System for determining and regulating EGR (Exhaust Gas Recirculation) mass flow and use method thereof

A mass flow and EGR valve technology, which is applied in the system field of determining and adjusting EGR mass flow, can solve the problems of high cost and complicated measurement methods, and achieve the effects of occupying less space, simplifying measurement methods, and reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

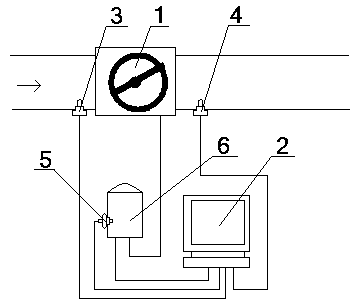

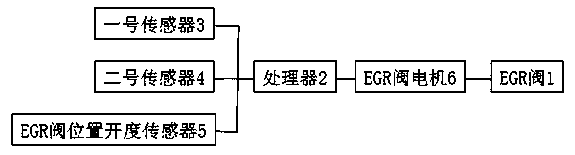

[0057] see figure 1 , figure 2 , a system for determining and adjusting the EGR mass flow rate, comprising an EGR valve 1 and a processor 2, the EGR valve 1 is a butterfly valve, the processor 2 is an engine electronic control unit, and the EGR valve 1 passes through an EGR valve motor 6 Connected to the output end of the processor 2, the entrance of the EGR valve 1 is provided with a No. 1 sensor 3, the exit of the EGR valve 1 is provided with a No. 2 sensor 4, and the EGR valve motor 6 is provided with an EGR valve position opening Sensor 5, the No. 1 sensor 3 is a temperature and pressure sensor, the No. 2 sensor 4 is a pressure sensor, and the output terminals of the No. 1 sensor 3, No. 2 sensor 4, and EGR valve position opening sensor 5 are all connected to the input of the processor 2 terminal signal connection.

[0058] A method for using the above-mentioned system for determining and adjusting EGR mass flow rate, the method includes the following steps in sequence: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com