Line paper rolling wheel of printer

A technology of printers and rollers, which is applied in the direction of printing devices, printing, and object separation. It can solve the problems of difficult to improve the quality of recorded images, reduce the precision of recording paper transmission, and change the transmission speed, so as to improve the quality of recorded images and reduce production costs. , the effect of reducing the degree of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

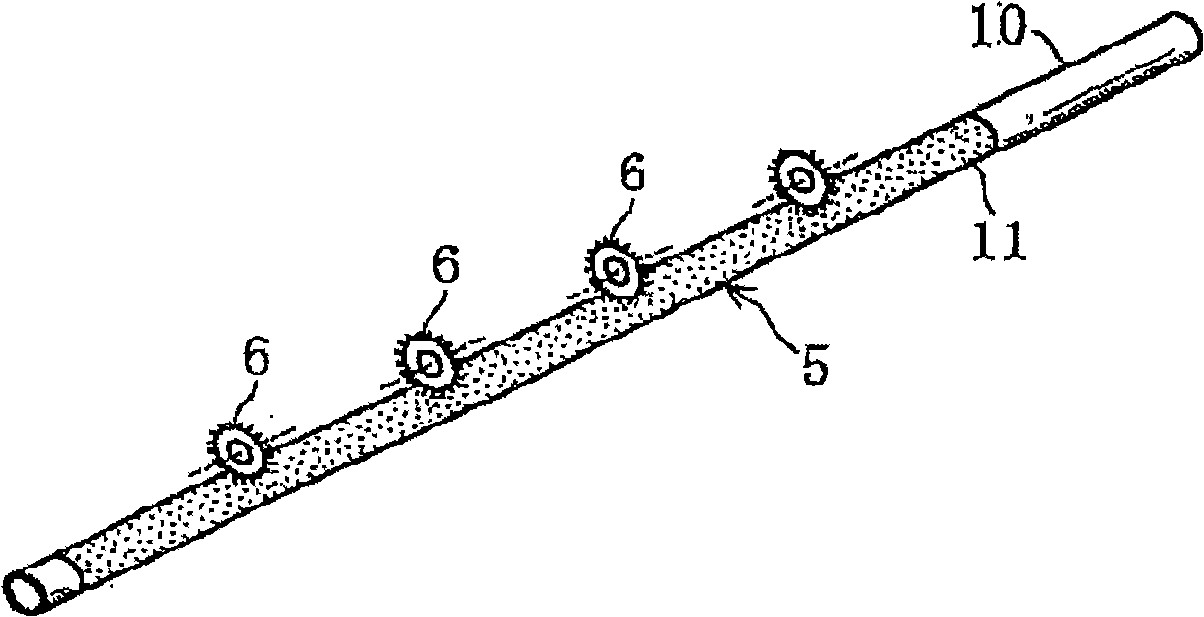

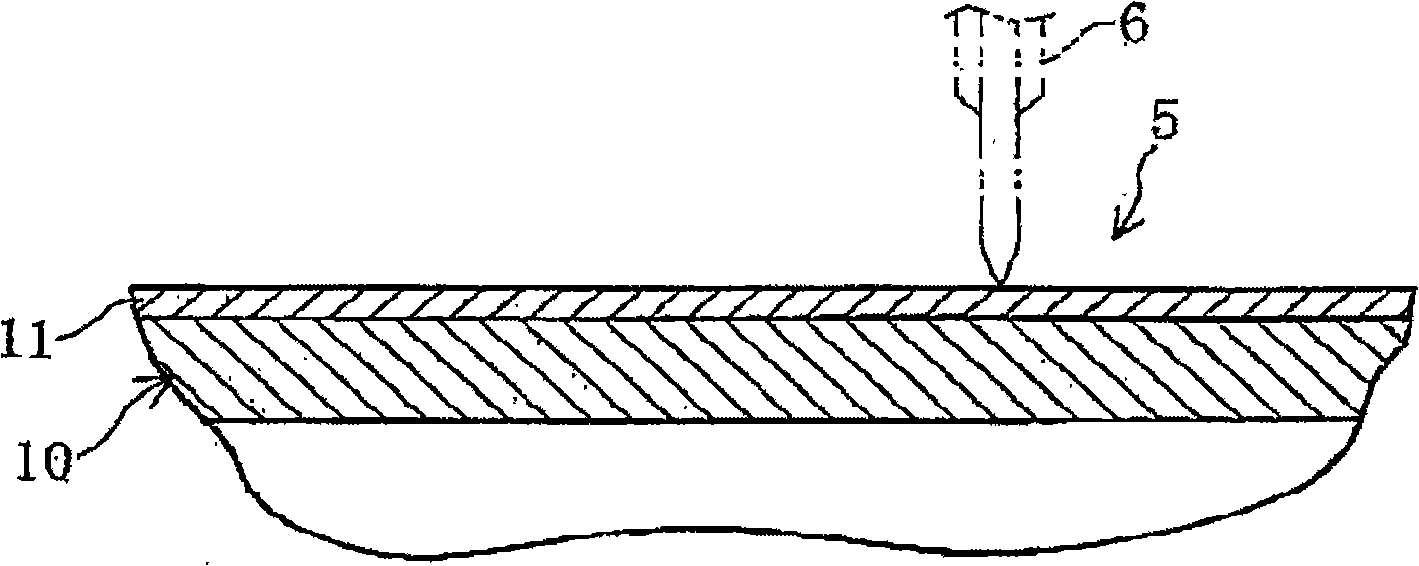

[0021] The paper discharge roller of the printer in the present invention comprises: a steel roller body with a cylindrical shape or a solid round bar in the center; and a metal thermal sprayed layer formed on the surface of the roller body, wherein the metal thermal sprayed layer The structure is formed with a thermal sprayed layer containing a metal material with a hardness of 30-75HRB.

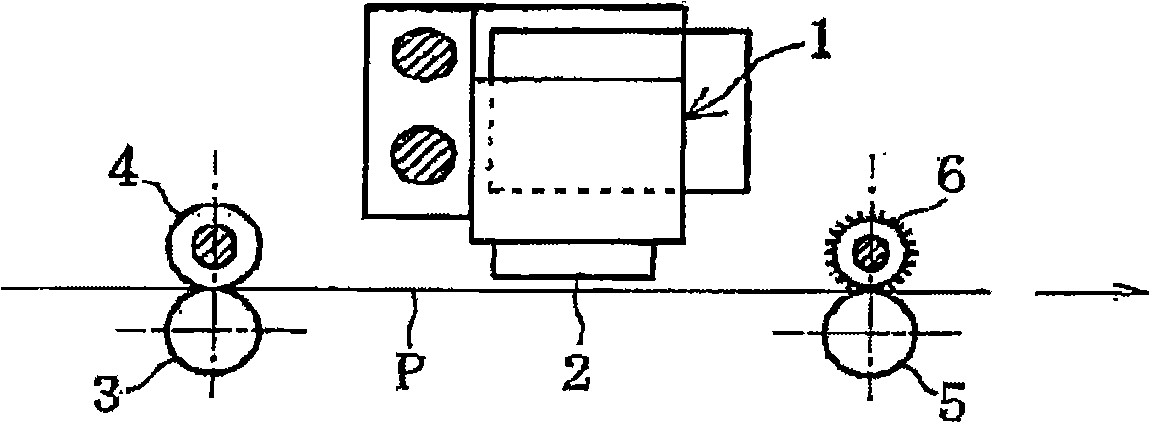

[0022] Such as figure 1 As shown, the inkjet printer in the figure is provided with a paper feed roller 3 and a pinch roller 4 of the paper feed roller 3 at the front end of the recording paper conveying direction of the recording paper P to the recording range 2 of the recording printing head 1, wherein in the recording The rear end in the paper transport direction is provided with a paper discharge roller 5 and four gear-shaped rollers 6 made of, for example, metal disks, and the recording paper P is conveyed by these rollers 3 to 6 .

[0023] First, the configuration of the discharge ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com