Z-direction zero-tension suture needle special for composite materials and using method thereof

A composite material, zero tension technology, applied in the direction of trocars, etc., can solve the problems of wrong hooking of crochet needles, fiber lines destroying the fiber line of the tile layer structure, continuous fiber disconnection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

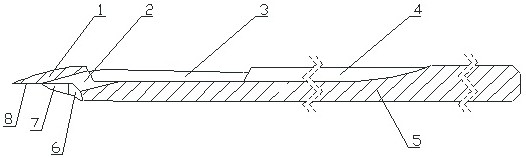

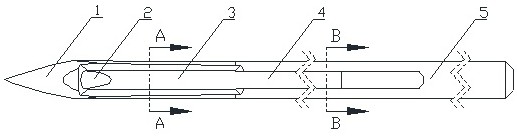

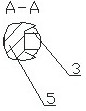

[0027] Such as Figure 1-6 The special Z-direction zero-tension suture needle for composite materials shown is provided with a round rod-shaped needle body 5, and an axially arranged yarn (fiber thread) guide chute is provided on the upper side of the needle body 5. figure 1 , figure 2 , Figure 5It can be seen from the figure that the guide chute is composed of a guide limit groove 4 and a yarn buffer groove 3, the yarn buffer groove 3 is located at the front of the needle body 5, and the guide limit groove 4 is located at the rear side of the yarn buffer groove 3 ; The cross-section of the yarn buffer groove 3 is greater than the cross-section of the guiding and limiting groove 4 . The front end of the needle body 5 is provided with a tapered puncture needle point 1, the rear part of the puncture needle point 1 and the front end of the needle body 5, and the connection between the two is provided with a rear end communicating with the front end of the yarn buffer groove 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com