Digital rebound tester

A rebound hammer, digital technology, applied in the direction of testing material hardness, etc., can solve the problems affecting the measurement accuracy and error of the rebound value, achieve the effect of improving durability and service life, improving measurement accuracy, and eliminating measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

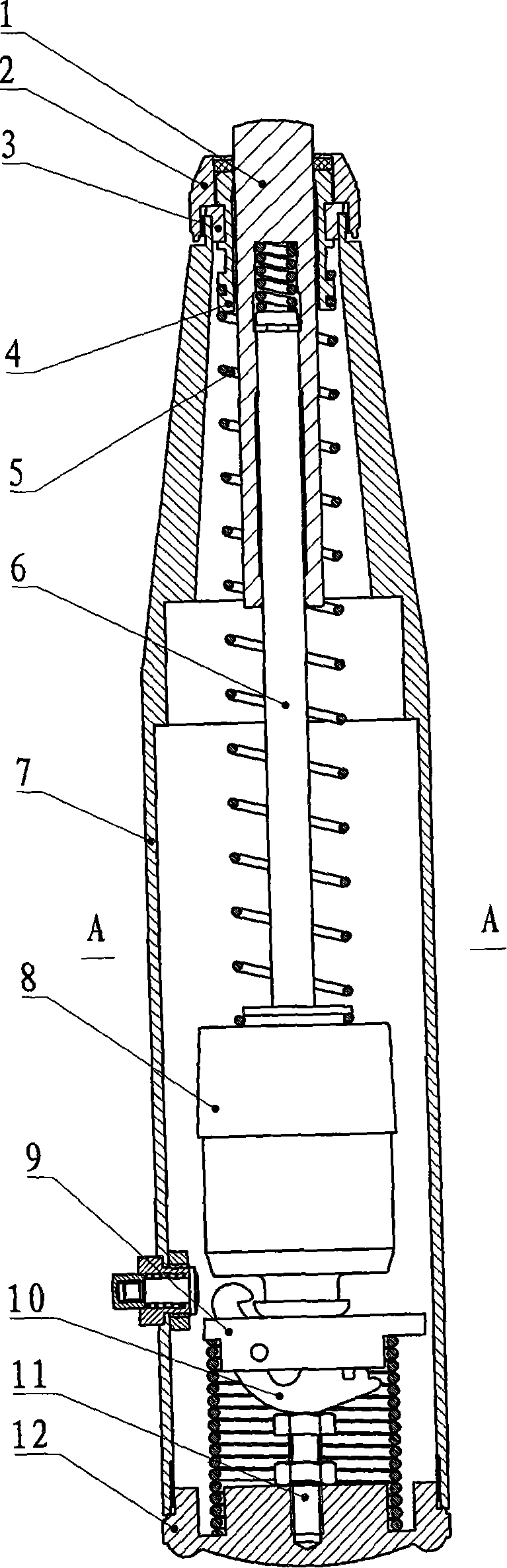

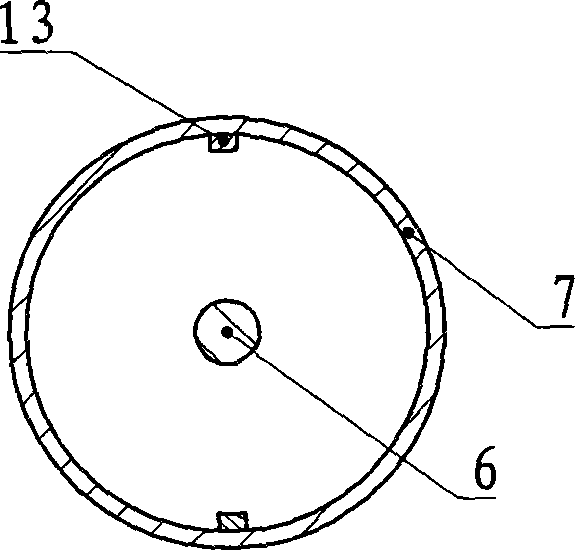

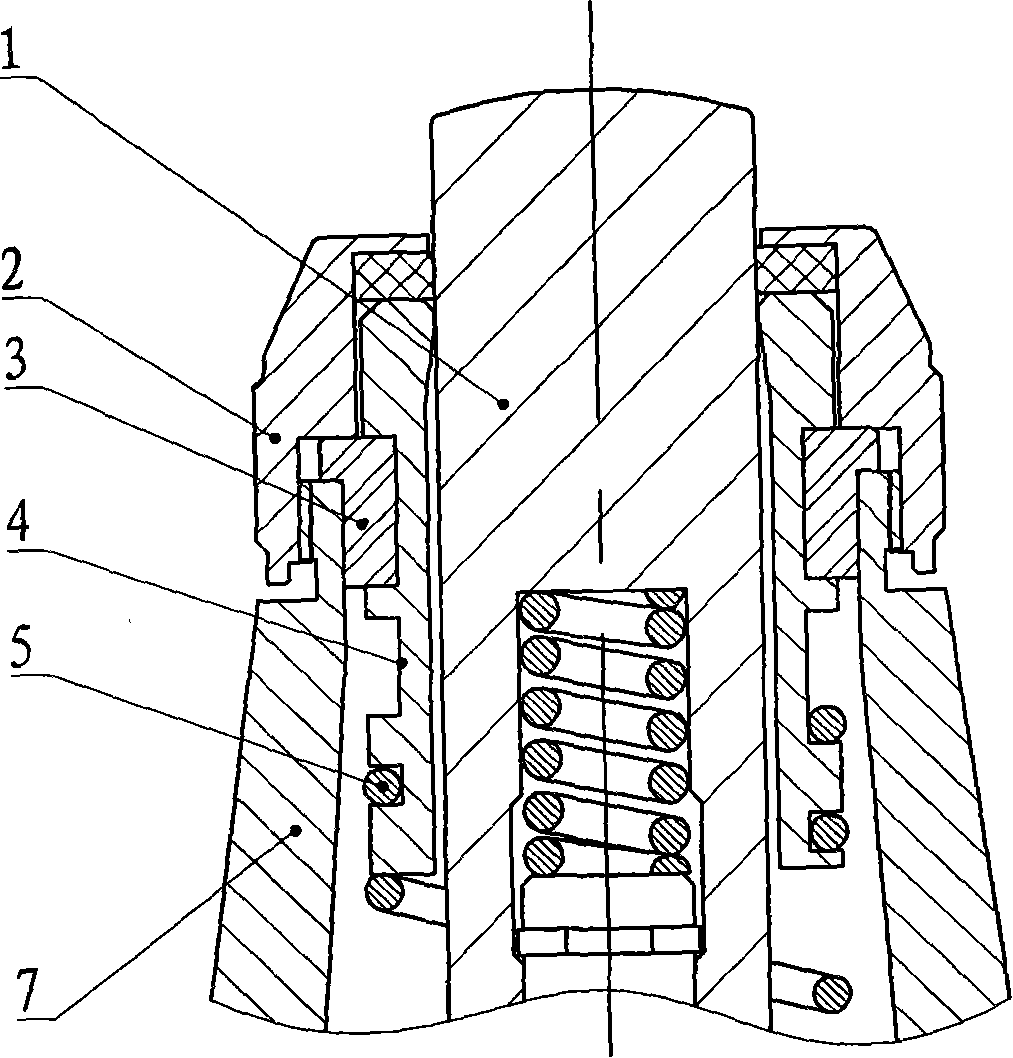

[0037] 1. The digital rebound hammer in this example consists of two parts: the rebound hammer and the computer. The structure of the hammer hammer is as follows: figure 1 , 2 shown. There is a rebound hammer housing composed of a front end cover 2, a main body 7 and a rear end cover 12. A central guide rod 6 is installed on the axis in the housing, the rear end of the central guide rod is fixedly connected with the flange 9, and the flange is stuck on the flange guide rail 13 parallel to the axis on the housing main body with its upper notch. The front end of the center guide rod is coaxially inserted in the rear end hole of the ejection rod 1 through the buffer spring, and the front end of the ejection rod passes through the front end cover. The center guide rod is covered with a bounce hammer 8, and the bounce hammer front end is connected with the bounce extension spring seat 4 that is enclosed within the bounce lever through a bounce extension spring. Ring pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com