Location control method for strip head of thin strip steel

A positioning control, thin strip technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problem of no control method for the length of the strip head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for controlling the positioning of a thin strip steel strip head includes the following steps:

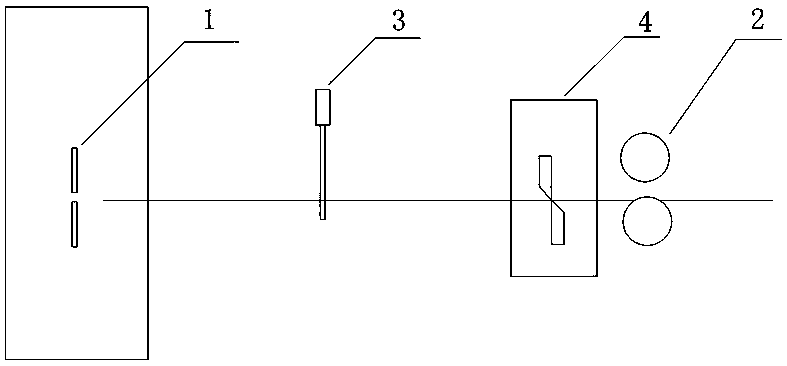

[0031] 1) Such as figure 1 with figure 2 As shown, the welding machine 1 is installed, the pinch roller device 2 is installed at the side of the entrance channel of the welding machine 1, the grating detector 3 is installed between the pinch roller and the welding machine 1, and the grating detector 3 and the welding machine 1 are set The distance between them is Kcm.

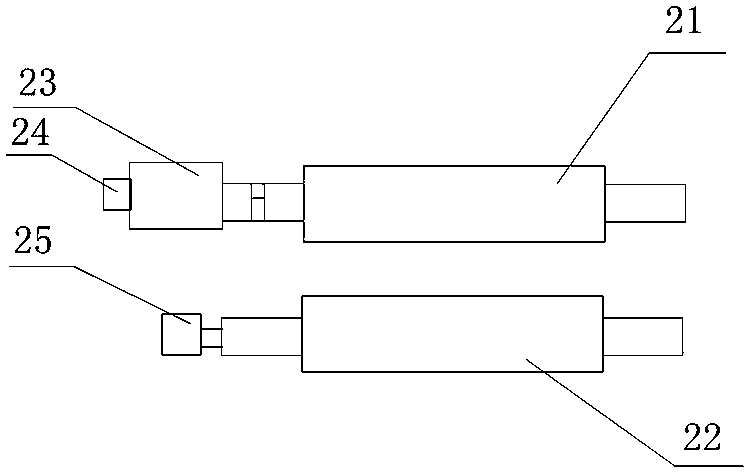

[0032] The pinch roller device 2 includes an upper pressure roller 21, a lower roller 22, a motor 23 connected to one end of the upper pressure roller, and a motor tail encoder 24 connected to the motor. At least one end of the upper pressure roller 21 is provided with a power cylinder. 23 By controlling the power cylinder to make the upper pressure roller 21 fall and lift, a lower roller encoder 25 is installed on the shaft end of the lower roller 22;

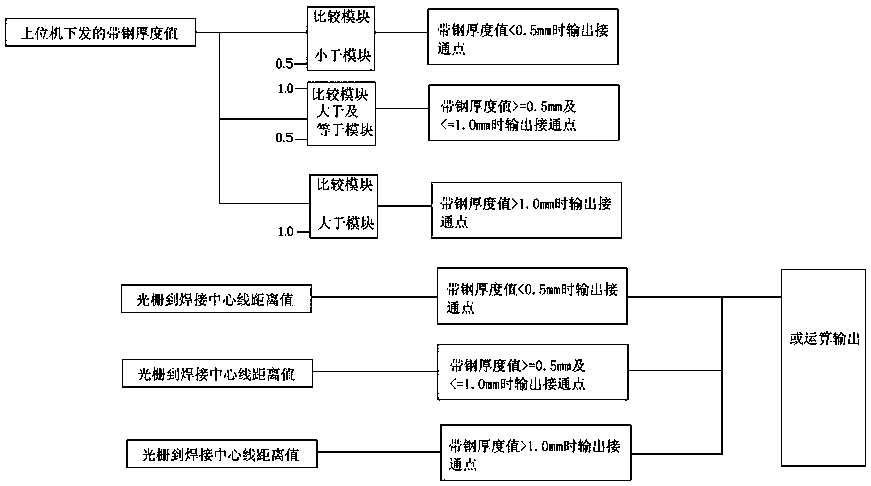

[0033] 2) Such as image 3 As shown, there are thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com