SCARA robot accurate positioning method based on granularity model

A granular model and robot precision technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as deviations and errors between actual points and expected points, and achieve the effect of ensuring effectiveness, precise positioning, and single parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific implementation cases and with reference to the accompanying drawings.

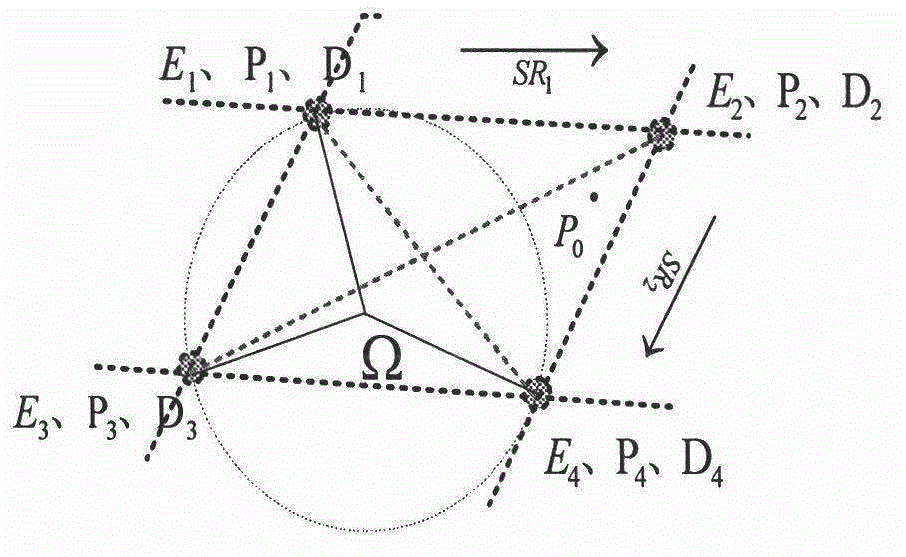

[0022] The basic idea of the present invention is to propose a SCARA robot precise positioning method based on the granularity model combined with the principle of minimum distance error approximation. Determine the initial granularity model parameters, calculate the distance error between the granularity point and the expected point, and determine the granularity model parameter adjustment strategy.

[0023] For further explanation, the specific implementation steps are:

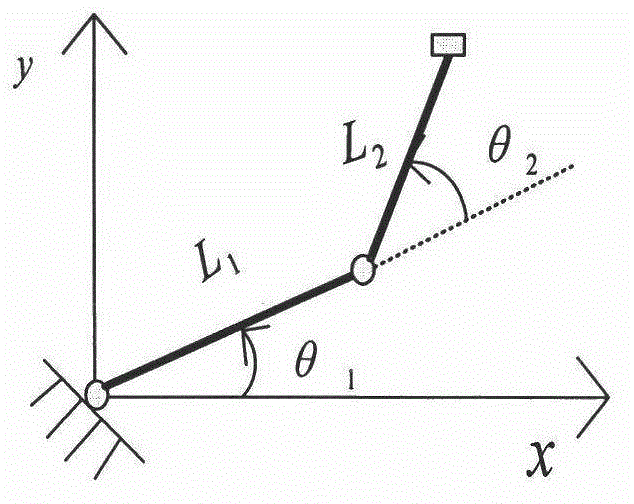

[0024] (1) Construct a simplified model of the 1-axis and 2-axis of the robot.

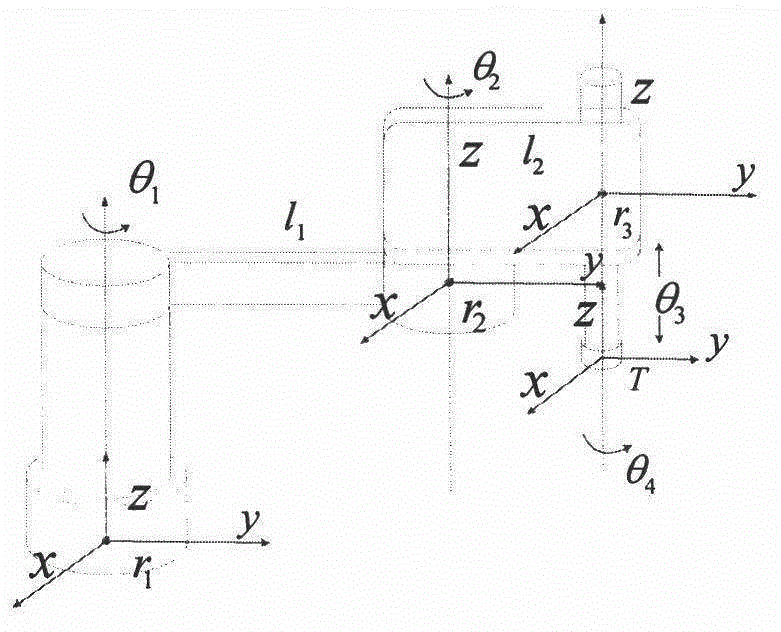

[0025] attached figure 1 It is a SCARA robot model diagram, and the positioning of the SCARA robot on the plane depends on the 1-axis θ 1 with 2 axis θ 2 j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com