Experimental testing device for mechanical properties of horizontal axis composite wind turbine blades

A technology of wind turbine blades and composite materials, which is applied in wind turbines, monitoring of wind turbines, engines, etc., can solve the problems of small deformation, affecting the accuracy of data analysis, etc., and achieve the effect of reducing distance errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

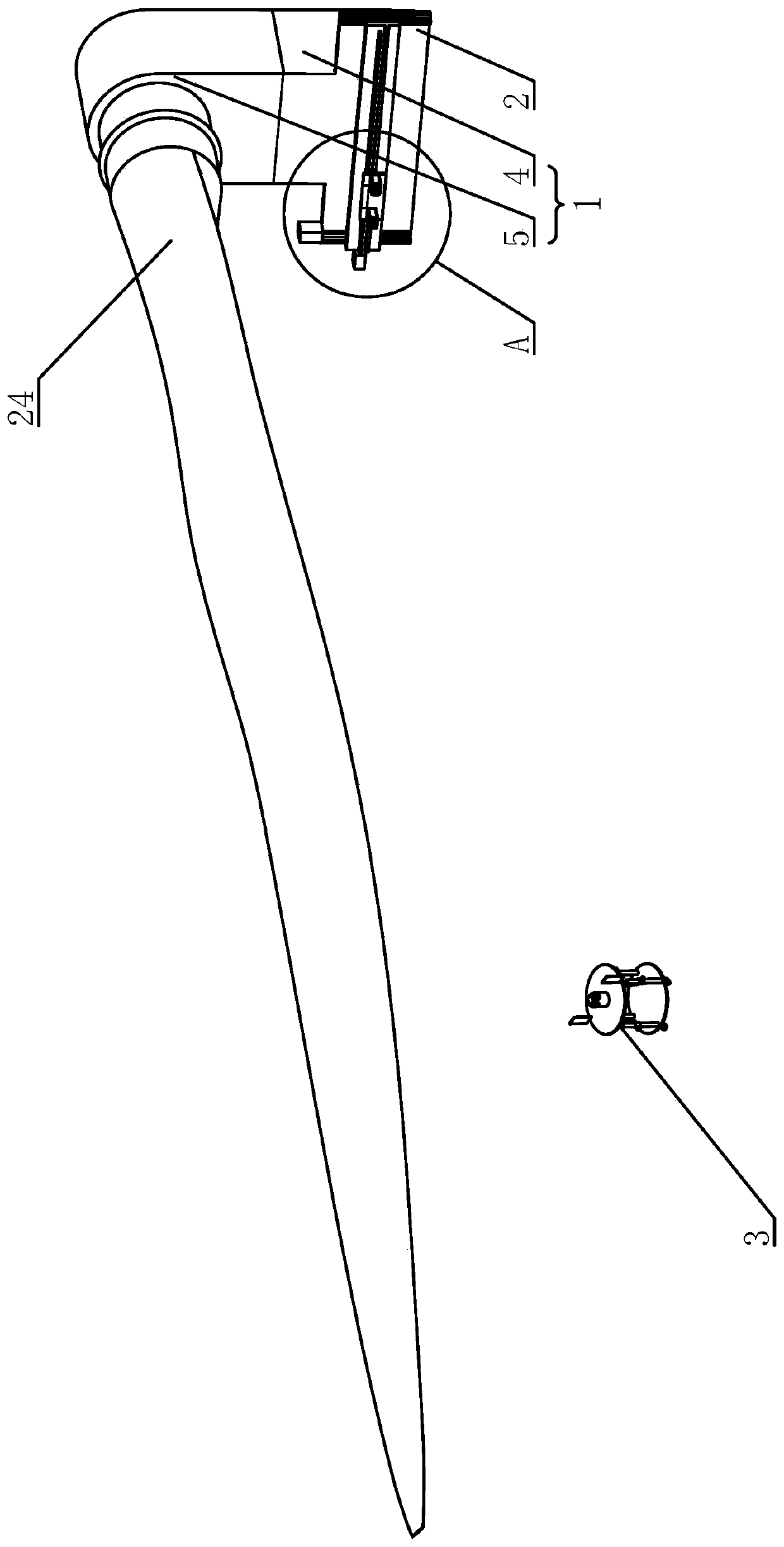

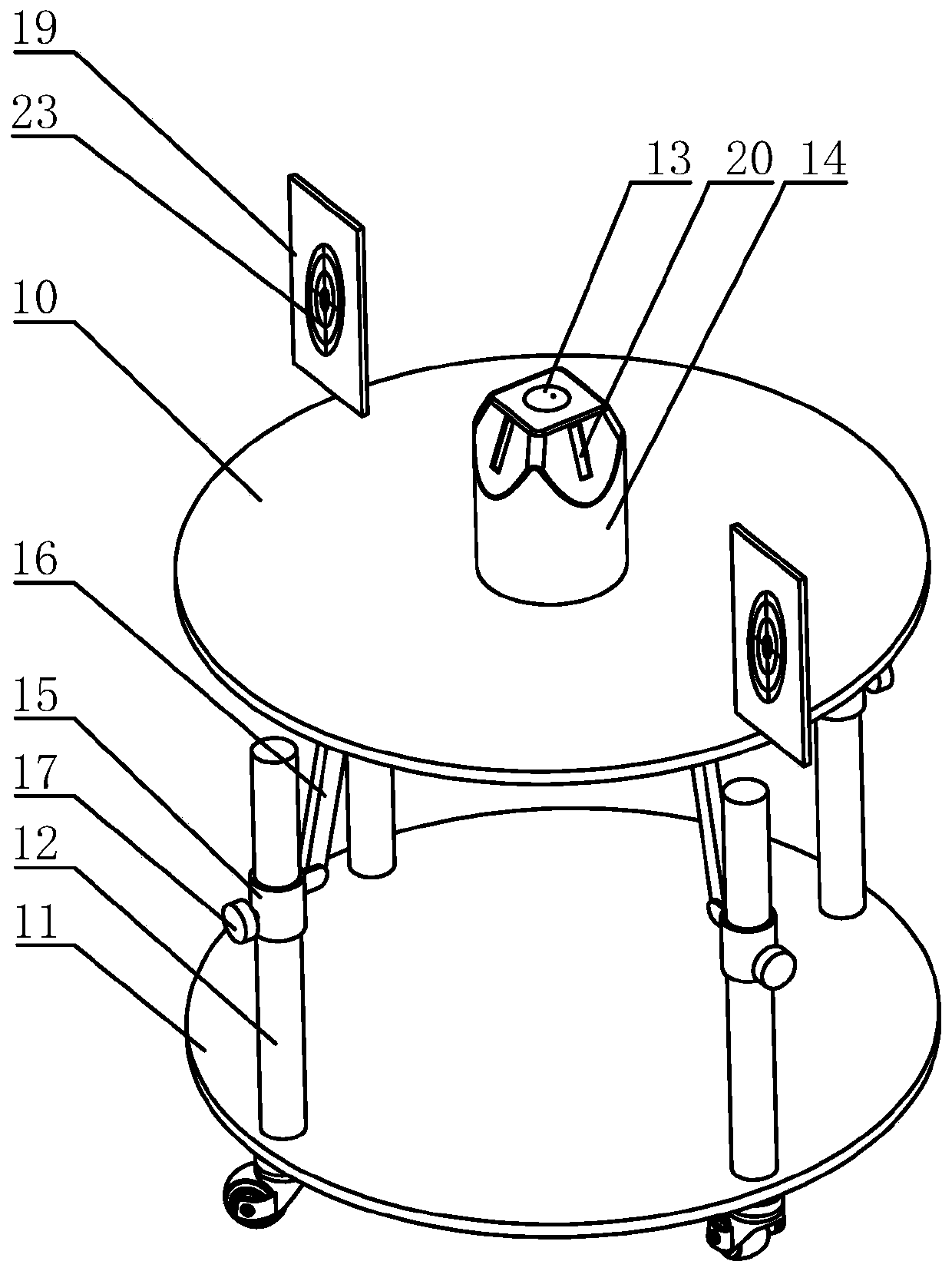

[0024] Embodiment: An experimental test device for the mechanical properties of horizontal axis composite material wind turbine blades, including a base 1, a level correction platform 2 and a positioning vehicle 3, the bottom of the base 1 is a fixing seat 4, and the upper part of the base 1 is a mounting seat 5. A fixed flange is arranged on the mounting seat 5, and the fixed flange is arranged on one side of the mounting seat 5. The end surface of the fixed flange is perpendicular to the horizontal plane, and the blade 24 is fixed on the fixed flange by bolts. The blades 24 are placed horizontally.

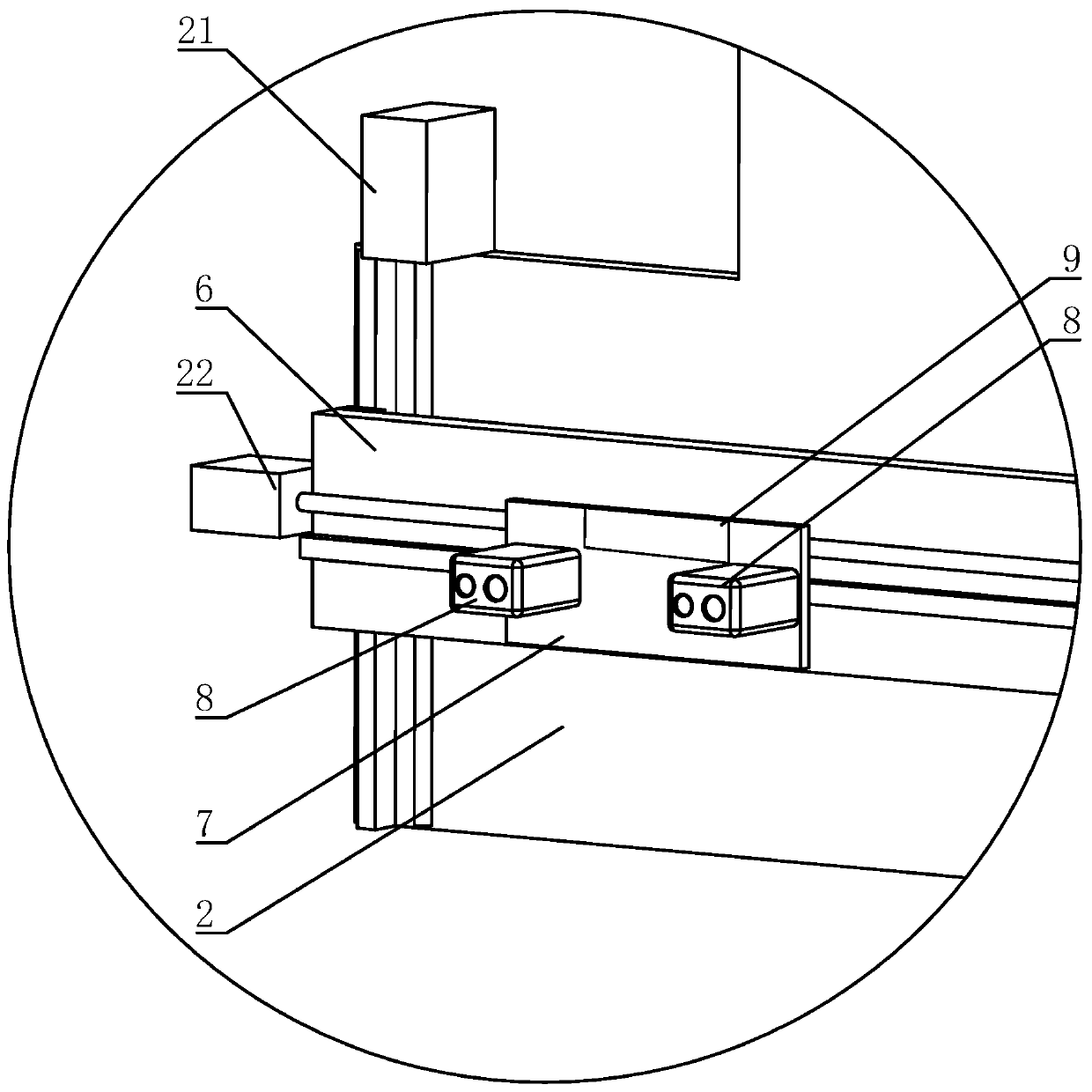

[0025] The horizontal correction platform 2 is fixed on one side of the fixed seat 4, the horizontal correction platform 2 is arranged on the same side as the fixed flange, and the horizontal correction platform 2 is arranged parallel to the fixed flange. A height slide table 6 is provided, the length of the horizontal direction of the horizontal correction table 2 is equal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com