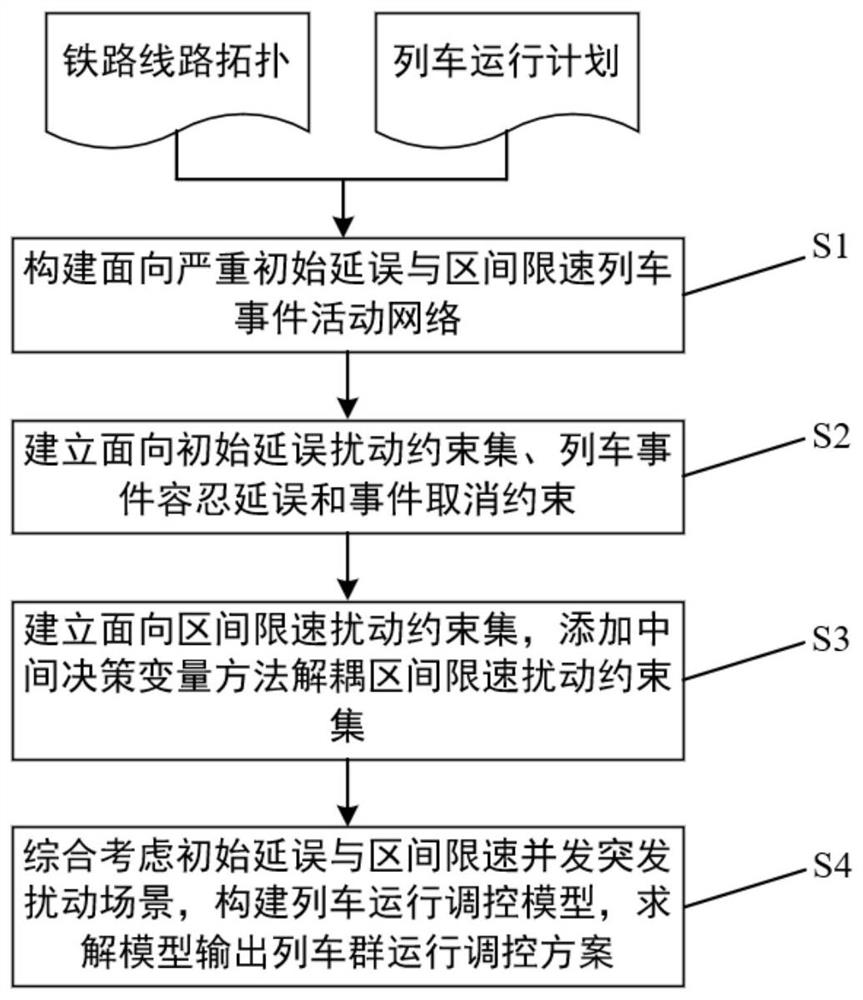

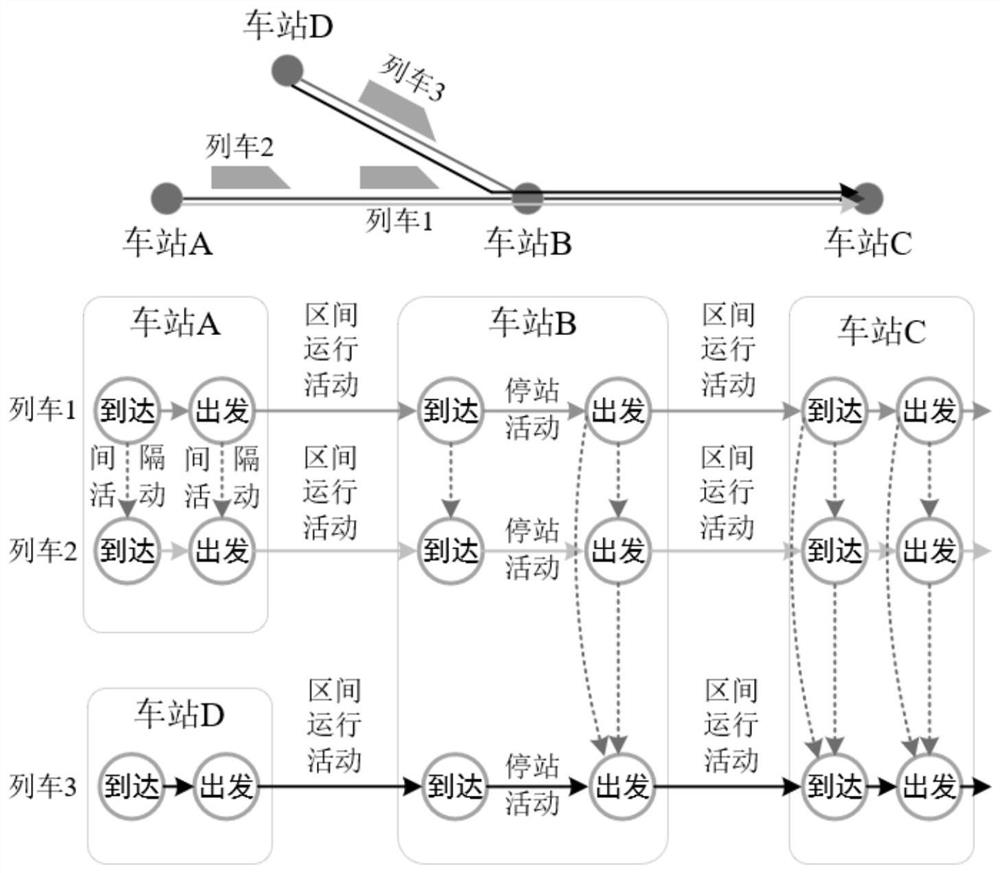

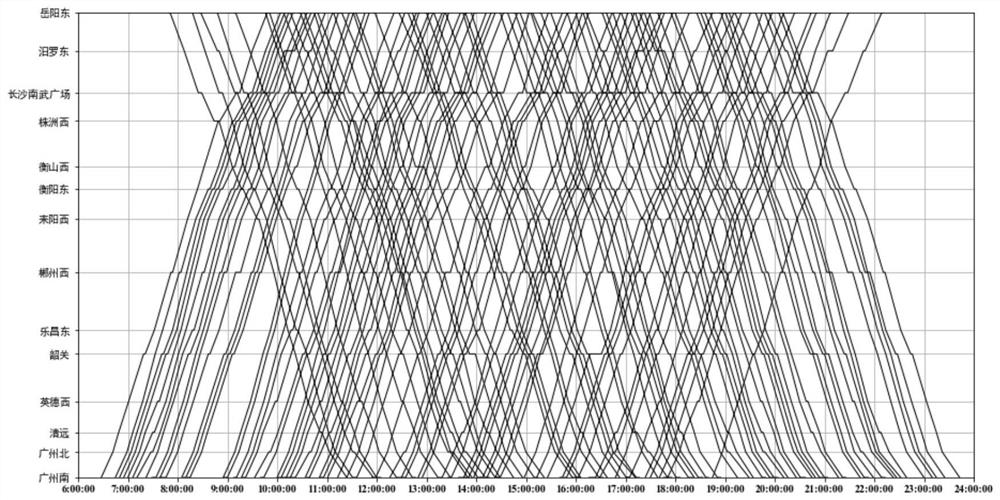

Train operation regulation and control method and system for initial delay and interval speed limit

ActiveCN113715875ARealize online generationReduce the degree of deviationRailway traffic control systemsControl engineeringControl theory

The invention provides a train operation regulation and control method and system for initial delay and interval speed limit and a storage medium. The method comprises the steps of constructing a train event activity network which represents a train group operation logic relationship and faces initial delay and interval speed limit; establishing constraint sets for initial delay disturbance, train event tolerance delay, train event cancellation and interval speed limit disturbance by taking a train event and a train activity as basic units, and comprehensively considering an initial delay and interval speed limit concurrent sudden disturbance scene; and adding decoupling results of constraint sets such as initial delay, train event tolerance delay, train event cancellation and interval speed limit disturbance into a train group operation regulation and control model, and solving the train group operation regulation and control model to output an optimal train group operation regulation and control scheme. The optimal train operation regulation and control scheme can be generated, the deviation degree between the regulated and controlled train operation scheme and the original plan scheme is reduced, and the train operation safety and the train service quality under emergencies are guaranteed.

Owner:BEIJING JIAOTONG UNIV

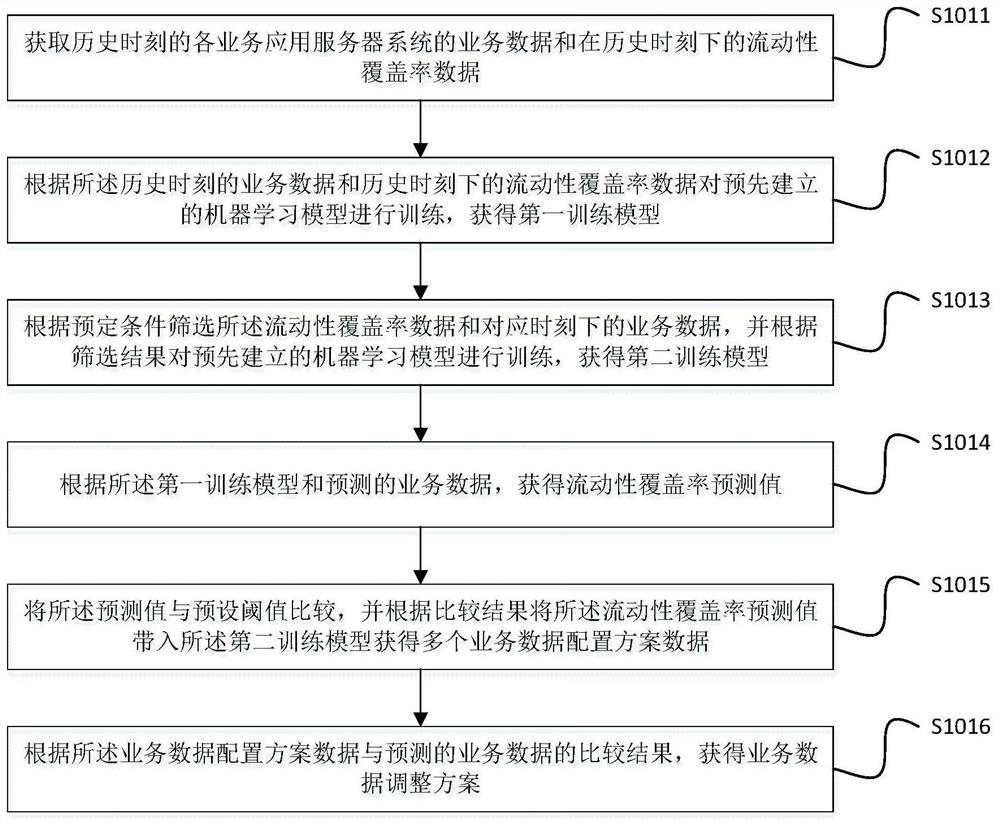

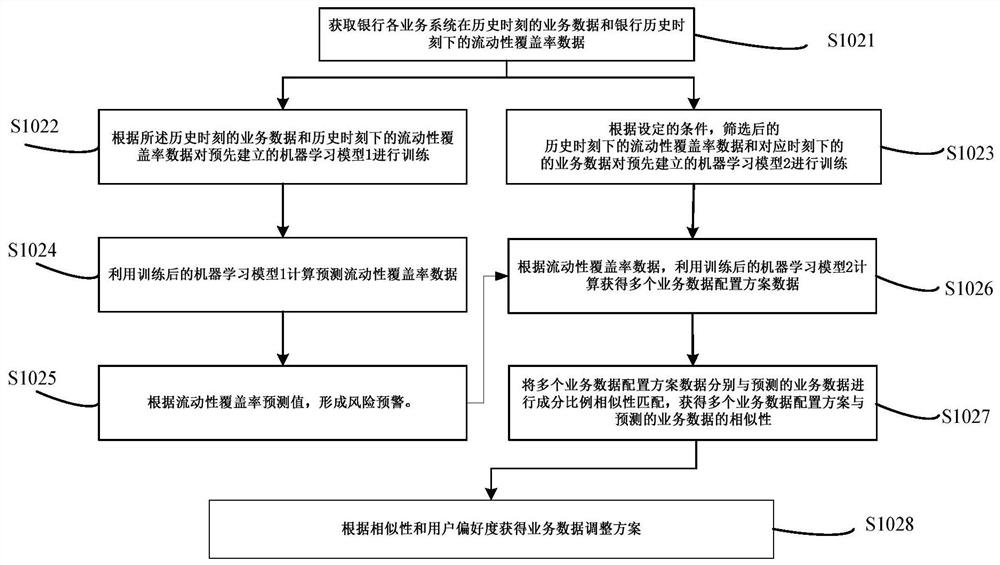

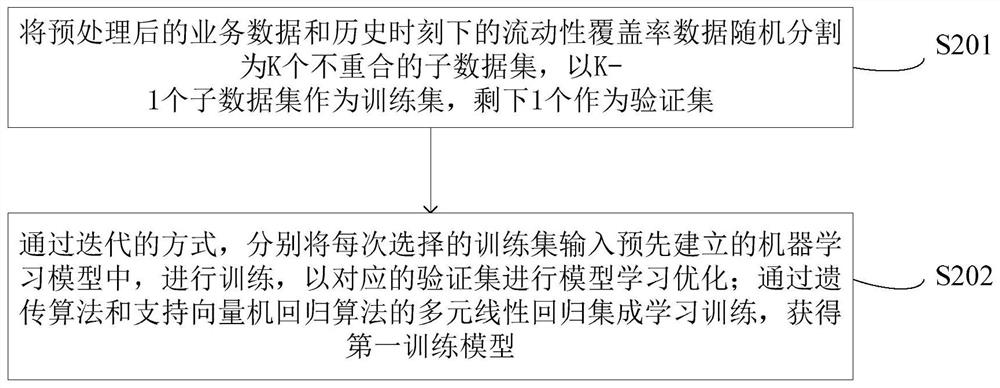

Flowability coverage rate prediction method and device

PendingCN112734565AIncrease resilienceWide range of applicationsFinanceKernel methodsData AdjustmentsApplication server

The invention discloses a fluidity coverage rate prediction method and device, and belongs to the technical field of big data and artificial intelligence. The method comprises the steps: obtaining the service data of each service application server system at a historical moment and the fluidity coverage rate data at the historical moment; training the first training model according to the service data at the historical moment and the liquidity coverage rate data at the historical moment; screening the liquidity coverage rate data and the service data at the corresponding moment according to a preset condition, and training a second training model according to a screening result; obtaining a fluidity coverage rate prediction value according to the first training model and the predicted service data; comparing the prediction value with a preset threshold value, and substituting the fluidity coverage rate prediction value into a second training model according to a comparison result to obtain multiple parts of service data configuration scheme data; and obtaining a service data adjustment scheme according to a comparison result of the service data configuration scheme data and the predicted service data.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

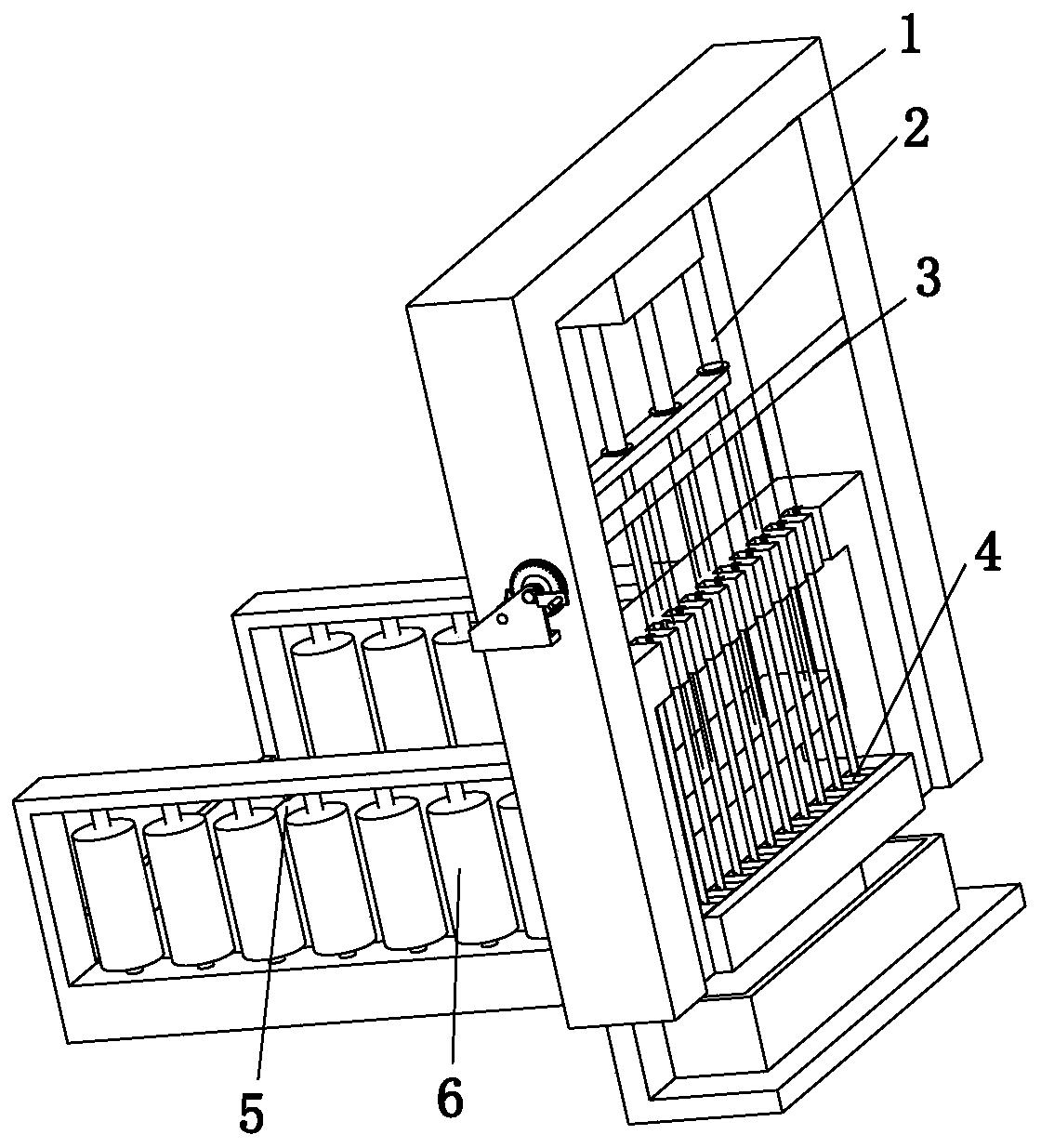

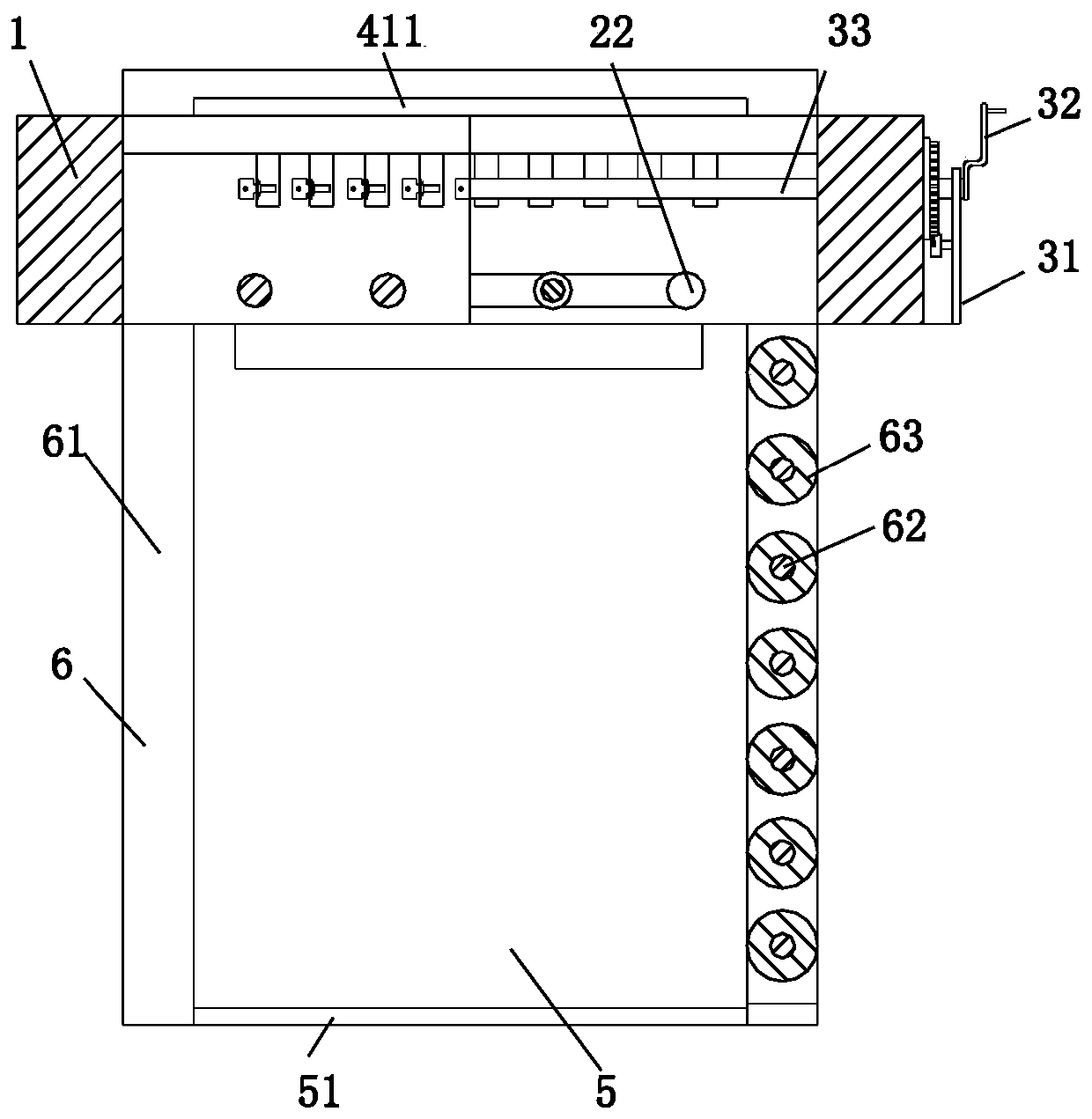

Secondary machining forming machine for industrial sponge manufacturing

ActiveCN110405818AReduce warpageReduce the degree of deviationMetal working apparatusEngineeringPortal frame

The invention relates to a secondary machining forming machine for industrial sponge manufacturing. The secondary machining forming machine for industrial sponge manufacturing comprises a portal frame, a sheet pressing device, a winch device, a slicing device, a conveyer belt and a limiting device. The sheet pressing device is installed on the lower end face of the portal frame. The winch device is installed in the middle of the portal frame. The sheet pressing device is located in front of the winch device. The lower end of the winch device is provided with the slicing device. The slicing device is installed at the back end of the conveyer belt. The left side and the right side of the conveyer belt are symmetrically provided with limiting devices. The secondary machining forming machine for industrial sponge manufacturing can solve the problem that in the cutting process, edges of sponges can be upward warped, the problem that due to light weight of the sponges, the sponges are proneto deviation in cutting, and then the shape of the cut sponges deforms or the cut sponges are scrapped, and the problem that due to little friction between the sponges and the conveyer belt, when thesponges are in contact with the blades, the sponges are prone to not advancing along with the conveyer belt, and then cutting work cannot be completed.

Owner:东莞永华海棉制品有限公司

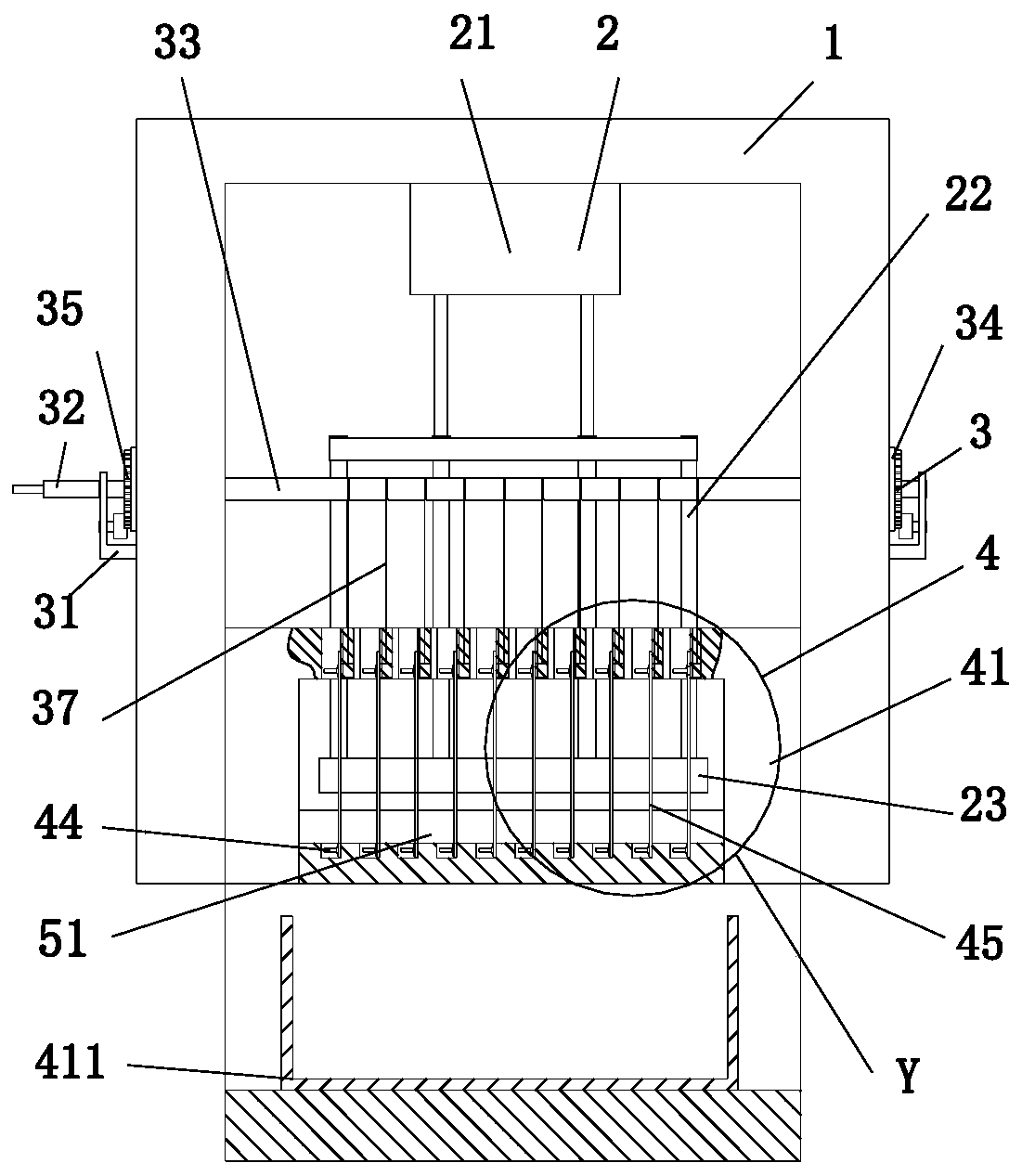

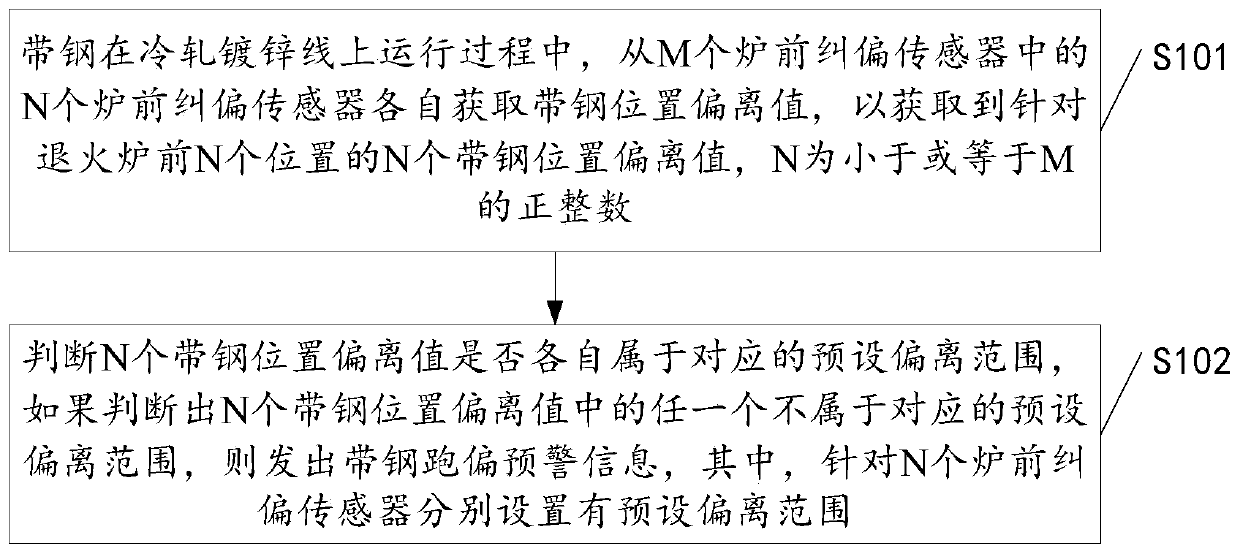

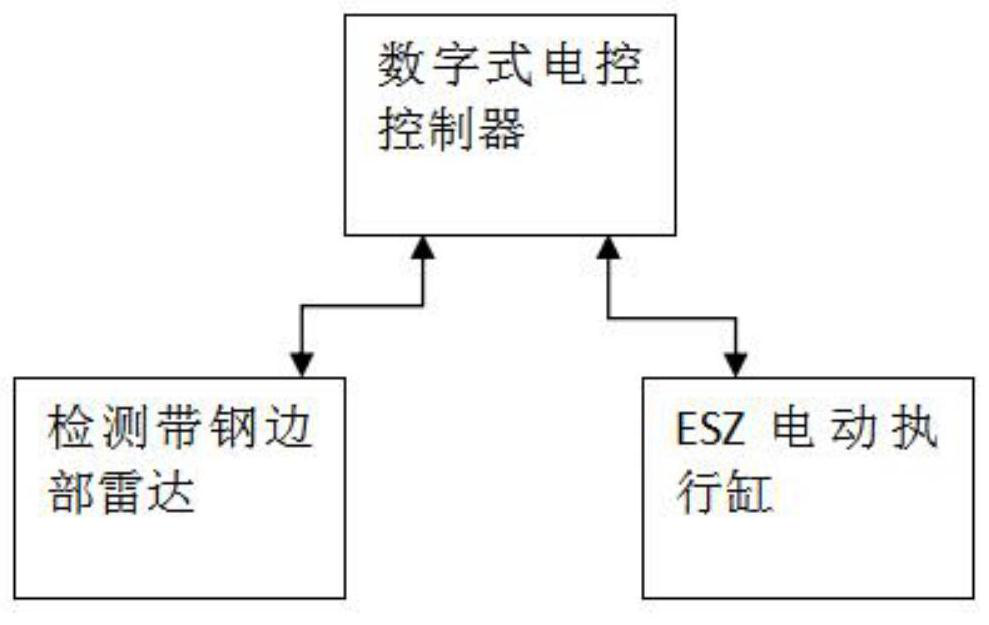

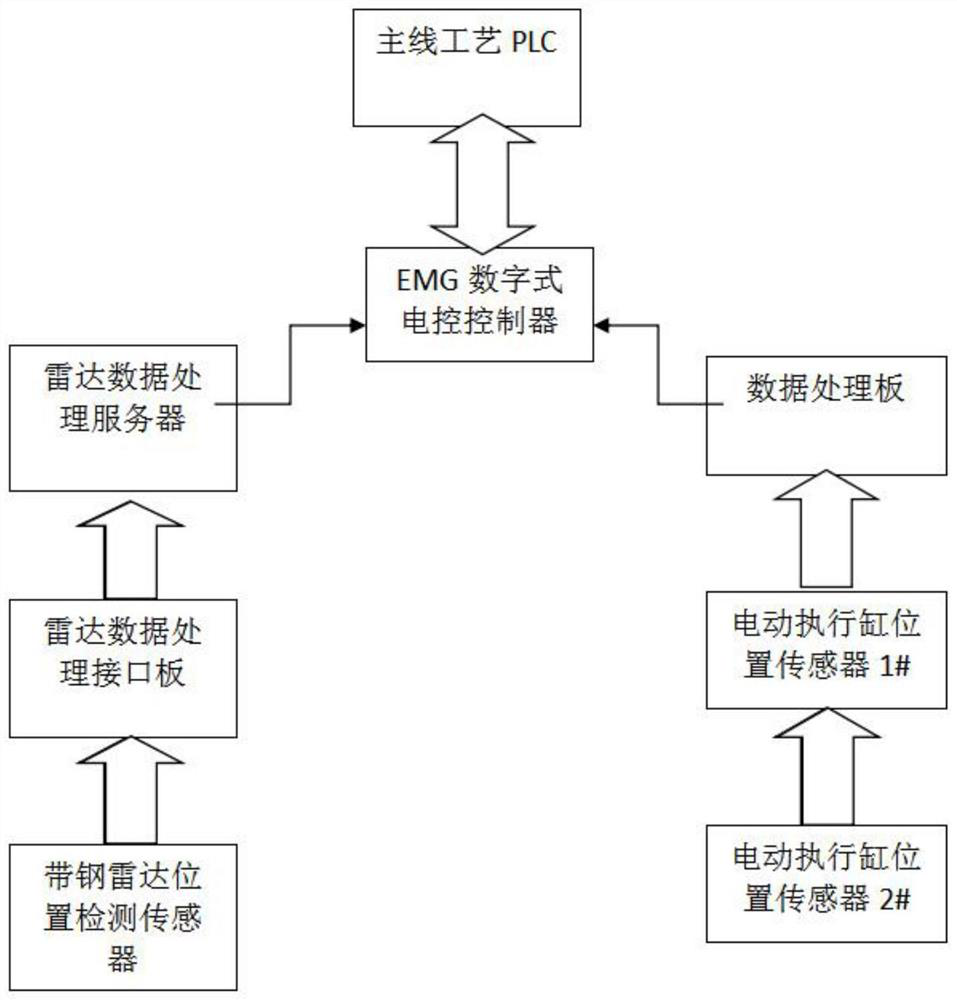

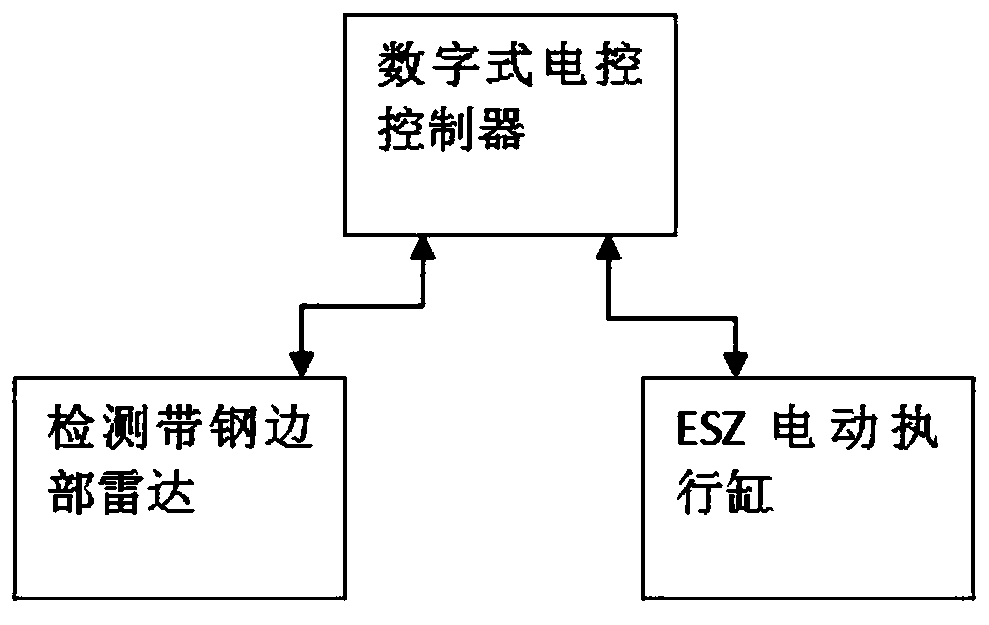

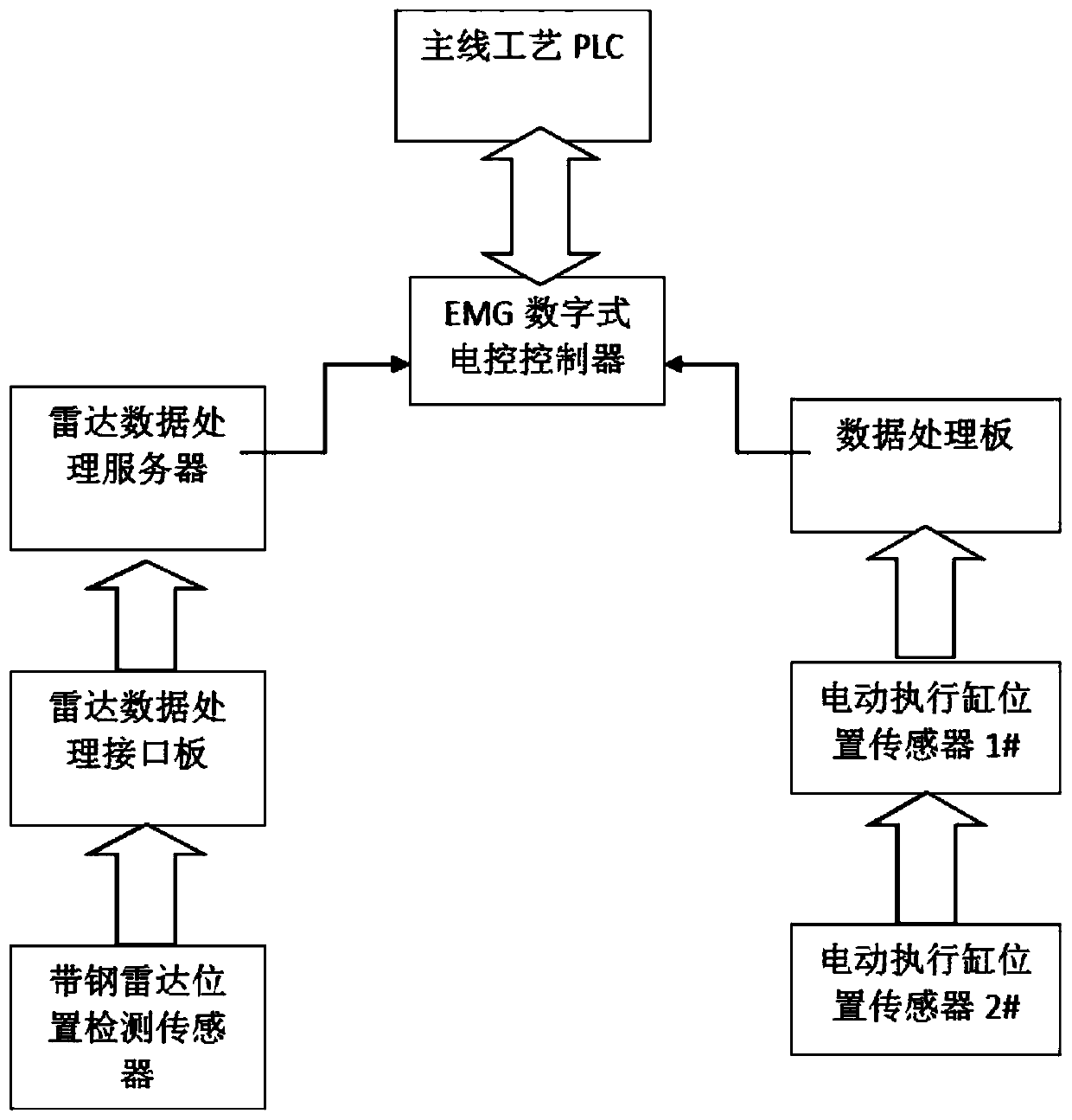

A method and device for early warning of strip deviation on a cold-rolled galvanizing line

ActiveCN107226373BImprove the correction effectReduce the degree of deviationWebs handlingStrip steelMaterials science

The embodiment of the invention discloses an early-warning method and device for deviation of strip steel on a cold rolled galvanizing line. The method comprises the following steps: acquiring strip steel position deviation values from N furnace-front deviation correcting sensors in M furnace-front deviation correcting sensors when the strip steel runs on the cold rolled galvanizing line so as to obtain N strip steel position deviation values of N positions in front of an annealing furnace; determining whether the N strip steel position deviation values are within the corresponding preset deviation range; and if any one of the N strip steel position deviation values is beyond the corresponding preset deviation range, sending out strip steel deviation early-warning information, wherein for the N furnace-front deviation correcting sensors, preset deviation ranges are correspondingly set. With the adoption of the method and the device, the technical problem of low capacity of correcting the deviation in the annealing furnace on the cold rolled galvanizing line can be solved; the deviation degree of the strip steel in the annealing furnace can be reduced, and moreover, the strip steel deviation in the annealing furnace can be timely handled, so that stable travelling of the strip steel in the annealing furnace is ensured, and as a result, the galvanizing line output and the product quality can be improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

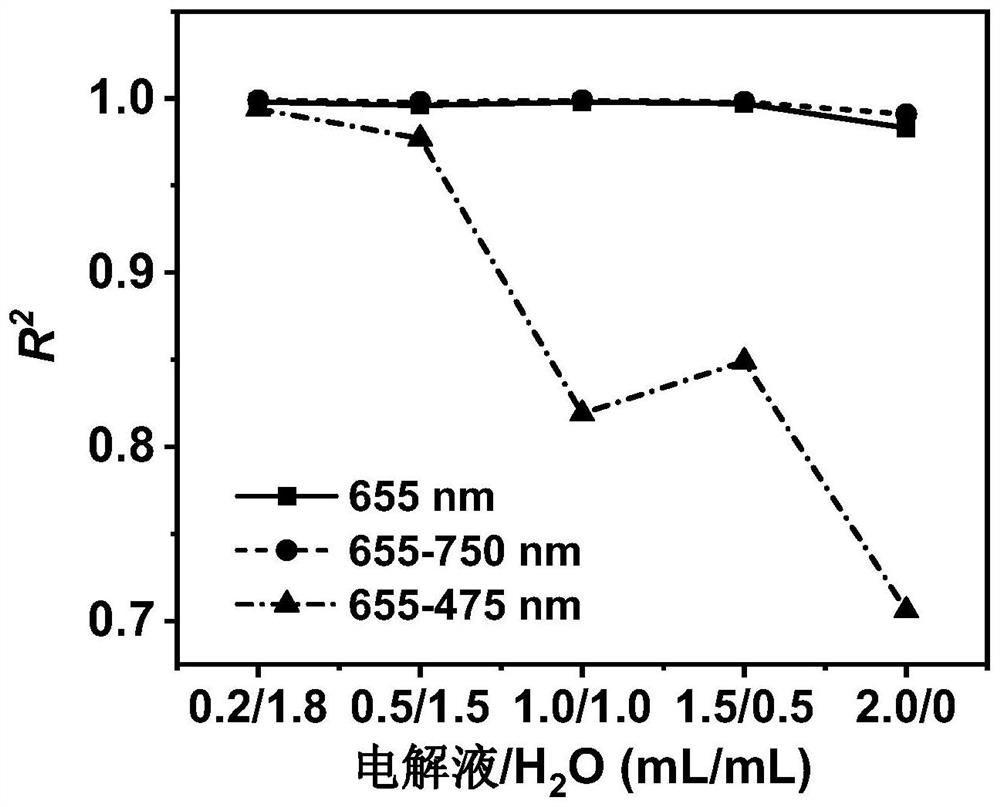

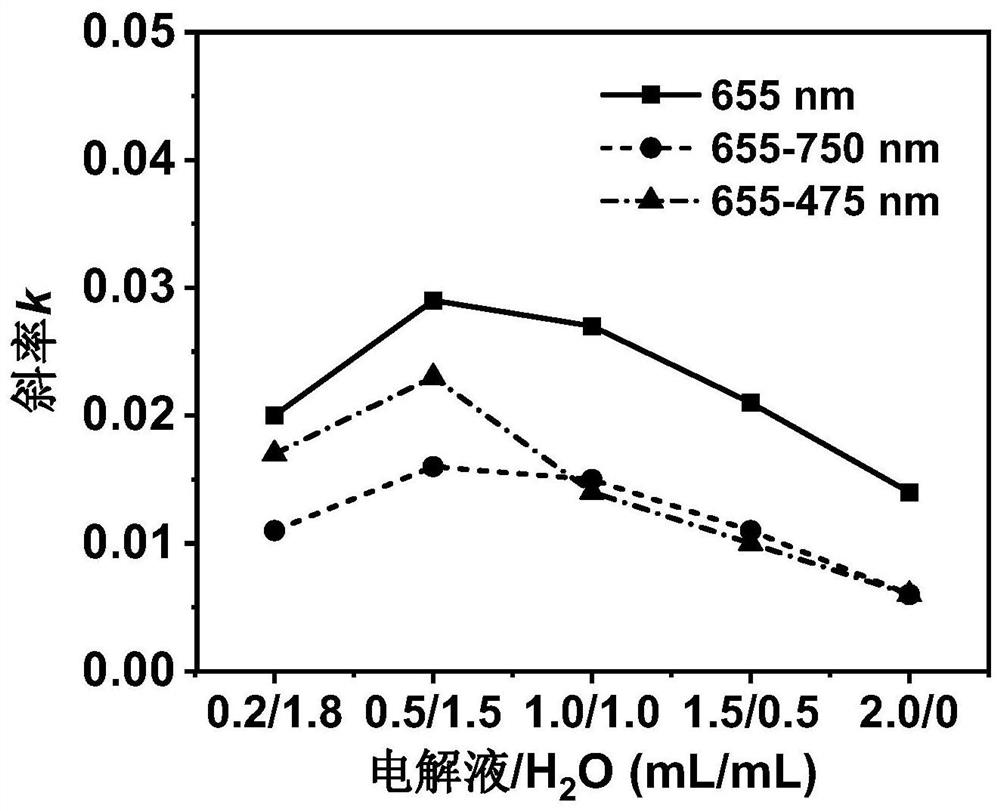

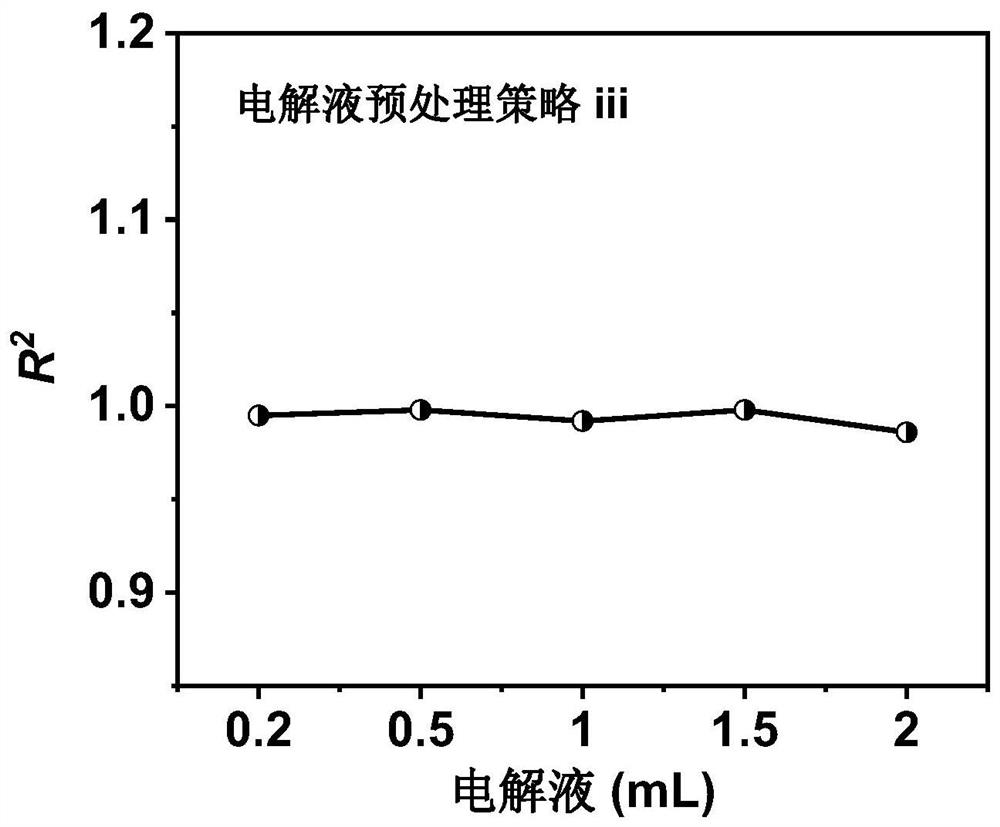

A kind of product detection method of organic electrochemical ammonia synthesis reaction system

ActiveCN111693477BReduce the degree of deviationSolve the problem that the ammonia product cannot be accurately qualitative and quantitativeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsElectrolytic agentUv absorbance

The invention discloses a product detection method of an organic electrochemical ammonia synthesis reaction system. The method comprises: carrying out the conventional indophenol blue method test on the electrolytic solution of the organic electrochemical ammonia synthesis reaction system to obtain a color-developing solution; performing ultraviolet spectrophotometric analysis on the color-developing solution to obtain a full-spectrum curve, taking the absorbance value, and calculating the product ammonia content. In the present invention, the product detection method is the optimized indophenol blue colorimetric method, and the organic electrolyte pretreatment and the ultraviolet absorption spectrum analysis are two-pronged, eliminating the baseline shift problem that sometimes occurs due to the optical fiber design of the ultraviolet spectrophotometer, thereby reducing due to Possibility of overestimating ammonia concentration due to baseline shift. The product detection method of the organic electrochemical ammonia synthesis reaction system provides an accurate quantitative and performance evaluation method for the research of synthetic ammonia under an organic system. The invention can be used for ammonia product detection in an organic system.

Owner:SOUTH CHINA UNIV OF TECH

A method and system for sla 3D printing time estimation based on learning algorithm

ActiveCN112380716BEasy to scanHigh precisionDesign optimisation/simulationComplex mathematical operationsAlgorithmData information

The present invention relates to a method and system for predicting SLA 3D printing time based on a learning algorithm. The method includes importing a graphics file and extracting the contour data information of an object to be printed; calculating each action according to the contour data information and preset printing parameter information The execution time of each action, and obtain the actual time of each action; calculate the time deviation coefficient of each action according to the execution time and actual time, and determine the estimated printing time of each layer according to the time deviation coefficient of each action; and calculate the total Estimated time. The present invention determines the time deviation coefficient in accordance with the characteristics of the machine and the working environment through learning, and corrects the execution time of each action, so as to obtain the estimated printing time of each layer, and finally obtain the accurate total estimated time, and With the use of the machine, continuous learning and iteration, to achieve the effect of accurate prediction, greatly improving the prediction accuracy of printing time.

Owner:武汉奇造科技有限公司

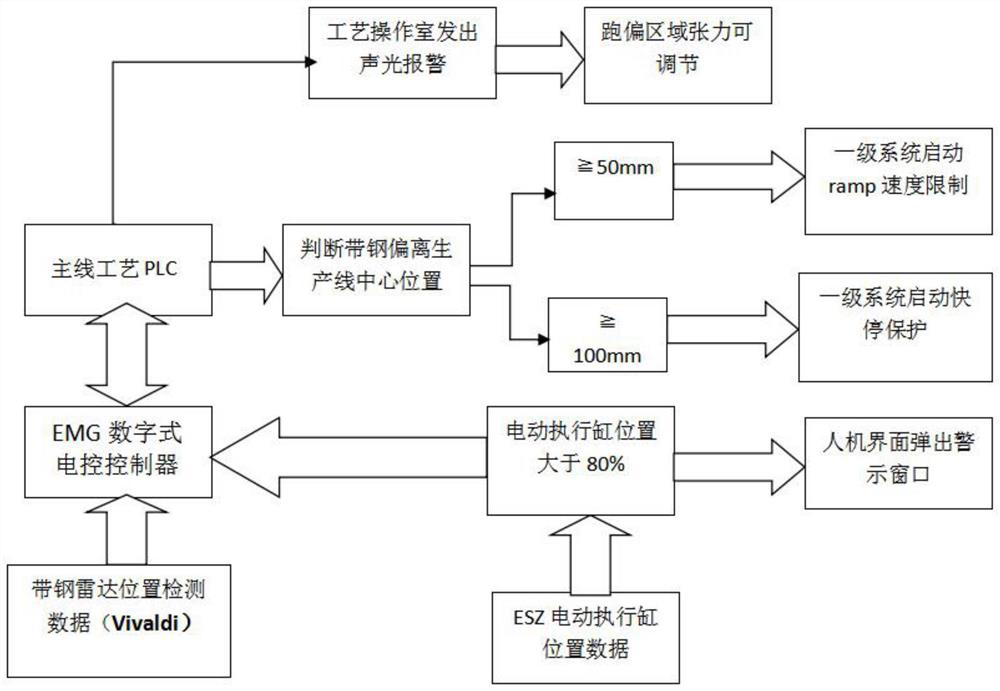

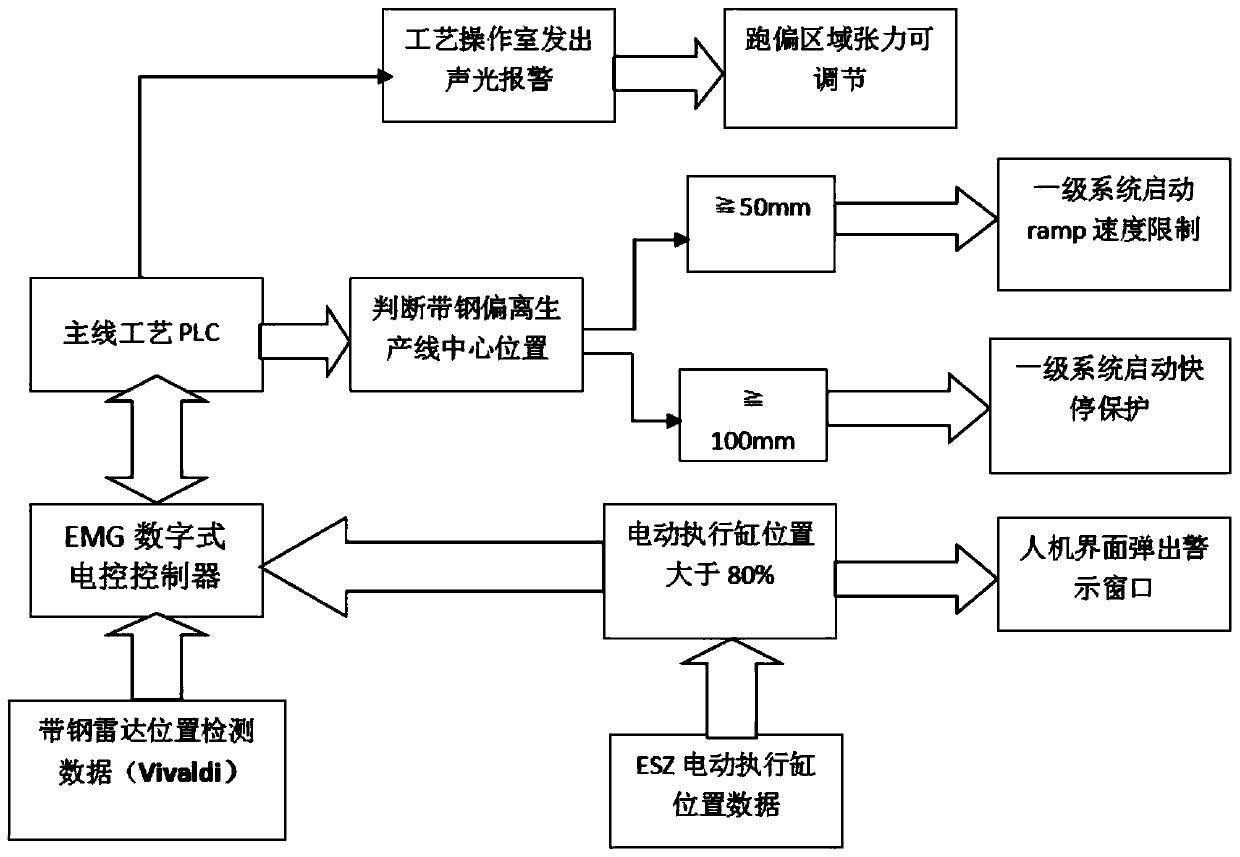

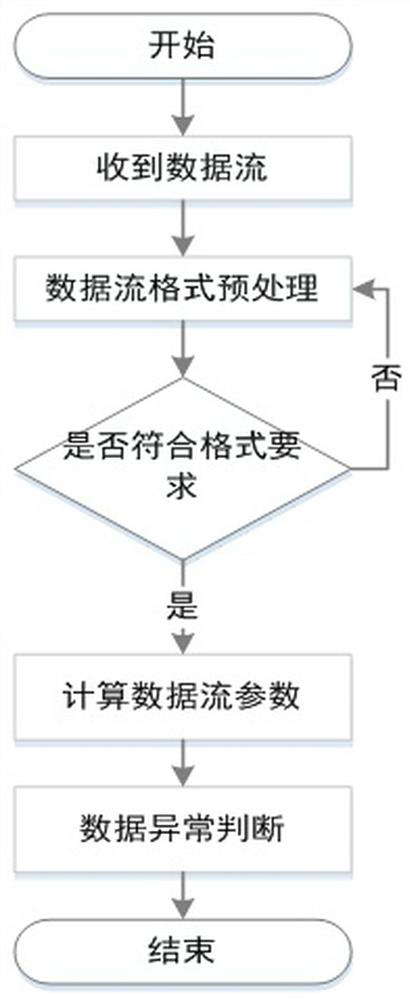

A control method for preventing strip breakage in annealing furnace of cold rolling processing line

ActiveCN111440942BReduce the degree of deviationAvoid serious deviationFurnace typesHeat treatment process controlEarly warning systemControl system

The invention discloses a control method for preventing strip breakage in the annealing furnace of a cold rolling processing line. A backup protection function is added to the original correction system. Ramp speed limit, early warning prompt system, tension compensation system control, when the strip steel deviates from the production center line by 50mm, the starting ramp speed limit is 60m / min, even if the shape of the incoming material is poor, the degree of deviation of the strip steel can be significantly reduced. It effectively avoids the serious deviation of the strip in the furnace, and at the same time greatly reduces the accident of strip breakage in the annealing furnace, so that the continuous and reliable operation of the cold rolling processing line is guaranteed.

Owner:SD STEEL RIZHAO CO LTD

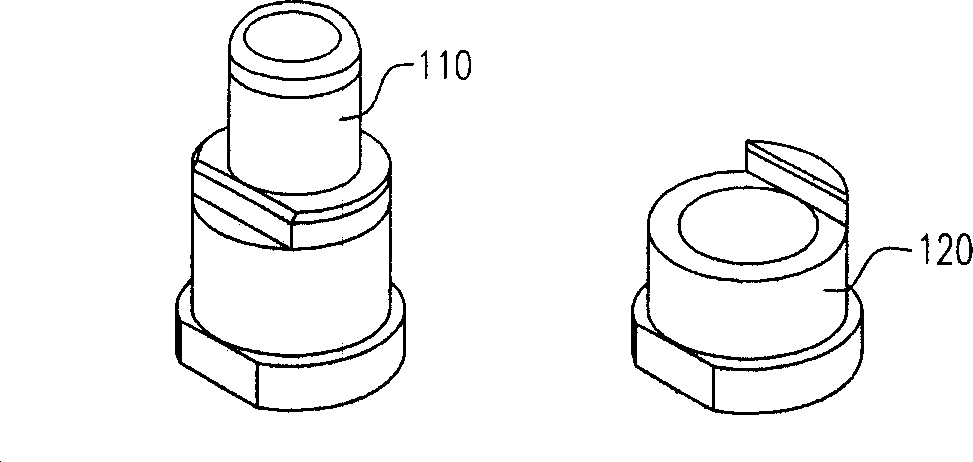

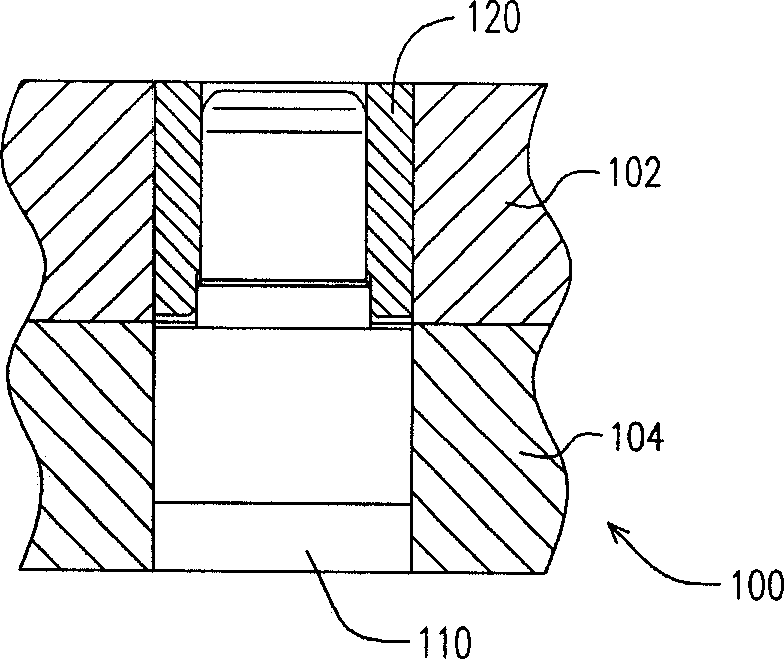

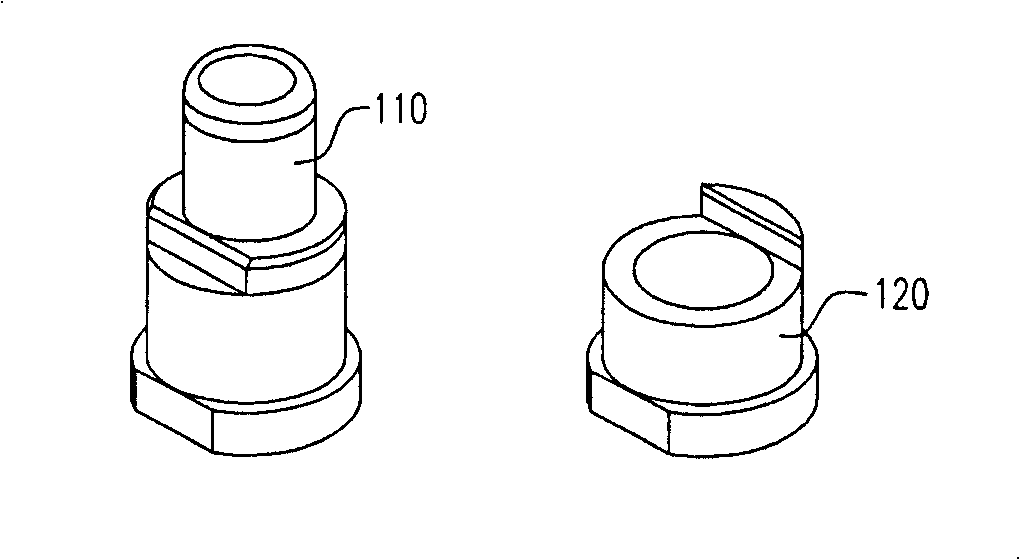

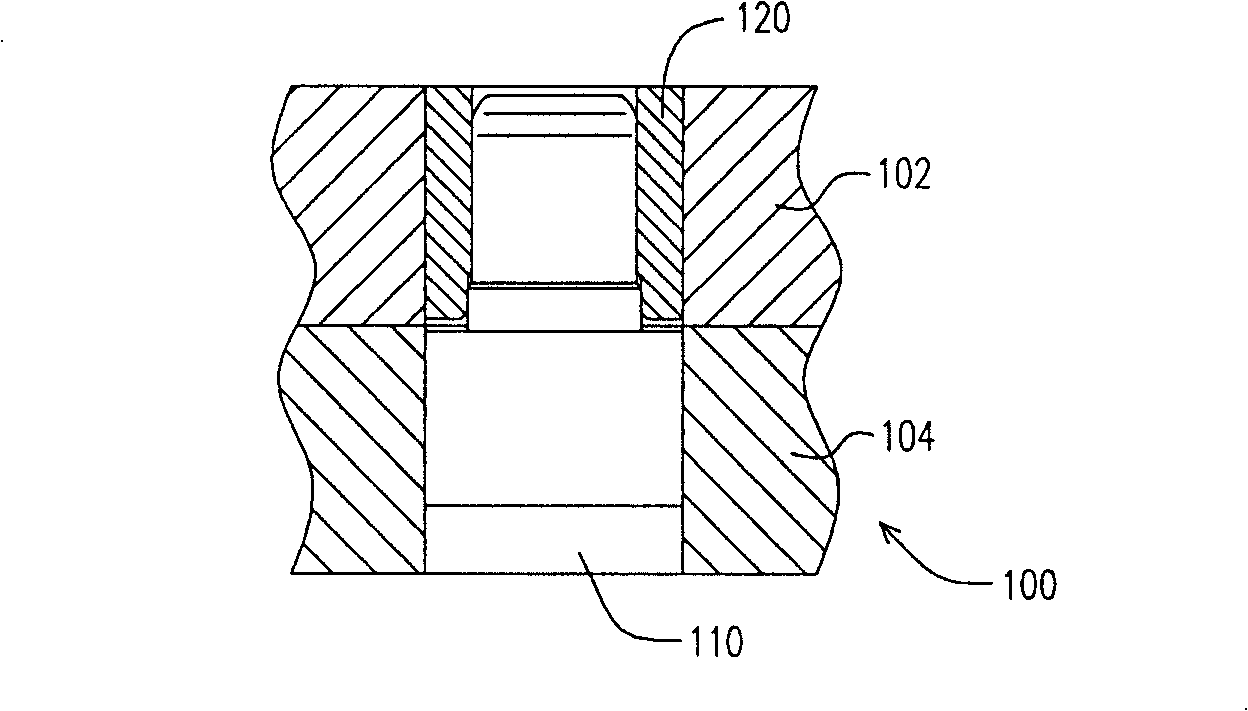

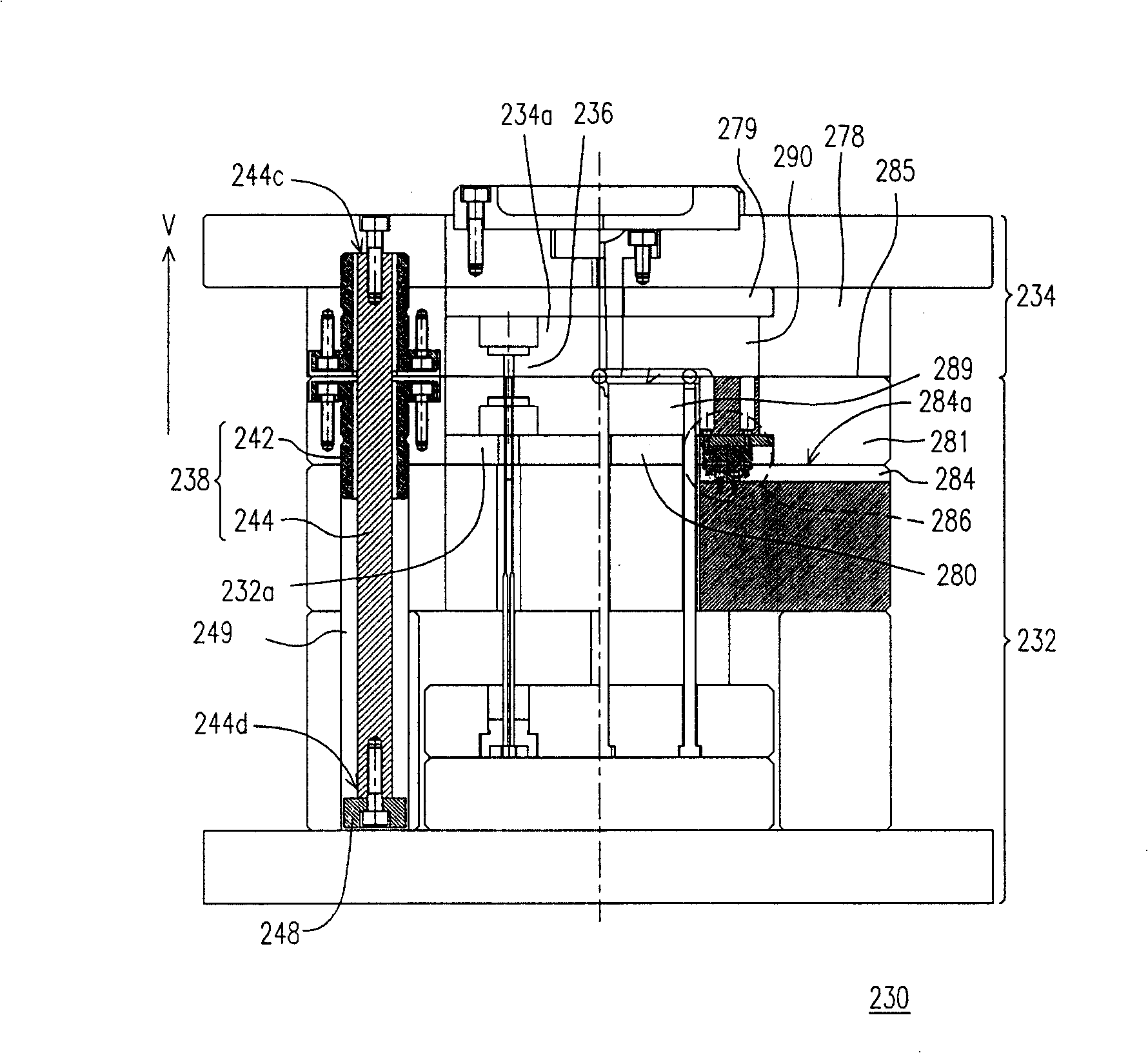

Die unit and injection forming machine

InactiveCN1883914AReduce the degree of deviationReduce wearInjection molding machineBiomedical engineering

One kind of mold unit and injection molding machine. The mold unit consists of the first member, the second member, at least one sliding localizer, at least one guide pin and at least one guide sleeve. Of them, the first member contains the cavity retainer plate, the first back plate, the first insert and the first cavity. The first insert is fixed onto the first back plate. The first cavity is placed in the hole in the cavity of the first insert and can perform relative 2D movements against the cavity retainer plate. The second member is located on the opposite of the first member, with the second cavity being fixed on the second insert and a cavity being formed between the first cavity and the second cavity. The sliding localizer is equipped between the cavity retainer plate and the first back plate, so the first cavity can be at a desired 2D position in respect of the supporting plate. What's more, the guiding pin is on either the first cavity or the second cavity and the guiding sleeve is on the other cavity.

Owner:ASIA OPTICAL CO INC

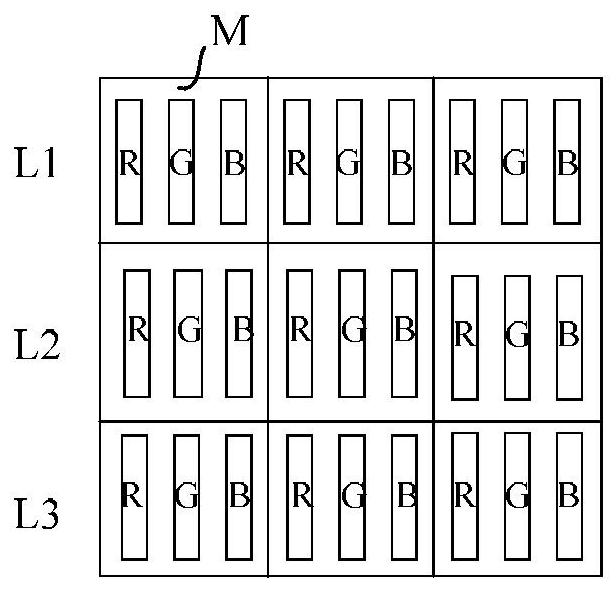

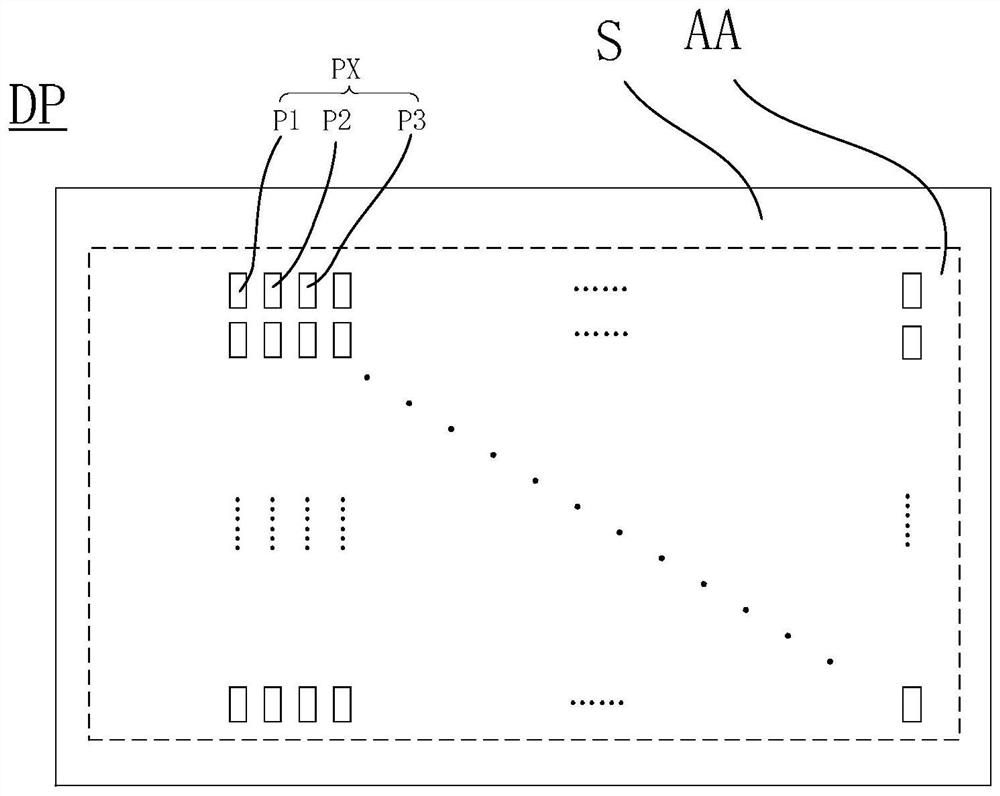

Display panel and display device

ActiveCN113012640BSmall color differenceReduce the degree of deviationSolid-state devicesCathode-ray tube indicatorsComputer graphics (images)Display device

Embodiments of the present invention provide a display panel and a display device, which relate to the field of display, and are used to solve the problem that, in a picture displayed by a display device in a dark background mode in the prior art, the light-colored display content is shifted as the position changes. color issue. The display panel includes a first subpixel displaying a first color, a second subpixel displaying a second color, and a third subpixel displaying a third color. When the picture displayed on the display panel is switched from the black picture to the maximum grayscale picture of the first color, the second color and the third color, the ratio of the brightness of the first frame picture to the maximum brightness of the multi-frame pictures after stabilization is the first The brightness ratio of the first frame, the brightness ratio of the second frame, and the brightness ratio of the third frame. The brightness ratio of the first first frame, the extreme difference between the brightness ratio of the second first frame and the brightness ratio of the third first frame is less than or equal to 20%.

Owner:BOE TECH GRP CO LTD +1

Die unit and injection forming machine

One kind of mold unit and injection molding machine. The mold unit consists of the first member, the second member, at least one sliding localizer, at least one guide pin and at least one guide sleeve. Of them, the first member contains the cavity retainer plate, the first back plate, the first insert and the first cavity. The first insert is fixed onto the first back plate. The first cavity is placed in the hole in the cavity of the first insert and can perform relative 2D movements against the cavity retainer plate. The second member is located on the opposite of the first member, with the second cavity being fixed on the second insert and a cavity being formed between the first cavity and the second cavity. The sliding localizer is equipped between the cavity retainer plate and the first back plate, so the first cavity can be at a desired 2D position in respect of the supporting plate. What's more, the guiding pin is on either the first cavity or the second cavity and the guiding sleeve is on the other cavity.

Owner:ASIA OPTICAL CO INC

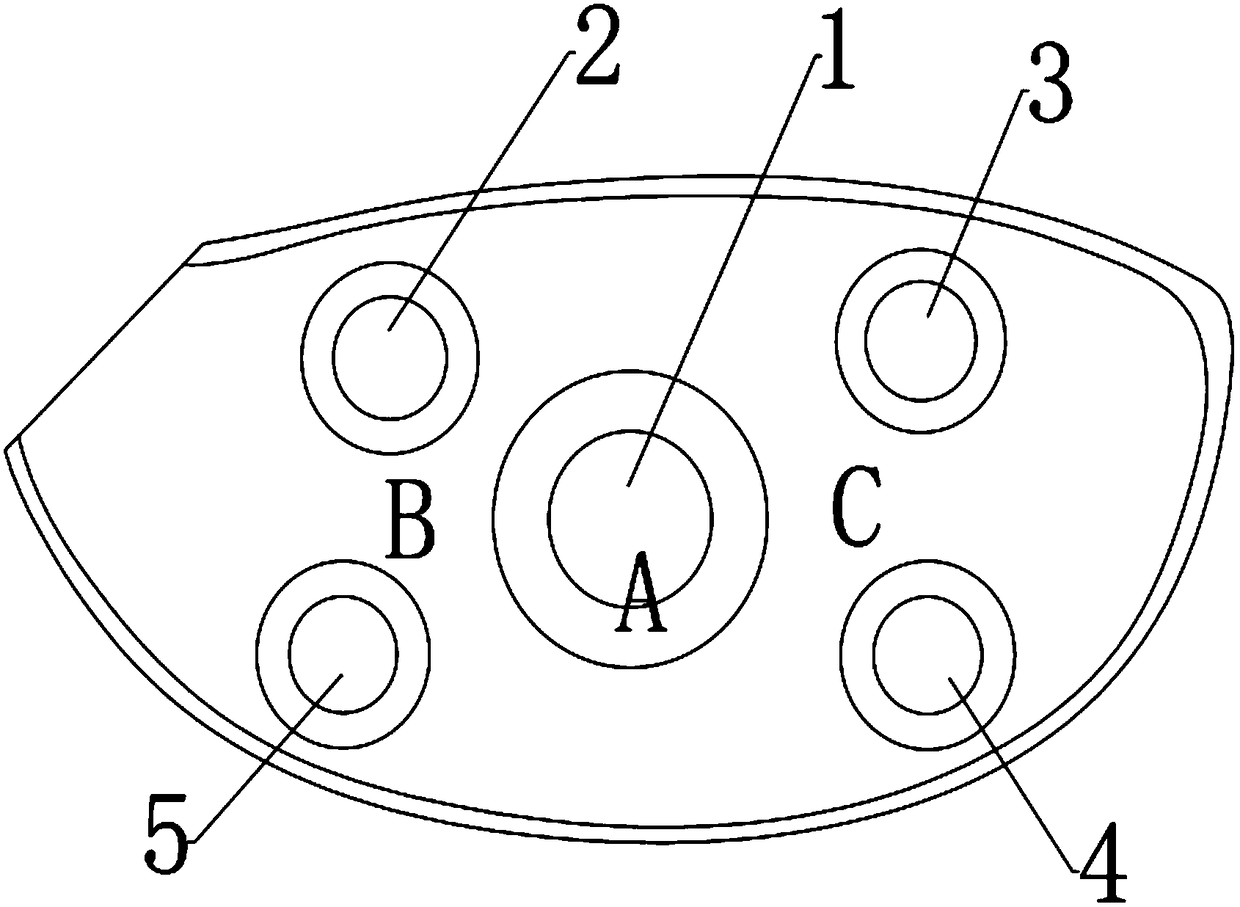

Hollow golf club head

InactiveCN108654029AImprove hitting performanceIncrease elasticityGolf clubsRacket sportsEngineeringGolf Ball

The invention discloses a hollow golf club head. The hollow golf club head includes a ball hitting face; the ball hitting face includes a main thickening area and an auxiliary thickening area, whereinthe main thickening area is protrudedly arranged at the center of the ball hitting face, and the auxiliary thickening area is uniformly and protrudedly arranged at the periphery of the main thickening area; the main thickening area is provided with a smooth edge. The hollow golf club head has the advantages that when a ball hitting position diverges from the central thickening portion, large rebound force can be also generated, it is ensured that a golf ball flies right ahead, distance loss is greatly reduced, and the deviation degree is reduced, so that a golf player is assisted in obtaininga better ball hitting effect, and the score is significantly increased.

Owner:范德平

A camera and its day and night mode switching method, device, equipment and medium

ActiveCN111726514BImprove accuracyReduce the degree of deviationImage enhancementTelevision system detailsIlluminanceLightness

The present application discloses a camera and a day-night mode switching method, device, equipment, and medium thereof. The method includes: if the current camera mode is the night mode, determining the color temperature value of the current imaging picture; using the color temperature value and a color temperature value based on the current imaging picture The infrared light contribution rate of the picture brightness obtained from the white balance statistical information determines the visible illuminance of the current imaging picture, and uses the magnitude relationship between the above-mentioned visible illuminance and the first preset illuminance threshold to determine whether to switch the current night mode to the daytime mode. In the process of determining the visible illuminance in the night mode, the present application not only considers the influence of the infrared light contribution rate obtained based on the white balance statistical information on the visible illuminance, but also further considers the effect of the color temperature value of the imaging screen in the current night mode on the visible light Therefore, the degree of deviation from the actual visible illuminance is reduced, and the problem of repeated switching between day and night modes is effectively solved.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

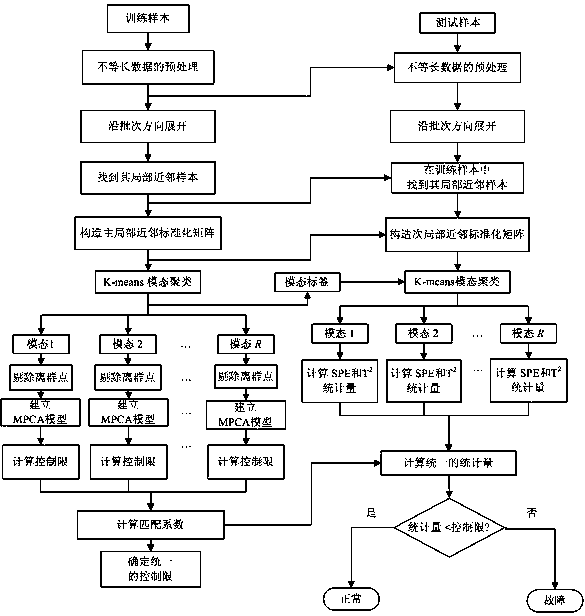

Multimodal Process Fault Detection Method Based on Local Neighbor Normalization Matrix

InactiveCN105511445BValid reservationAvoid missingProgramme controlElectric testing/monitoringMatrix methodLocal outlier factor

Multimodal process fault detection method based on local neighbor normalization matrix, involving industrial process fault detection method, using historical data under normal state as the training set of modeling data, using local neighbor normalization matrix method for multimodal process modeling and Troubleshooting. Firstly, the local weighting algorithm is used to preprocess the unequal-length batch data. Determine the maximum retainable length of unequal-length data in the training samples, and use k-nearest neighbor information to reconstruct the missing data points of unequal-length batches through weighting. Secondly, the main local neighbor normalization matrix is constructed for the training set of equal length, the K-means algorithm is used for mode clustering, and the outlier samples of each mode are eliminated by the local outlier factor method. This method can avoid the loss of information from affecting the modal clustering effect of the multi-modal process, and remove outliers at the same time. By constructing the primary and secondary local neighbor normalization matrix, the fault diagnosis results of the multi-modal intermittent process are more accurate.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

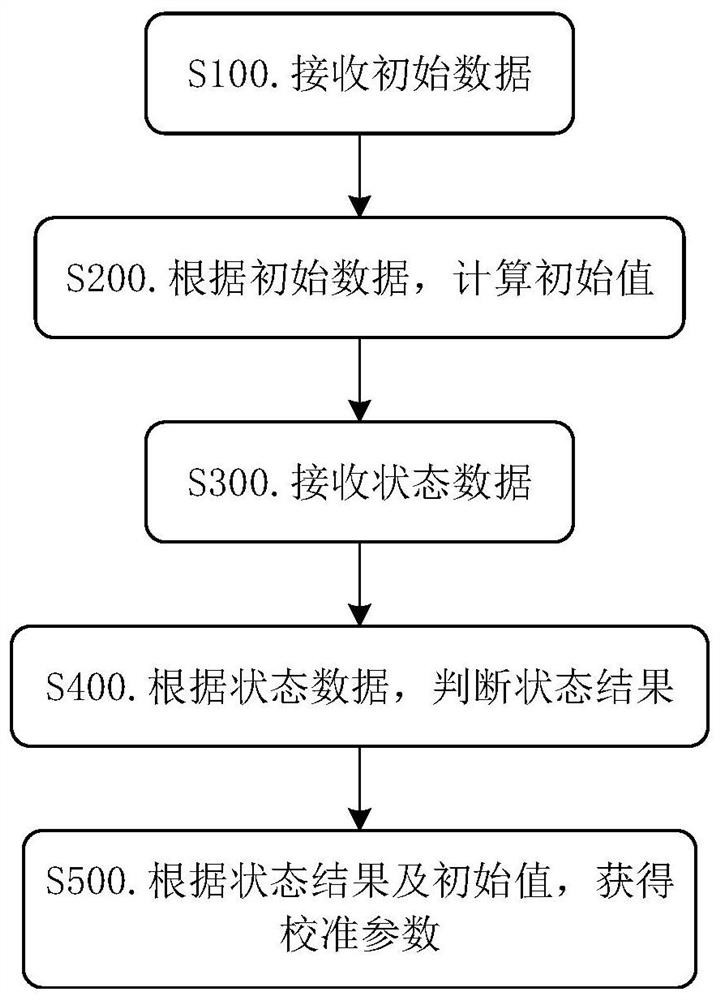

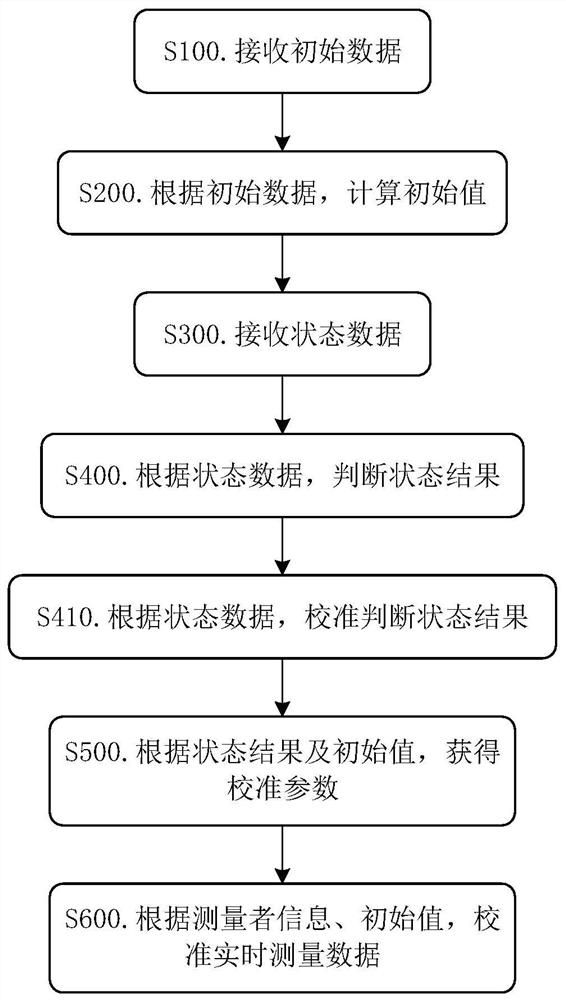

Cardiac-cerebral parameter calibration method and device and storage medium

PendingCN112401858AGuarantee statusReduce the degree of deviationDiagnostic signal processingEvaluation of blood vesselsBiomedical engineeringMeasurement precision

The invention provides a cardiac-cerebral parameter calibration method and device and a storage medium. The cardiac-cerebral parameter calibration method comprises the following steps: receiving initial data; calculating an initial value according to the initial data; receiving state data; judging a state result according to the state data; and obtaining a calibration parameter according to the state result and the initial value. According to the method, firstly, through setting the initial data, an adjustment basic value can be added for measurement work to ensure that a measurement result has a relatively low deviation degree; secondly, through state judgment, the state of a measurer can be ensured when measurement data is acquired, the influence caused by the measurement state of the measurer can be eliminated, and the blood pressure measurement accuracy can be effectively improved; and thirdly, measurement data with large deviation values can be removed, measurement data in a floating range is reserved, the measurement precision is improved, and the authenticity of the data is ensured.

Owner:北京智康人人科技有限公司

Control method for preventing strip breakage in annealing furnace of cold rolling treatment line

ActiveCN111440942AReduce the degree of deviationAvoid serious deviationFurnace typesHeat treatment process controlControl systemControl engineering

The invention discloses a control method for preventing strip breakage in an annealing furnace of a cold rolling treatment line. A backup protection function is added on the basis of an original deviation rectifying system. A primary control system acquires data of deviation rectifying equipment through a communication protocol. Through the control of the ramp speed limitation of the primary control system, an early warning prompt system and a tension compensation system, the ramp starting speed is limited to 60 m / min when strip steel deviates from a production center line by 50 mm, so that the deviation degree of the strip steel can be obviously reduced even if an incoming plate type is poor, and serious deviation of the strip steel in the furnace is effectively avoided. Meanwhile, stripbreakage accidents in the annealing furnace are greatly reduced, and continuous and reliable operation of the cold rolling treatment line is guaranteed.

Owner:SD STEEL RIZHAO CO LTD

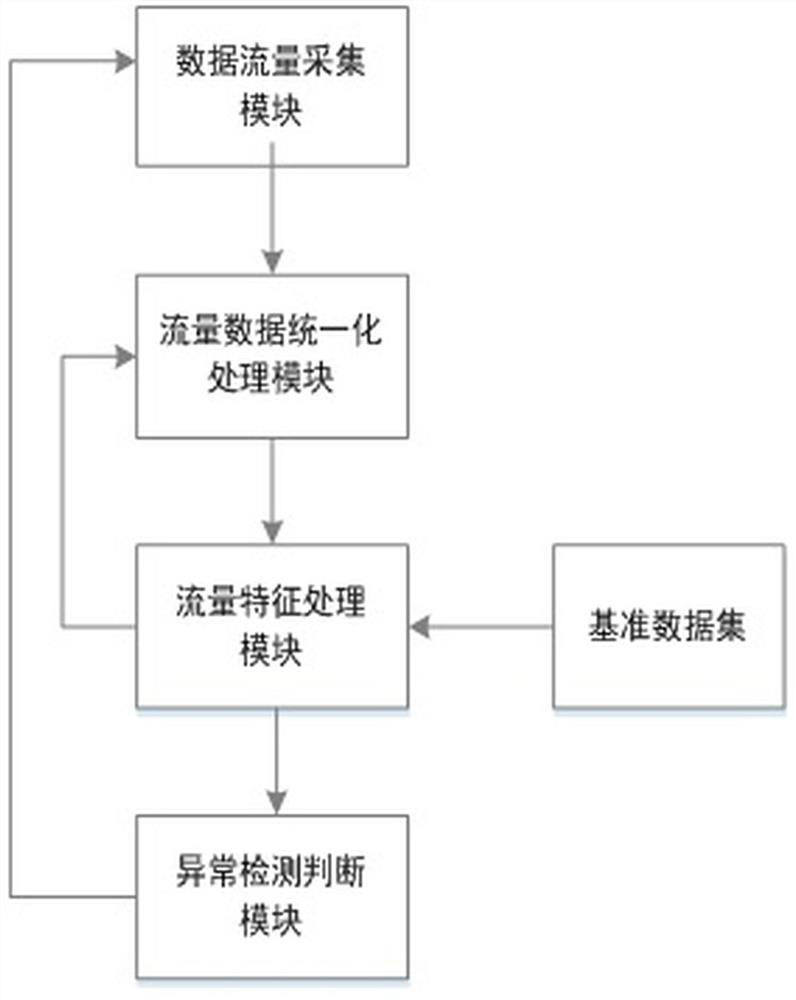

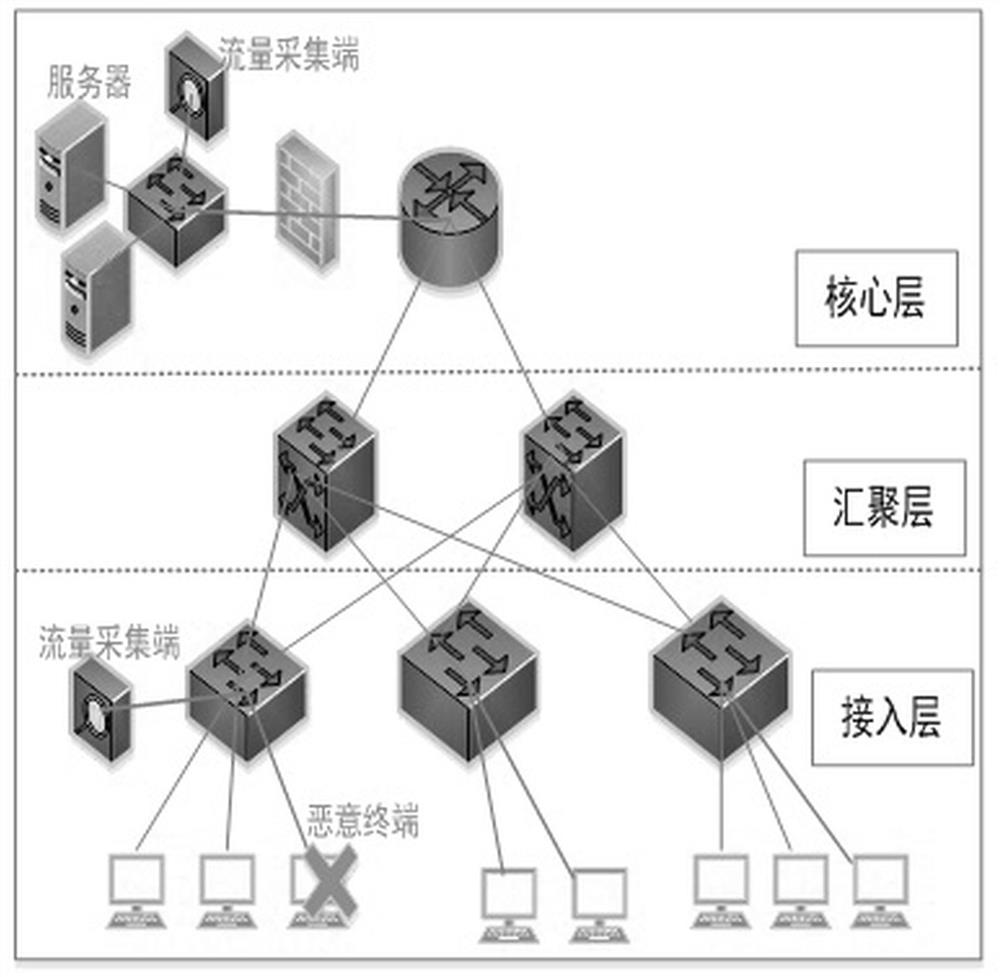

Network Anomaly Detection Method Based on Traffic Data Sample Statistics and Balance Information Entropy Estimation

ActiveCN109361673BReduce the degree of deviationReduce mistakesTransmissionInternet trafficAnomaly detection

The invention discloses a network anomaly detection method based on flow data sample statistics and balance information entropy estimation. Small sample data characteristics of network traffic, use the balance method of sample information entropy to estimate the overall situation, identify the detection method of DoS and Port Scan attack rejection in the network.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

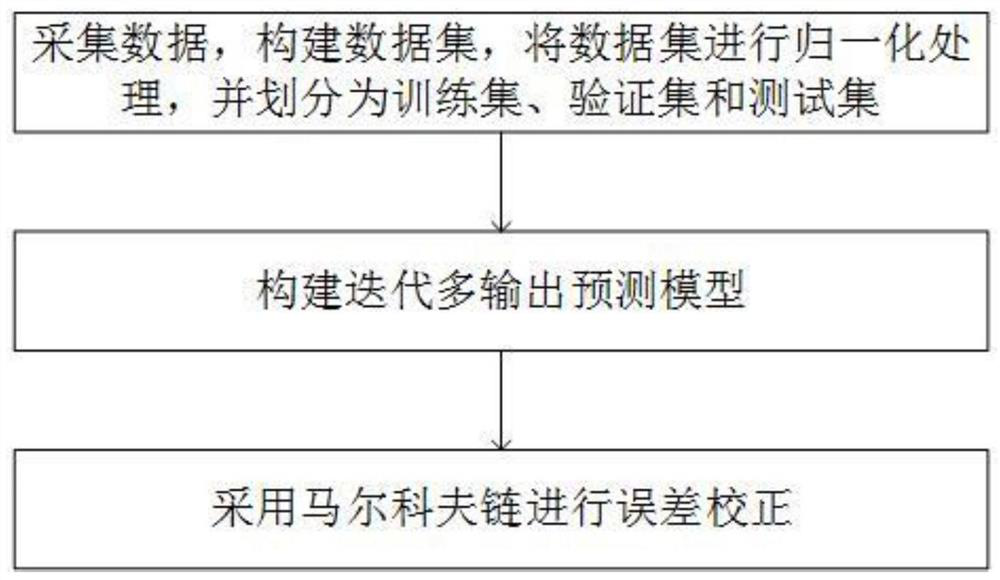

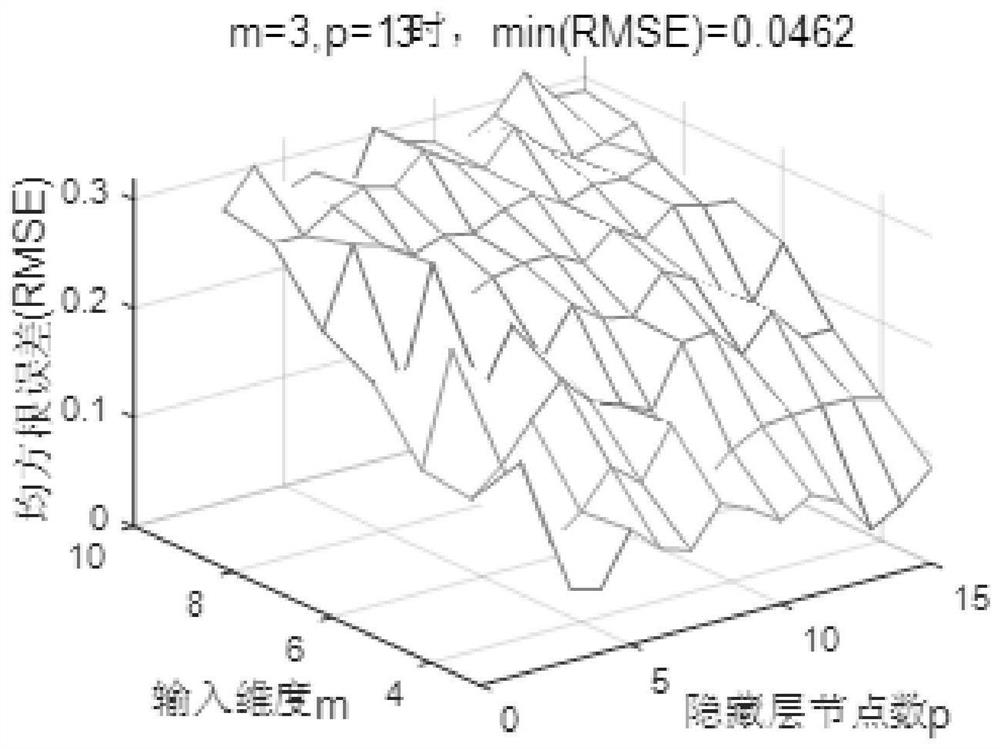

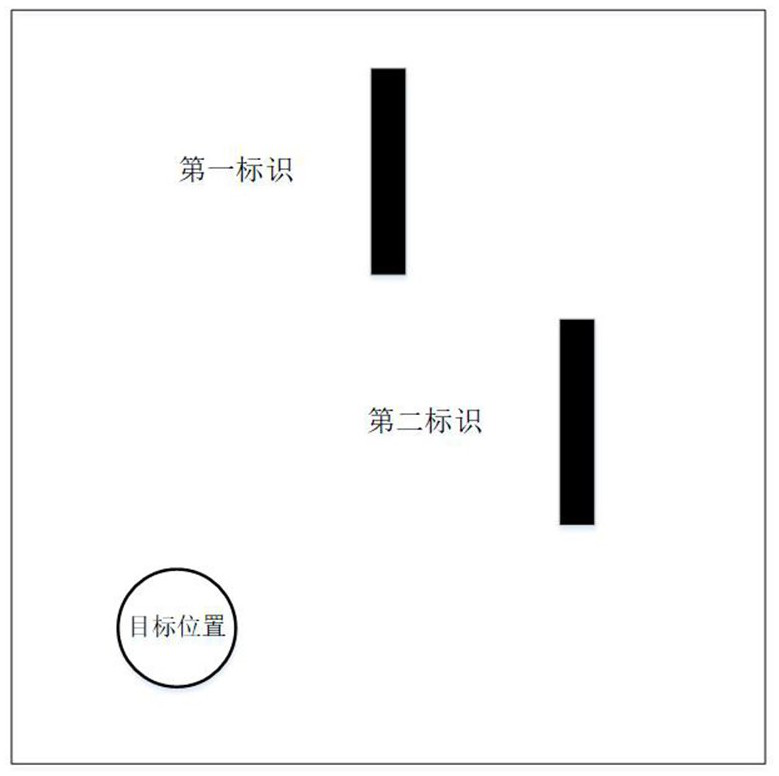

Air separation system argon fraction variable multi-step prediction method based on iterative multi-output-Markov chain

PendingCN113255207AReduce Iterative Error AccumulationImprove applicabilityDesign optimisation/simulationComplex mathematical operationsMarkov chainData set

The invention discloses an air separation system argon fraction variable multi-step prediction method based on an iterative multi-output-Markov chain, and the method comprises the following steps: S1, collecting data, constructing a data set, carrying out the normalization processing of the data set, and dividing the data set into a training set, a verification set and a test set; S2, constructing an iterative multi-output prediction model; s3, carrying out error correction by adopting a Markov chain. According to the method, the iterative multi-output method is combined with the Markov chain, on one hand, the optimal input and output dimension of the prediction model is determined in a parameter optimization mode, iteration error accumulation of the model is effectively reduced, and the applicability and flexibility of the model are enhanced; and on the other hand, the Markov chain can determine the correction range and direction of the prediction value by calculating the error state of the prediction value, so that the deviation degree of the prediction value and the real value is smaller, the prediction precision is higher, and the method has better applicability to variable time sequence multi-step prediction of the air separation system.

Owner:HANGZHOU DIANZI UNIV

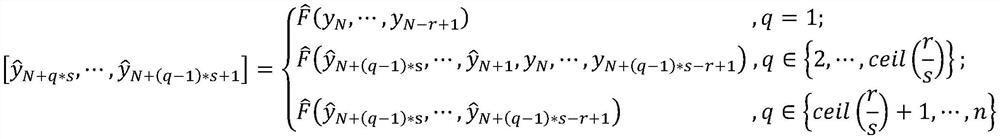

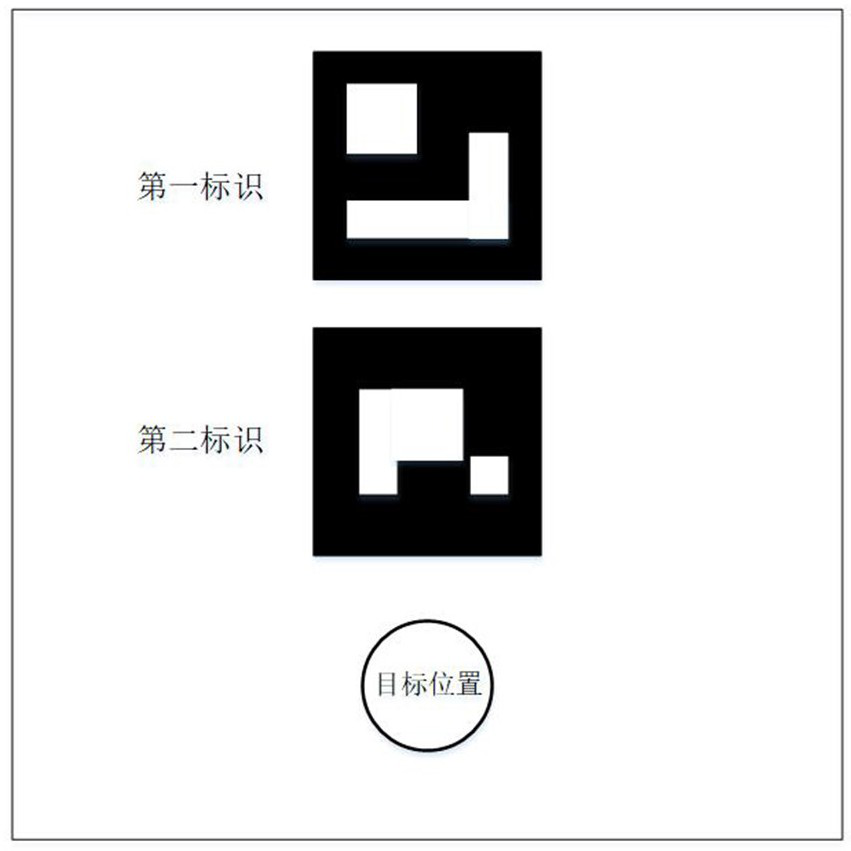

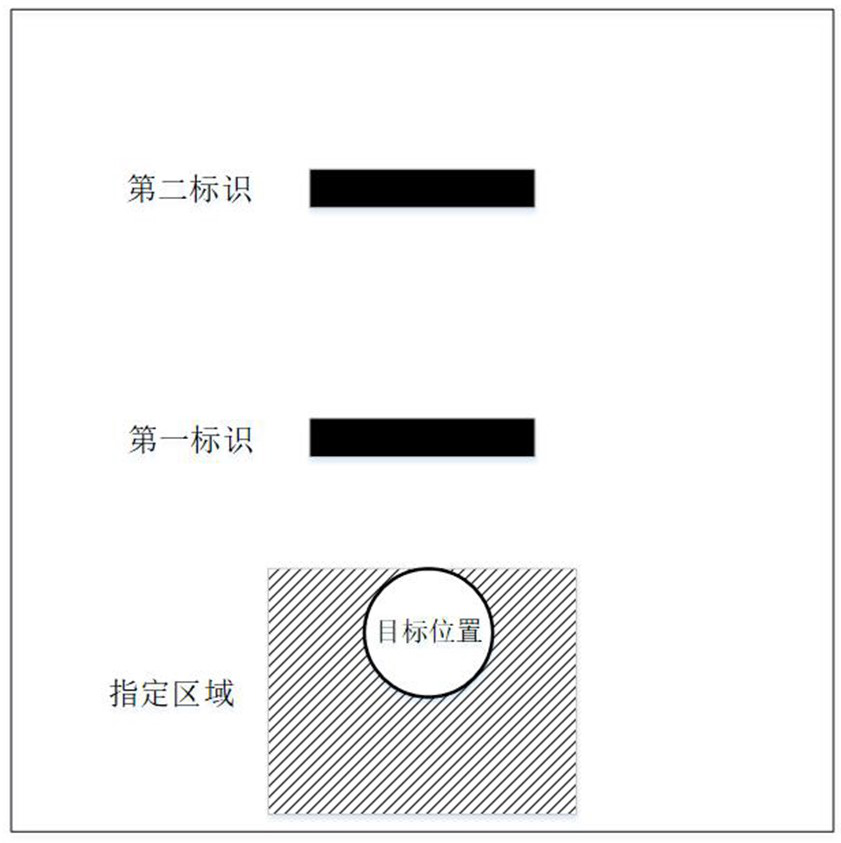

A robot positioning method, device, electronic device and storage medium

ActiveCN114511625BReduce the degree of deviationPrecise positioningAutomatic obstacle detectionImage analysisEngineeringComputer vision

The present disclosure provides a robot positioning method, device, electronic device and storage medium. A first mark and a second mark are constructed and arranged on the same side of a target position; under the first coordinate system in the top view direction, the target position, the first mark The abscissa of the center point of the logo and the second logo is the same, and the ordinate increases in turn; in the second coordinate system of the side view direction, the first ordinate of the bottom edge of the first logo is greater than the second ordinate of the top edge of the second logo , the abscissa of any point of the target position is smaller than the abscissa of the first mark, including: controlling the robot to move to a designated area through navigation; adjusting the robot to move towards the first direction and move to the center point of the first mark and the second mark in the collected image The distance is less than the set threshold; adjust the robot to move in the second direction until only the second mark is included in the collected image; adjust the robot to move in the third direction until the side length of the second mark in the image reaches the preset value , to determine that the robot has reached the target position.

Owner:史河机器人(合肥)有限公司

A rubber wear-resistant test equipment for plastic products

ActiveCN111089814BReduce maintenance costsIncrease gravity pressureInvestigating abrasion/wear resistanceStructural engineeringTest equipment

The invention discloses a rubber wear-resisting test equipment for plastic products, which comprises a test table, on which a test board is movable left and right, and the test board is connected with the test table through an electric slide rail; it is used for positioning workpieces. The positioning clamping device is set on the test table; the friction device is located above the clamping device and is used for friction testing the surface of the workpiece to be tested; the pressure device is used to apply different degrees of pressure to the friction device; The liquid storage cylinder at the upper end of the moving column, the columnar liquid storage cavity arranged in the liquid storage cylinder, and the liquid inlet connected to the liquid storage cavity in the upper part of the liquid storage cylinder. The present invention adopts the method of liquid weighting to increase the gravity pressure on the rubber, and converts the final gravity by multiplying the volume of the liquid by the density, so that the magnitude of the gravity change value can be accurate to a smaller degree, the degree of deviation is reduced, and the control accuracy is improved.

Owner:绍兴市宇德塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com