A rubber wear-resistant test equipment for plastic products

A wear-resistant test and plastic product technology, which is applied in the field of plastic product processing, can solve the problems of unsatisfactory gravity adjustment, manual replacement, low work efficiency, etc., and achieve the effect of reducing maintenance costs, reducing the degree of deviation, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

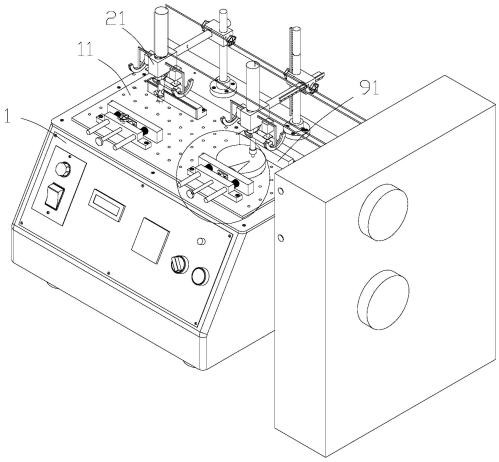

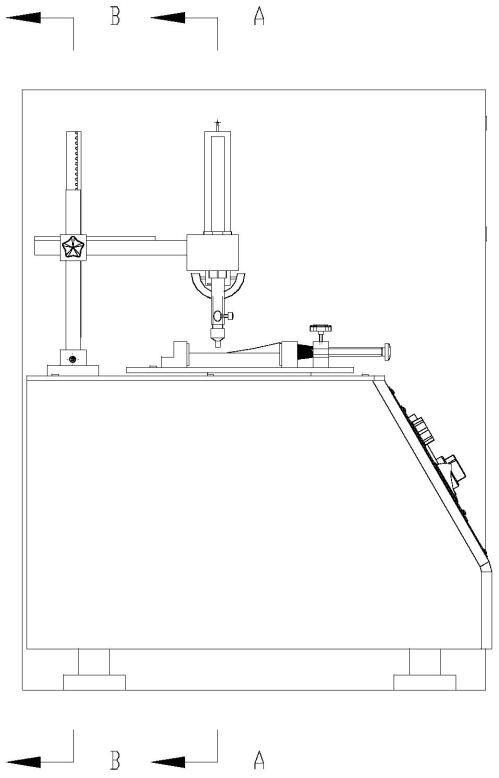

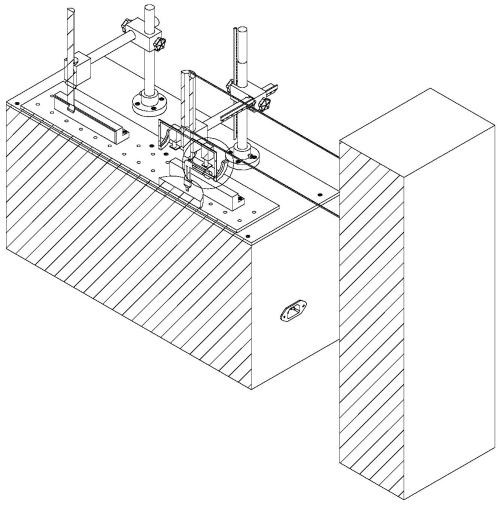

[0027] Such as Figure 1-10As shown, a kind of rubber wear-resistant test equipment for plastic products includes a test bench 1, a clamping device, a friction device and a pressurizing device. The test bench 1 is provided with a test plate 11, which is a metal plate , and connected to the test bench 1 through the electric slide rail, which is purchased directly from the market. When the electric rail starts, it can drive the test board 11 to move left and right on the test bench; the friction device is located above the clamping device , used for friction testing on the surface of the workpiece to be detected; specifically includes a moving seat 21 that can move up and down relative to the test platform, a moving column 22 that can move up and down and is installed in the moving seat, and a grinding assembly located below the moving column. Be connected with this moving base 21 and be used to drive this moving base to realize the driving part that moves up and down, front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com