Die unit and injection forming machine

A technology for injection molding machines and molds, applied in the field of mold units and injection molding machines using sliding positioners, can solve the problems of loss of precision of mold unit 100, unfavorable positioning of molds 102 and 104, etc., and reduce wear and contact area Small, wear-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

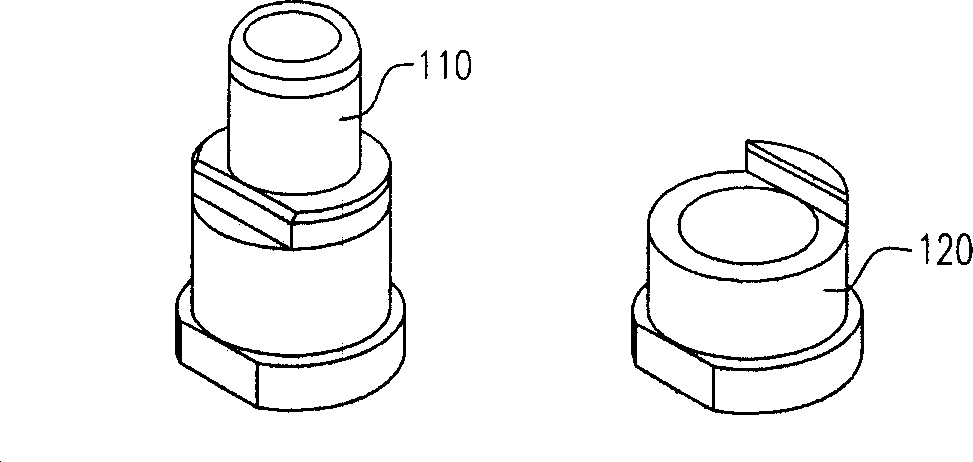

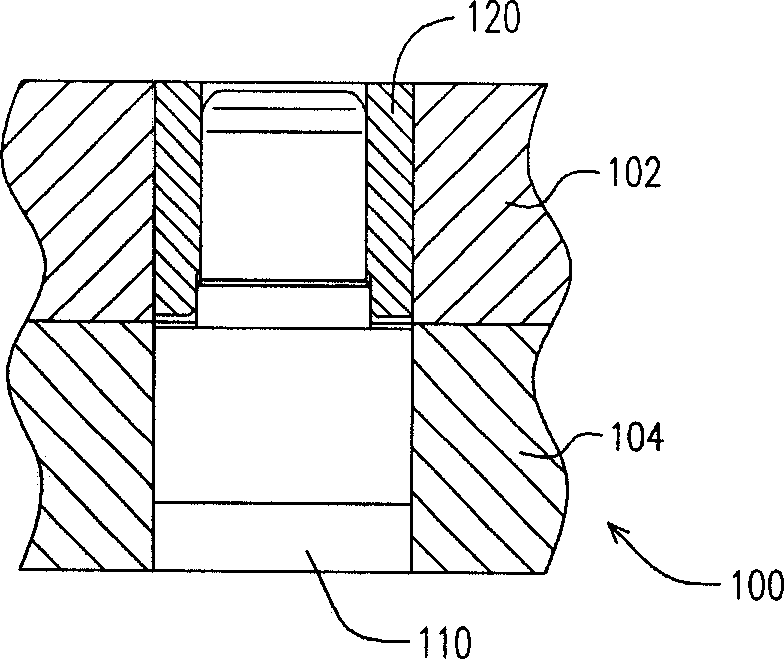

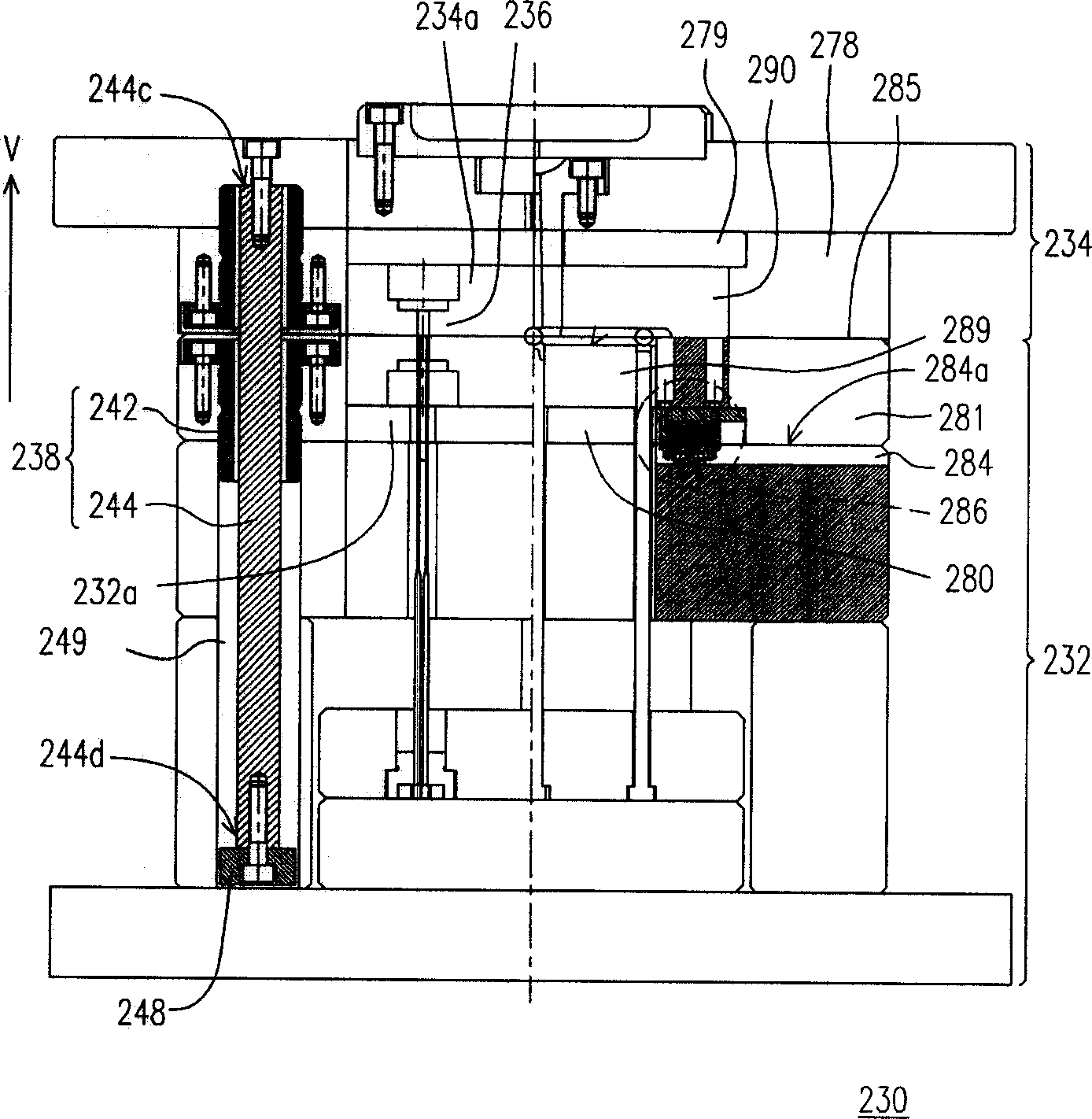

[0076] Figure 3A ~ Figure 3C It is a schematic diagram of a mold unit according to an embodiment of the present invention. in, Figure 3A is the front view of the die unit, Figure 3B is the bottom view of the second member of the mold unit, and Figure 3C is a top view of the first member of the mold unit.

[0077] Please refer to Figure 3A ~ Figure 3C , the mold unit 230 includes a first member 232, a second member 234, at least one slide positioner 286 (four in this embodiment), at least one guide pin 282 (four in this embodiment), and at least one Guide sleeves 283 (4 in this embodiment). Wherein, the first component 232 includes a carrier plate 284 , a first back plate 280 , a first insert 289 , a first mold plate 281 and a first mold core 232 a. The first mold core 232a is disposed on the first insert 289, and the first insert 289 and the first back plate 280 move relative to the support plate 284 on the two-dimensional plane 284a. The second member 234 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com