Patents

Literature

36results about How to "Reduce distance error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

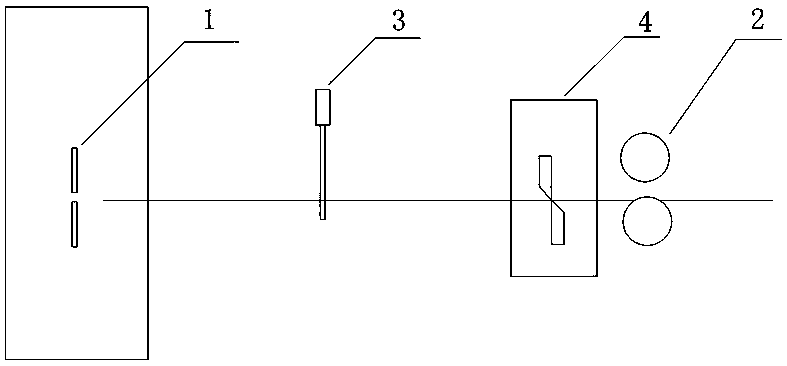

Intelligent portable hand-held vision screening instrument and optometry method

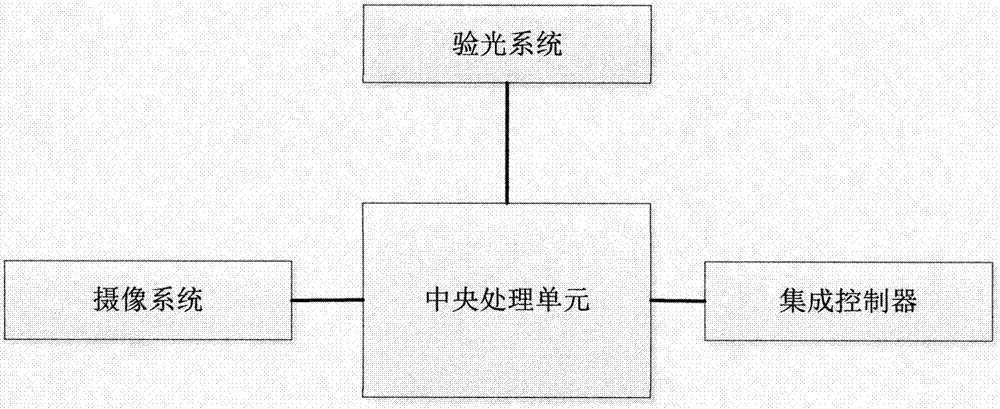

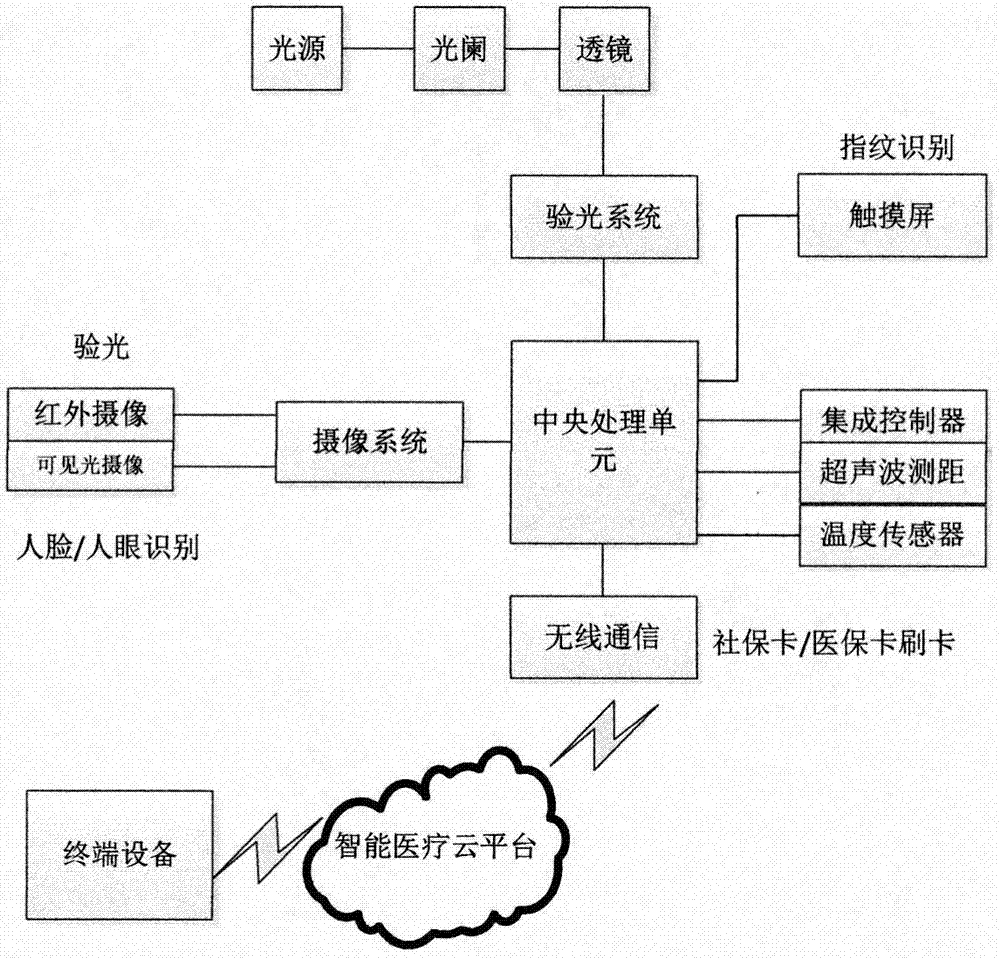

InactiveCN107184178AReduce recordsReduce error rateDigital data authenticationRefractometersCommunications systemControl system

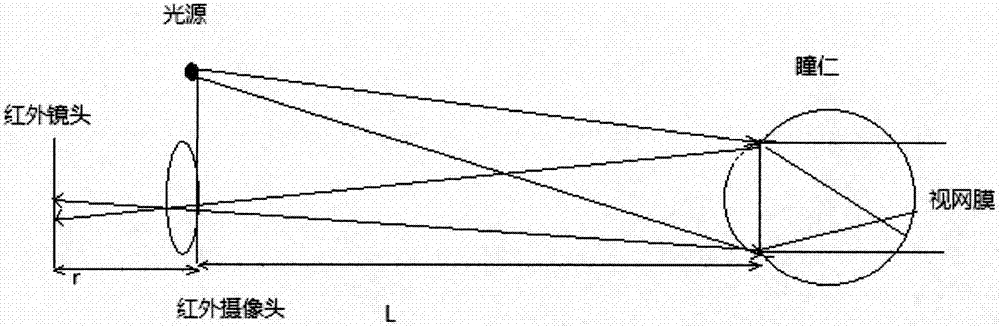

The invention belongs to the technical field of medical optometry equipment and especially relates to an intelligent portable hand-held vision screening instrument and an optometry method. The instrument comprises an optometry system, a camera shooting system, an integral control system and a wireless communication system which are connected to a central processing unit, wherein the optometry system is composed of a light source, a diaphragm and a lens and is used for emission of the light source, diaphragm isolation and lens transmission; functions of distance and temperature measurement are achieved through combination of an ultrasonic ranging and a temperature sensor; the optometry system can shoot eye images by an infrared lens and a visible light lens; the integral control system executes different modes including a preview mode, a camera shooting mode and a checking mode; the wireless communication system carries out card reading functions of a social insurance card and a medical service card as well as wireless data transmission; and the central processing unit carries out collection and processing of data, image recognition, gray analysis and diopter computation. The intelligent portable hand-held vision screening instrument is connected to an intelligent medical cloud platform by a wireless communication system.

Owner:廖亮举

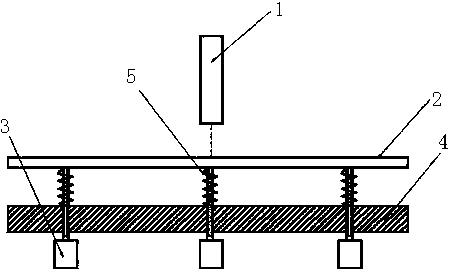

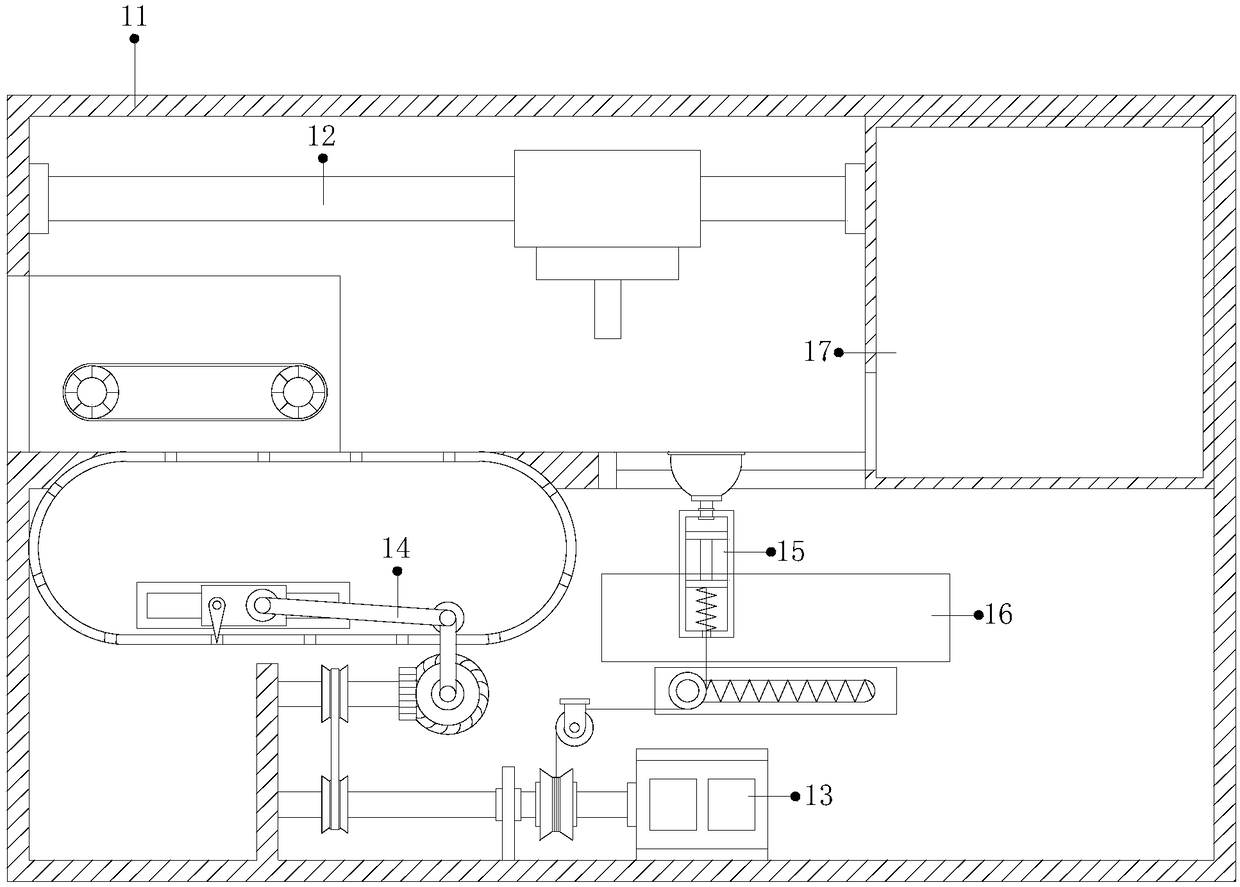

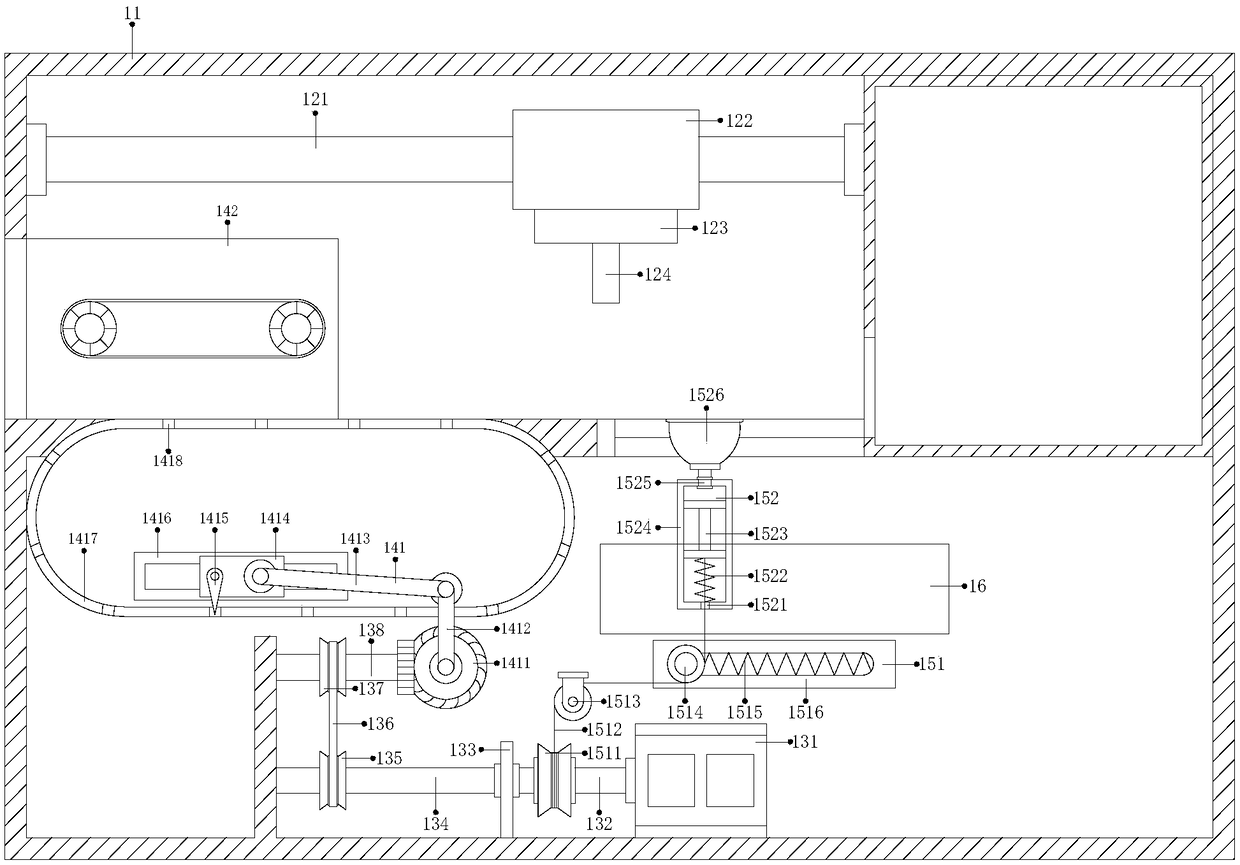

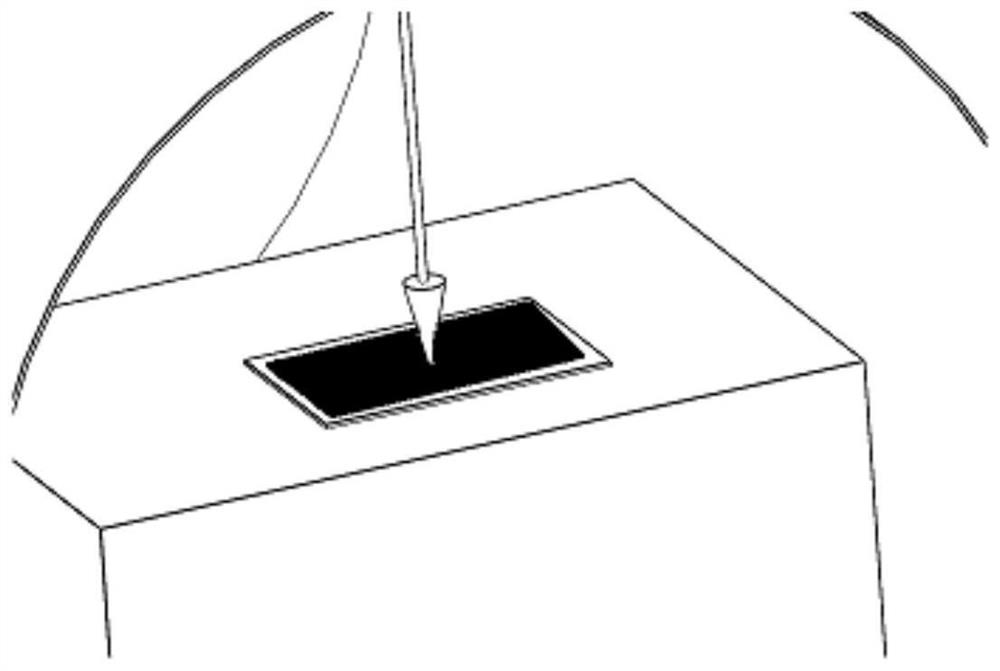

Large 3D printer based on FDM principles

The invention discloses a large 3D printer based on FDM principles. The 3D printer comprises an automatic leveling system, a heat dissipation control system, a material suspension control system and a process display system. The automatic leveling system comprises a range finder, a work panel, a pedestal, motors and springs, wherein the range finder is mounted above the work panel, the work panel is connected with the motors, and motor shafts are provided with the springs. The heat dissipation control system adopts a large area of fans. The material suspension control system comprises a material support, a material supporting rod, a material coil and wire rod plastics. The process display system comprises an LCD display screen and a circuit of a corresponding LCD. The large 3D printer based on the FDM principles in the invention can print large plastic structural members, enables the success rate of printing to be increased and improves reliability of FDM-series 3D printing equipment.

Owner:西安非凡士机器人科技有限公司

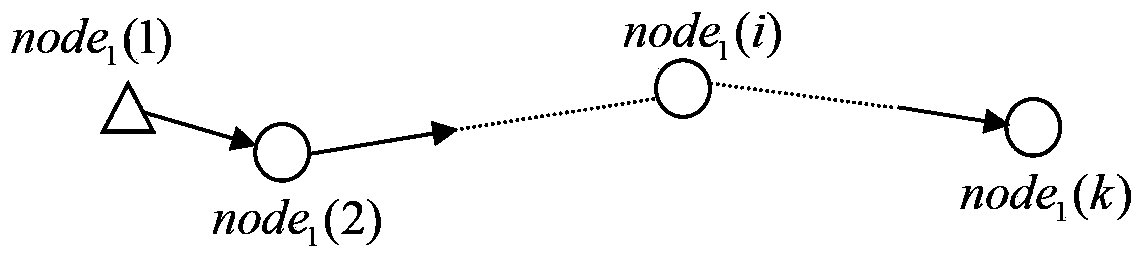

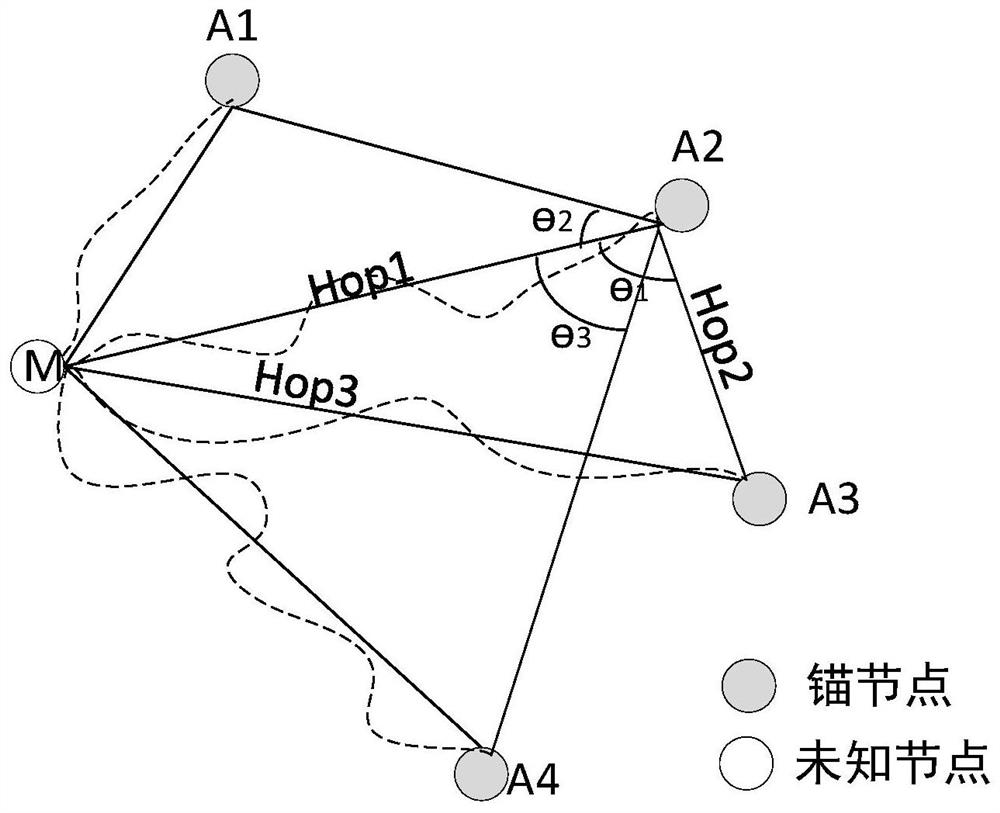

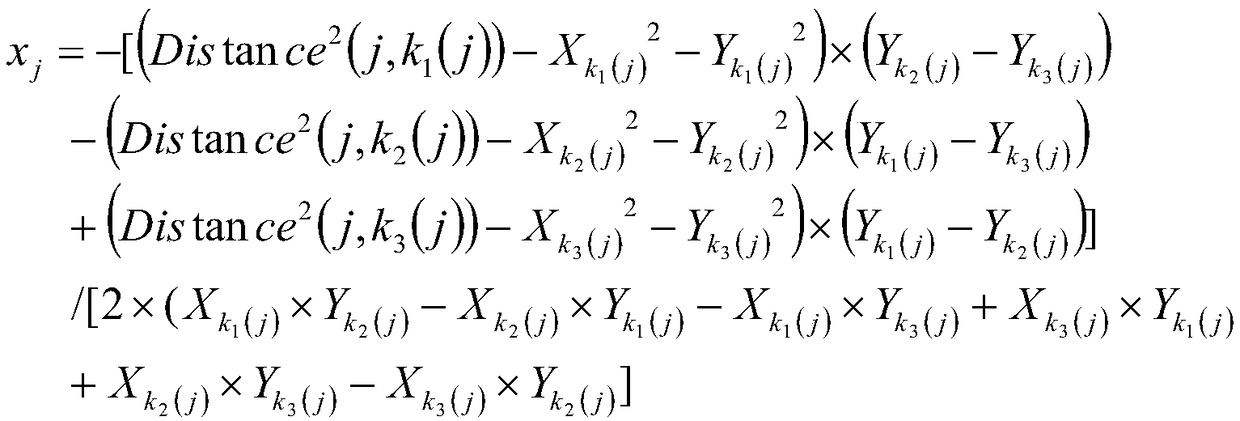

DV-Hop positioning method based on distance weighting and genetic optimization

InactiveCN106993273AEasy accessCan't reflect the distanceNetwork topologiesPosition fixationAlgorithmColatitude

The invention provides a DV-Hop positioning method based on distance weighting and genetic optimization. The method mainly comprises a step of establishing a relation between signal strength and a distance to carry out position calculation through a least squares algorithm and a new optimization method. The method specifically comprises the following steps of firstly, restraining a minimum hop count through an RSSI mean value between anchor nodes; secondly, utilizing the minimum hop between the anchor nodes to weight an average hop distance; and lastly, utilizing an improved genetic algorithm to optimize a position estimation result of the least squares algorithm to improve the positional accuracy.

Owner:JIANGNAN UNIV

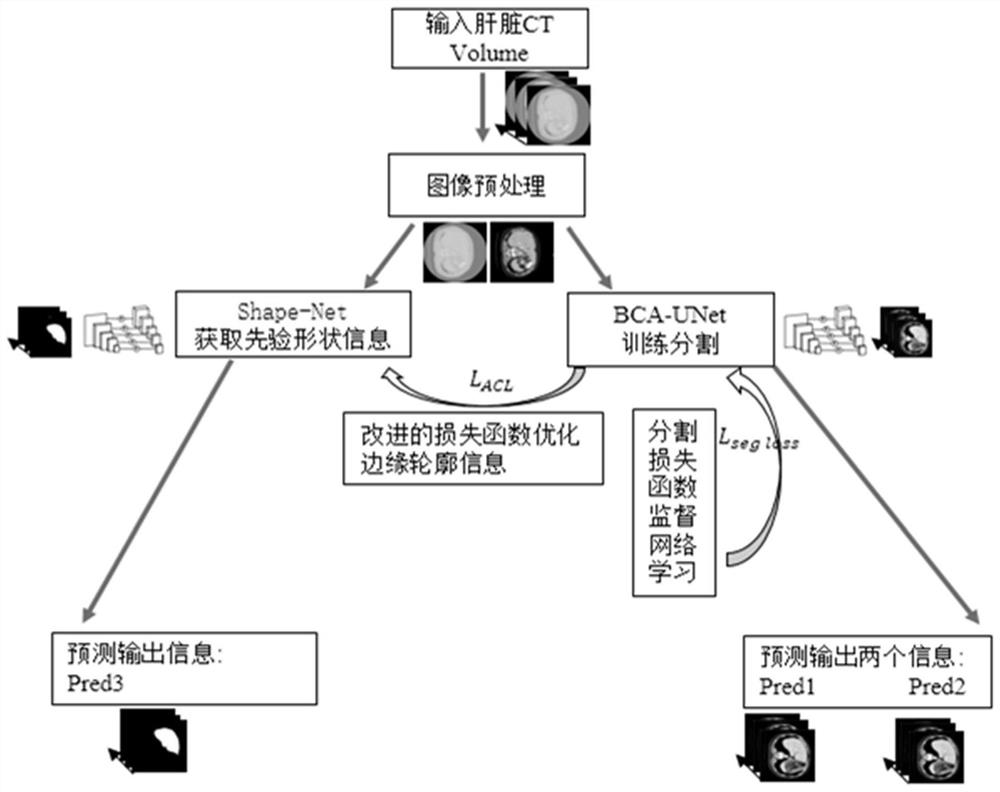

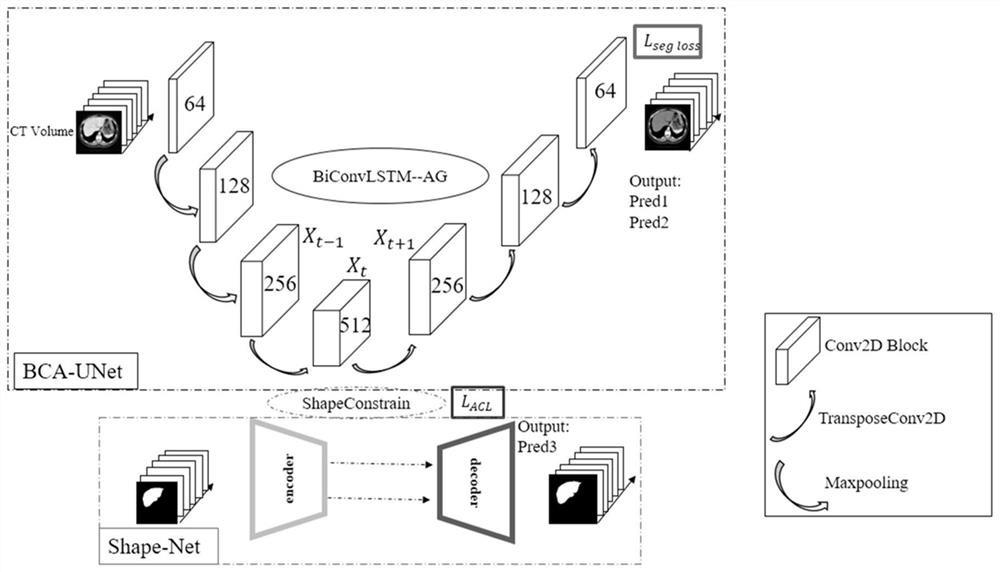

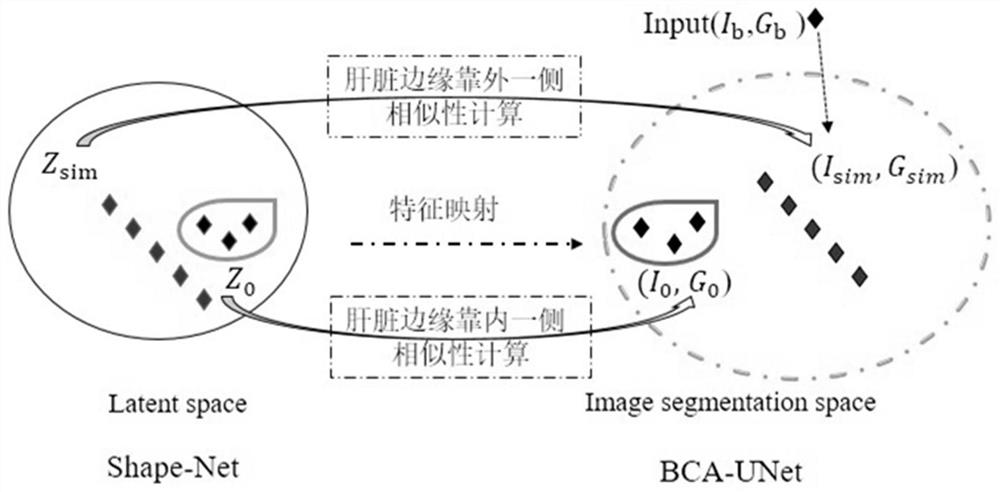

priori shape constraint-based BCA-UNet liver segmentation method

ActiveCN112561860AAvoid lossMake up for the defect of constraint lossImage enhancementImage analysisLiver ctRadiology

The invention relates to the technical field of computer vision, in particular to a priori shape constraint-based BCA-UNet liver segmentation method, which comprises the following steps of: inputtinga liver CT image, preprocessing the liver CT image to obtain a preprocessed liver CT image, inputting the preprocessed liver CT image into a trained liver segmentation model, and obtaining a BCAUNet liver segmentation model; obtaining liver segmentation results. According to the method, the optimized active contour loss function is adopted to calculate the loss of the high-dimensional features, the features between the two networks are fused to serve as the attention signal of the next layer, the attention signal is used for constraining the segmentation network (BCAUNet, error back propagation is optimized layer by layer, and the loss of edge contours is avoided. Besides, the liver segmentation model is sensitive to the edge contour of the image so that the segmentation precision can be enhanced and the surface distance error can be reduced.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

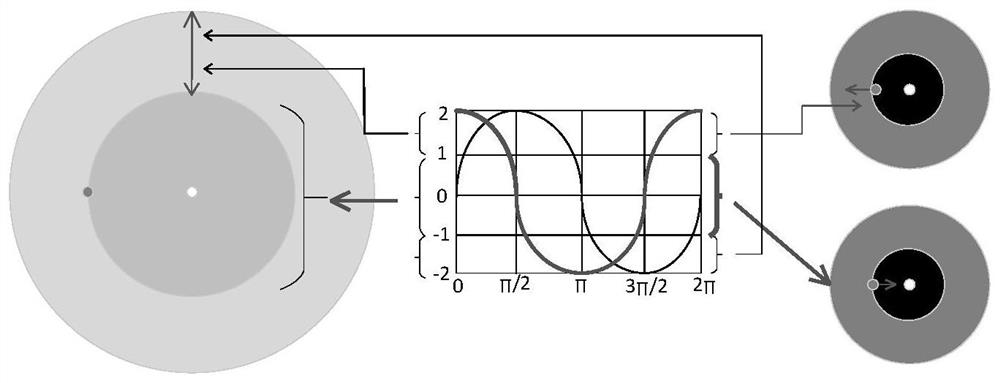

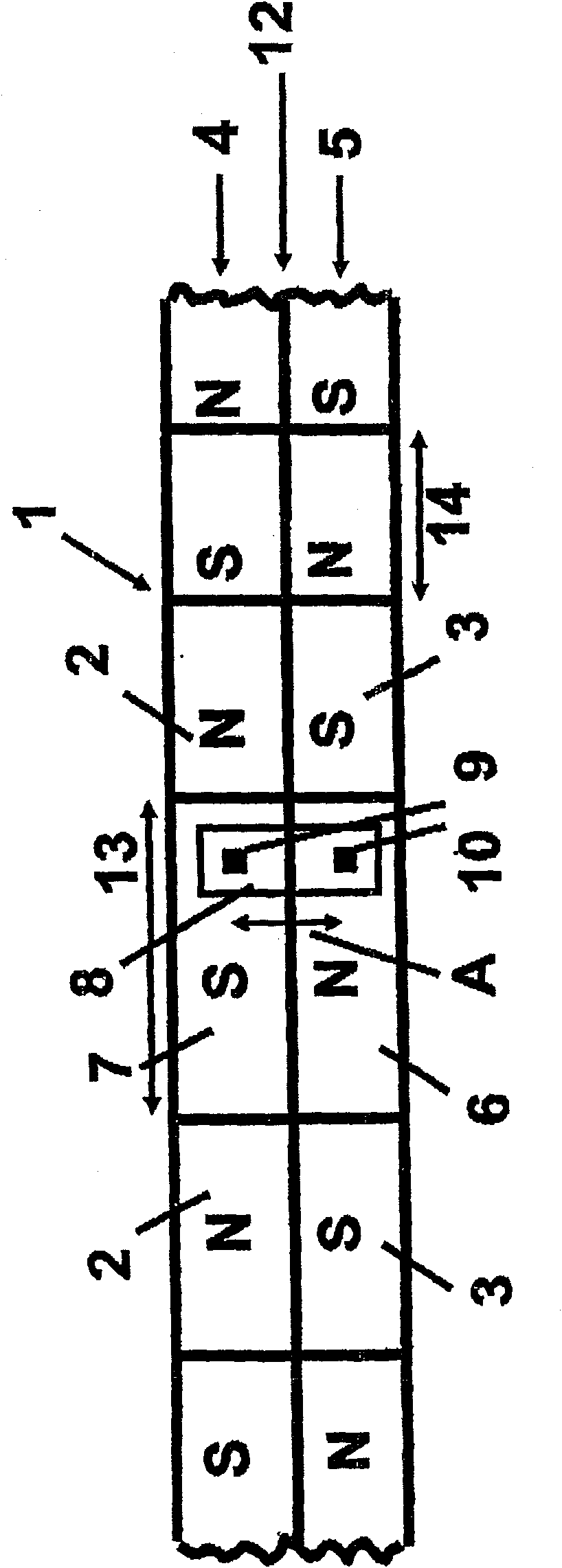

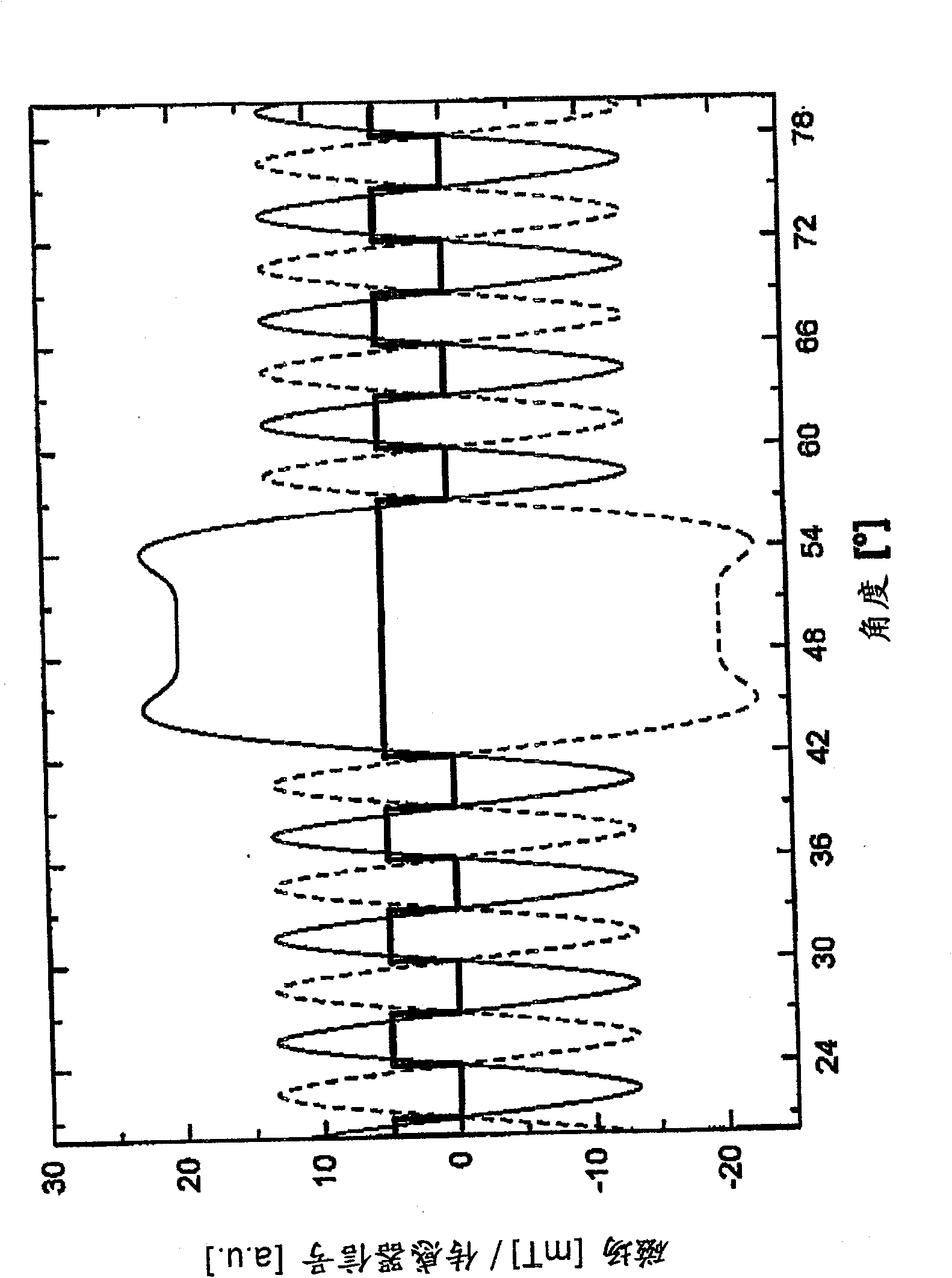

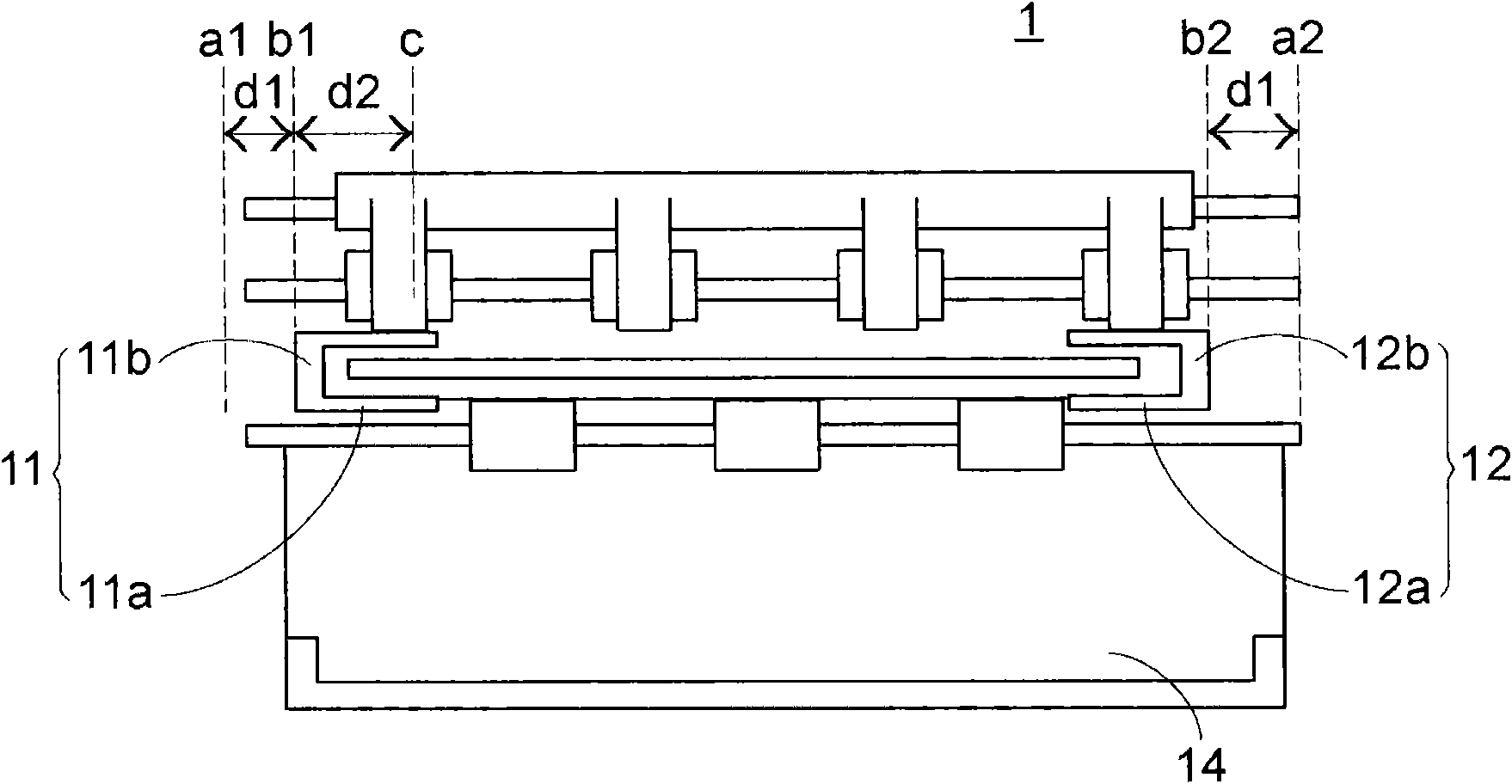

Device for contactless determination of rotation and/or position of an object having an encoder

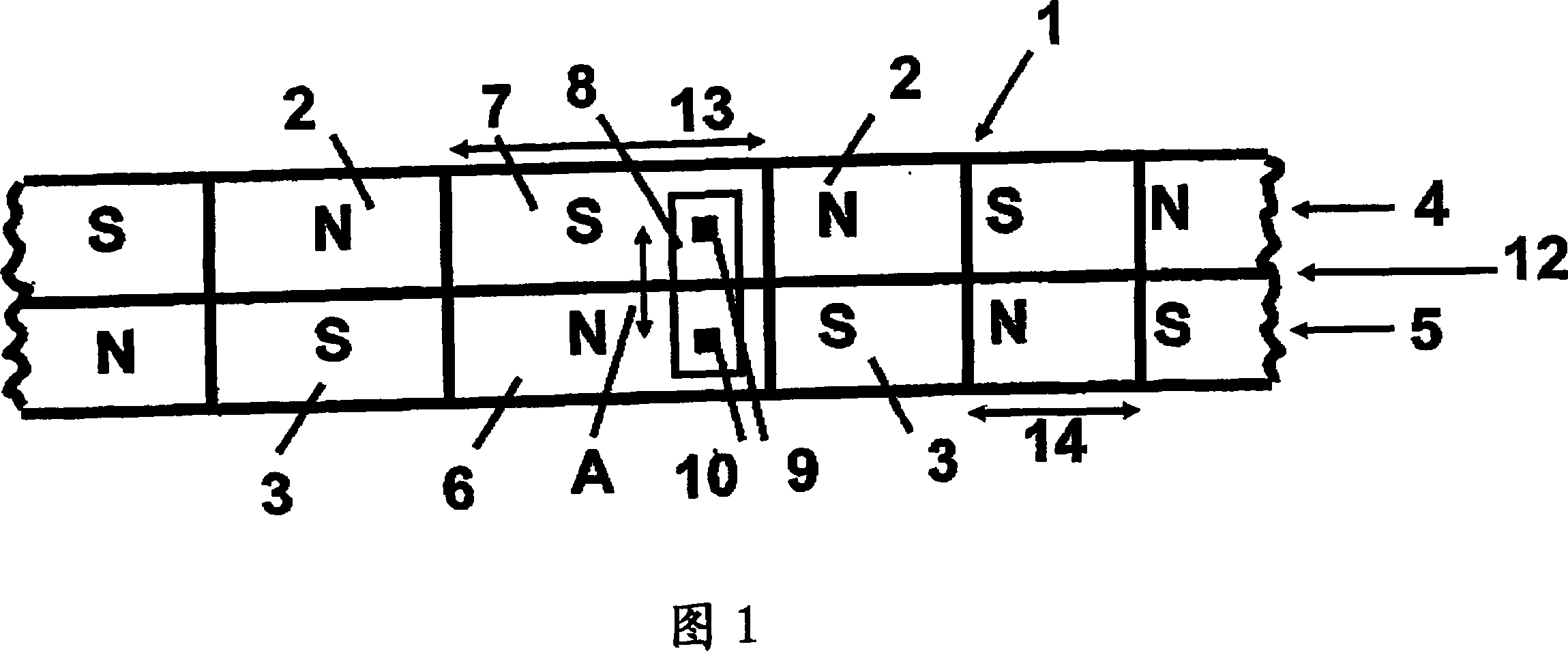

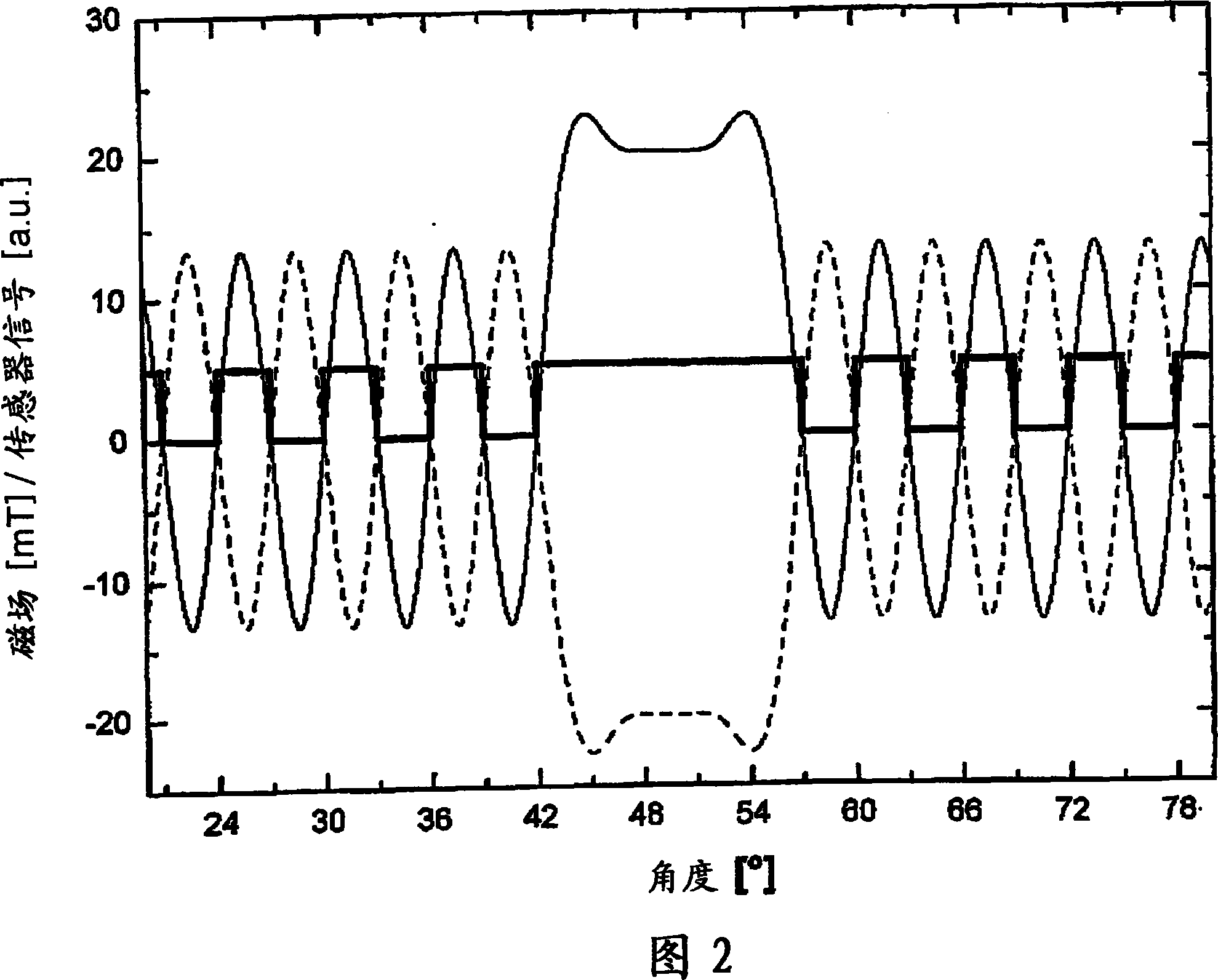

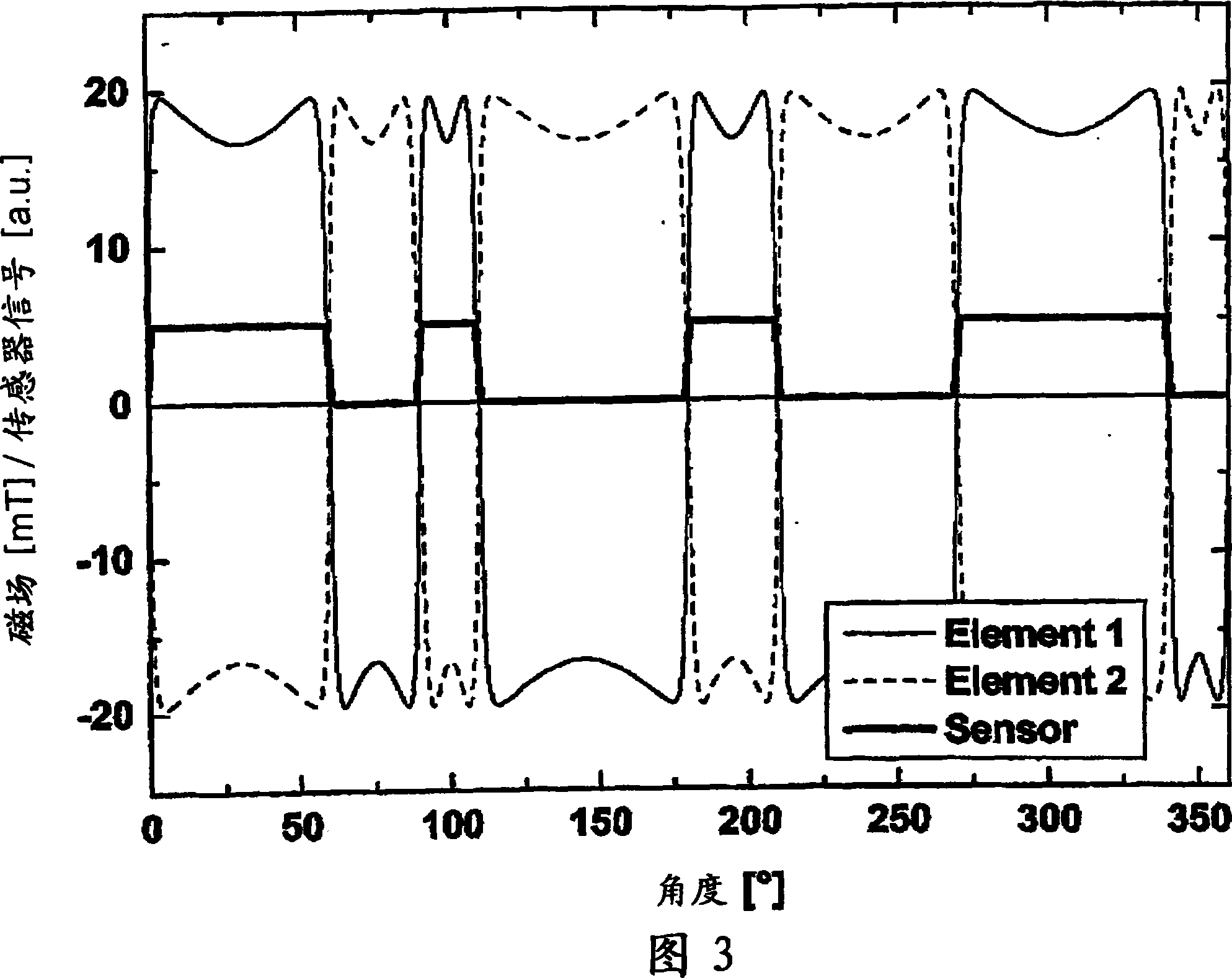

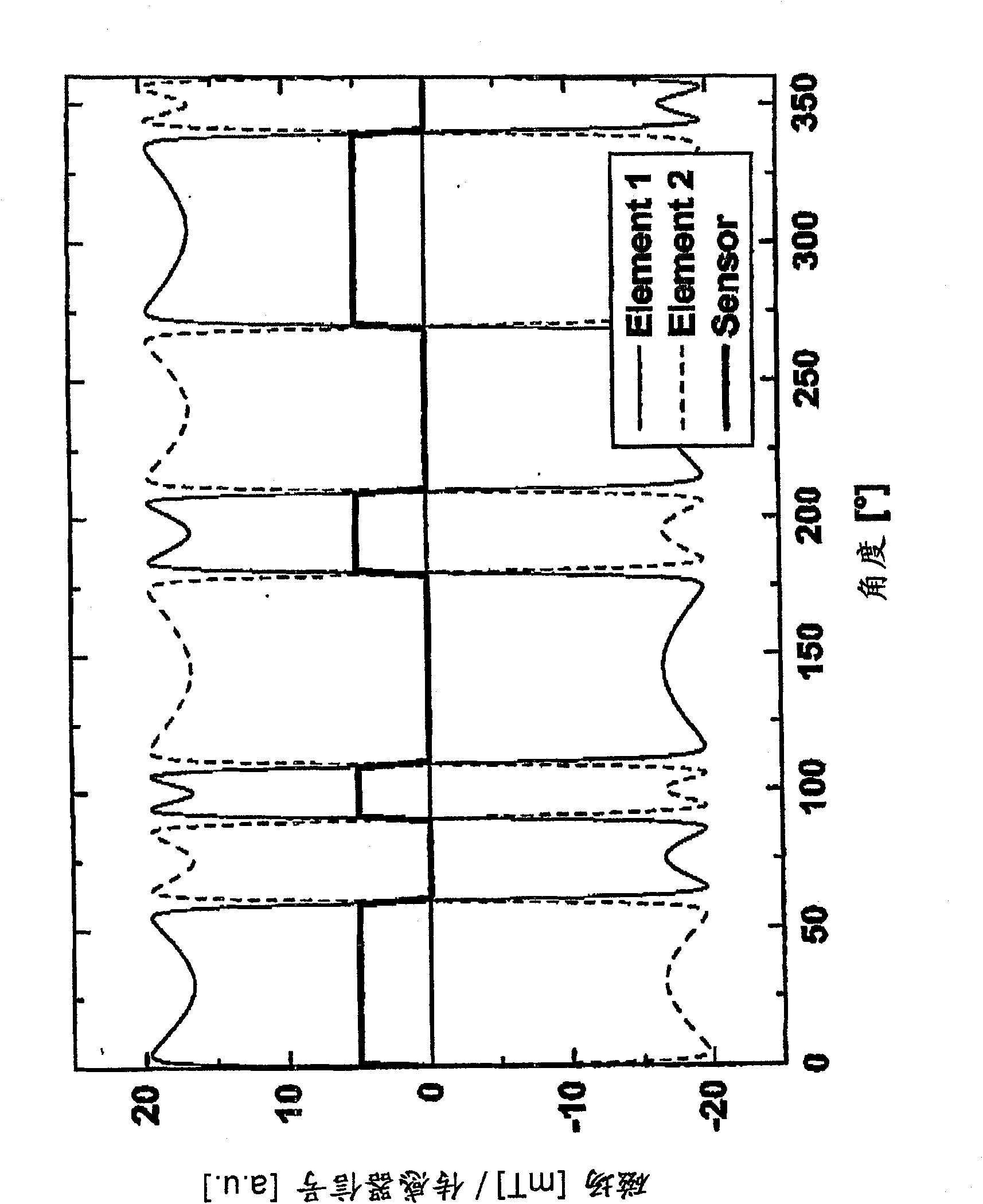

ActiveCN101097225ASmall indexing errorPosition measurement accuracy has no effectElectrical controlLinear/angular speed measurementMagnetizationTransducer

The present invention relates to a device which is used for measuring the rotary speed and / or position of the generator component which can rotate around the axial cord without contact, the device is provided with a circular permanent-magnet encoder which includes a N pole and a S pole which are alternately arranged in the circumference direction and at least two different pole width, the encoder is provided with a scanning head with difference hall transducer, wherein, the encoder is designed to be a double rail encoder (1) with inverse magnetizations; and each sensor element (9, 10) of the difference hall transducer (8) is arranged to one of the encoder rails (4, 5).

Owner:CARL FREUDENBERG KG

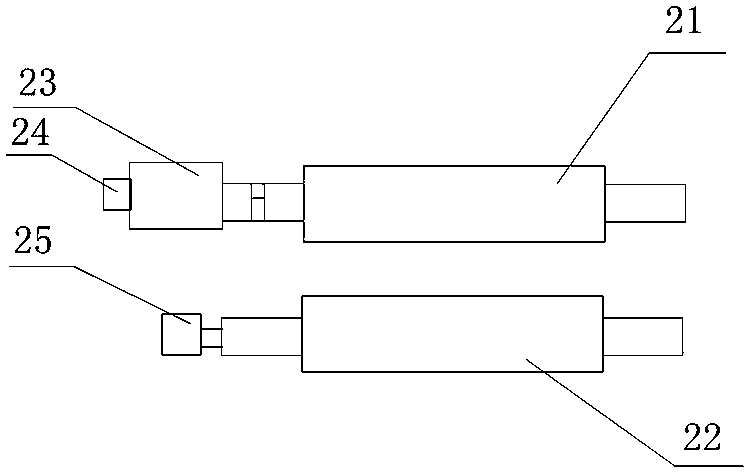

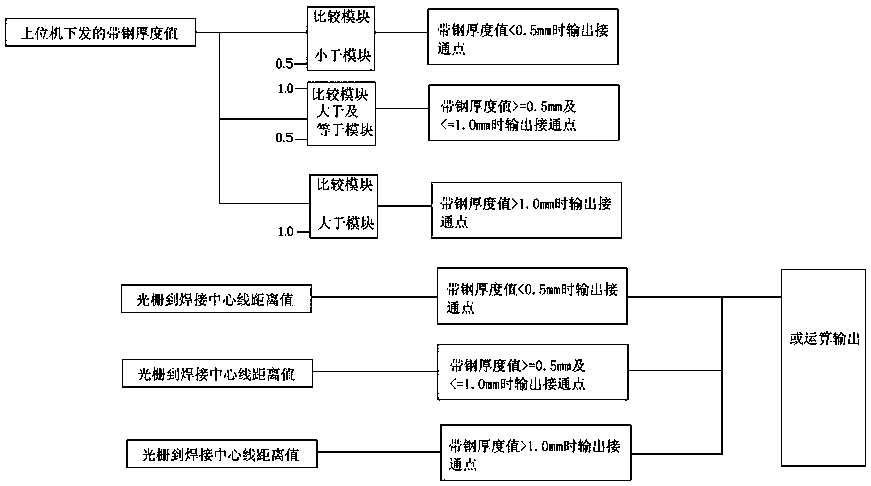

Location control method for strip head of thin strip steel

ActiveCN110315245AInertial Force ReleaseImprove Feedback AccuracyWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlGrating

The invention discloses a location control method for a strip head of thin strip steel, and belongs to the technical field of automatic control. The method comprises the following steps: 1) a weldingmachine, a pinch roll device and an optical grating detector are installed, and the pinch roll device comprises an upper press roll, a lower roll, a motor, a motor tail coder, a power cylinder and a lower roll coder; 2) three thickness specification interval sections of the strip steel are divided and input into a main-line PLC, the upper press roll is controlled to fall off by the main-line PLC until the strip steel is clamped between the upper press roll and the lower roll by virtue of a set clamping force separately; and 3) the running speed of the motor is calculated through the motor tailcoder, the strip steel is conveyed at a speed V1, when the optical grating detector detects the strip steel, the strip steel is conveyed at a speed V2, and meanwhile, the lower roll coder installed on the lower roll starts to calculate the length L of the strip steel passing through the optical grating detector, and location for the strip head is completed. According to the method, the distance error of the strip head at a welding stopping position is reduced, so that the compensation accuracy is increased; and the method is completely feasible, and capable of achieving a good effect.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

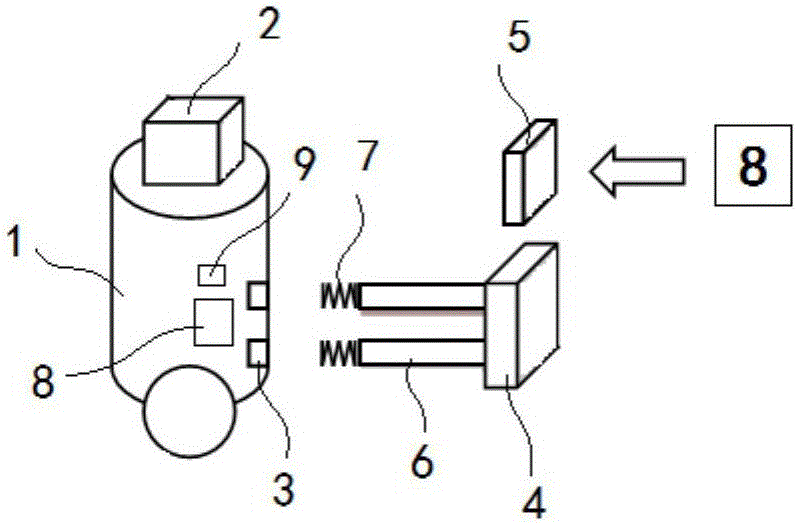

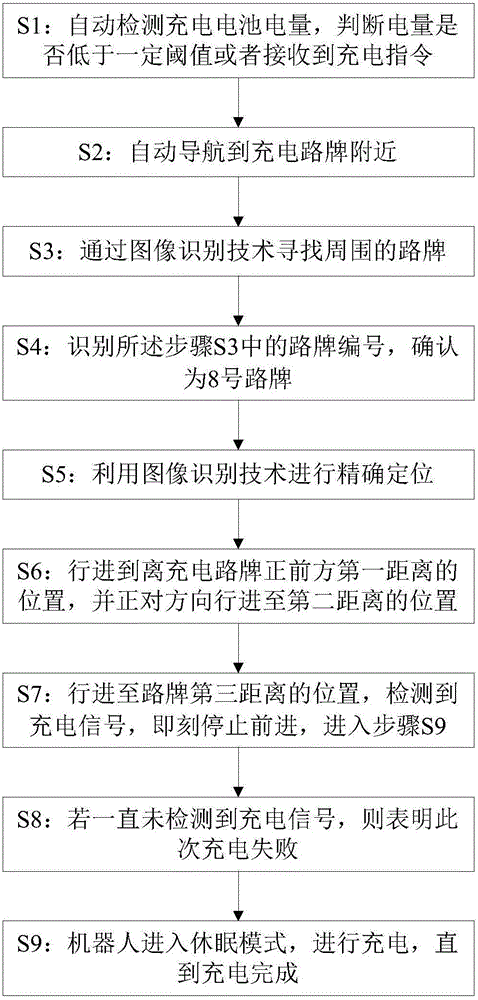

Automatic charging system based on image recognition positioning technology, and charging method thereof

InactiveCN106200640AIncrease the lateral areaImprove charging efficiencyCharacter and pattern recognitionPosition/course control in two dimensionsEngineeringContact type

The invention discloses an automatic charging system based on the image recognition positioning technology, and a charging method thereof. The system achieves the precise positioning through employing the image recognition and employing a charging signboard for recognizing the fixing position of a charging pile, so as to move a specific position for contact-type charging. The system employs the contact-type charging, and is high in charging efficiency, wherein the charging efficiency can reach 95% or more. The system just can complete the automatic charging with the only need of a printing guideboard and one contact-type charging power supply matched with a robot, so the system is simple in structure and is low in building cost. The lateral area of the contact surface of a contact piece of a robot end is set to be greater than the lateral area of the contact surface of a contact pipe of a charging pile end, i.e., increasing the lateral area of the contact piece of the robot end, thereby reducing the lateral error. The contact piece of the charging pipe is provided with a conductive spring, thereby reducing the distance error. The system provides a reasonable solution to the existing errors, and is simple and reliable.

Owner:广东大仓机器人科技有限公司

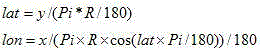

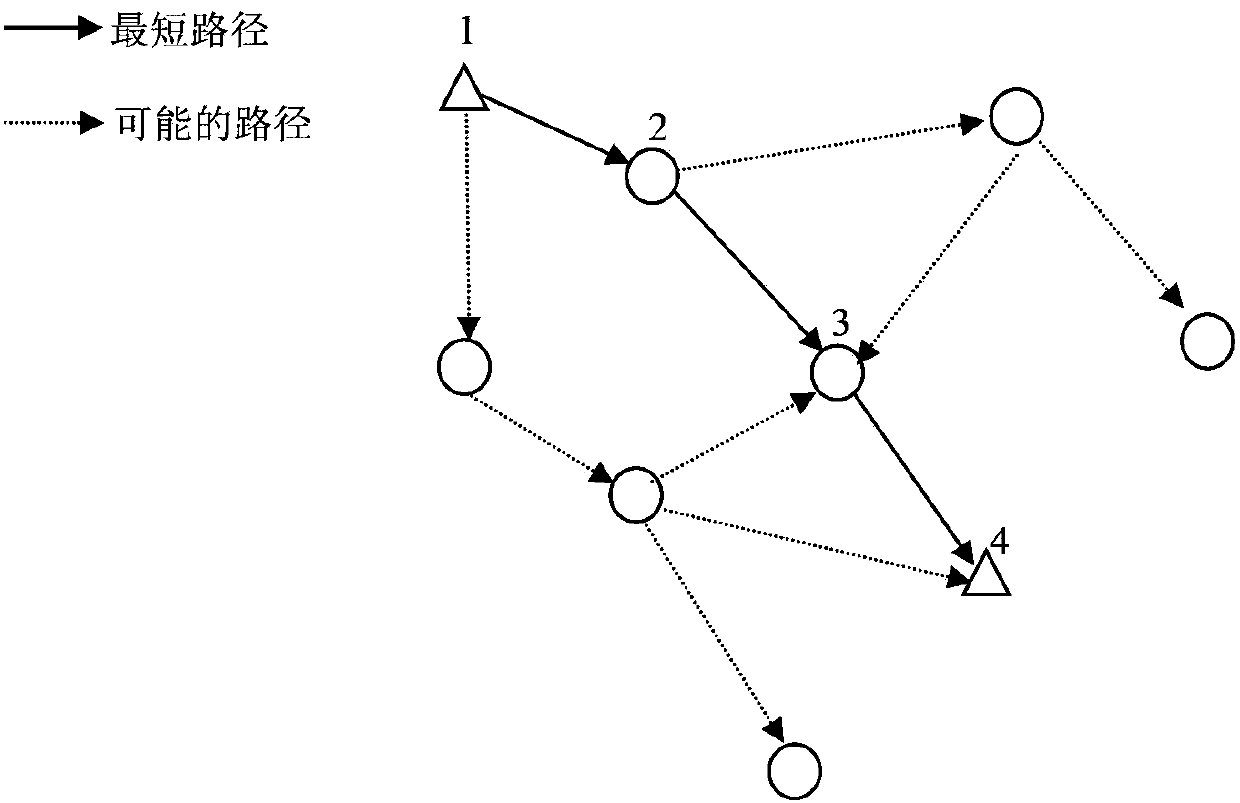

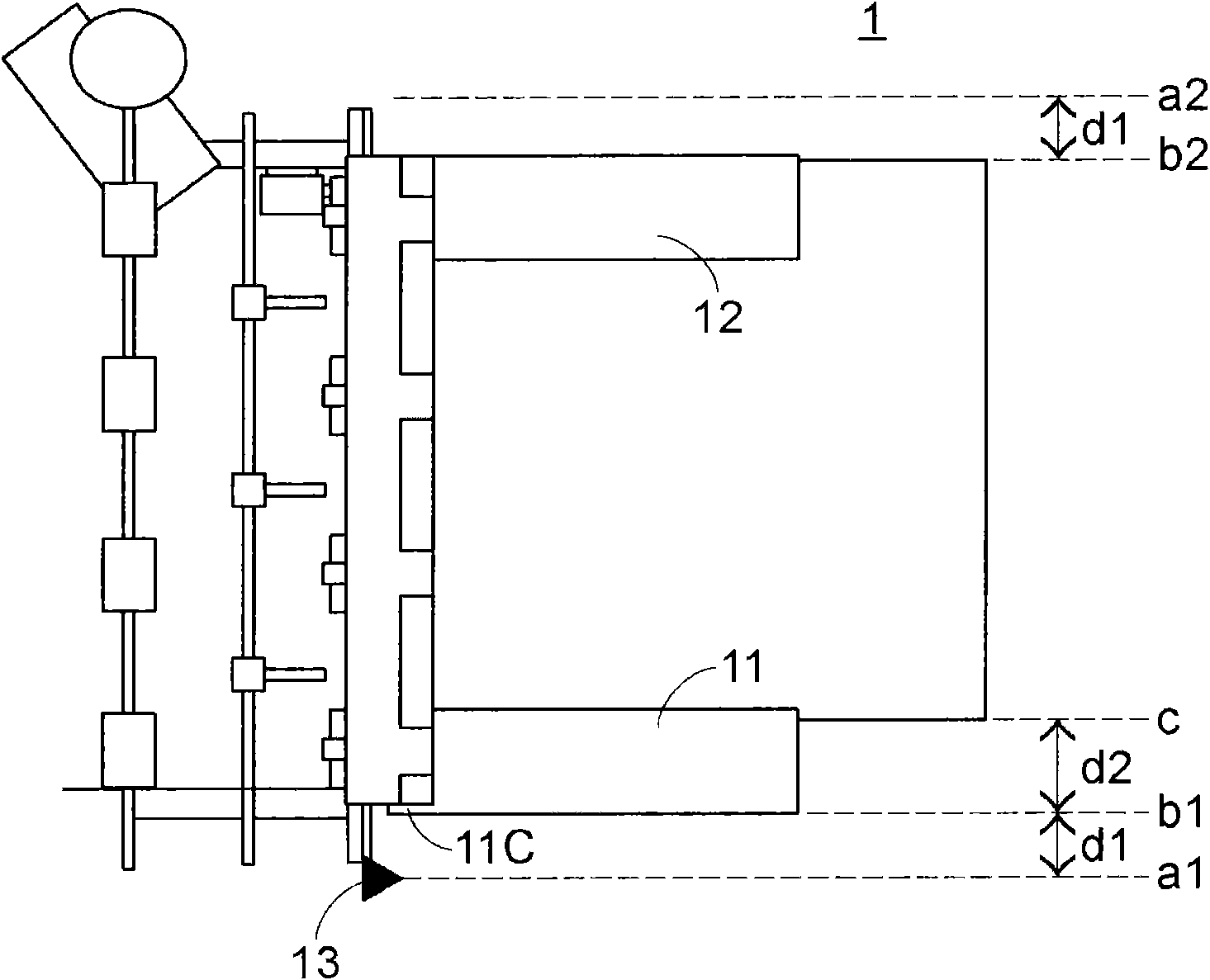

Base station location method based on AT instructions in GSM network

InactiveCN104602336AEasy to operateReduce distance errorWireless communicationShortest distanceLongitude

The invention provides a base station location method based on AT instructions in a GSM network. The base station location method is not limited by hardware and relatively small in location error, and comprises the steps of obtaining cell information and inquiring the longitude and latitude position coordinates of n base stations by use of the AT instructions, obtaining the time advance TA of each base station by use of the AT instructions, calculating the distance r of each base station according to a formula as shown in the description, in unit Km, taking the base station having the shortest distance as the origin of coordinates, and converting the longitude and latitude coordinates of each base station into base station plane coordinates xn and yn according to the following formula, namely setting the equipment plane coordinates as x and y, constructing n equations according to the formula as shown in the description and solving x and y, and then converting the equipment plane coordinates as x and y into the longitude and latitude coordinates.

Owner:DALIAN ROILAND SCI & TECH CO LTD

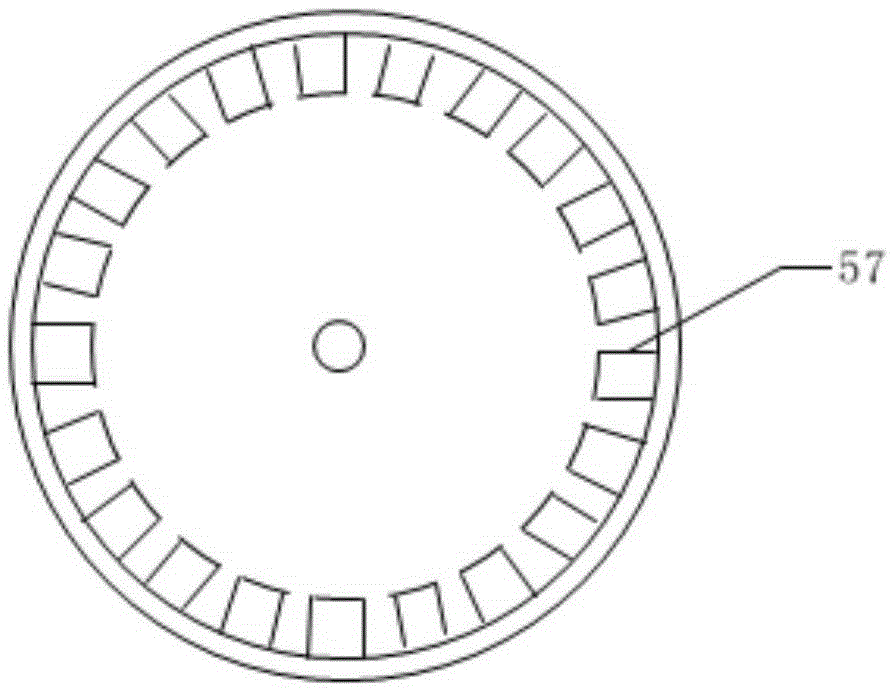

Capsule endoscopy having accurate positioning function

ActiveCN105395160AReduce roll overStable recordGastroscopesOesophagoscopesCapsule endoscopyBiomedical engineering

The invention discloses a capsule endoscopy having an accurate positioning function. The capsule endoscopy comprises a capsule shell, a pH sensor, a photographic device, a control device and a positioning device; the positioning device comprises micro legs, rubber wheels, pressure sensors, springs and a motor, wherein the micro legs are arranged on the outer sides of the capsule shell; one end of each of the micro legs is connected to the corresponding rubber wheel; revolution measuring devices are arranged on the rubber wheels; the springs and the motors are connected to the other ends of the micro legs; under the control of the springs, the micro legs are expanded; the micro legs, driven by the motor, contract; and the pressure sensors are additionally arranged on the springs. According to the capsule endoscopy having the accurate positioning function provided by the invention, through the rotation of the rubber wheels and by converting the revolution into a distance, accurate positioning inside the digestive tract of a human body is achieved; and meanwhile, by virtue of the micro legs and the rubber wheels connected to the micro legs, any instable and non-forward movement is minimized, so that the photographic device in the capsule can record stable images or videos.

Owner:CAS HEFEI INST OF TECH INNOVATION

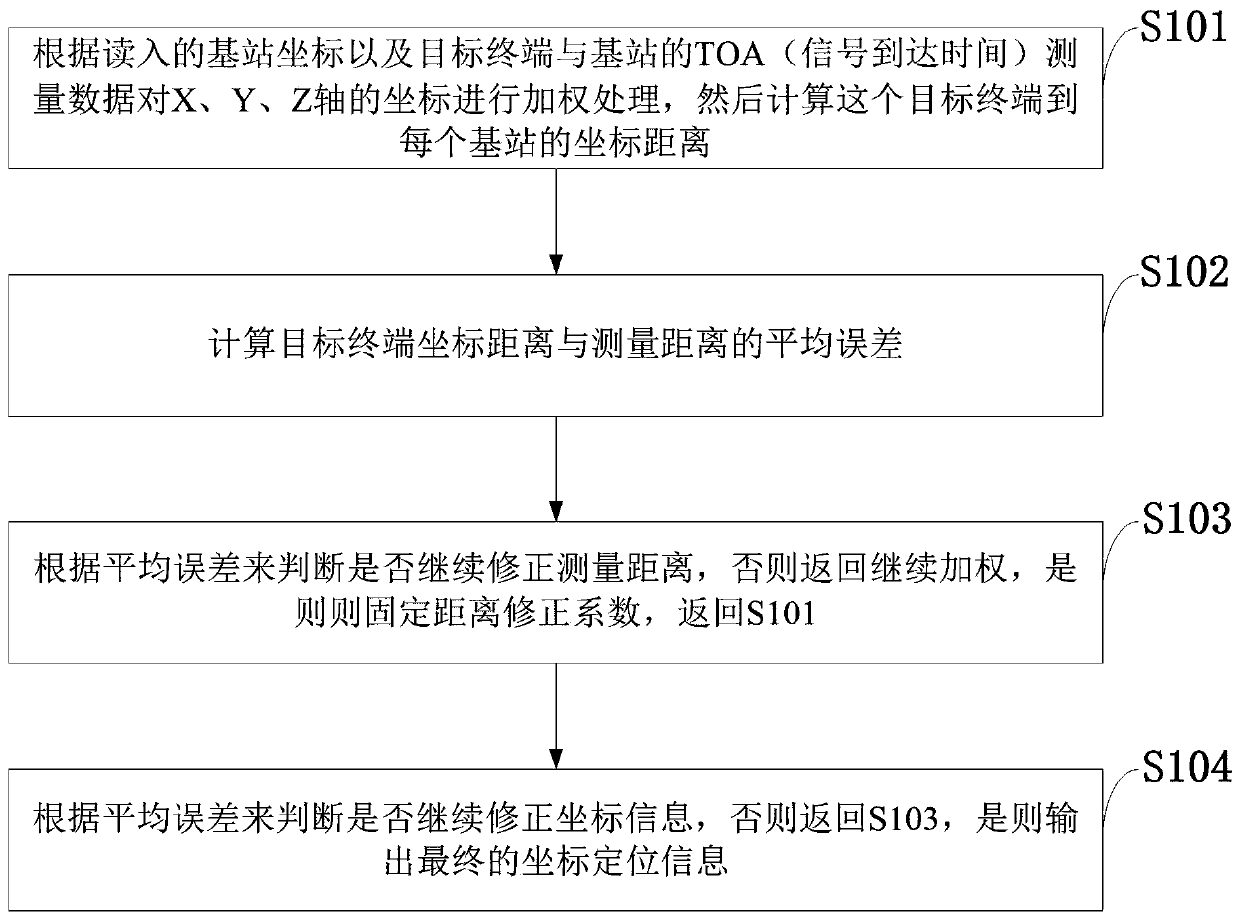

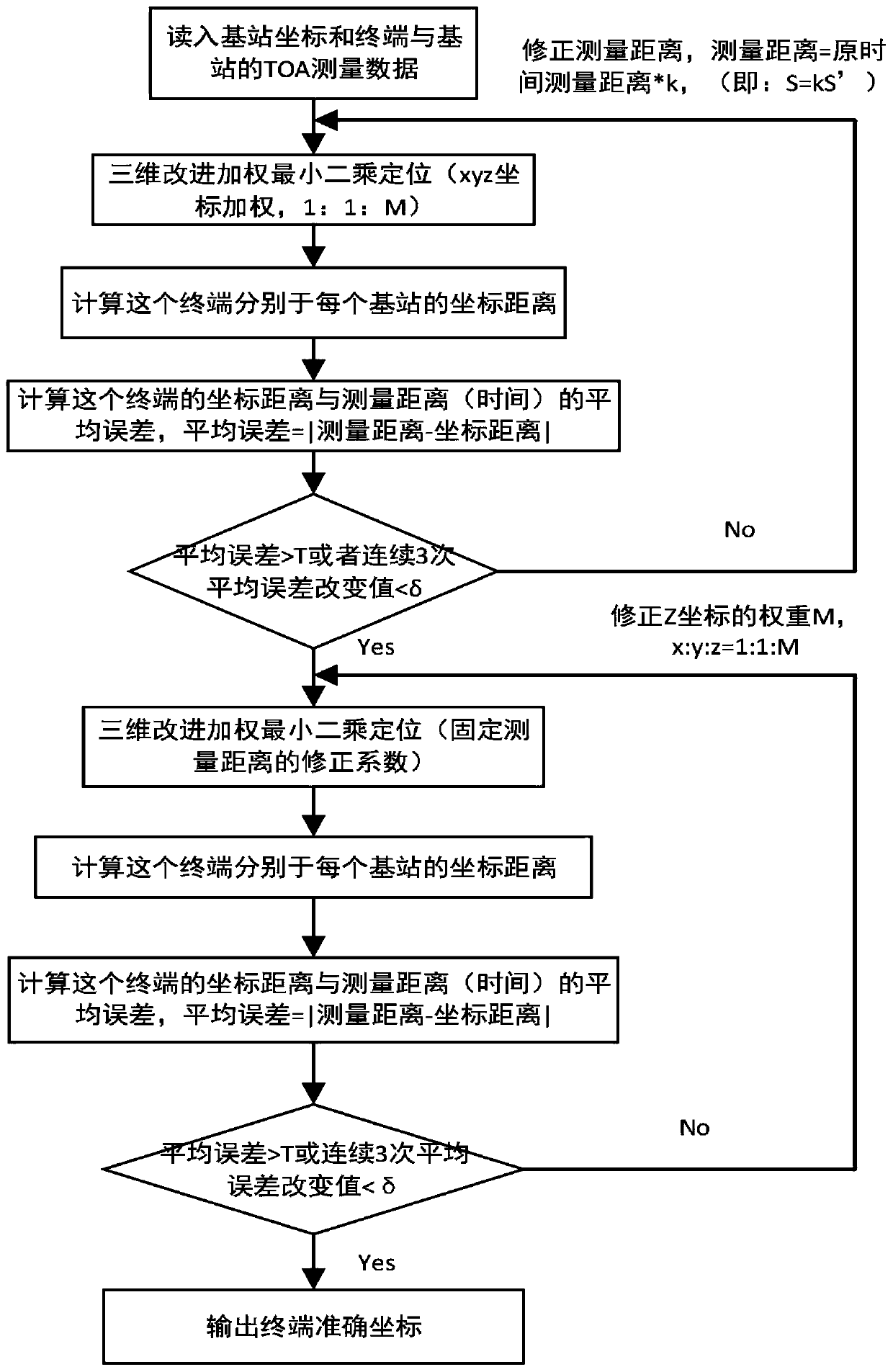

Correction target three-dimensional positioning method based on wireless communication base station and wireless communication system

InactiveCN111491366AHigh similarityReduce mistakesPosition fixationWireless communicationCommunications systemDistance correction

The invention belongs to the technical field of wireless communication. The invention discloses a correction target three-dimensional positioning method based on a wireless communication base stationand a wireless communication system, and the method comprises the steps: carrying out the weighting of the coordinates of an X axis, a Y axis and a Z axis according to the read coordinates of the basestation and the signal arrival time TOA and measurement data of a target terminal and the base station, and then calculating the coordinate distance from the target terminal to each base station; calculating an average error between the coordinate distance of the target terminal and the measurement distance; judging whether to continuously correct the measurement distance or not according to theaverage error, otherwise, returning to continuously weigh, and if so, fixing a distance correction coefficient; and judging whether to continuously correct the coordinate information according to theaverage error. According to the method, the average positioning error of the X axis and the Y axis is smaller than 0.3 m, the average positioning error of the Z axis coordinate is smaller than 0.5 m,the algorithm complexity is low, the convergence speed is high, good robustness is achieved for noise, and high practical application value is achieved.

Owner:XIDIAN UNIV

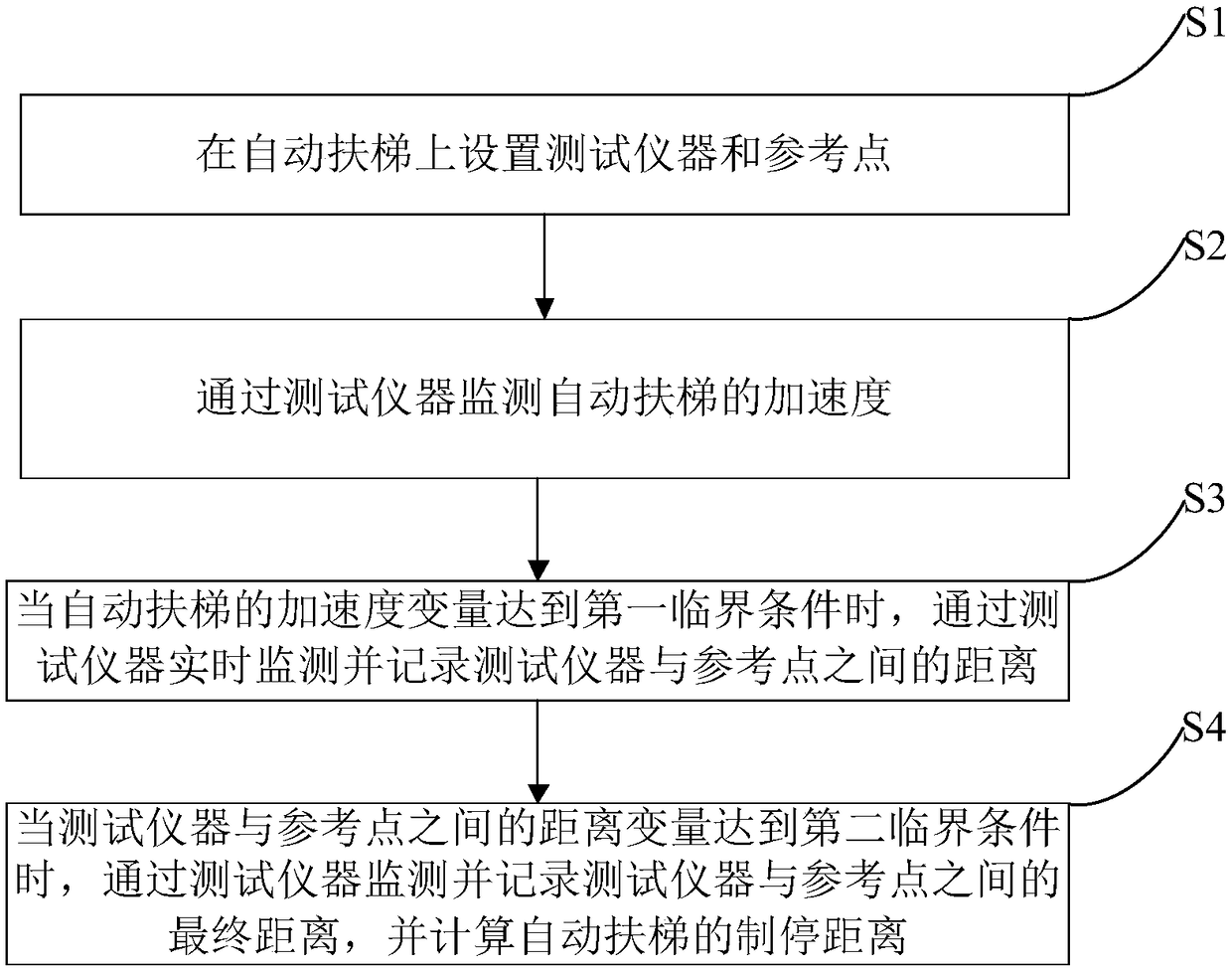

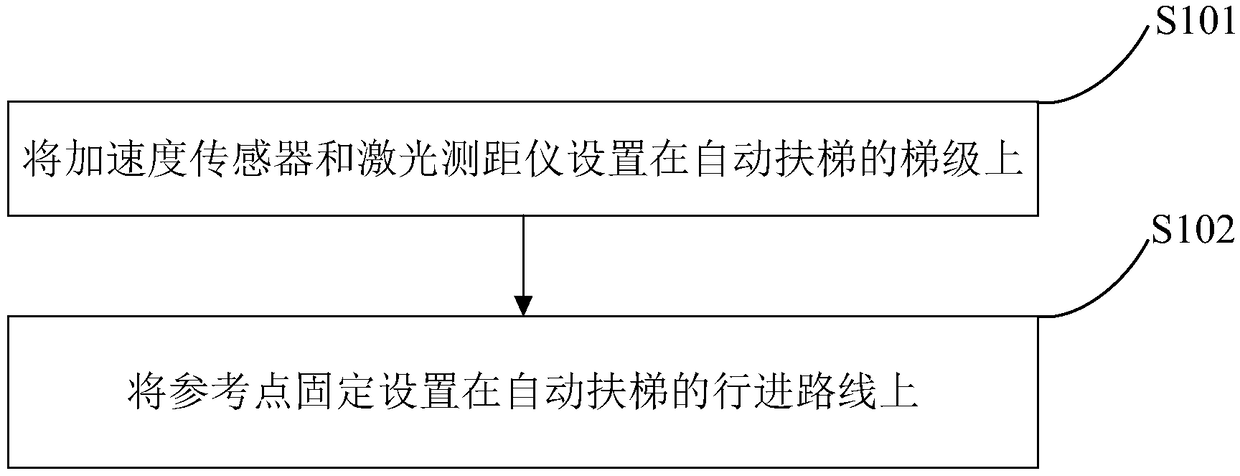

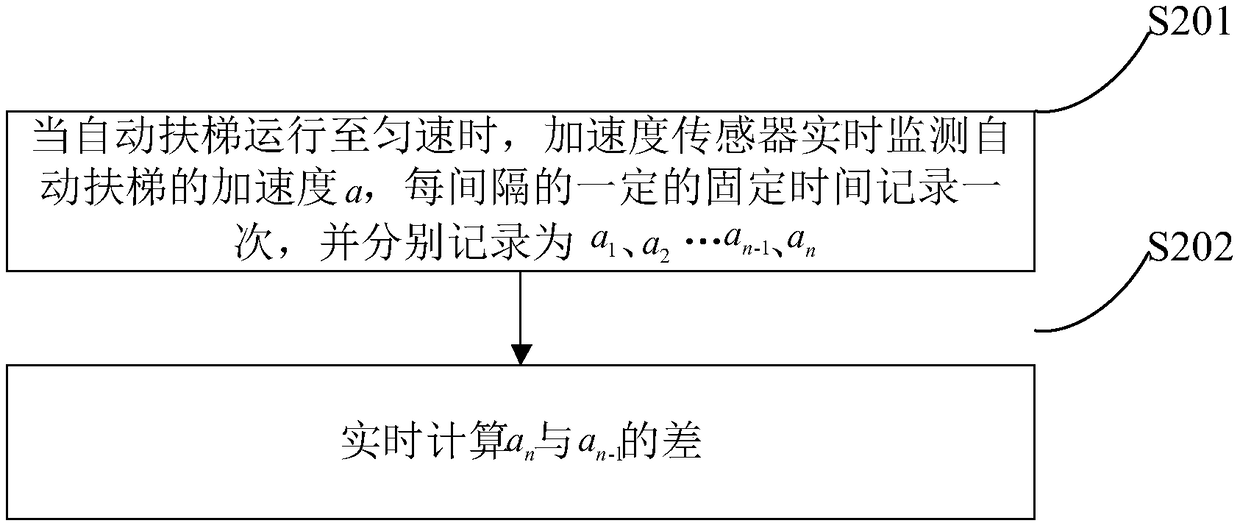

Method for precisely testing brake distance of escalator

ActiveCN108726339AReduce distance errorPrecise test stop distanceEscalatorsEngineeringDistance error

The invention provides a method for precisely testing the brake distance of an escalator. The method includes the steps of S1, setting a testing instrument and a reference point; S2, using the testinginstrument to monitor the acceleration of the escalator; S3, when the acceleration variable of the escalator reaches a first critical condition, using the testing instrument to monitor and record thedistance between the testing instrument and the reference point; S4, when the distance variable between the testing instrument and the reference point reaches a second critical condition, using the testing instrument to monitor and record the final distance between the testing instrument and the reference point, and calculating the brake distance of the escalator. The method has the advantages that the brake distance of the escalator can be precisely tested, the distance errors of manual brake distance testing are lowered effectively, and brake starting time and ending time can be precisely captured and calculated.

Owner:GUANGZHOU SPECIAL MECHANICAL & ELECTRICAL EQUIP INSPECTION & RES INST

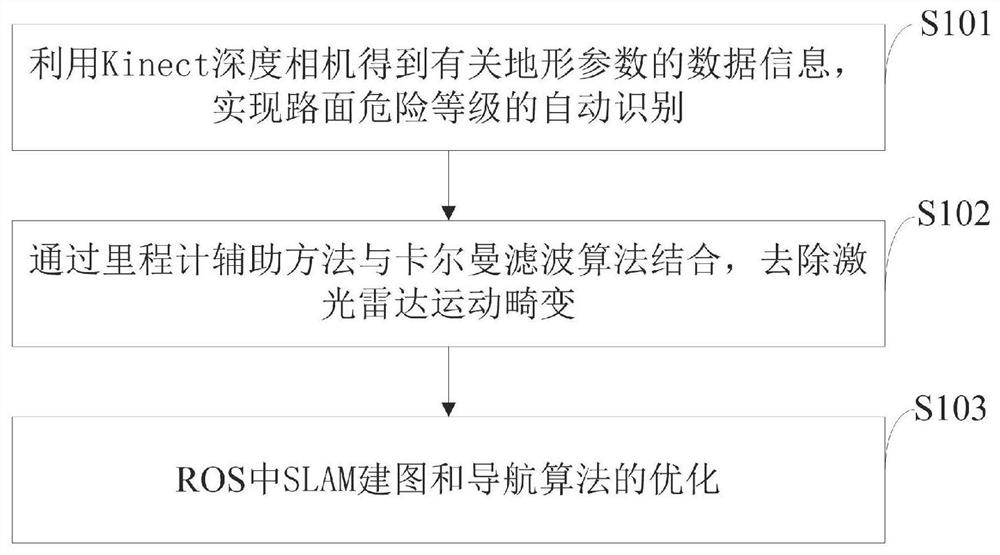

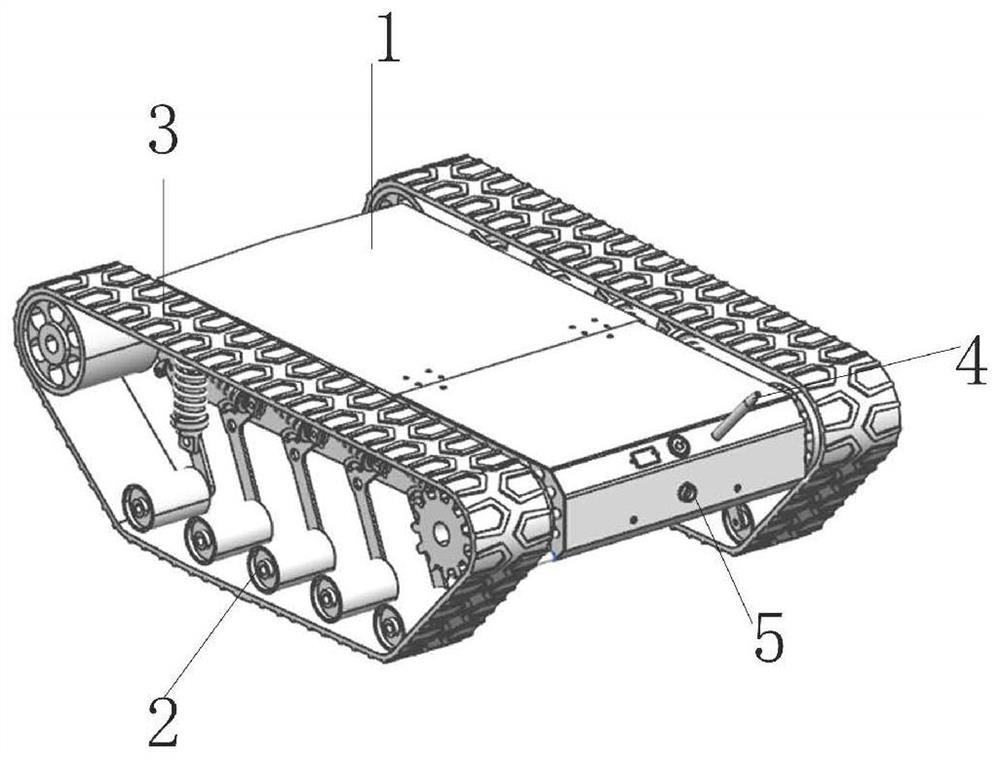

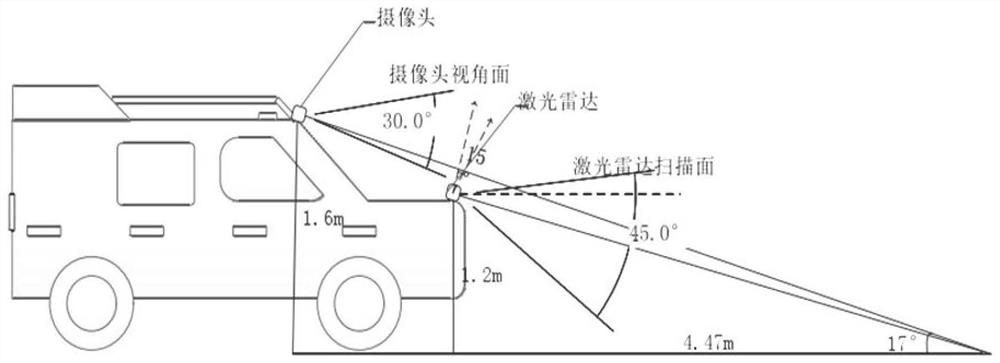

Terrain sensing method and system thereof, storage medium and computer equipment

ActiveCN113465728AReduce the degree of deviationReduce distance errorSubsonic/sonic/ultrasonic wave measurementInternal combustion piston enginesEngineeringRoad surface

The invention belongs to the technical field of terrain perception, and discloses a terrain perception method and a system thereof, a storage medium and computer equipment, a Kinect depth camera is utilized to obtain data information related to terrain parameters, and automatic identification of a road surface danger level is realized; a speedometer auxiliary method is combined with a Kalman filtering algorithm to remove laser radar motion distortion; and SLAM mapping and navigation algorithm optimization in ROS is realized. According to the method, the robot is globally positioned on the X axis and the Y axis, the distance error is smaller than 10 cm, and the angle error is smaller than 0.2 rad; the size error between the grid map and the real environment is less than 1cm; the deviation degree between the real navigation path of the robot and the algorithm estimation path is less than 10cm; the mobile robot can carry out loopback when mapping is carried out in an environment with a similar structure; and the variance of the preprocessed point cloud data collected by the laser radar is less than 0.1.

Owner:CHONGQING VOCATIONAL INST OF ENG

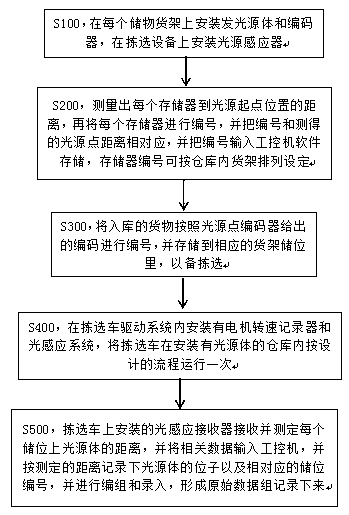

Method for positioning intelligent warehouse

InactiveCN105501785AImprove the level of intelligenceDoes not affect miscastStorage devicesMotor speedLogistics management

The invention relates to the field of storage, in particular to a method for positioning an intelligent warehouse. The method stores goods and finds and selects the goods according to numbers, so that the intelligent storage and selection are realized, and the working efficiency is improved. As each measured storage position corresponds to a light source distance, the positioning is accurate, no errors occur, and the goods are facilitated to be managed by a computer. The walking distance of a selecting car can be calculated according to the speed of a motor and the diameter of a driving wheel through a motor speed reporter and is input to an industrial personal computer, and the industrial personal computer gives out the distance of the goods needing to be stored or selected according to the input number of the goods needing to selected, so that an operator picks and stores the goods under the guidance of the industrial personal computer; one number corresponds to one stored goods; as the diameter variation of the driving wheel is tiny, the error of the distance calculated by the motor speed reporter and the distance measured by a light distance inductor is relatively small and cannot affect the wrong throwing of the storage positions, the accuracy rate is high, and the intelligence level of logistics storehouse is greatly increased.

Owner:ANHUI KAESAR IND EQUIP FACTORY

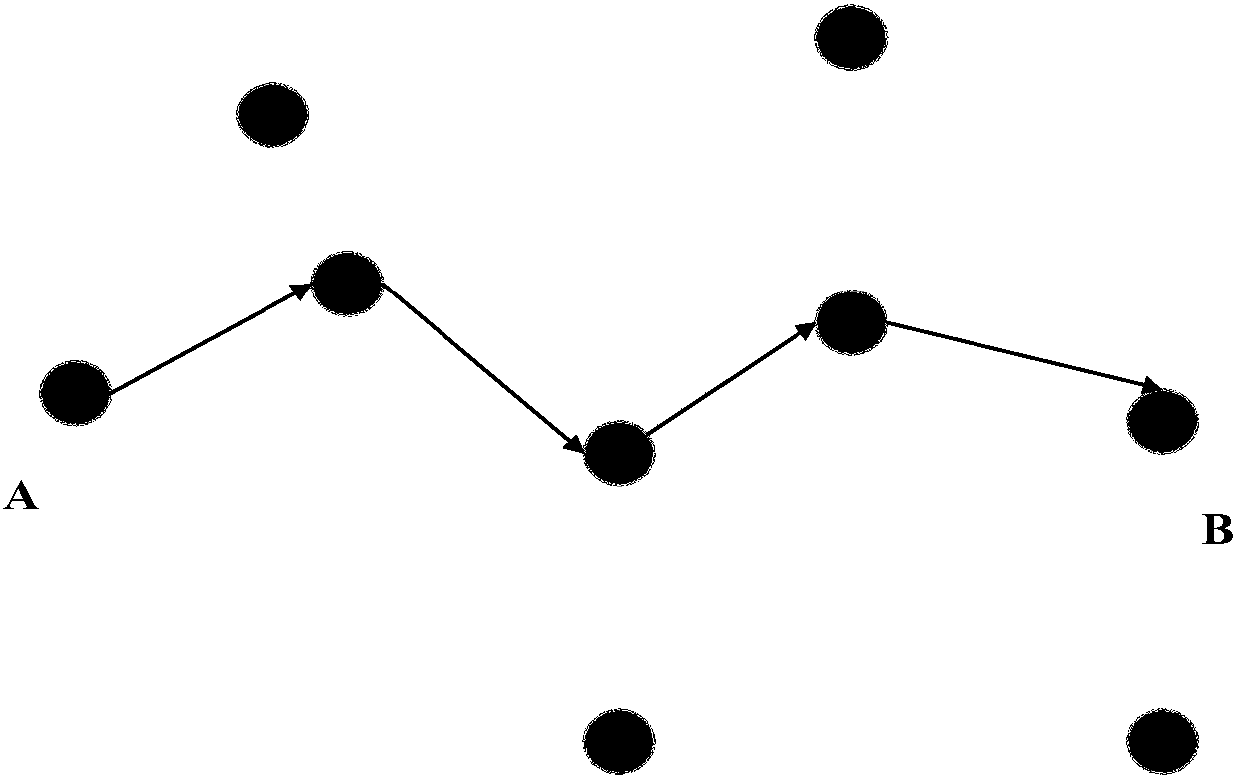

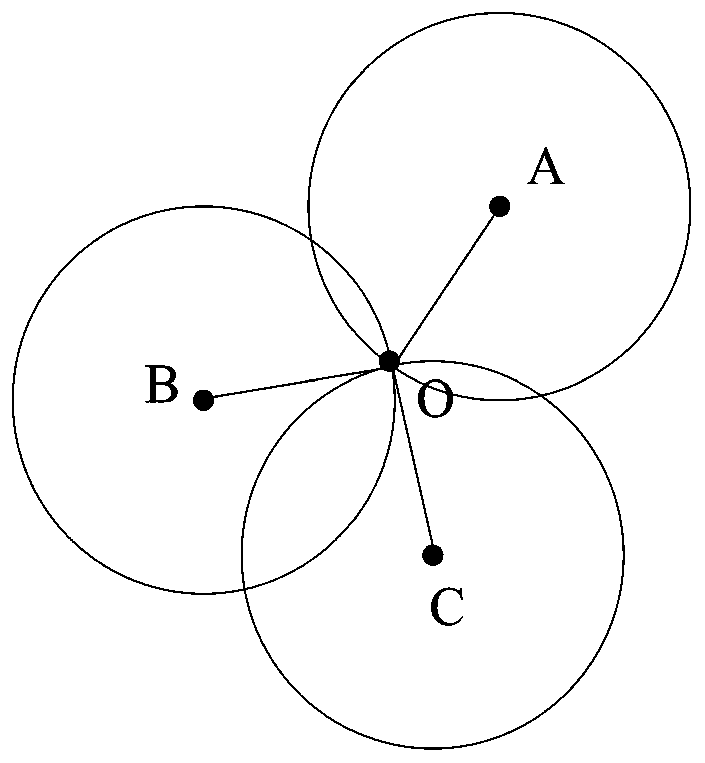

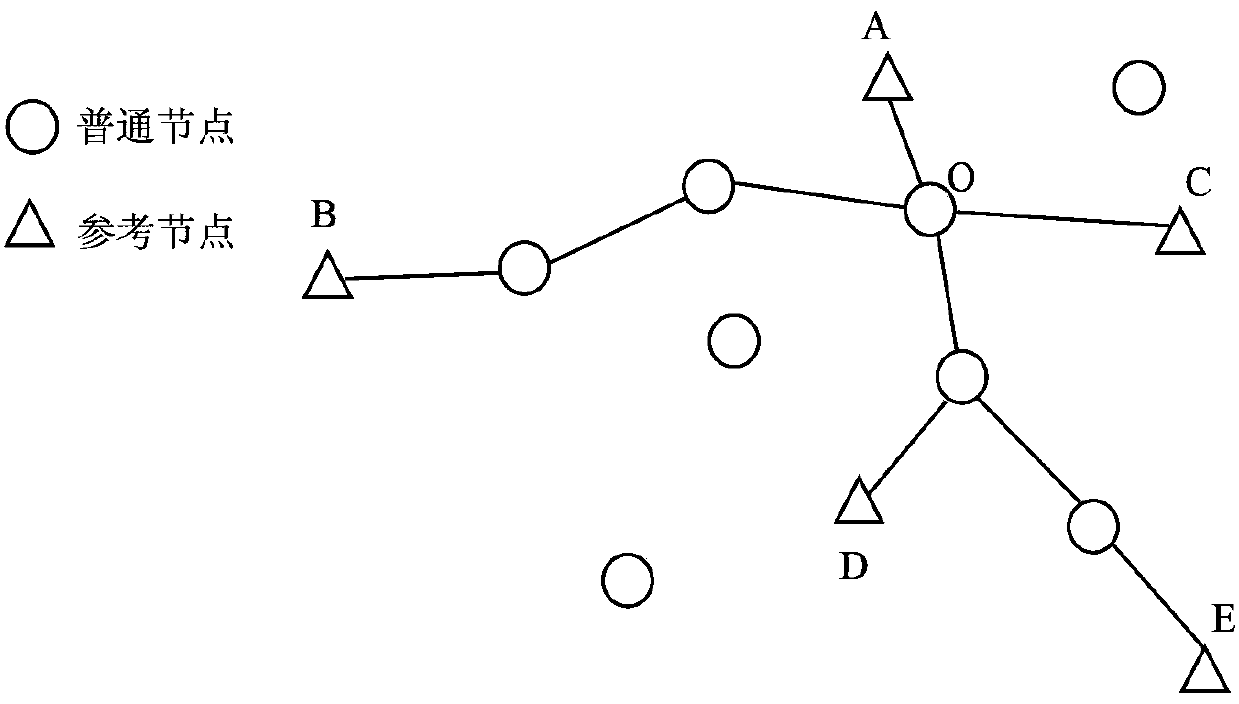

Underwater multistage positioning method

InactiveCN103391615AIncrease coverageReduce distance errorNetwork topologiesWireless sensor networkingRADIUS

The invention provides an underwater multistage positioning method and belongs to the technical field of wireless sensor network positioning. According to the method, a traditional trilateration algorithm and a multistage positioning algorithm are improved, for isolated nodes outside the communication radius of a reference node, other unknown nodes between the reference node and a node to be positioned are taken as a routing node to forward position information of the reference node, through included angle between a receiving signal and a sending signal of the routing node, errors of the distance between the reference node and the node to be positioned are further reduced by using the cosine law, and finally, positioning is finished by using the trilateration. By means of the underwater multistage positioning method, the positioning coverage rate is improved, and positioning errors are reduced.

Owner:NANJING UNIV OF POSTS & TELECOMM

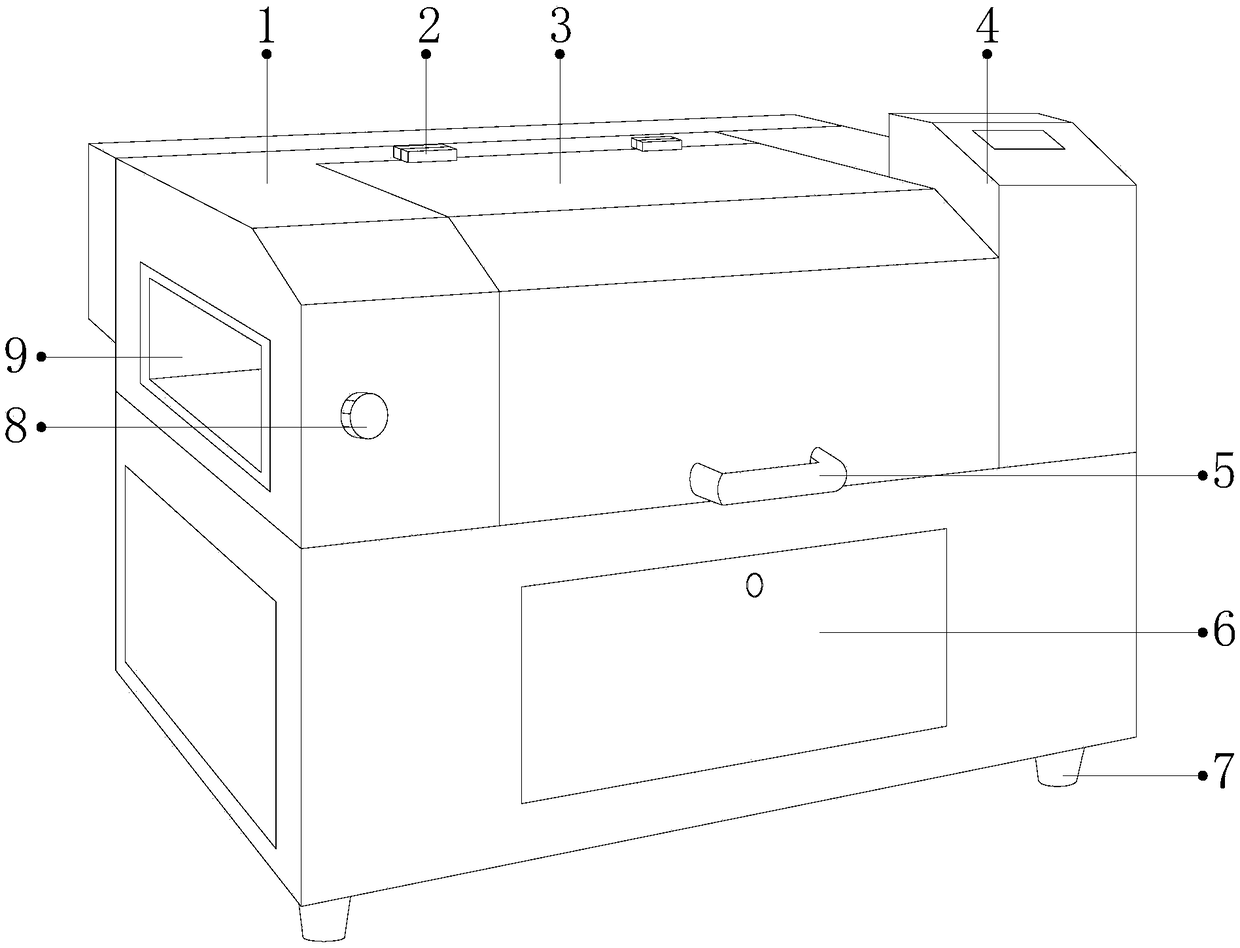

Novel plastic cutting equipment

InactiveCN109048081ASmooth transmissionUniform transmissionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAtmospheric pressure

The invention discloses novel plastic cutting equipment. The novel plastic cutting equipment structurally comprises a cutting main machine, hinges, a box door, a control box, a handle, a maintenance door, supporting legs, an adjusting button and a feeding opening. The top end of the cutting main machine and the hinges are welded. The hinges and the box door are welded. The cutting main machine ishinged to the box door through the hinges. The control box is fixedly mounted at the top end of the cutting main machine and is electrically connected with the cutting main machine through a wire. Thehandle is arranged on the box door. The maintenance door is mounted at the bottom end of the cutting main machine. Through a size adjusting mechanism, plastic of different sizes can be reinforced, and conveying is more stable; meanwhile, through cooperation with an air pressure suction cup mechanism, the head ends and the tail ends of the plastic are reinforced, the situation that violent vibration happens in the cutting process, consequently, cutting positions shift, and the cutting positions are wrong is avoided; and the cut plastic moves through a translation mechanism to be away from a cutting mechanism, it is ensured that the plastic can be pushed by a normal distance during cutting of next time, and the plastic is prevented from being cut too short.

Owner:董芬芳

Quick measurement range finder

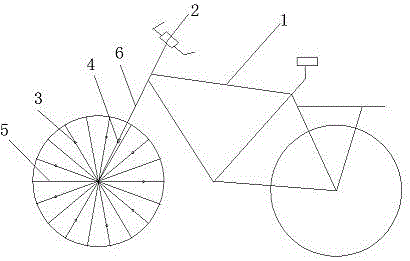

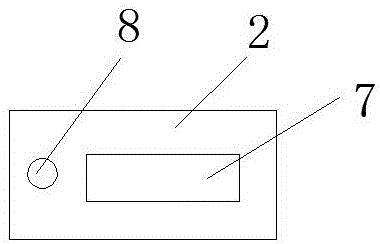

PendingCN106839961AReduce the distance error range valuePrecise positioningUsing electrical meansCounting NumberRange finding

The invention discloses a quick measurement range finder which comprises a bicycle body and a range finding device which is mounted on the bicycle body. The range finding device comprises a miniature electronic counter, a plurality of magnets and an induction coil in mutual magnetic induction, wherein the plurality of magnets are mounted on steel wires on the rim of a front wheel of the bicycle and are equidistantly distributed on the circumference at the same height. The induction coil is mounted on a front bumper of the bicycle. The height of the induction coil is same with that of the magnet. Mutual induction between the magnets and the induction coil can be realized without contact. The miniature electronic counter is mounted on the handle of the bicycle and is connected with the induction coil through a lead. Along with riding of the bicycle, successive induction between the plurality of magnets and the induction coil is realized and furthermore counting is performed through the miniature electronic counter. Consistency between a front sight distance and a back sight distance is ensured through ensuing consistency of counting numbers which are measured in two times.

Owner:南通市测绘院有限公司

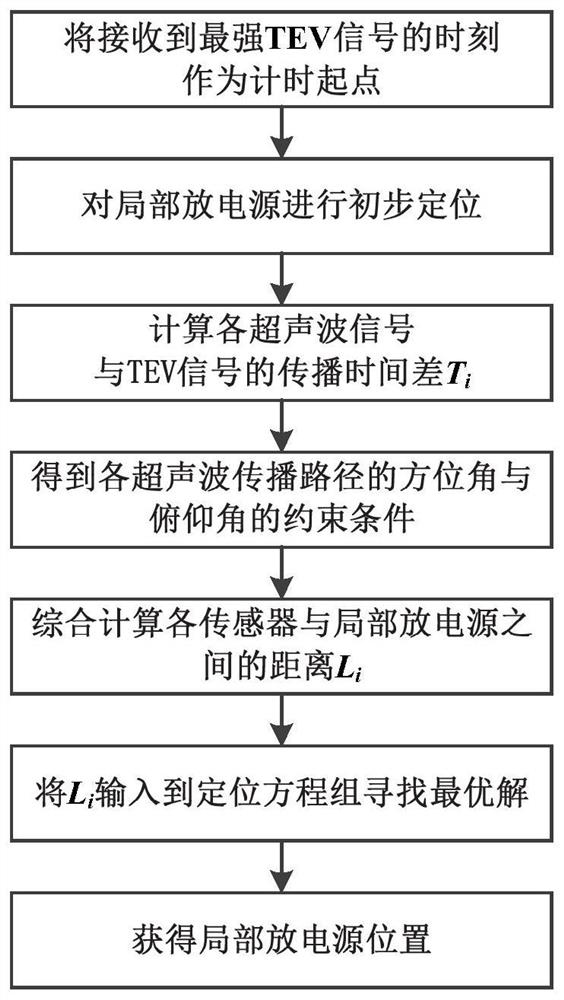

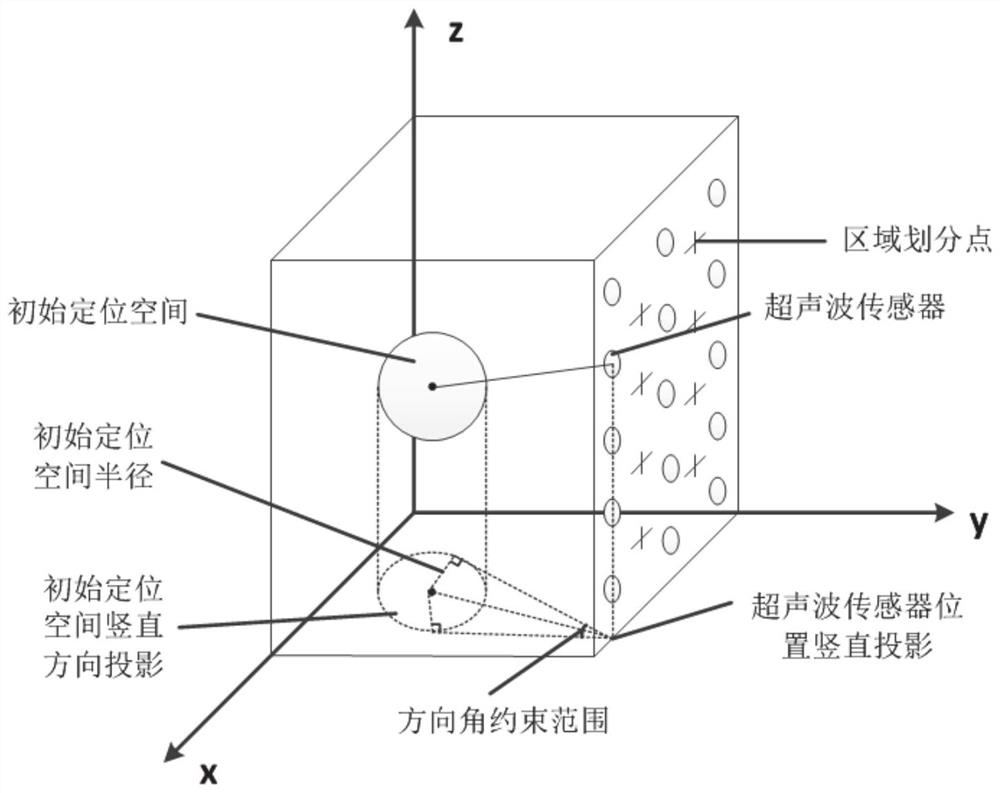

High-voltage switch cabinet partial discharge positioning method and system considering temperature field change

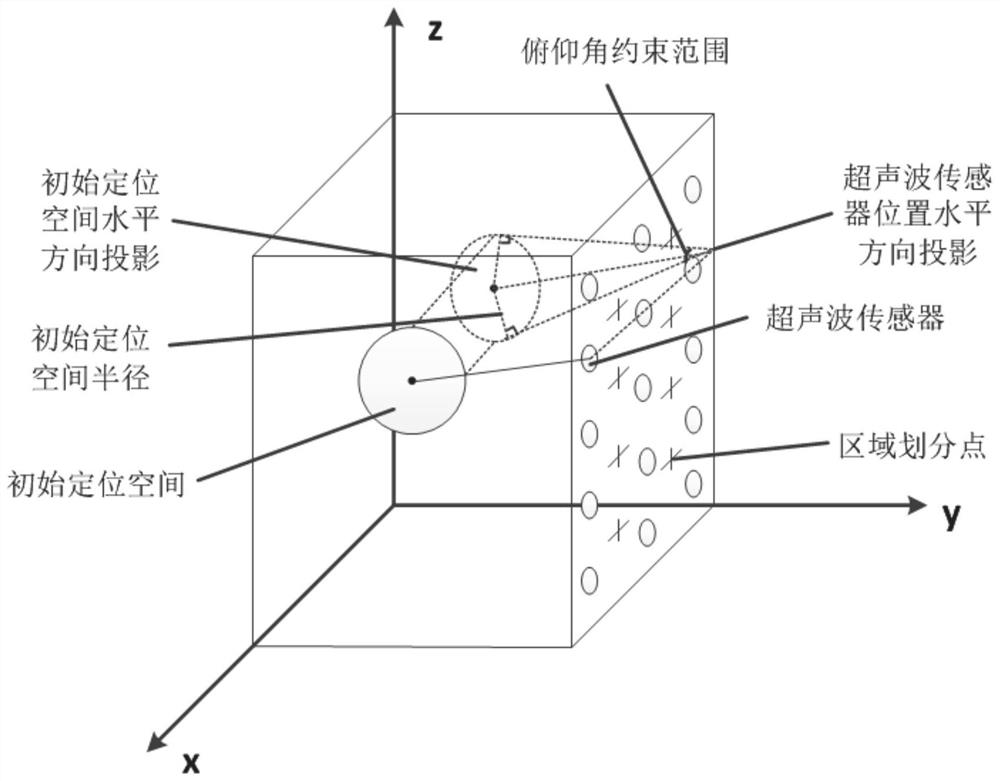

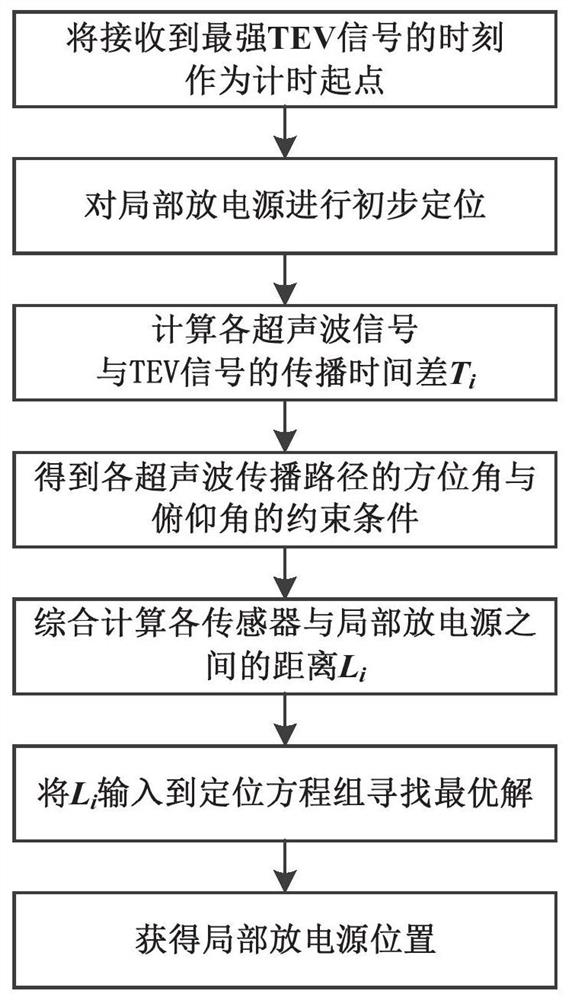

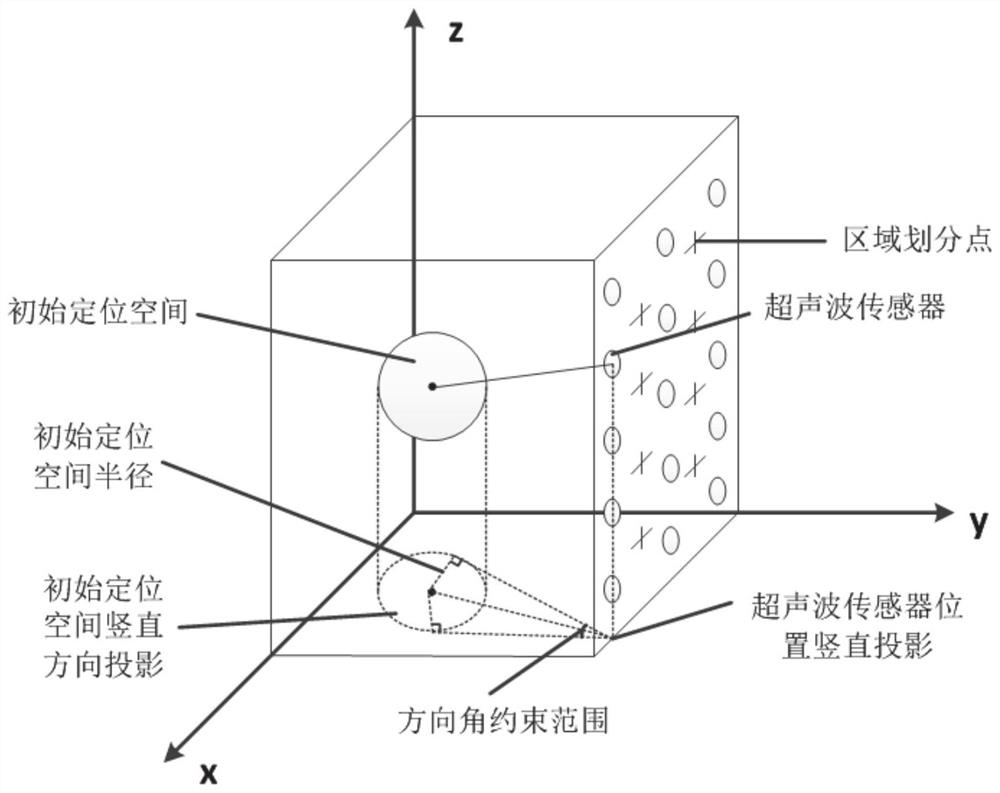

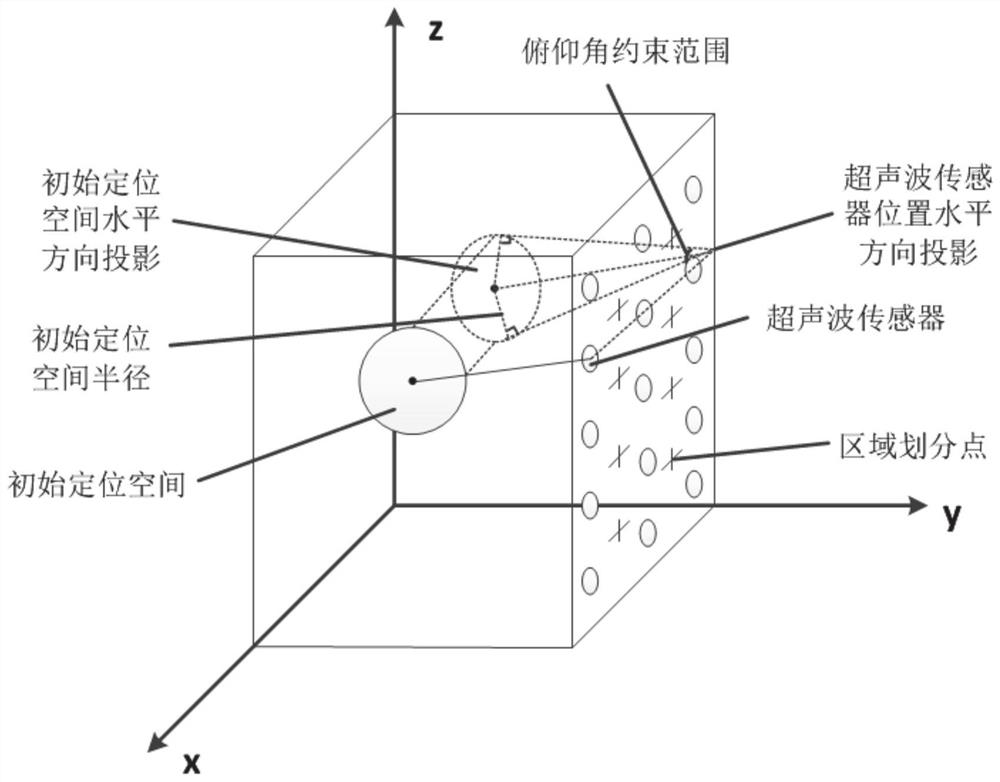

InactiveCN112213585AReduce computing pressureReduce calculation errorsPosition fixationDesign optimisation/simulationPropagation timeEngineering

The invention discloses a high-voltage switch cabinet partial discharge positioning method and system considering temperature field changes, and the method comprises the steps: obtaining the constraint conditions of all ultrasonic propagation paths according to the position relation between the initial positioning space of a partial discharge source of a high-voltage switch cabinet and all ultrasonic sensors in the high-voltage switch cabinet; constructing a three-dimensional temperature field of the high-voltage switch cabinet to obtain a temperature distribution condition of an ultrasonic propagation path; calculating the distance between each ultrasonic sensor and the partial discharge source according to the temperature distribution condition of the ultrasonic propagation path; inputting the propagation time difference between the starting moment of the signal measured by each ultrasonic sensor and the timing starting point and the distance between each ultrasonic sensor and the partial discharge source into a positioning equation, and searching an optimal solution in combination with constraint conditions to obtain the position of the partial discharge source.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

High-voltage switch cabinet partial discharge positioning method and system considering temperature field change

ActiveCN112904139AReduce computing pressureReduce calculation errorsPosition fixationDesign optimisation/simulationPropagation timeSound wave

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

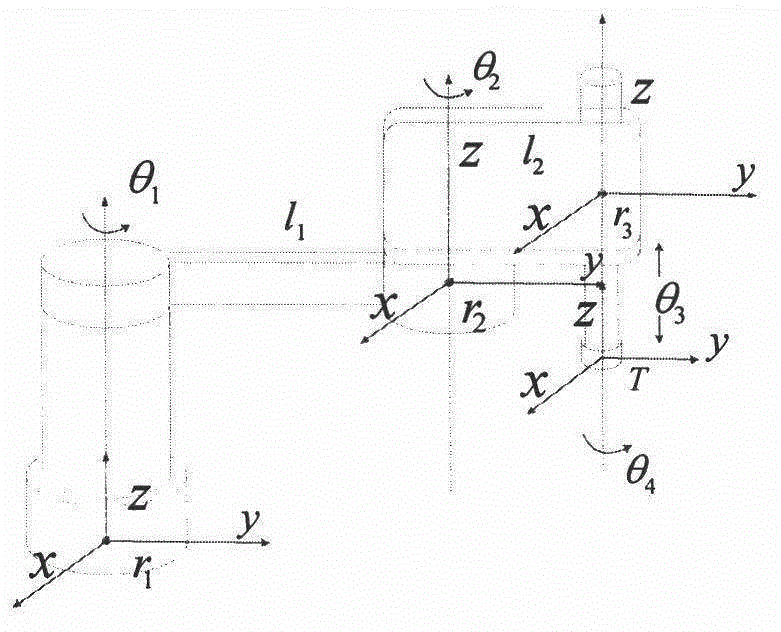

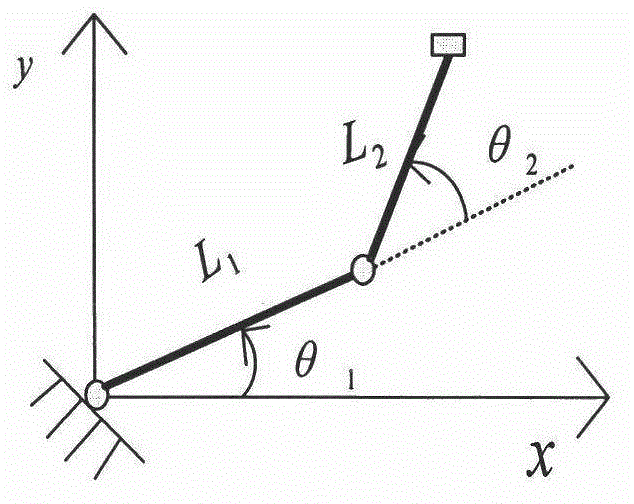

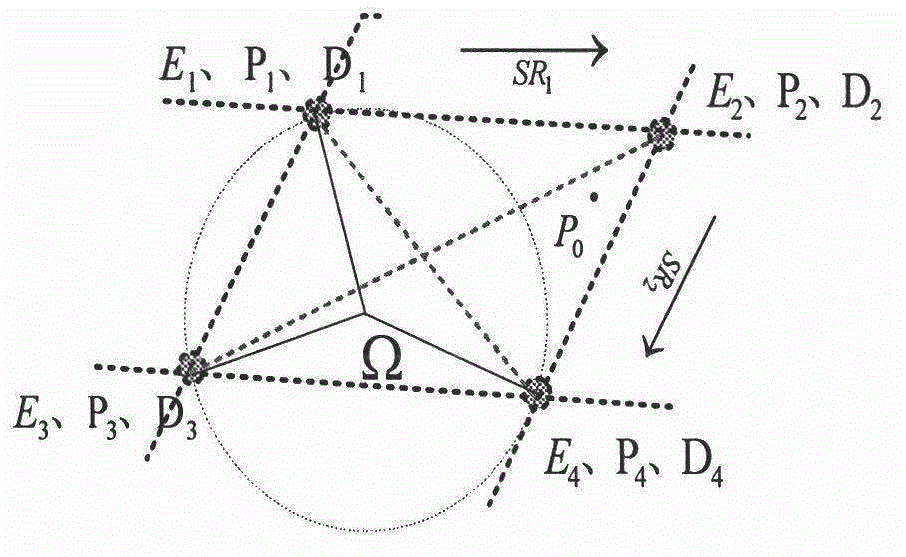

SCARA robot accurate positioning method based on granularity model

InactiveCN104908030AImprove absolute positioning accuracyDoes not affect repeat positioning accuracyProgramme-controlled manipulatorGranularityModel parameters

The invention provides an SCARA robot accurate positioning method based on a granularity model combined with minimum distance error approximation principle. With the method, the spatial position distance relationship between an actual point and an expectation point that a robot end arrives for the first time is firstly analyzed; an initial granularity model of variable parameter is established; the distance error between four granularity points of the model and the expectation point is calculated; the granularity point with the minimum distance error within the model is established as the initial point of the variable parameter granularity model for the next step; and the regulation of the granularity model parameter is determined by a specific position of the granularity model on which the expectation point is located; only the simplified mathemetics structure model of a shaft 1 and a shaft 2 of the SCARA robot is needed to know; the SCARA robot accurate positioning method has the advantages of single parameter regulation, clear movement frequency, less movement frequency, strong industrial practicality and improved absolute positioning accuracy without changing SCARA robot repeating positioning accuracy; under the circumstance of big absolute positioning error, constriction is realized rapidly; and under the circumstance of small absolute positioning error, accurate positioning is realized.

Owner:JIANGNAN UNIV

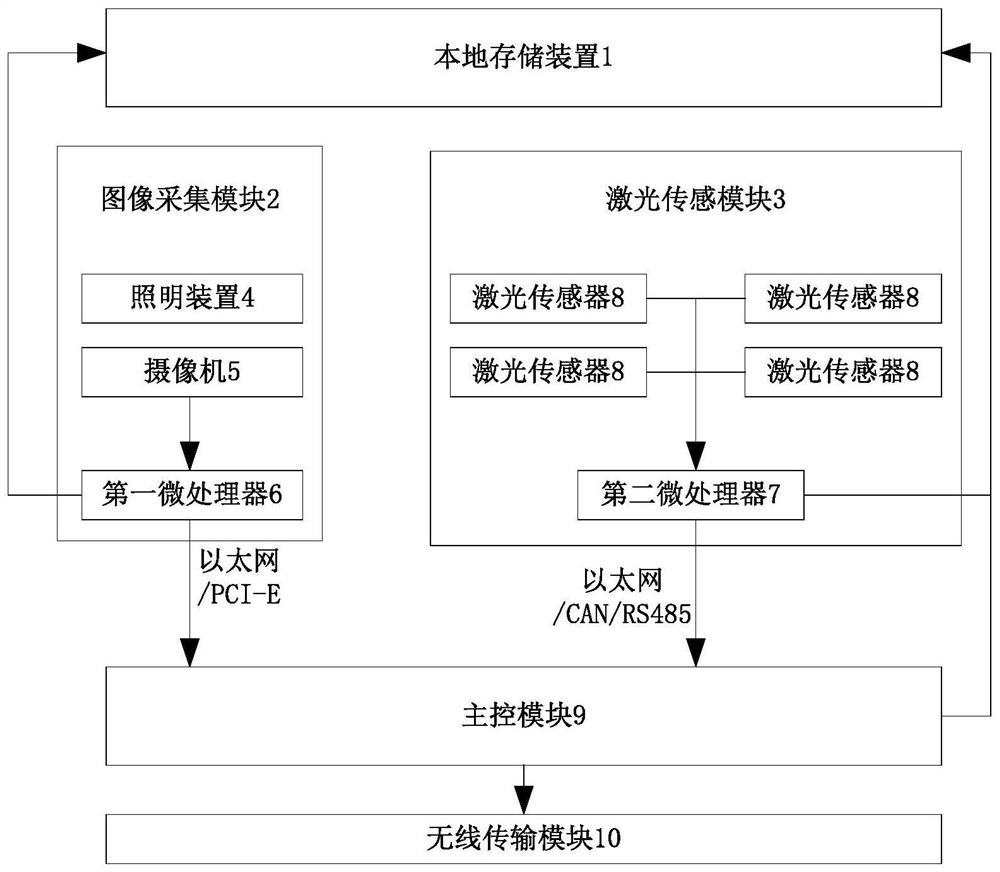

Turnout detection system and method

ActiveCN113753094AImprove real-time judgment accuracyIncrease redundancyImage enhancementImage analysisWireless transmissionLaser sensor

The invention discloses a turnout detection system and method. The system comprises a main control module, and an image acquisition module, a laser sensing module and a wireless transmission module which are respectively connected with the main control module; the image acquisition module comprises a camera and a first microprocessor connected with the camera, and the laser sensing module comprises a laser sensor and a second microprocessor connected with the laser sensor; and the first microprocessor and the second microprocessor are respectively connected with the main control module. The method comprises the steps: a camera and a laser sensor collect turnout initial image data and turnout initial point cloud data and respectively transmit the data to a first microprocessor and a second microprocessor; the first microprocessor and the second microprocessor respectively preprocess the received data and transmit the processed data to the local storage device and the main control module; the main control module judges the turnout state according to the received data; and the main control module sends the turnout state judgment result to the control terminal through the wireless transmission module.

Owner:北京杰迈科技股份有限公司

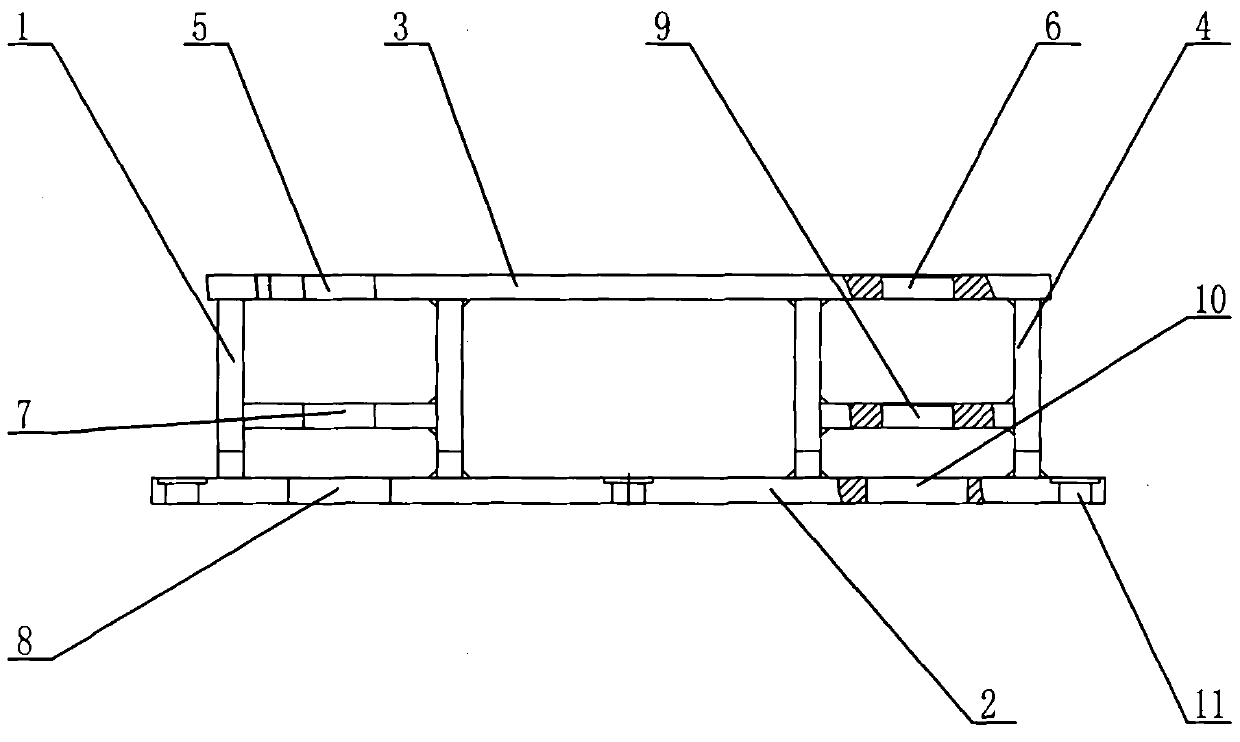

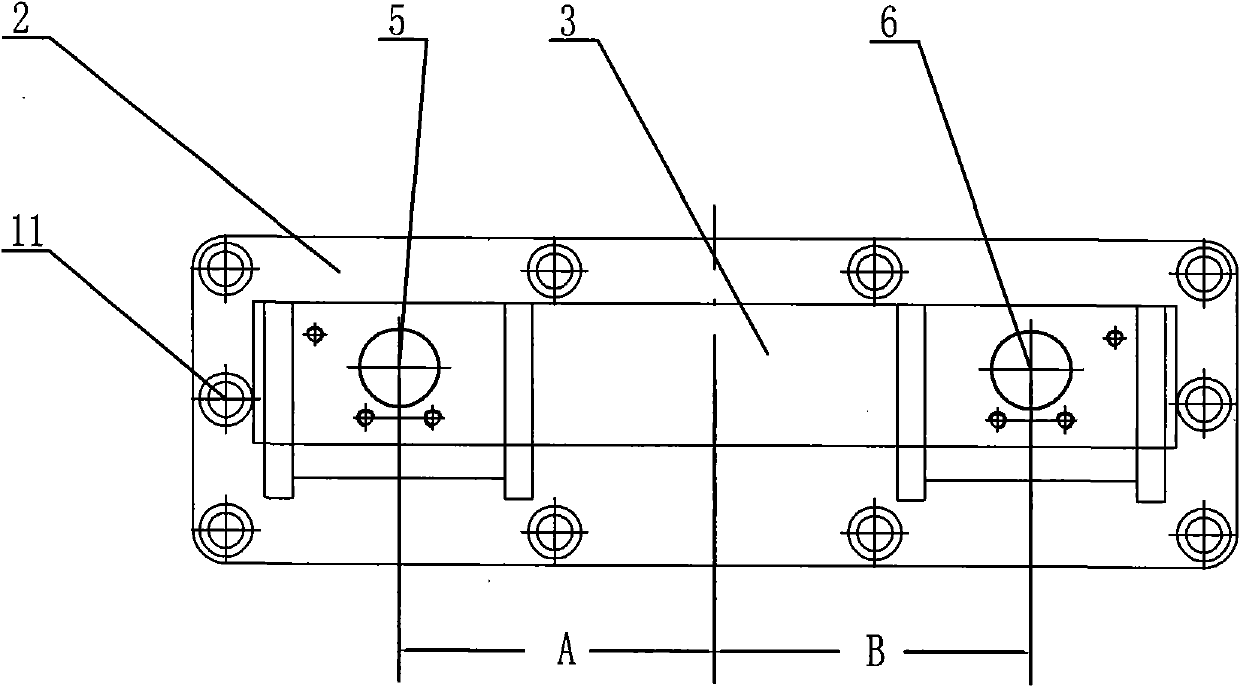

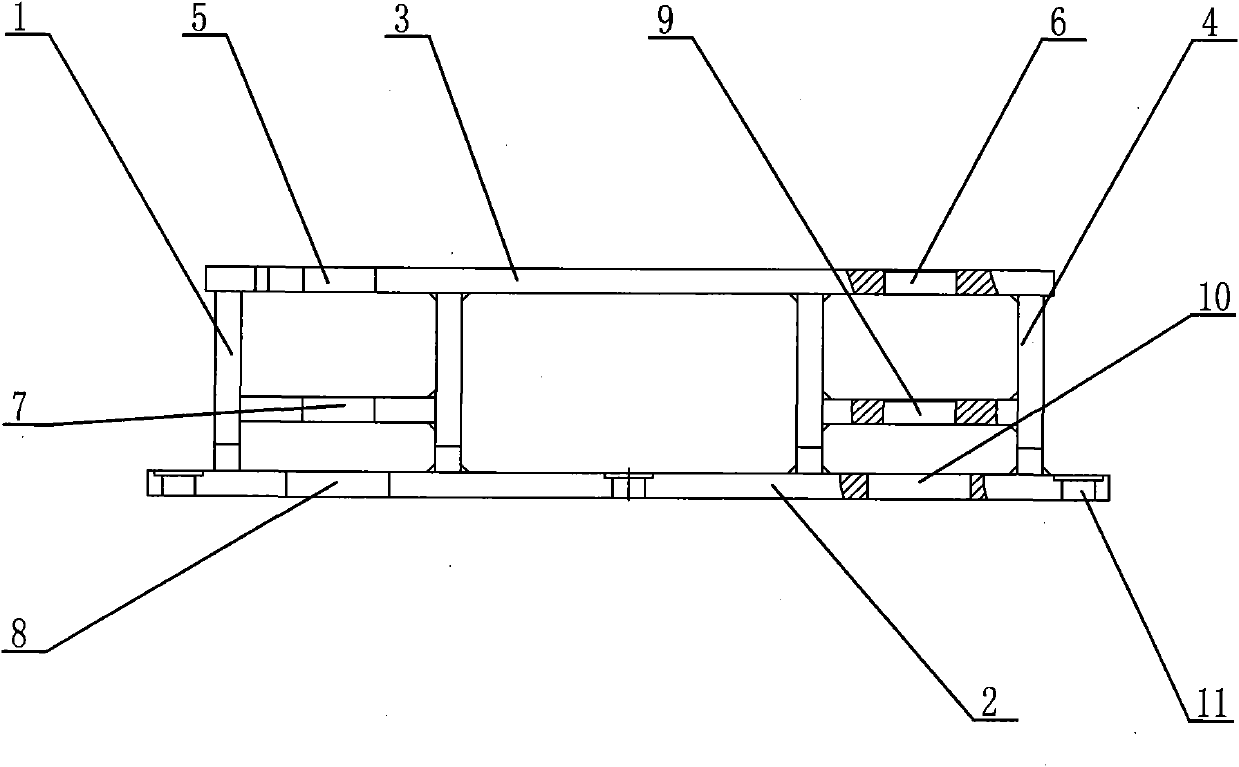

Integral oil cylinder base

InactiveCN101949400AReduce workloadReduce distance errorFluid-pressure actuatorsEngineeringPetroleum engineering

The invention relates to an integral oil cylinder base, which comprises a first oil cylinder seat and a second oil cylinder seat. The integral oil cylinder base is characterized in that: the upper ends of the first and second oil cylinder seats are connected by an upper support plate, while lower ends are connected by a lower support plate; the upper support plate above the first oil cylinder seat is provided with a first hole; the upper support plate above the second oil cylinder seat is provided with a second hole; the first oil cylinder seat and one end of the lower support plate are provided with a third hole and a fourth hole respectively; the second oil cylinder seat and the other end of the lower support plate are provided with a fifth hole and a sixth hole respectively; the third and fourth holes are through holes concentric with the first hole; the fifth and sixth holes are the through holes concentric with the second hole; and a vertical distance between the center of circle of the first hole and the center line of the upper support plate is A, the vertical distance between the center of circle of the second hole and the center line of the upper support plate is B, and A is equal to B. The integral oil cylinder base reduces mounting workload and is convenient for maintenance and positioning.

Owner:WUXI DONGZHOU MARINE FITTINGS

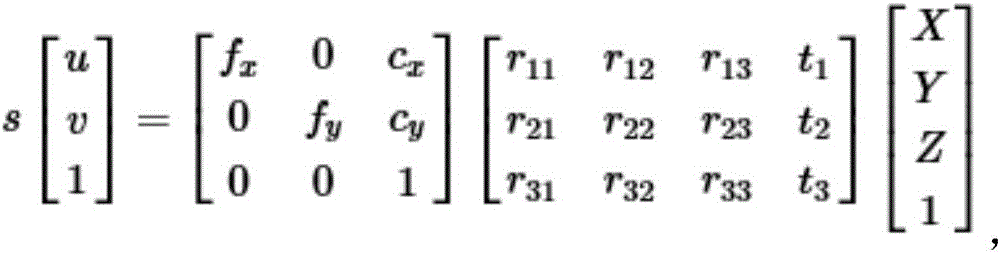

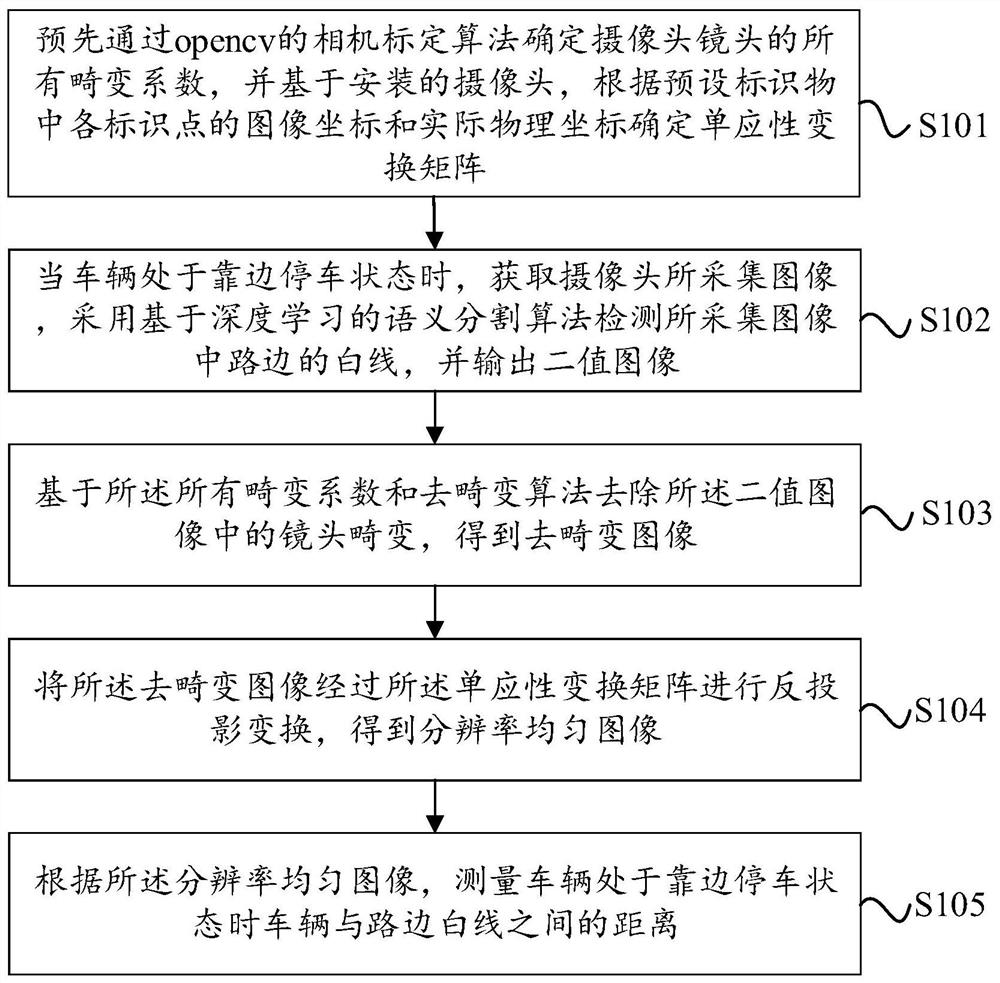

Vehicle parking distance measurement method and device based on deep learning, and electronic equipment

InactiveCN113034583AImprove efficiencyImprove accuracyImage enhancementImage analysisImage resolutionWhite line

The invention discloses a vehicle parking distance measurement method and device based on deep learning and electronic equipment, and the method comprises the steps: determining a camera distortion coefficient, and determining a homography transformation matrix based on an installed camera according to the image coordinates and actual physical coordinates of all identification points in a preset marker; when the vehicle is in a side parking state, acquiring an image acquired by the camera, detecting a white line of a roadside in the acquired image by adopting a semantic segmentation algorithm based on deep learning, and outputting a binary image; removing lens distortion in the binary image based on the distortion coefficient and a distortion removing algorithm, and obtaining a distortion-removed image; and performing back projection transformation through a homography transformation matrix to obtain an image with uniform resolution, and measuring the distance between the vehicle and the roadside white line. According to the invention, the position of the roadside white line can be accurately detected in different scenes, the detection accuracy of the position of the white line and the actual application scene are improved, lens distortion in camera imaging is removed, and the distance between the vehicle and the white line is accurately measured.

Owner:车轮互联科技(上海)股份有限公司

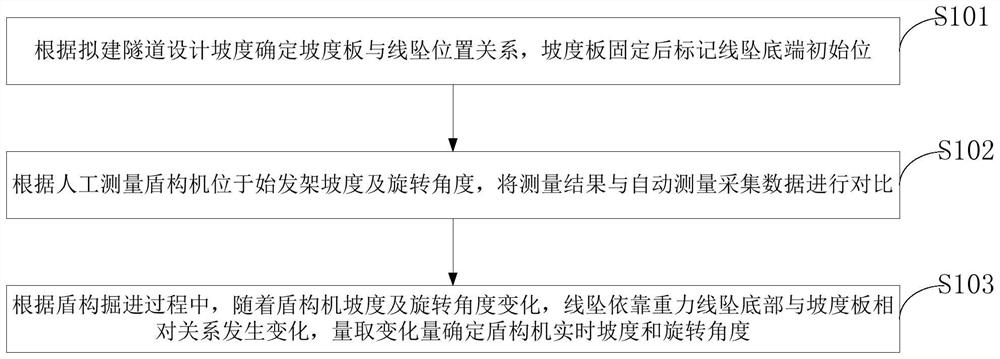

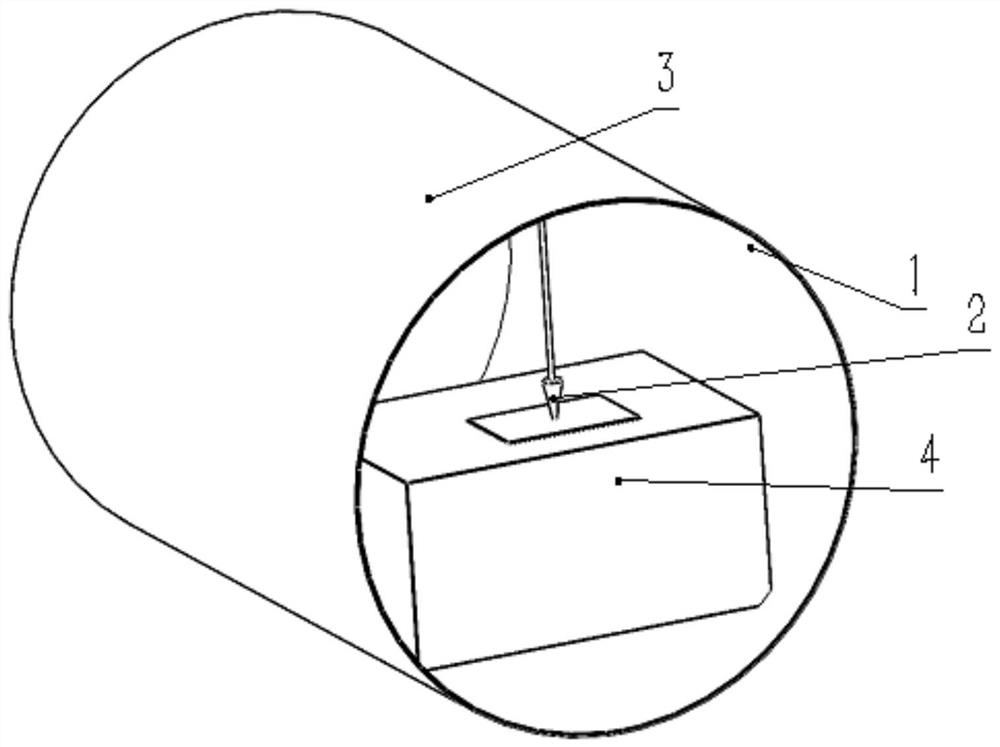

Method and system for measuring gradient and rotation angle of shield tunneling machine, terminal and medium

PendingCN114184171AReduce the difficulty of manual measurementManual measurement is fastAngle measurementPlumb lines for surveyingMeasurement deviceEngineering

The invention belongs to the technical field of tunnel measurement, and discloses a gradient and rotation angle measurement method and system for a shield tunneling machine, a terminal and a medium. Determining the position relation between a slope plate and a line pendant according to the designed slope of a proposed tunnel, and marking the initial position of the bottom end of the line pendant after the slope plate is fixed; meanwhile, the gradient and the rotation angle of the shield tunneling machine located on the starting frame are manually measured, and the measurement result is compared with automatically measured and collected data; in the shield tunneling process, along with changes of the gradient and the rotation angle of the shield tunneling machine, the line pendant changes by means of the relative relation between the bottom of the gravity line pendant and the gradient plate, and the real-time gradient and the rotation angle of the shield tunneling machine are determined by measuring the variable quantity. Compared with a traditional mode, the manual measurement difficulty of the gradient and the rotation angle of the shield tunneling machine is reduced, and meanwhile the precision of a measurement result is improved. And manual measurement can be carried out quickly when the automatic measuring device of the shield tunneling machine goes wrong.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

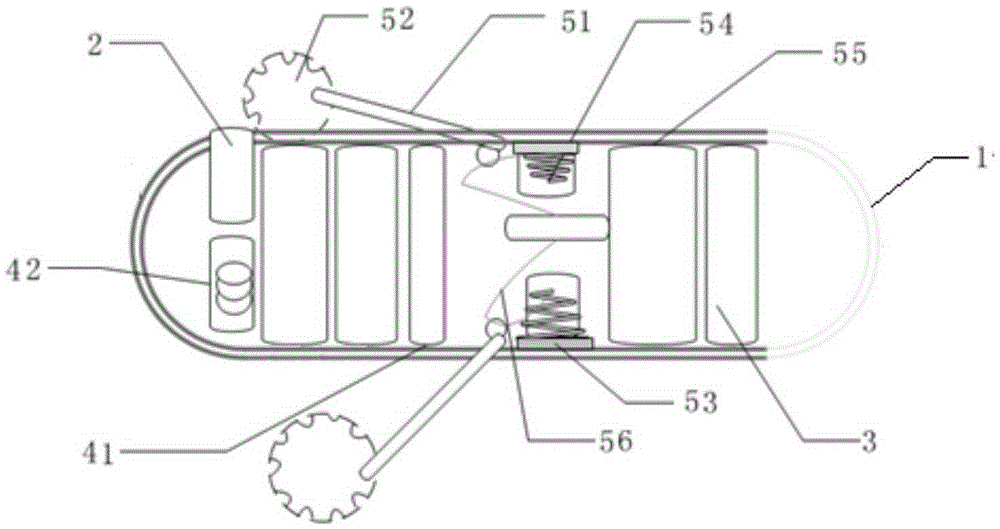

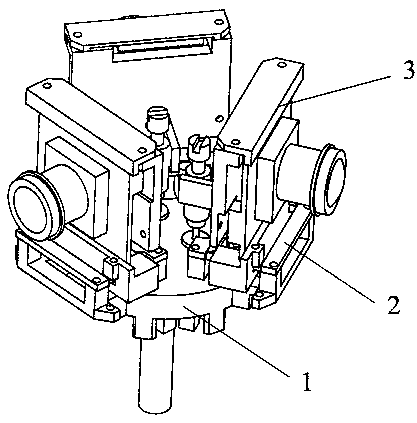

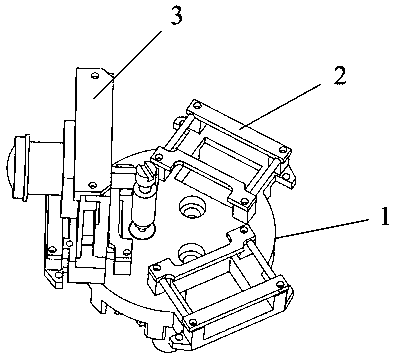

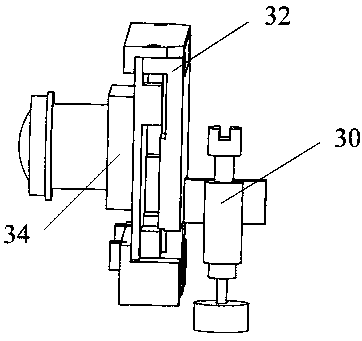

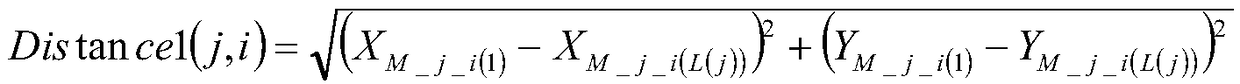

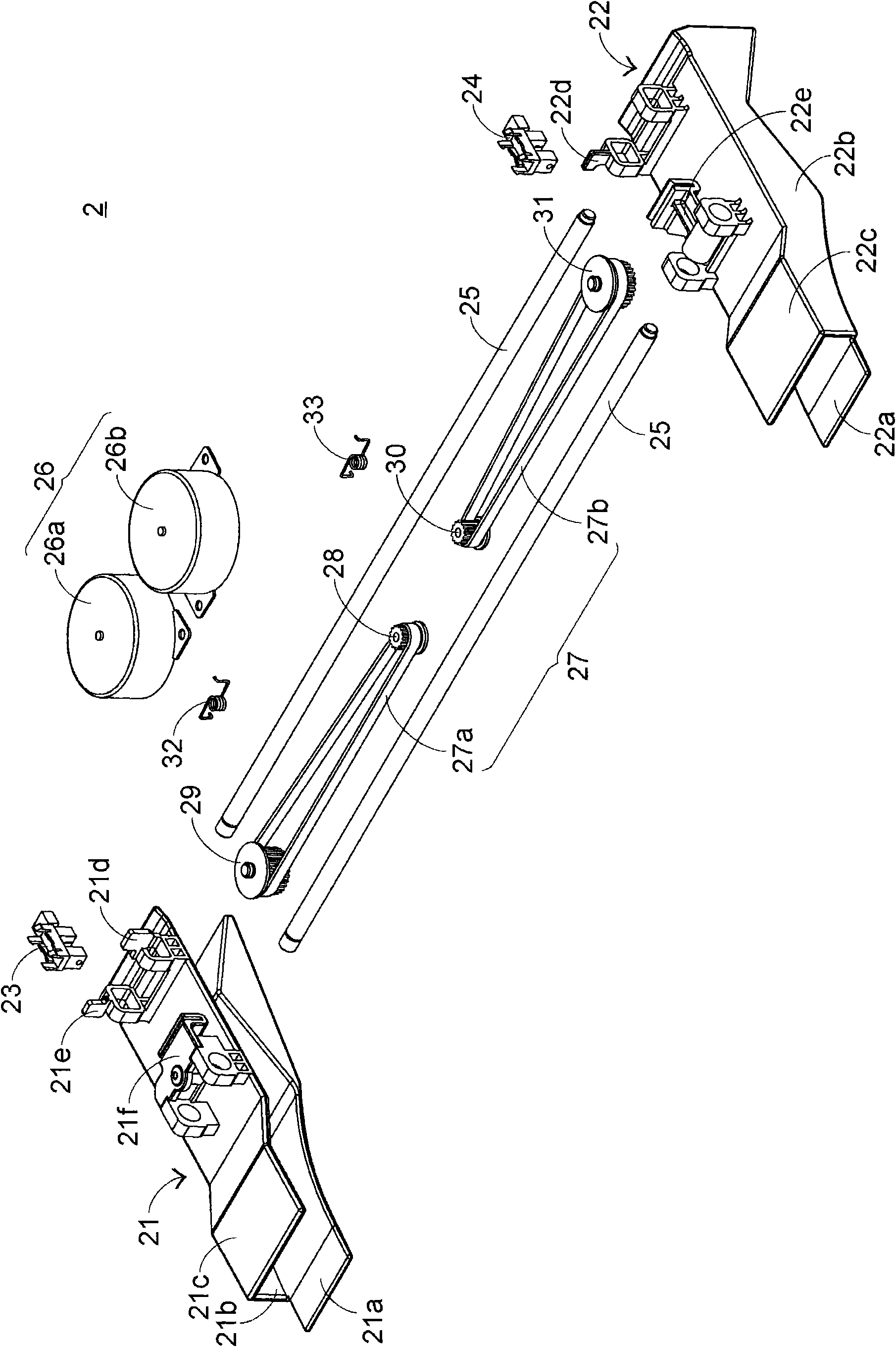

A lens position fine-tuning device for a multi-lens panoramic camera

ActiveCN106990498BReduce distance errorImprove calibration accuracyMountingsPanoramic photographyOphthalmologyPanorama

The invention discloses a lens position fine-tuning device for a multi-lens panoramic camera. The upper end of the frame is movably connected with the lens position fine-tuning module of the support frame. The present invention is simple in structure and compact in design. By rotating the micro-motion gear to drive the micro-motion rack to move forward and backward in a straight line, the fine-tuning operation of the front and rear positions of multiple lenses can be realized, which is convenient and flexible, and has high adjustment accuracy. Fine-tuning can effectively reduce the distance error between each lens in the imaging system of the panoramic camera and the sensor, and improve the calibration accuracy of the panoramic camera.

Owner:SHENZHEN PISOFTTECH TECH CO LTD

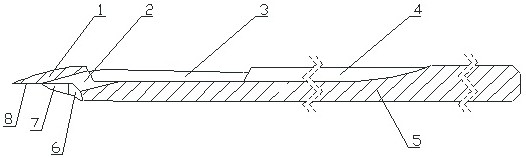

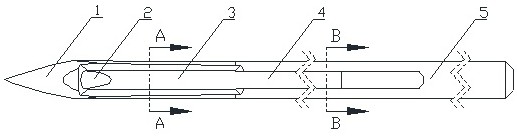

Z-direction zero-tension suture needle special for composite materials and using method thereof

The invention relates to a Z-direction zero-tension suture needle special for composite materials and a using method thereof, and relates to the field of weaving and forming of composite materials. The suture needle is provided with a needle body, a yarn guide sliding groove is formed in the upper side of the needle body, a puncture needle tip is arranged at the front end of the needle body, a needle head threading hole is formed in the rear portion of the puncture needle tip, and a needle head wire hole is formed in the rear portion of the puncture needle tip. A puncture platform is arranged on the lower side of the puncture needle point, and a threading groove is formed in the puncture needle point. The use method comprises the following steps: sewing the tiled layer with the thickness of D; yarn goes out of the needle head at least 1mm through the guide chute and the needle head guide hole. During sewing, the needle body moves forwards, and the puncture needle tip drives the yarn to penetrate through the tiled layer and then continues to move forwards by 1 mmD; after the needle body moves backwards and the front end of the puncture needle tip is separated from the flat layer, the needle body translates by at least 1mm, and the actions are repeated to finish the suturing operation. The Z-direction zero-tension suture needle has the advantages of being simple in structure, convenient to use, good in product performance, high in consistency and the like, and the tiled layer structure and fiber lines thereof cannot be damaged.

Owner:HARBIN INST OF TECH AT WEIHAI +1

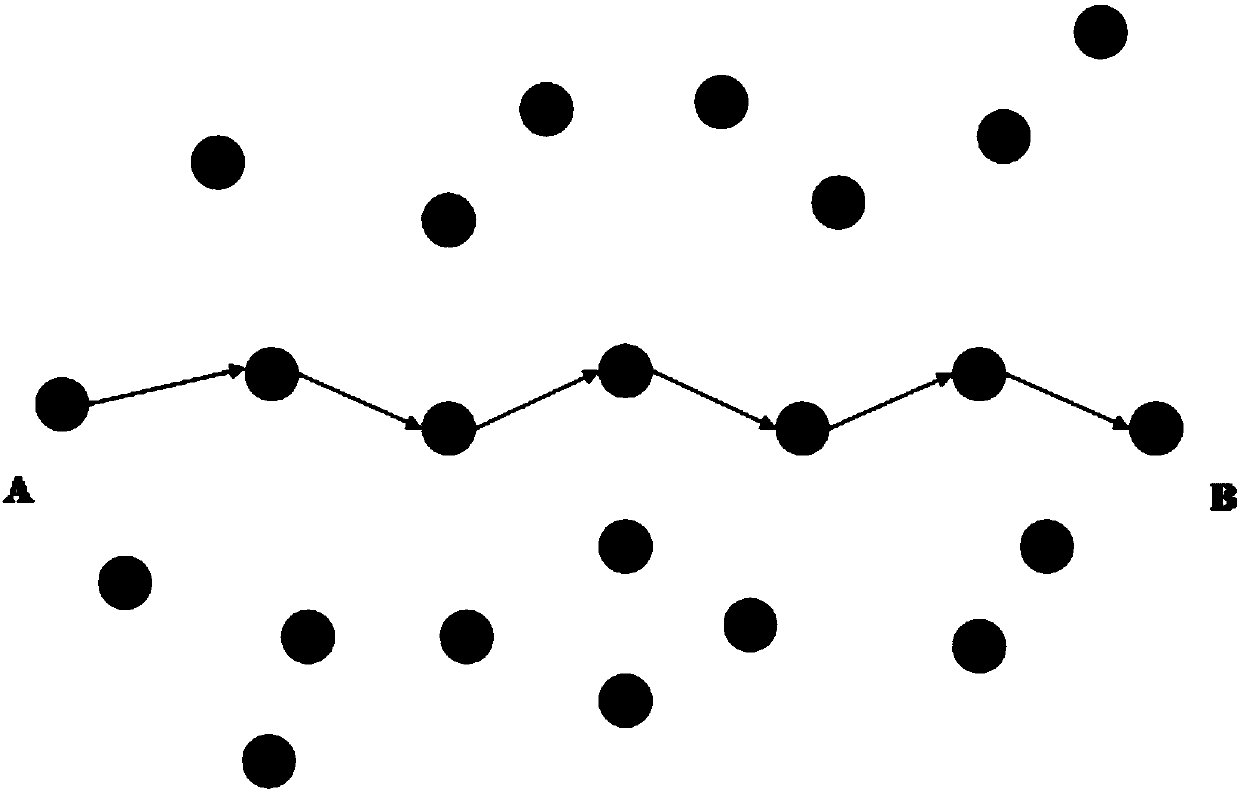

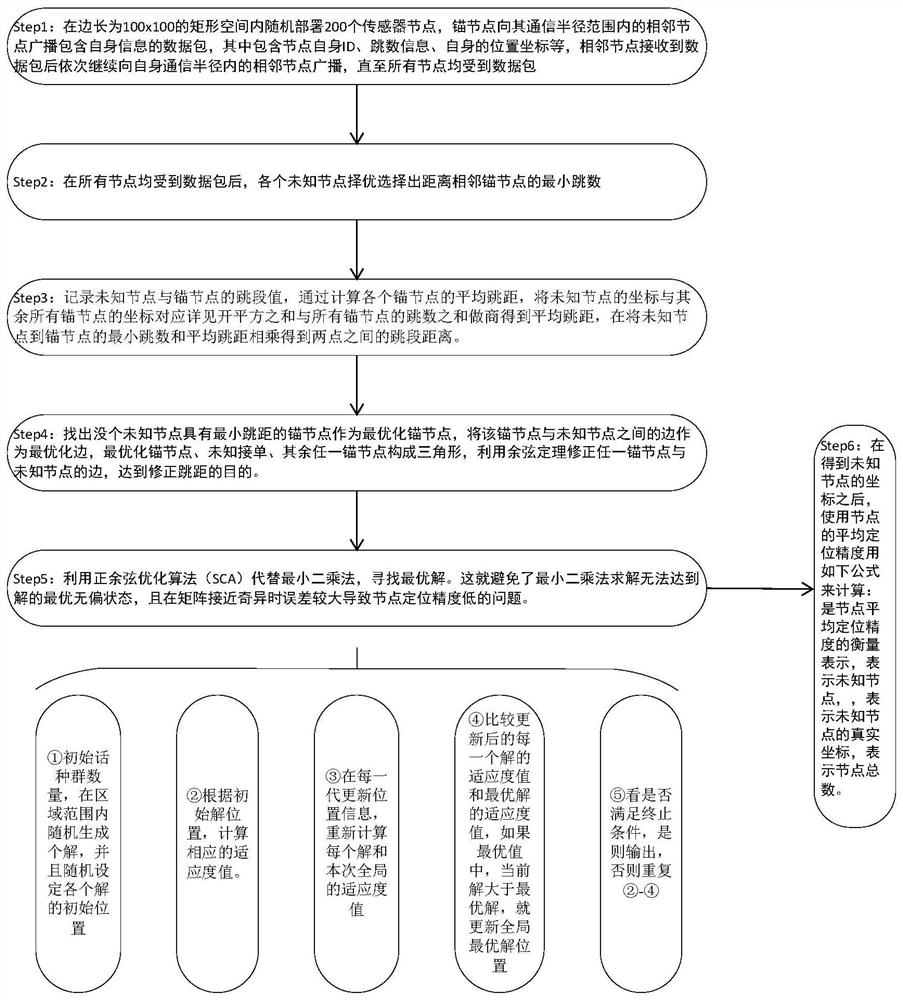

DV-Hop positioning algorithm based on sine and cosine optimization and hop optimization

PendingCN113490172AReduce distance errorSolve the problem of low positioning accuracy and large errorParticular environment based servicesLine sensorAlgorithm

The invention relates to a DV-Hop positioning algorithm based on sine and cosine optimization and hop optimization, and belongs to the field of wireless sensor network node positioning. The method comprises the following steps: firstly, defining a concept of an optimal anchor node, selecting an anchor node with the minimum average hop distance in all anchor nodes around each unknown node as the optimal anchor node, then selecting any one of the rest anchor nodes and the unknown nodes to form a triangle, and taking an edge from the optimal anchor node to the unknown nodes as an optimal edge in the triangle; secondly, calculating the distances from other anchor nodes to the unknown node by using the cosine theorem to achieve the purpose of optimizing the hop distance; and finally, improving the least square method by using a sine and cosine optimization algorithm (SCA), and searching the optimal position of an unknown node by using the volatility of a sine and cosine function. According to the method, the positioning precision can be improved while the positioning cost is reduced, and the application range is widened.

Owner:KUNMING UNIV OF SCI & TECH +1

Device for contactless determination of rotation and/or position of an object having an encoder

ActiveCN100594383CSmall indexing errorPosition measurement accuracy has no effectElectrical controlLinear/angular speed measurementMagnetizationTransducer

The present invention relates to a device which is used for measuring the rotary speed and / or position of the generator component which can rotate around the axial cord without contact, the device isprovided with a circular permanent-magnet encoder which includes a N pole and a S pole which are alternately arranged in the circumference direction and at least two different pole width, the encoderis provided with a scanning head with difference hall transducer, wherein, the encoder is designed to be a double rail encoder (1) with inverse magnetizations; and each sensor element (9, 10) of the difference hall transducer (8) is arranged to one of the encoder rails (4, 5).

Owner:CARL FREUDENBERG KG

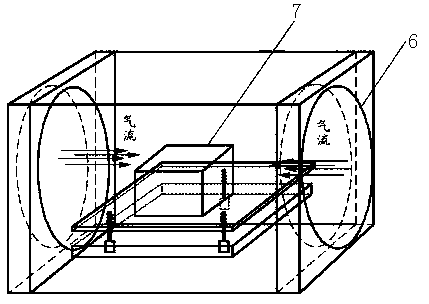

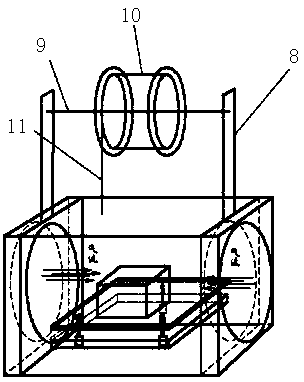

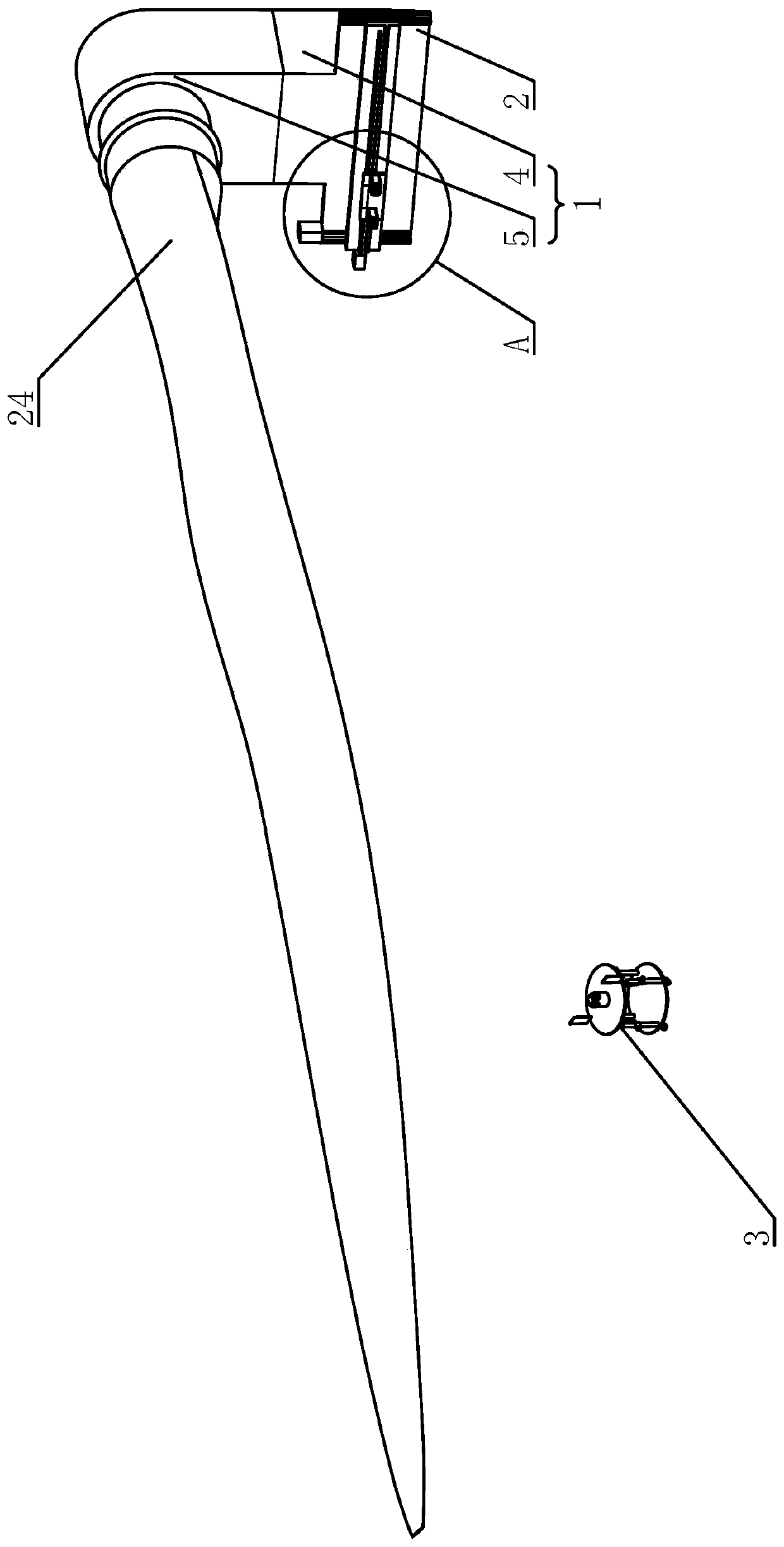

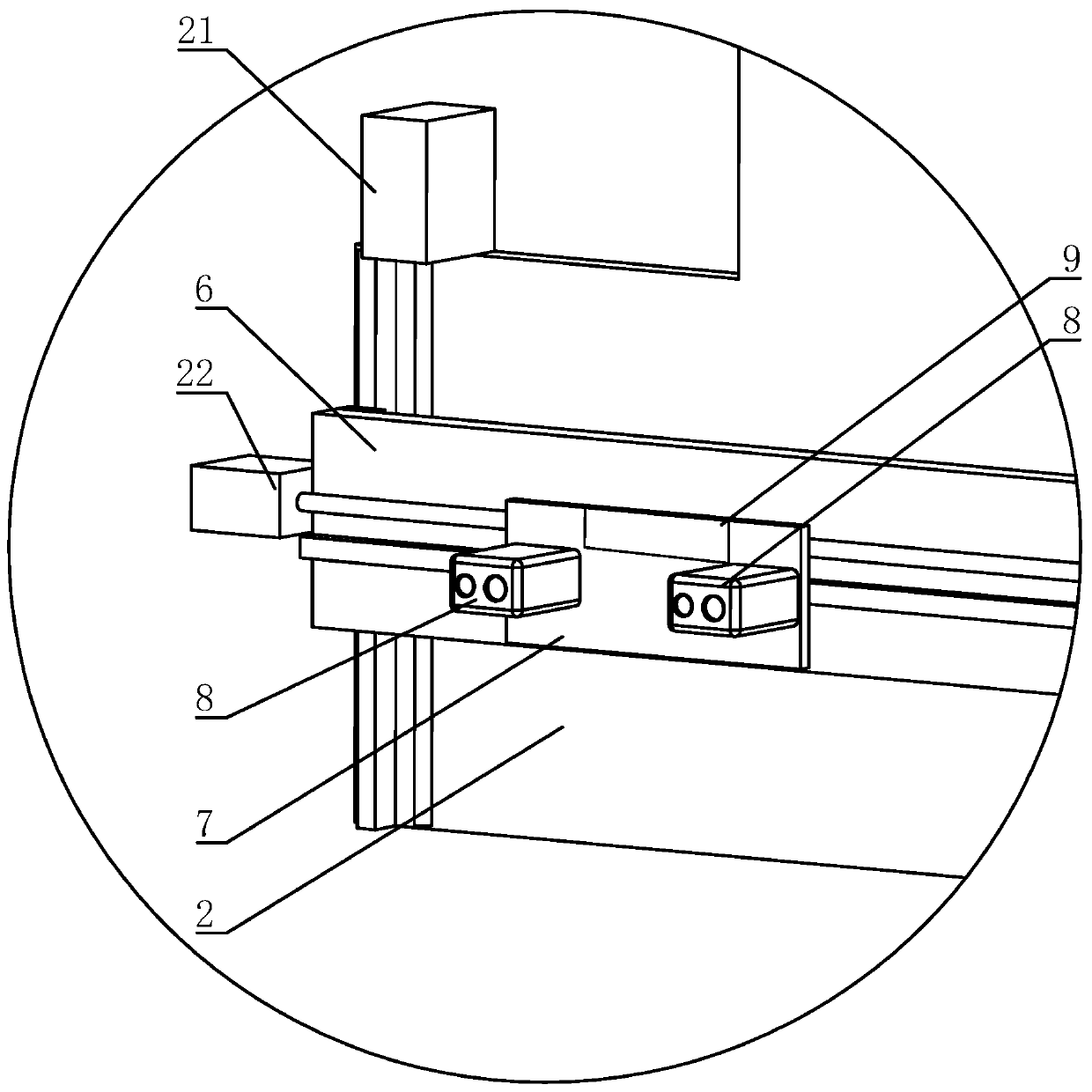

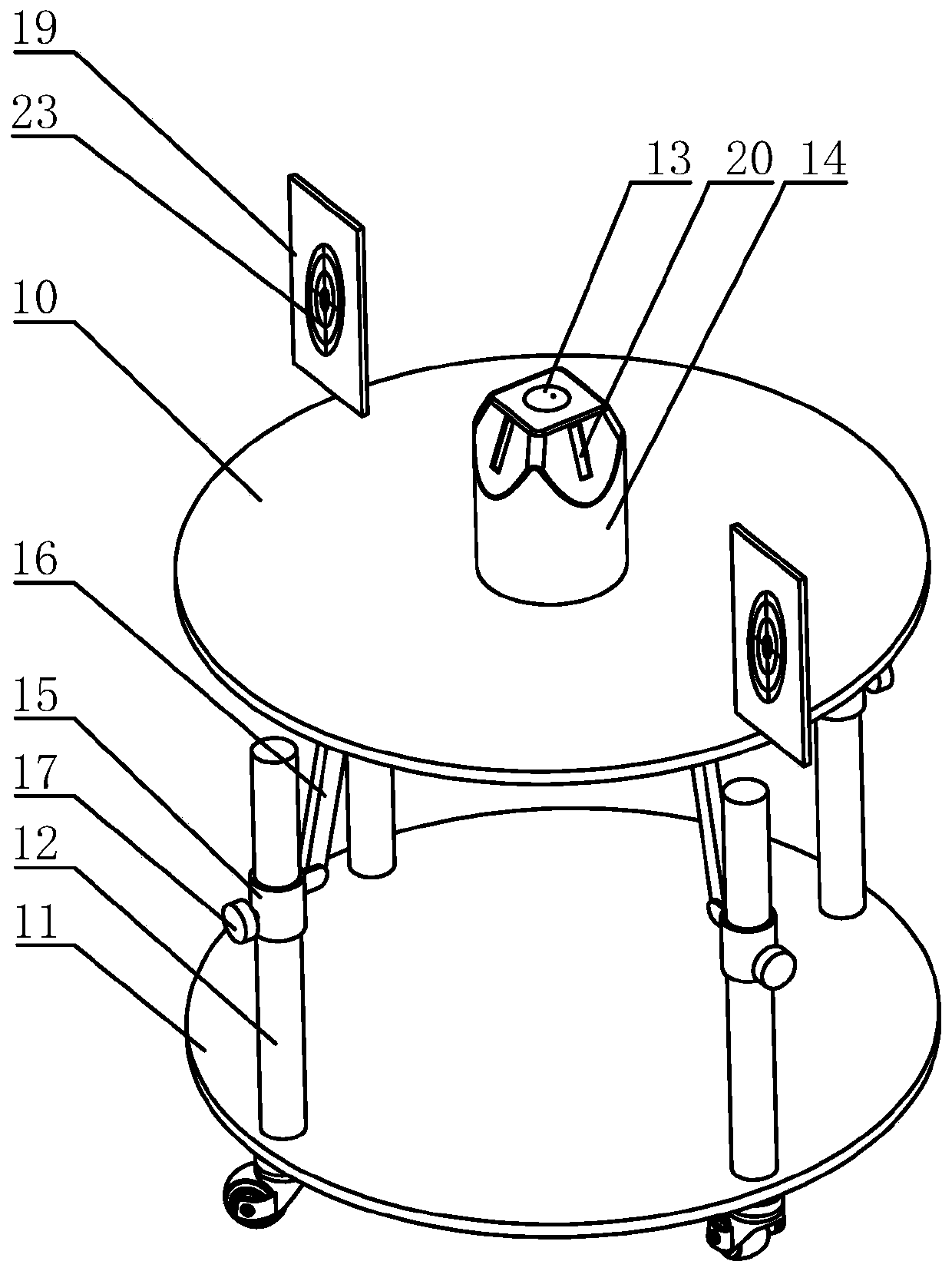

Experimental testing device for mechanical properties of horizontal axis composite wind turbine blades

ActiveCN109737015BReduce distance errorAccurate dataMachines/enginesWind motor monitoringLaser rangingExperimental testing

The invention discloses experimental testing equipment for the mechanical property of a horizontal axis composite wind turbine blade, and mainly relates to the field of mechanical testing equipment. The experimental testing equipment comprise a base, a horizontal correcting platform and a locating car; the bottom of the base is a fixing seat, and the upper part of the base is a mounting seat; themounting seat is provided with a mounting flange, and a blade is fixed to the mounting flange by a bolt; the horizontal correcting platform is fixed to the same side, as the mounting flange, of the fixing seat, and provided with a ranging module used for detecting the distance between the locating car and the horizontal correcting platform; the locating car comprises a horizontal platform, a pedestal and an adjusting rack, and the centroid of the top surface of the horizontal platform is fixedly provided with a laser level; the pedestal is fixedly connected with the horizontal platform throughthe adjusting rack, and the both sides of the horizontal platform are each provided with a horizon dial; and the two horizon dials are on the same plane, and the distance between the centers of the horizon dials is equal to the distance between the distance measuring ports of two laser range finders. The experimental testing equipment has the beneficial effect that the laser beam can be projectedto the blade at the specified distance for location.

Owner:INNER MONGOLIA UNIV OF TECH

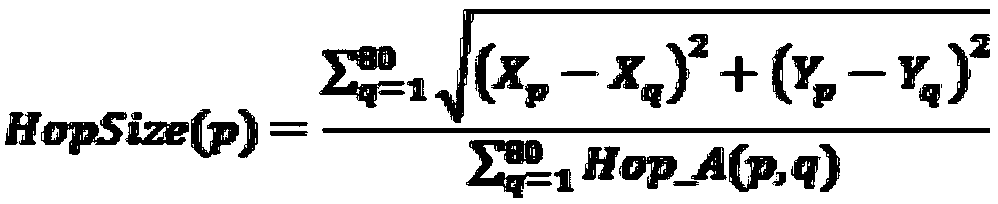

Non-ranging positioning method based on modified simulation curve fitting

The invention relates to a non-ranging positioning algorithm based on corrected simulation curve fitting, and is characterized in that equipment required by the algorithm and implementation steps are as follows: the required equipment is a wireless sensor node group. The wireless sensor node group includes 400 wireless sensor nodes, wherein positions of 80 wireless sensor nodes are known, the 80 wireless sensor nodes are called anchor nodes, and are represented by Node_A(i), i=1,2,...,80, and (Xi, Yi) represents x axis and y axis coordinates of Node_A(i) in a rectangular plane coordinate system; and positions of 320 wireless sensor nodes are unknown, the 320 wireless sensor nodes are called unknown nodes and are represented by Node_U(j), j=1,2,...,320, and (Xj, Yj) represents x axis and y axis coordinates of Node_U(j) in the rectangular plane coordinate system. The non-ranging positioning algorithm based on corrected simulation curve fitting solves the problem of low positioning accuracy in complex environment, and by modification of hop section distance and anchor node selection of an original algorithm, a distance error is reduced, and positioning accuracy is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Paper arraying device

The invention discloses a paper arraying device, which comprises a first arraying arm, a second arraying arm, a first sensing assembly and a controller, wherein the first arraying arm comprises a first catch and a second catch; in each paper arraying process, the first arraying arm moves towards the second arraying arm from a preparing position for a preset position; and then the first arraying arm moves back to the preparing position to wait for a next piece of paper. According to the paper arraying device disclosed by the invention, the second catch is additionally arranged, so that the controller begins to calculate the moving distance of the first arraying arm when the second catch of the first arraying arm does not obstruct the first sensing assembly. In each paper arraying process, the controller begins to calculate the moving distance of the first arraying arm from the same starting point, and therefore, the possibility of generating the movement distance error of the first arraying arm is lowered.

Owner:PRIMAX ELECTRONICS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com