Device for contactless determination of rotation and/or position of an object having an encoder

An encoder and generator technology, applied in the field of speed and/or position devices, which can solve problems such as unsatisfactory symmetry characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

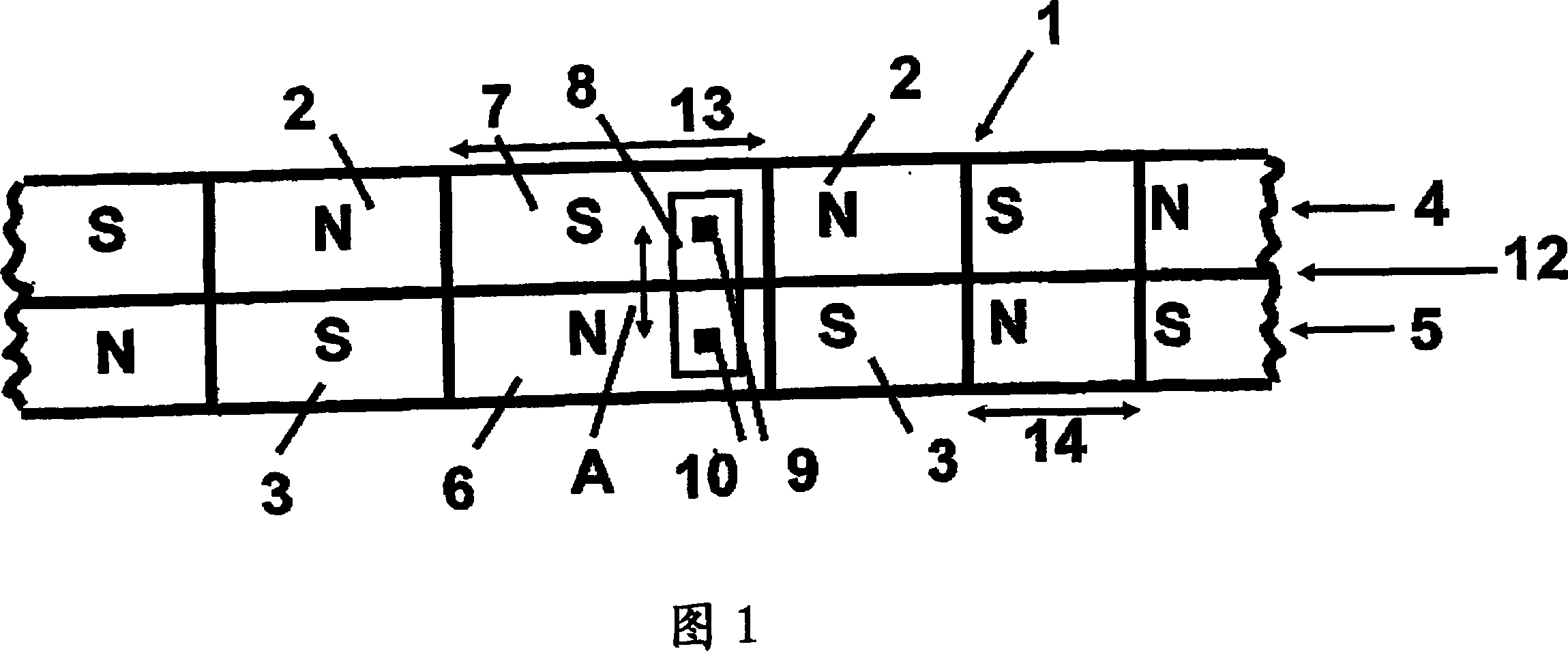

[0013] The various parts of the device are not shown in the figure, because these parts are known per se and can also be known from the aforementioned US publications belonging to the prior art. Therefore, FIG. 1 shows a part of the surface of an encoder designed as a dual-track encoder (Doppelspurencoder) 1, and the encoder is magnetized oppositely with regular N poles 2 and S poles 3. A corresponding number of poles 2 and 3 are arranged on each encoder track 4 and 5. The number of poles 2 and 3 is determined by a predetermined indexing angle, which is usually between 3° and 12° for regular poles 2 and 3. For each regular pole 2 and 3, the pole width or angular length 14 is the same size. In addition to the regular poles 2 and 3, irregular poles 6 and 7 with a larger angular length 13 (pole width) are arranged on each of the encoder tracks 4 and 5, which are also opposite to each other Geomagnetization. The dual-track encoder 1 is equipped with a differential Hall sensor 8 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com