Novel plastic cutting equipment

A new type of plastic technology, applied in the direction of welding/cutting auxiliary equipment, welding equipment, welding equipment, etc., can solve the problems of short plastic cutting, unable to advance the normal distance, position deviation, etc., and achieve the effect of uniform transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

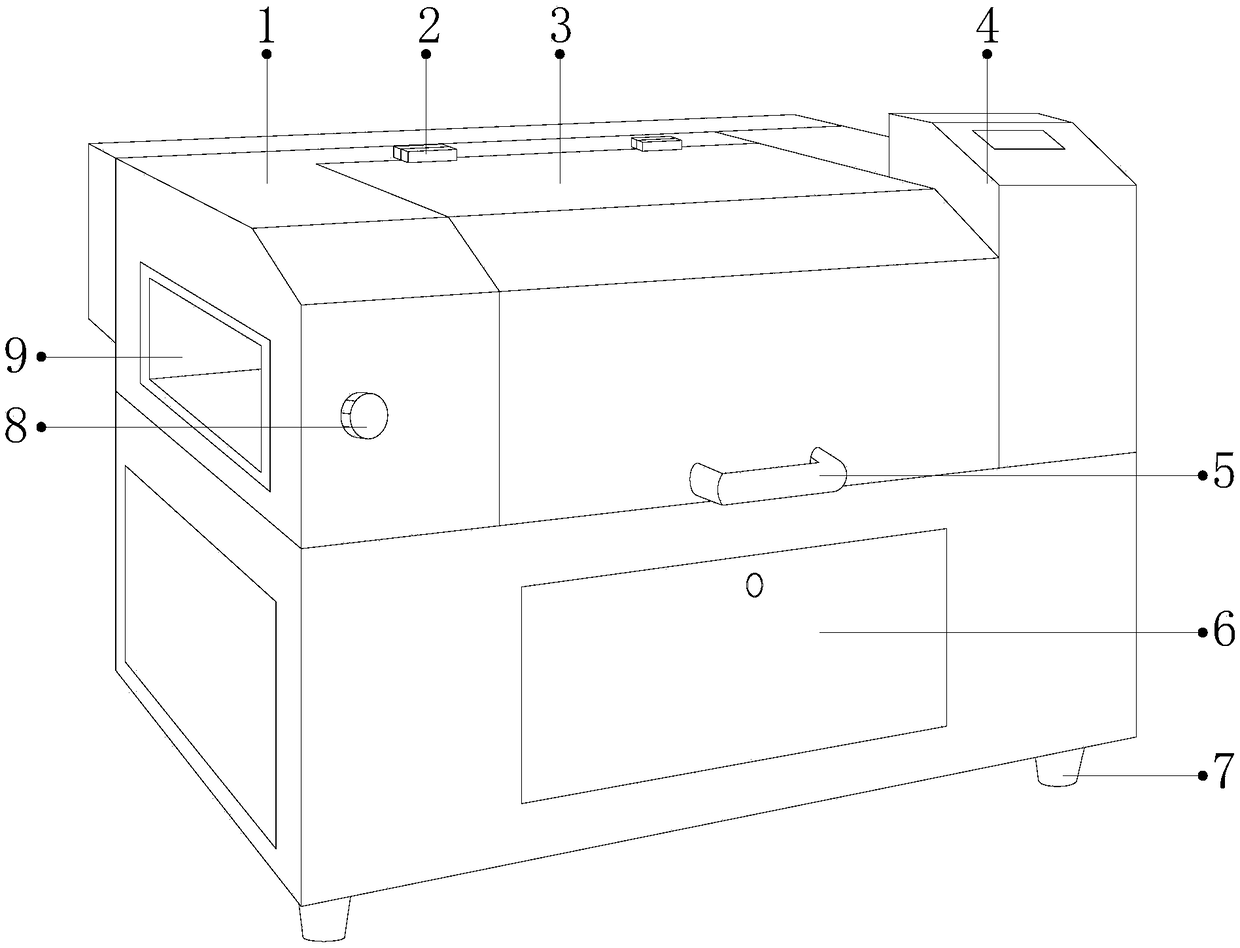

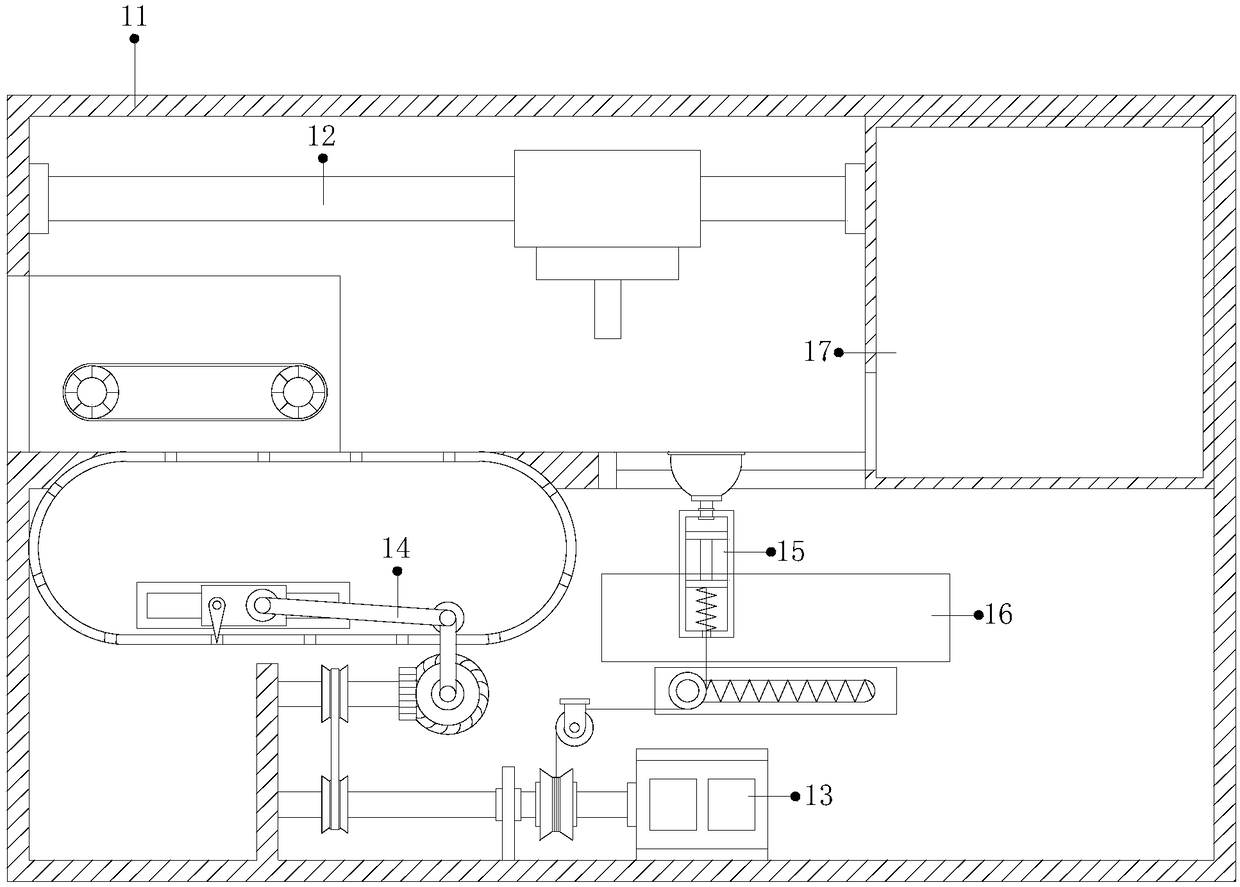

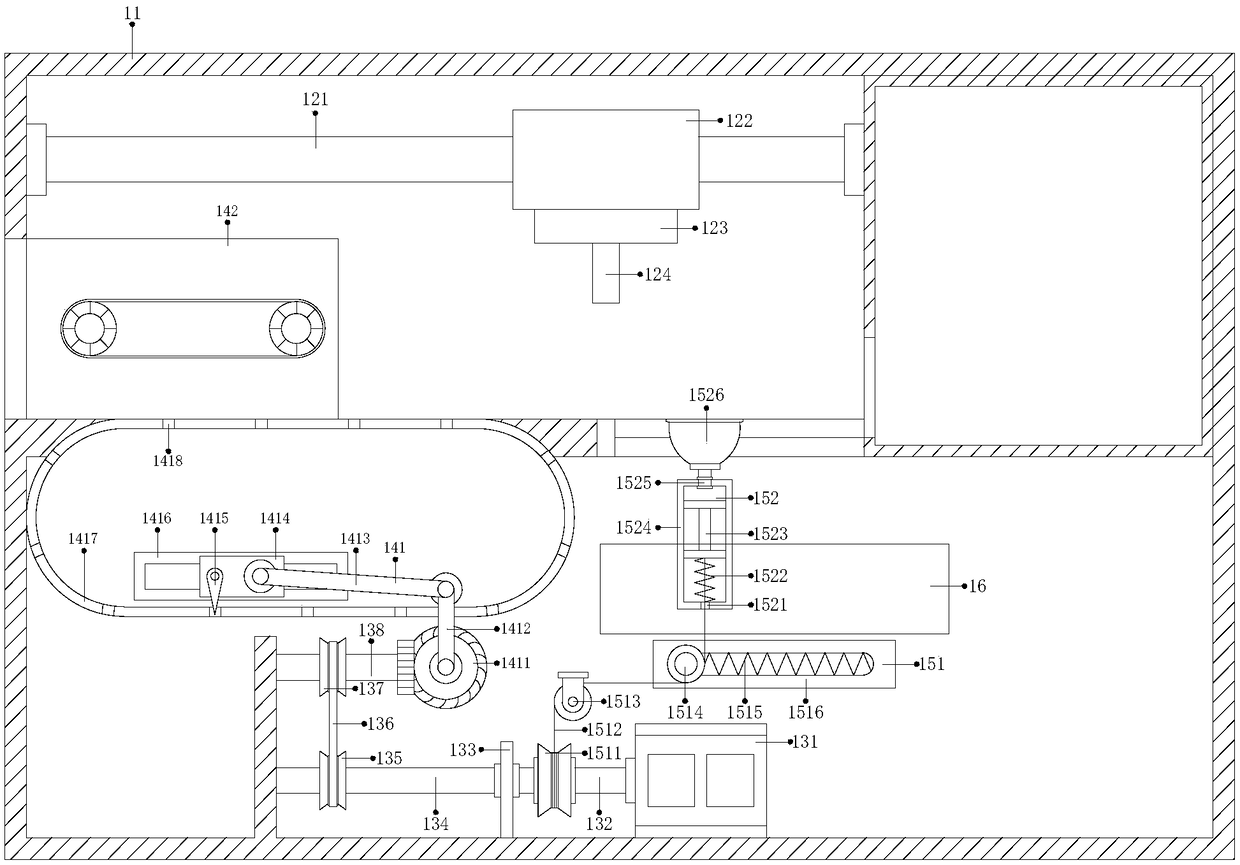

[0027] see Figure 1-Figure 5 , The present invention provides a new type of plastic cutting equipment, the structure includes a cutting host 1, a hinge 2, a box door 3, a control box 4, a handle 5, a maintenance door 6, a support foot 7, an adjustment button 8, and a feeding port 9. The cutting host 1 The top is welded with the hinge 2, the hinge 2 is welded with the box door 3, the cutting host 1 is hinged with the box door 3 through the hinge 2, and the control box 4 is fixedly installed on the top of the cutting host 1 and is electrically connected through wires. Connection, the handle 5 is arranged on the box door 3, the maintenance door 6 is installed on the bottom end of the cutting main machine 1, the supporting feet 7 are provided with four and are fixedly installed at the bottom four corners of the cutting main machine 1, the adjustment button 8 is embedded in the front surface of the cutting main machine 1 and adopts clearance fit. The feeding port 9 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com