Mechanical arm DH parameter identification method based on least square method

A least square method and parameter identification technology, applied in the field of robotics, can solve problems such as unsatisfactory absolute positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

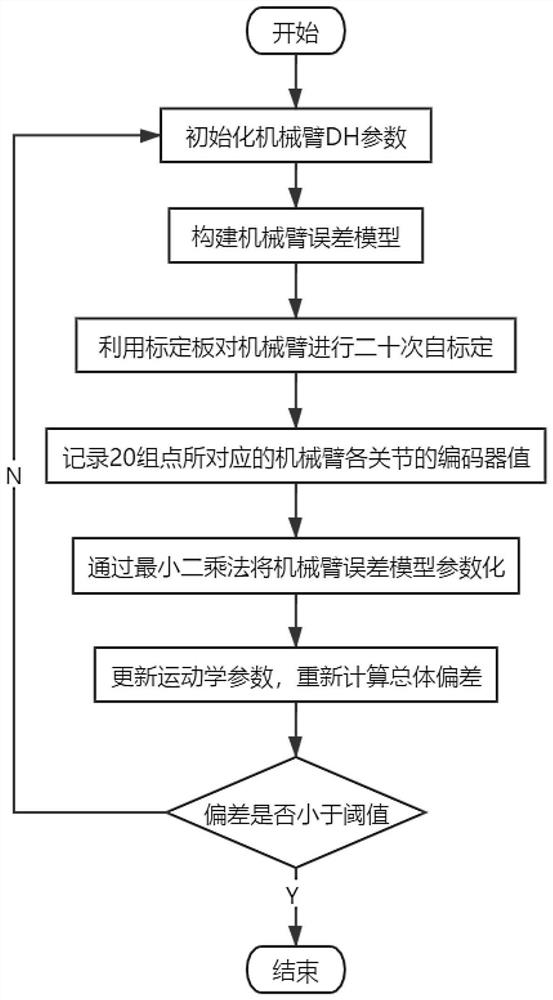

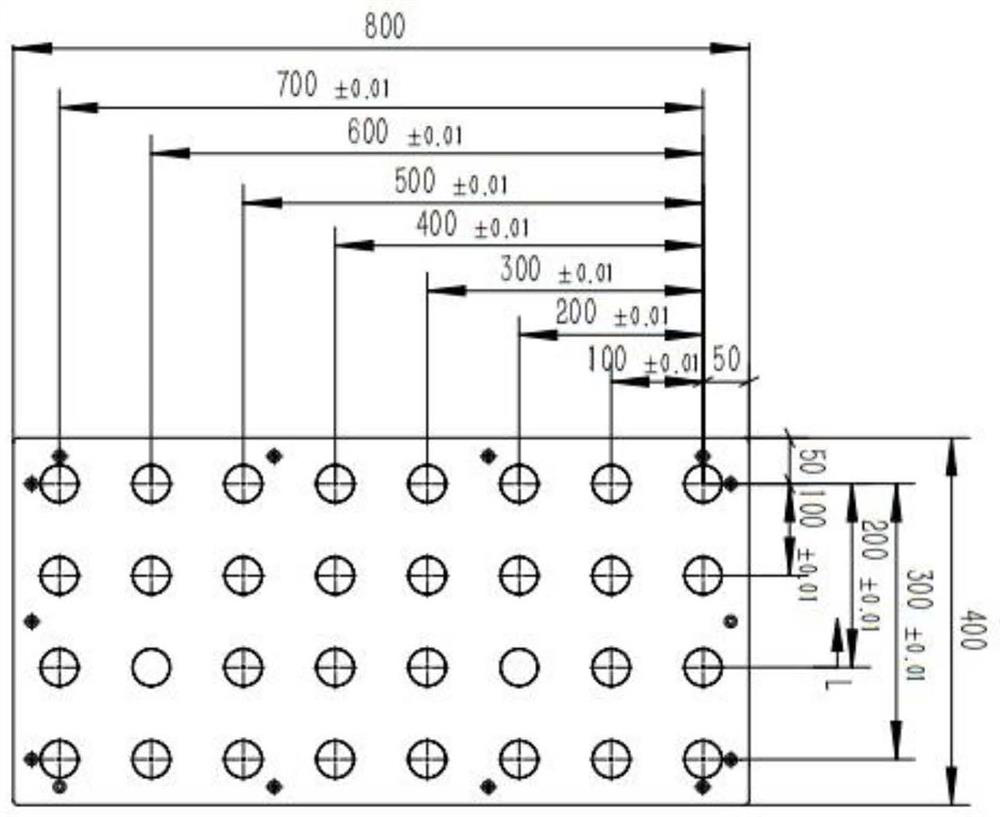

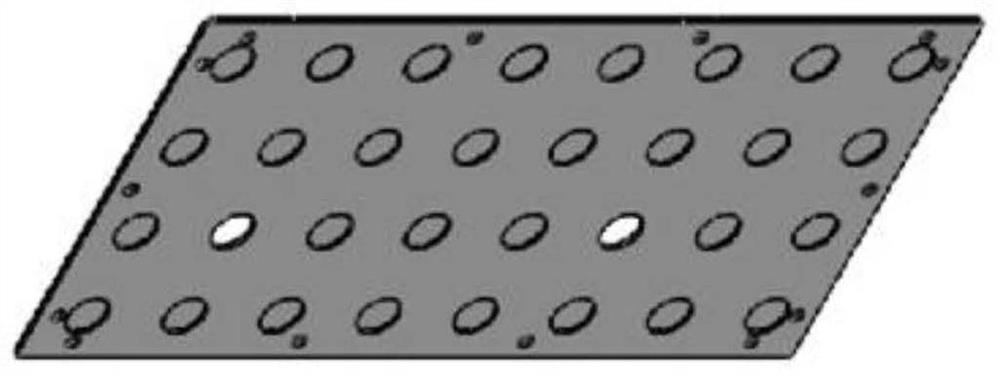

[0036] refer to Figure 1 ~ Figure 4 , which is the first embodiment of the present invention, this embodiment provides a method for identifying DH parameters of a manipulator based on the least squares method, including:

[0037] S1: Determine the initial DH parameters of the manipulator according to the configuration and structural parameters of the manipulator, and construct the error model of the manipulator according to the principle of differential motion.

[0038] What needs to be explained is that the differential motion of the robot is to study the relationship between the small changes in the robot joint variables and the small changes in the robot's hand posture, which can be used to deduce the speed relationship between different components.

[0039] The constructed manipulator error model is as follows:

[0040]

[0041] Among them, d x 、d y 、d z are the differential translations of the manipulator coordinates along the x, y, and z axes (that is, the origin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com